-8-

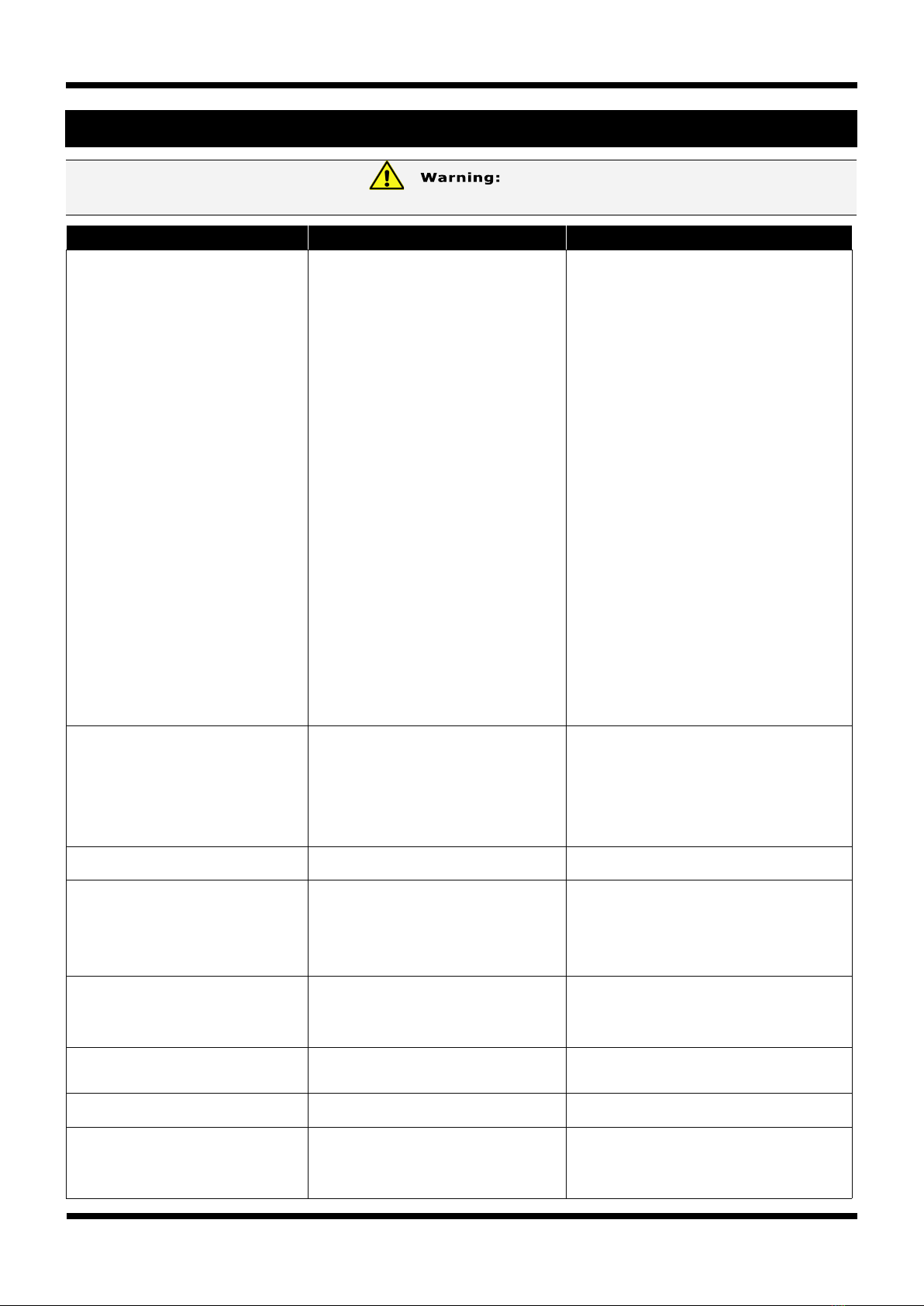

5. FAULT FINDING GUIDE

Versatile 2 Moulder with Light Guard Mouth © Copyright Moffat Ltd. 28 June 2022.

300166 Amdt 9

Problem Possible Cause Remedy

THE MOULDER DOES NOT OPERATE /

START.

Not plugged in to socket at main switch.

The main switch is 'Off'.

Fuse or circuit breaker at the power board is

tripped.

Emergency stop button locked in down

position.

Emergency stop button faulty.

A microswitch or safety key switch has been

activated or is faulty.

Start switch faulty.

(Refer Fault Diagnosis 6.1.1).

Stop switch faulty.

(Refer Fault Diagnosis 6.1.1).

Contactor faulty.

(Refer Fault Diagnosis 6.1.1).

Motor overload faulty.

(Refer Fault Diagnosis 6.1.1).

Circuit Breaker tripped (Canada Only).

(Refer Fault Diagnosis 6.1.1).

Plug in and turn 'On' main switch.

Turn 'On' main switch.

Check for electrical fault.

Release by pulling firmly.

Replace the emergency stop button.

(Refer Service Section 6.3.11).

Check all switches (safety key switch, front guard

switch, rear guard switch).

Replace left hand lightspeed horn.

(Refer Service Section 6.3.10).

Replace right hand lightspeed horn.

(Refer Service Section 6.3.10).

Replace contactor.

(Refer Service Section 6.3.12).

Replace motor overload.

(Refer Service Section 6.3.12).

Check Circuit Breaker is switched ‘On’.

Check 24V Power tripping fault.

THE MOULDER STARTS AND THEN

STOPS.

Moulder overload has been activated.

Motor overload incorrectly set.

Motor overload faulty.

(Refer Fault Diagnosis 6.1.1 and 6.1.2).

Motor faulty.

(Refer Fault Diagnosis 6.1.2).

Motor Overload resets automatically after 10mins.

Set Motor overload to 2.0 A.

Replace motor overload.

(Refer Service Section 6.3.12).

Replace motor.

(Refer Service Section 6.3.2).

THE MOULDER BELTS OPERATE IN THE

WRONG DIRECTION.

Electrical phase rotation incorrect. Swap two phases to ensure belts rotate in the

correct direction.

CHAIN JUMPING NOISES. Broken idler gear tensioning spring.

Motor operating in wrong direction (phase

rotation incorrect).

Replace idler gear tensioning spring.

(Refer Service Section 6.3.4).

Swap two phases to ensure belt rotates in the

correct direction.

(Refer Service Section 6.3.1 and

Fig 6.3.1a).

THE MOULDER LABOURS UNDER LOAD /

DRIVE BELT SLIPPING.

Dough too stiff / tight.

Stretched or loose drive belts.

Review and adjust the dough consistency or

adjust the rear belt settings to a wider gap.

Re-tension or replace drive belts.

(Refer Service Section 6.3.1 & 6.4.3).

MOTOR OPERATES BUT BELTS DO NOT

TURN.

Machine has been started in the wrong

direction causing the chain to jump off the

sprockets.

Refit chain and check electrical phase rotation.

BELT EDGES FRAYING. Tracking of belts is incorrect. Adjust belt tracking.

(Refer Service Section 6.4.2).

DOUGH STICKING TO SHEETING

ROLLERS.

Scrapers out of alignment.

Scraper spring broken.

Check alignment of scrapers.

(Refer Service Section 6.4.5 & 6.4.6).

Replace scraper spring.

(Refer Service Section 6.3.8 & 6.3.9).

All Installation and Service Repair work must be carried out by Qualified Persons Only.