molex 64005-3400 User manual

Other molex Crimping Tools manuals

molex

molex 207129 Series User manual

molex

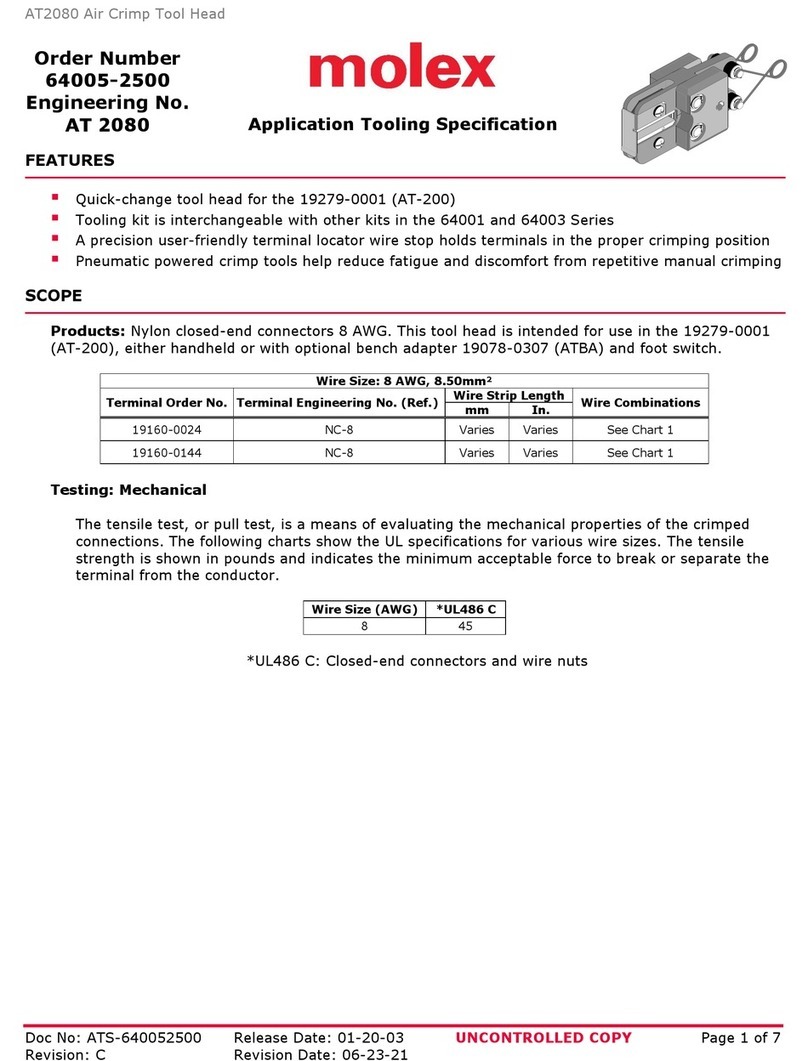

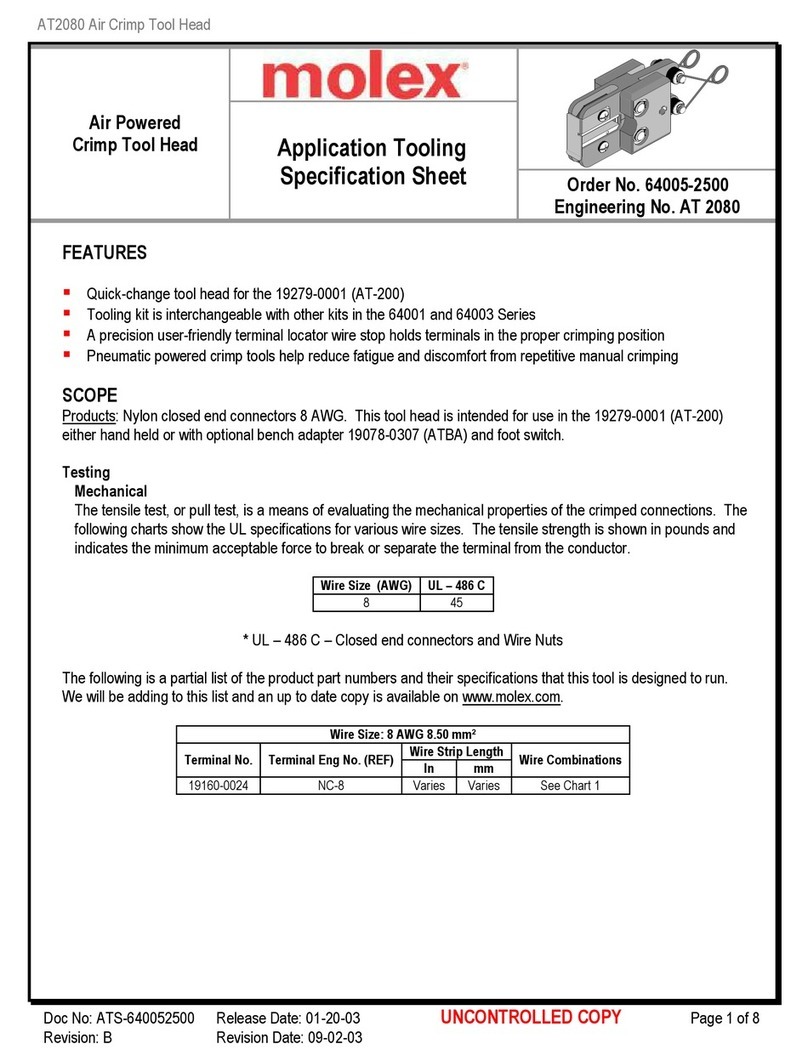

molex AT 2080 User guide

molex

molex 63816-1000 User manual

molex

molex 35768 Series User manual

molex

molex 207129 Series User manual

molex

molex AT-200 User manual

molex

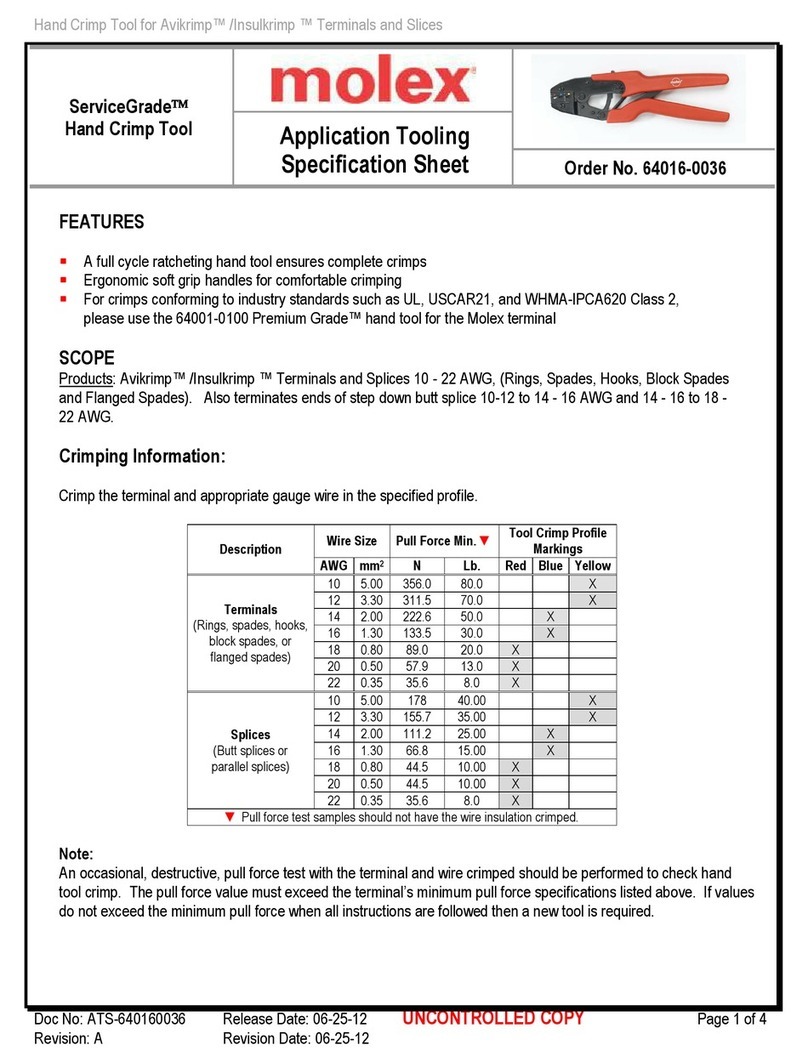

molex ServiceGrade 64016-0036 User guide

molex

molex 63819-4400 User manual

molex

molex AT-200 Manual

molex

molex 207129 Series User manual

molex

molex 207129 Series User manual

molex

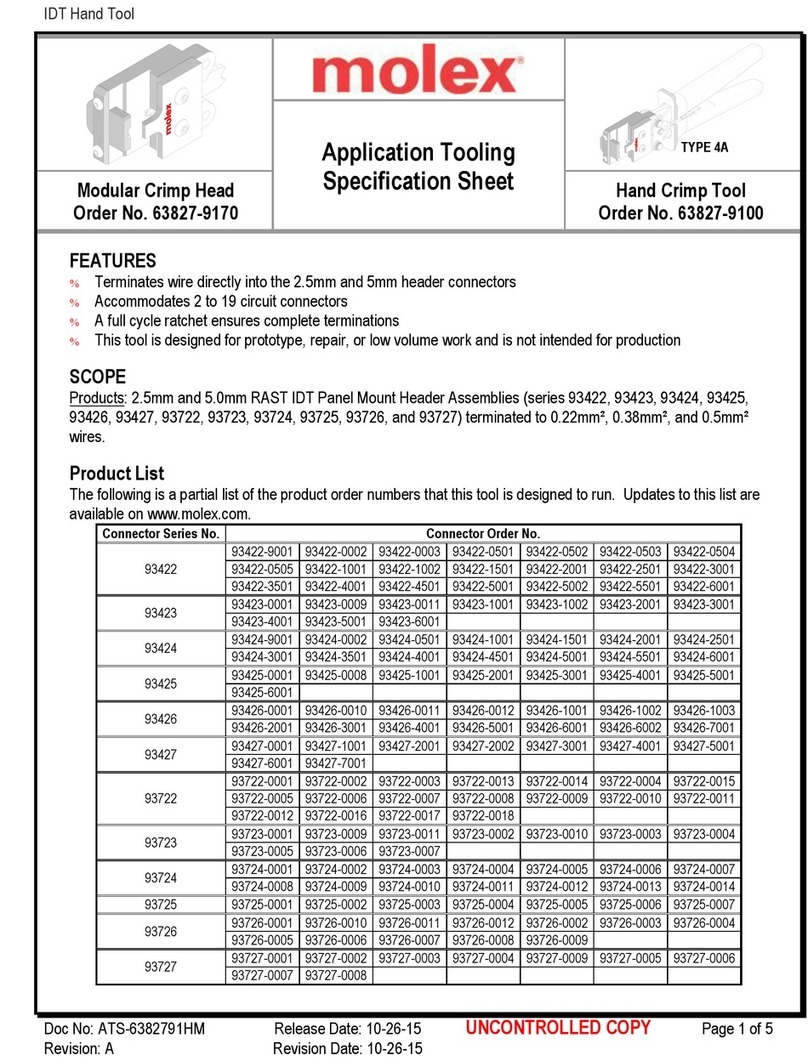

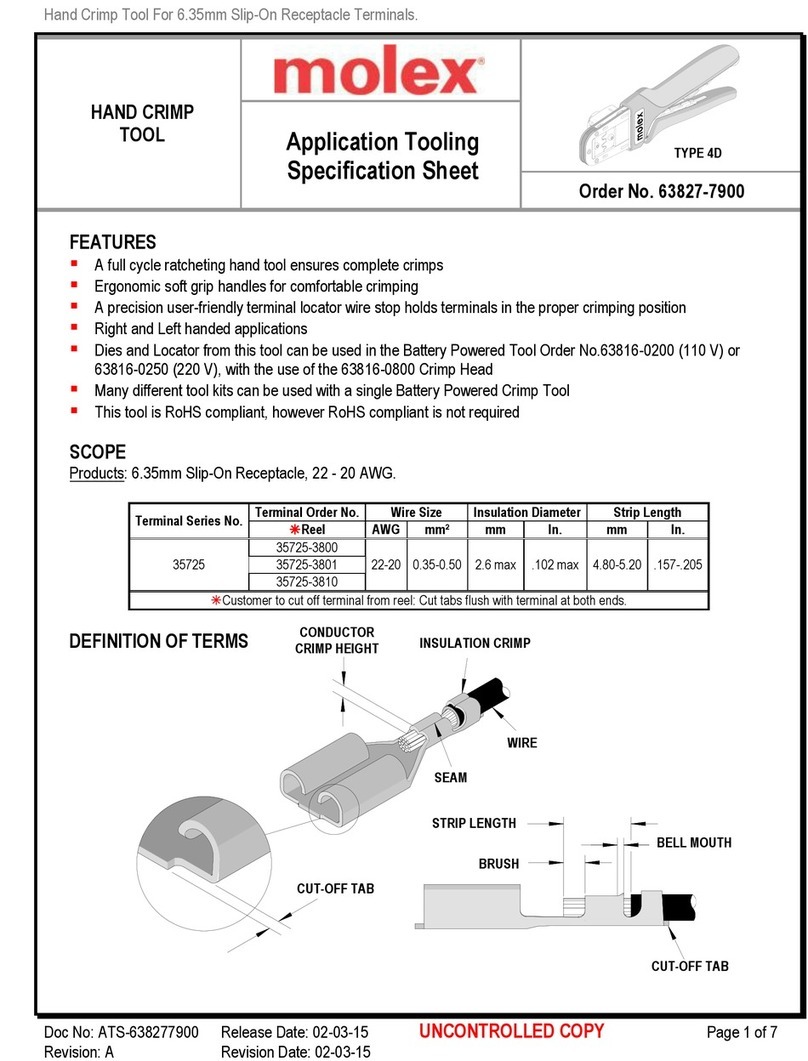

molex 63827-7900 User manual

molex

molex CR60927A User manual

molex

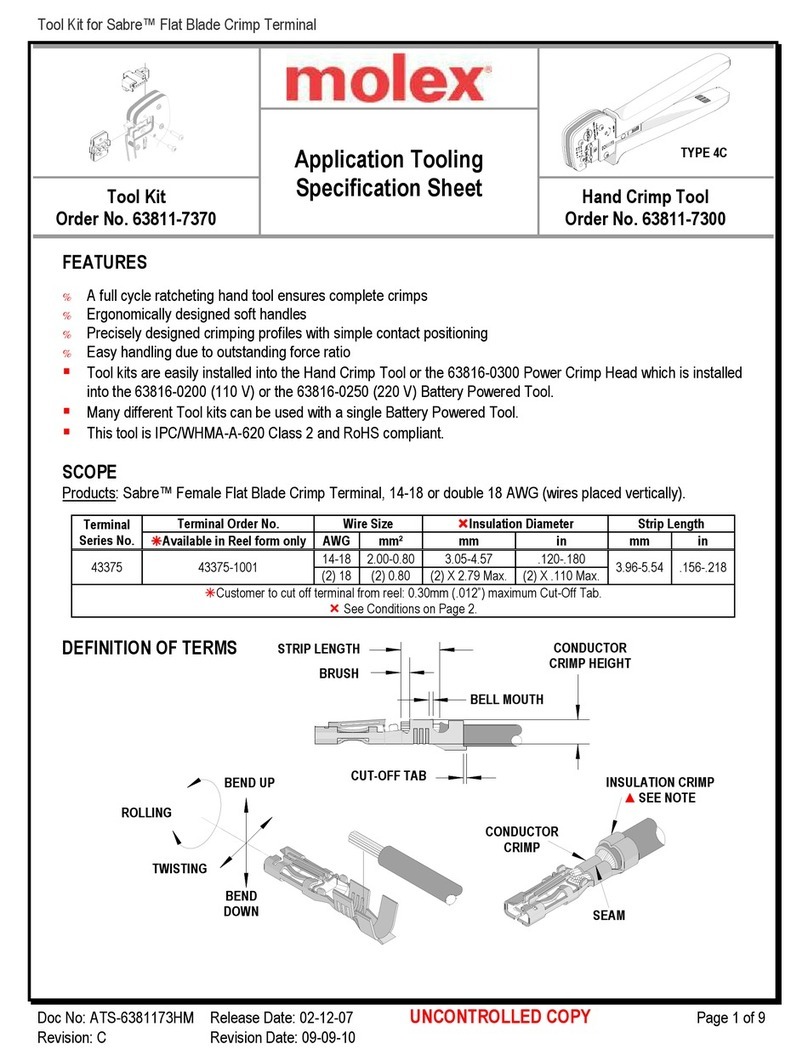

molex 63811-7000 User manual

molex

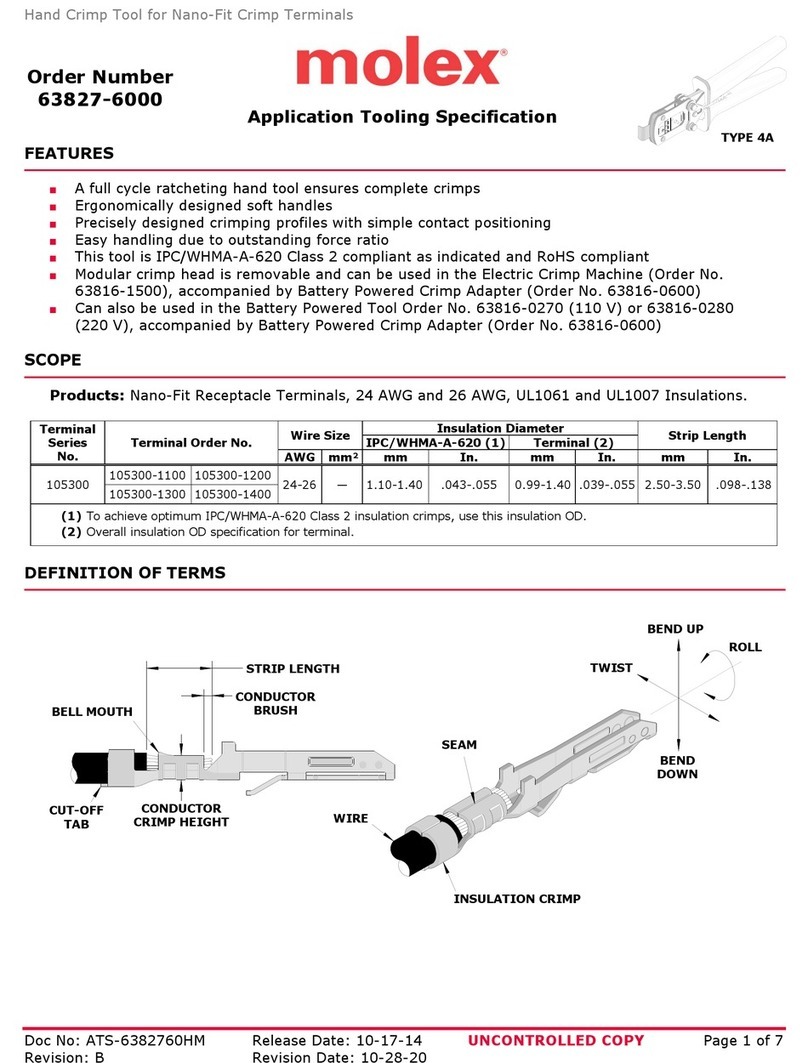

molex 105300 Series User manual

molex

molex 207129 Series User manual

molex

molex 207129 Series User manual

molex

molex 63811-5600 User manual

molex

molex 207129 Series User manual

molex

molex CR5904 User manual

Popular Crimping Tools manuals by other brands

Emerson

Emerson Klauke ES 20RMCCFB manual

Continental Refrigerator

Continental Refrigerator PC150HD quick start guide

TE Connectivity

TE Connectivity ERGOCRIMP 1-1579001-3 instruction sheet

Tyco Electronics

Tyco Electronics CERTI-CRIMP 90418-1 instruction sheet

Emerson

Emerson Klauke ES 105CFB manual

TE Connectivity

TE Connectivity 539 726-2 instruction sheet