AT-200 Air-Powered Crimp Tool

Doc No: TM-192790001 Release Date: 07-01-02 UNCONTROLLED COPY Page 9 o 18

Revision: D Revision Date:11-10-09

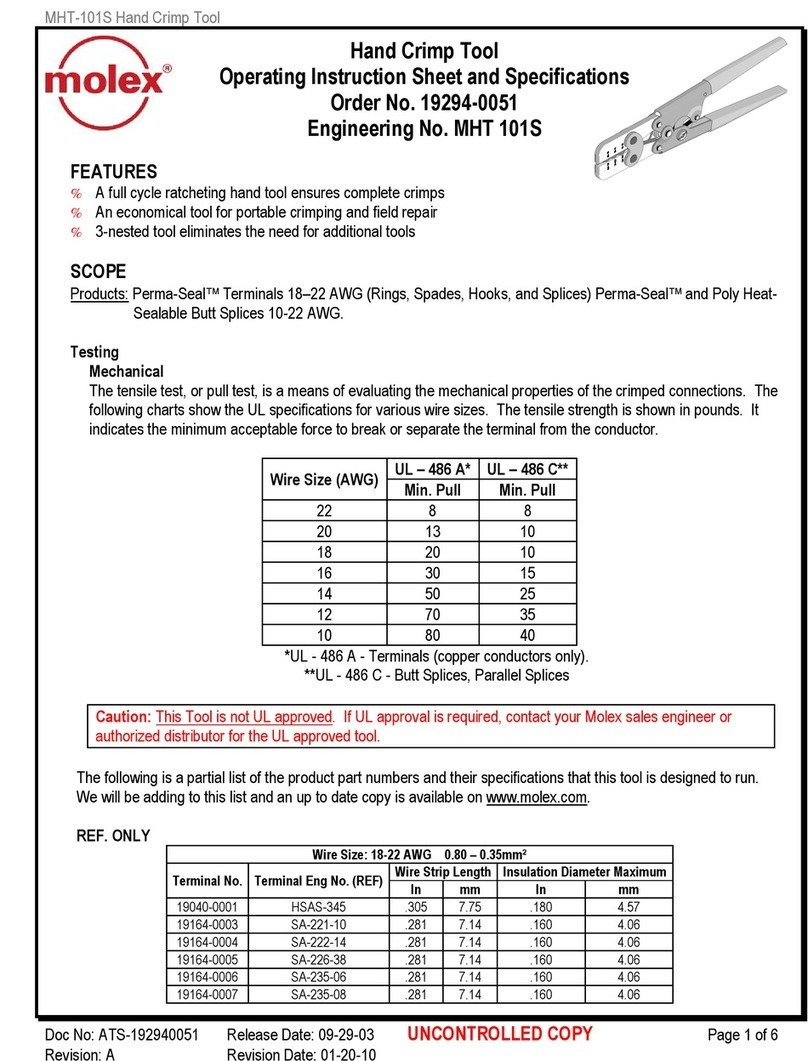

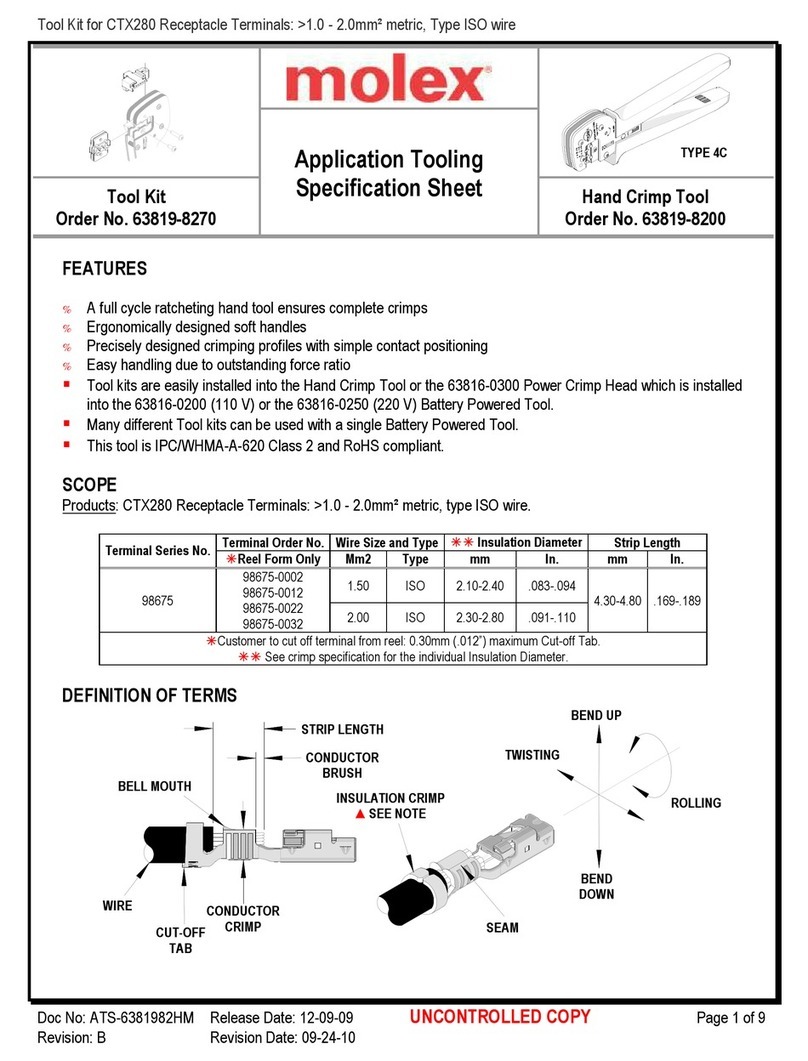

I the cam is not lined up, use the ollowing

procedure.

a) Disconnect the air supply with the cam

in the retracted position trigger is up.

b) Grasp the center section o the cam

with a long nose plier and rotate the

cam clockwise (CW) until the center

line o the wedge line up with (2) #1/4-

20 holes in power unit. See Figure 5

or the correct alignment.

c) Replace the head be ore cycling the

tool. Be sure both screws are in place

and tightened.

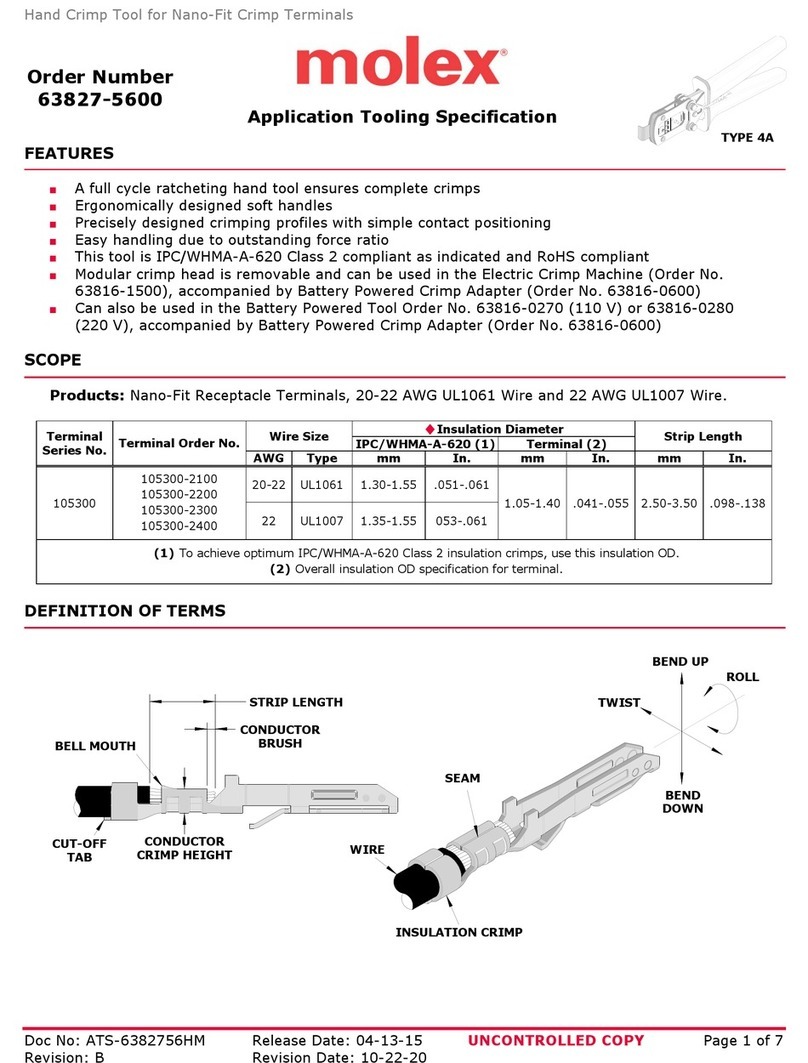

4. To replace the crimp tool head, hold power

unit in le t hand as shown in Figure 6.

5. Grasp the crimp tool head with the right

hand and with the terminal locator acing

you. Slide the crimp tool head assembly

into the body o the power unit until the side

plates o the crimp tool head butt against

the steps in the power unit. Be sure the jaw return springs clear the cam in the power unit. See Figure 6.

6. Line up the holes in the crimp tool head with the holes in the housing o the power unit.

7. Replace the (2) #1/4-20 screws and tighten securely. The tool is now ready or use.

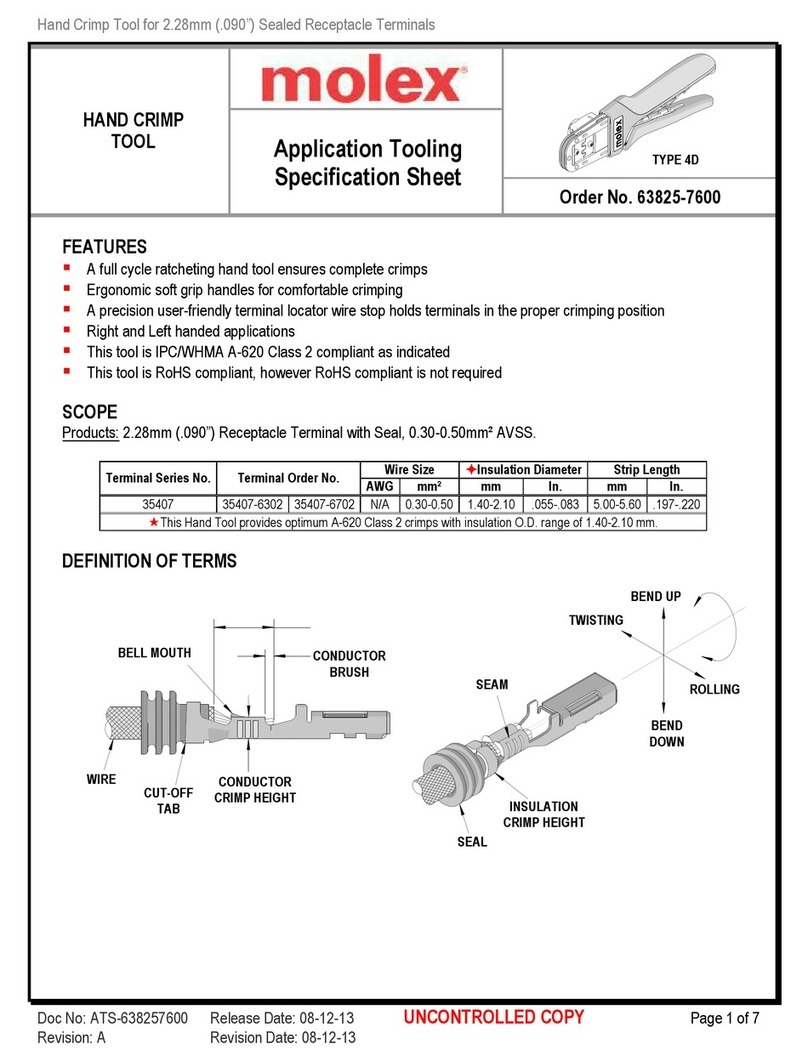

2.2 Ins lation S pport Crimp Adj stment

(Older style fixed jaw air powered crimp tools heads)

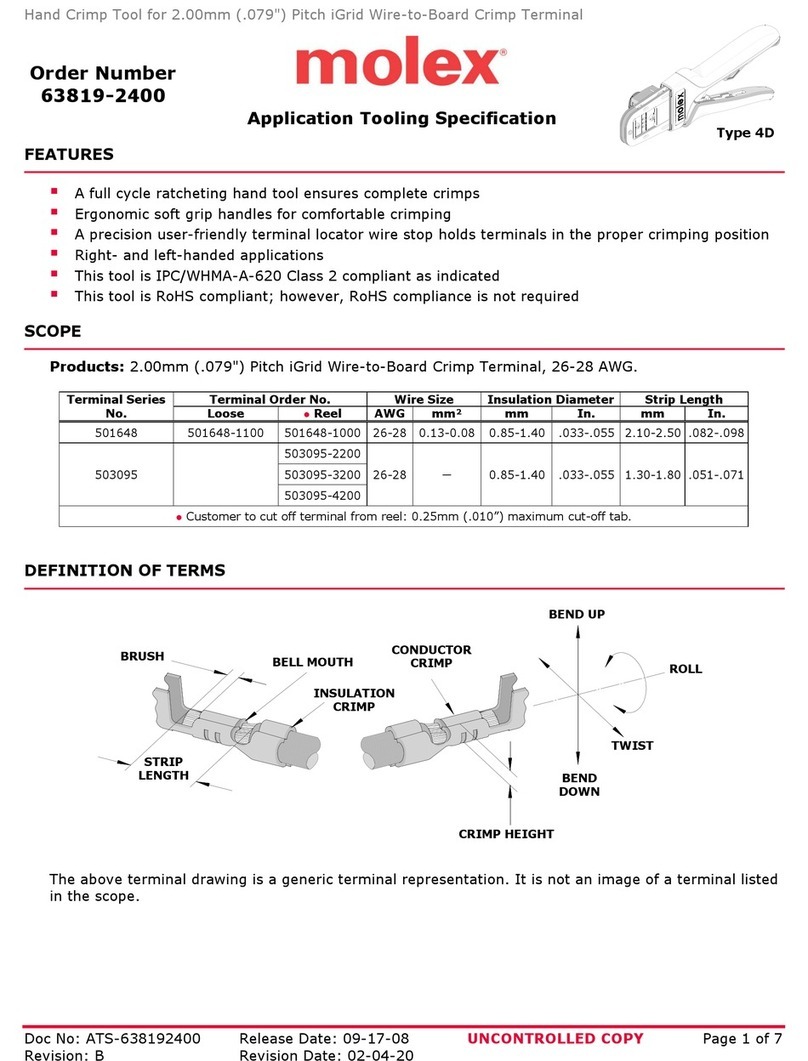

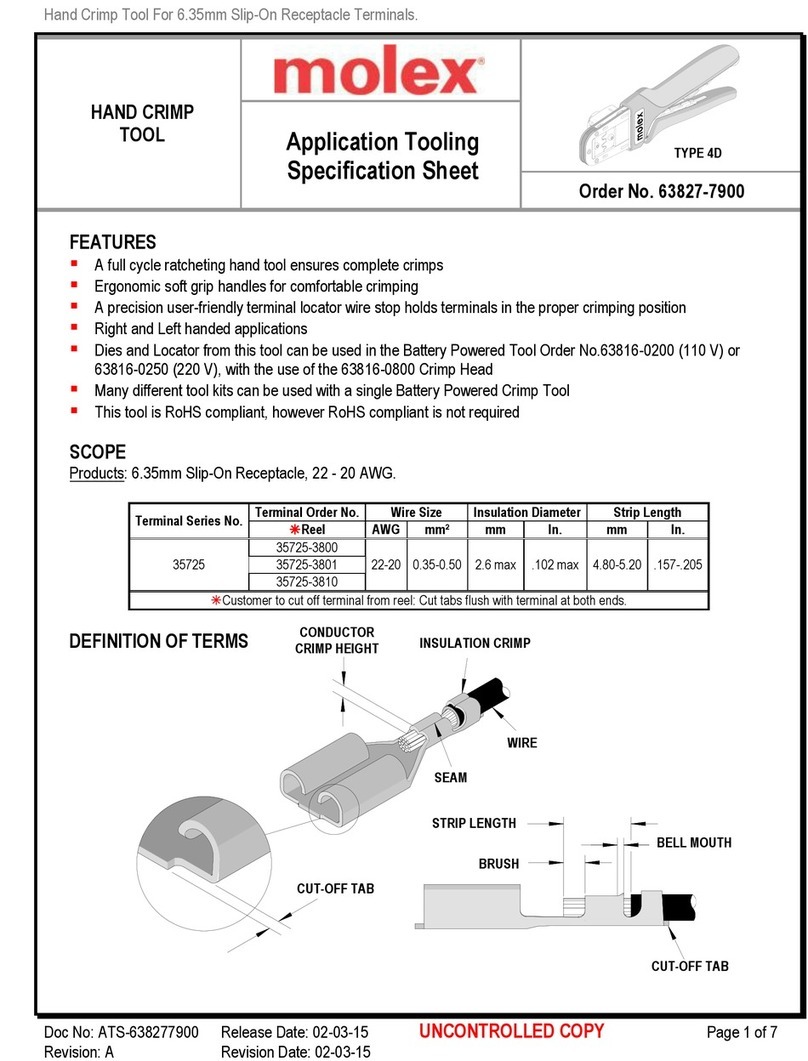

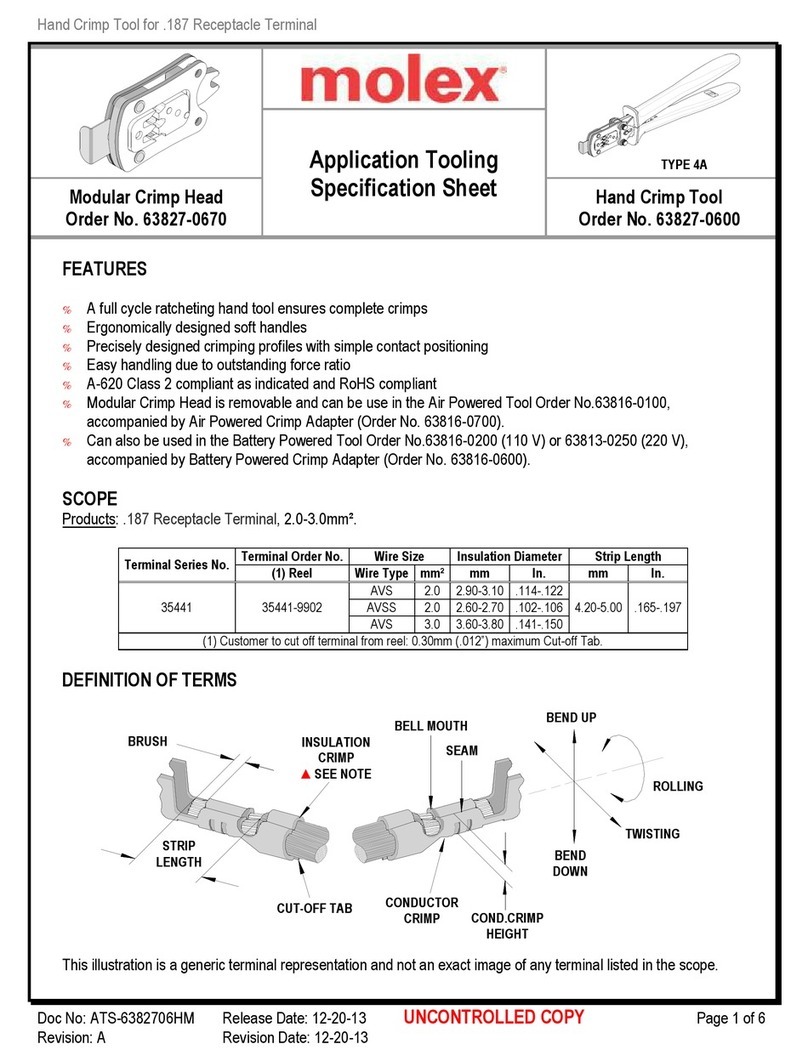

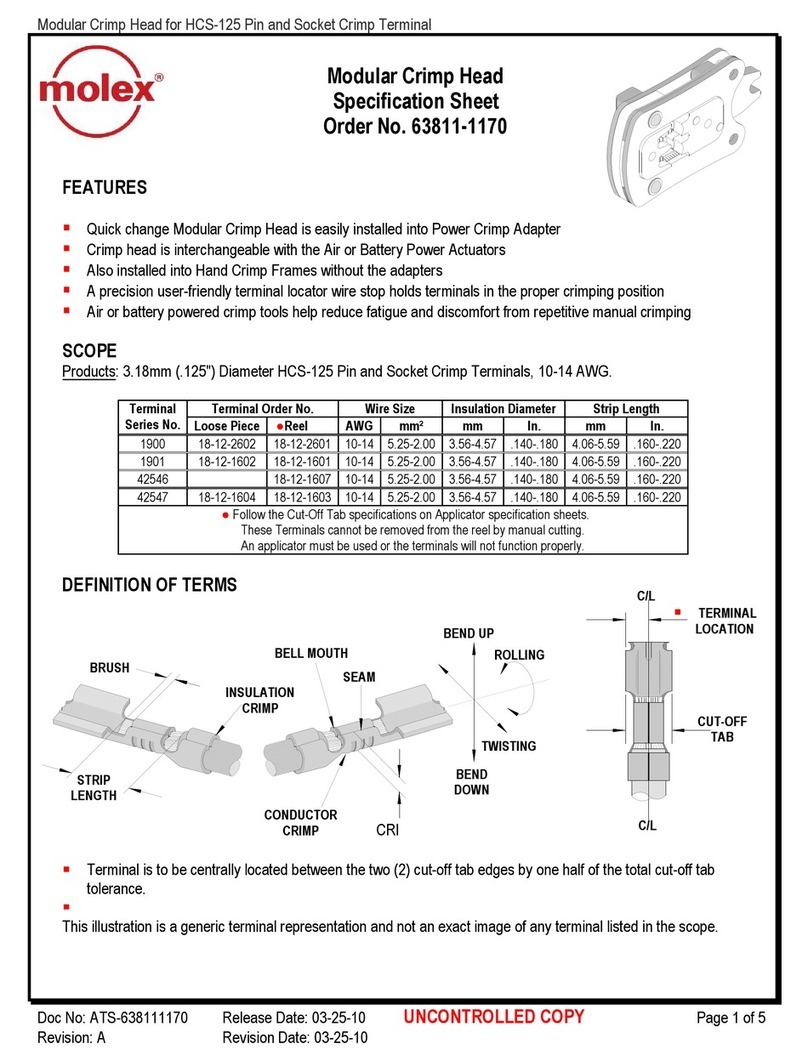

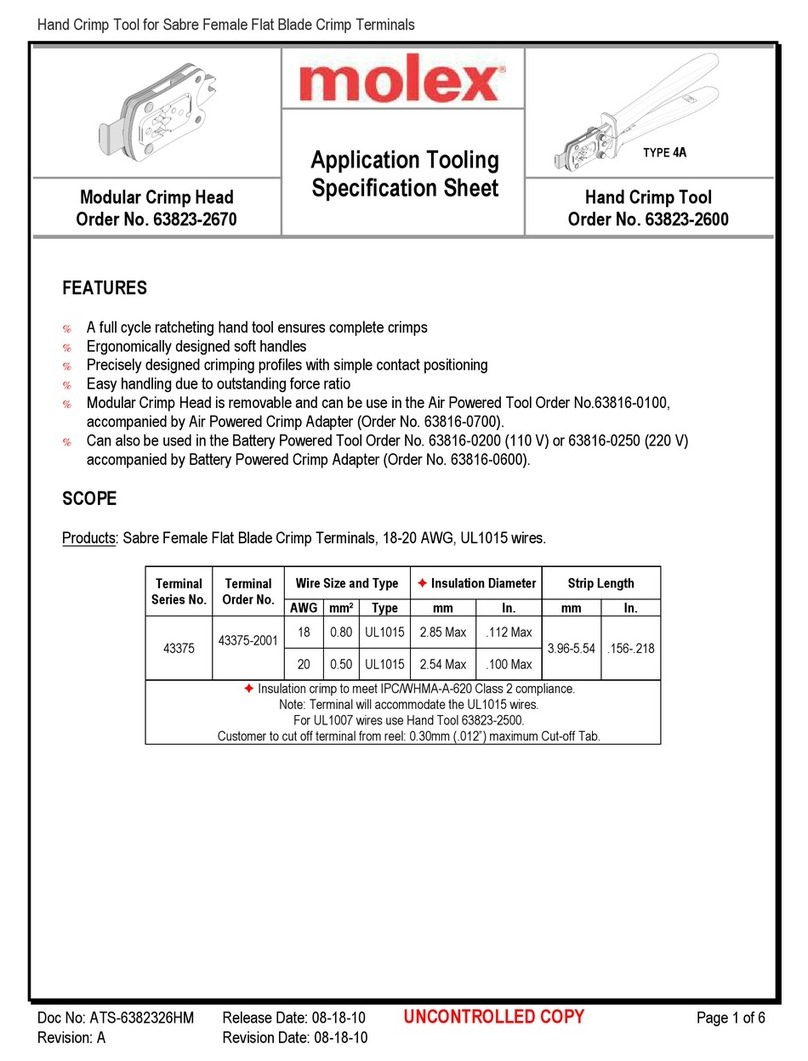

1. The crimp tool heads or the insulated terminals and

the connectors eature an adjustable insulation

support crimp to accommodate varying wire insulation

diameters (See Figure 7) or old style crimp tool head.

2. The adjustment screw on each crimp head tool is set

at the actory at the M position. This setting will give

the best crimp on most wires. Two other adjustment

settings are available: S, the smallest con iguration

and L, the largest con iguration.

3. Crimp a terminal or connector and inspect the

insulation support sleeve crimp or con iguration. A

properly crimped sleeve snugly grasps the wire

insulation.

4. I the crimp con iguration is too loose, change the

adjustment setting by removing the air powered crimp

tool head rom the AT-200 and setting adjustment screw to the S position. Re-insert the air powered crimp tool

head into the AT-200 and crimp, and inspect the insulation support sleeve.

5. I crimp con iguration is too tight, change adjustment setting by removing the air powered crimp tool head rom

the AT-200 and setting adjustment screw to the L position. Re-insert the air powered crimp tool head into the

AT-200 and crimp, and inspect insulation support sleeve.

BUTTS UP AGAINST STEPS

LIGHT OIL (EVERY MONTH

OR 5,000 CRIMPS)

ADJUSTMENT SCREWS