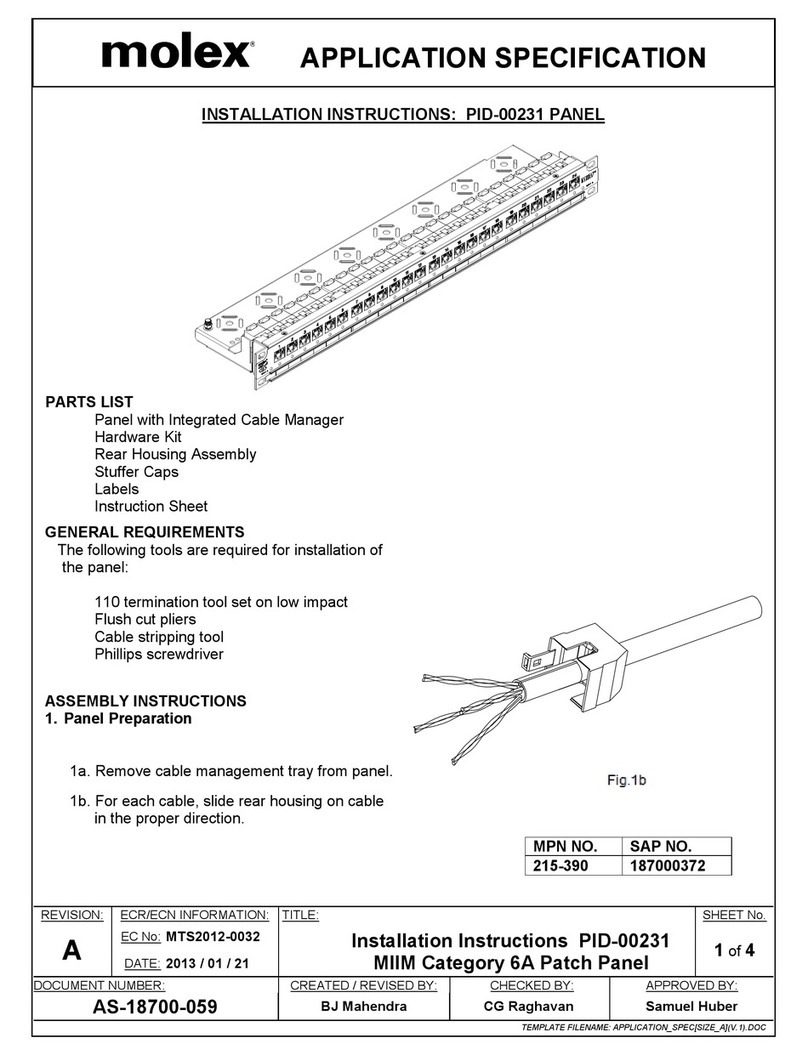

HarshIO 300 ePN

iv

IP67 Digital I/O Modules for PROFINET IO

STATEMENT OF LIMITED WARRANTY

BradControl™ from Molex, manufacturer of HarshIO products, warrants to Buyer that products, except

software, manufactured by BradControl™ will be free from defects in material and workmanship.

BradControl™ obligation under this warranty will be limited to repairing or replacing the defective parts

within one year of the date of installation. Products may be returned by Buyer only after permission has been

obtained from BradControl™. Buyer will prepay all freight charges to return any products to the repair facility

designated by BradControl™.

BradControl™ further warrants that any software supplied as part of a product sale, except obsolete

products, will be free from non-conformances with BradControl™ published specifications for a period of 90

days from the time of delivery. While BradControl™ endeavours to improve the features and performance of

software associated with its products, no effort on the part of BradControl™ to investigate, improve or

modify HarshIO modules firmware at the request of a customer will obligate BradControl™ in any way.

For the convenience of existing customers, BradControl™ continues to supply certain products that are

classified as obsolete. No warranty on the software features of these products is stated or implied and

BradControl™ specifically is not obligated to improve the design of these products in any way. Information

about the status of any product is available upon request and customers are advised to inquire about the

status of older products prior to making a purchase.

This limited warranty does not cover losses or damages which occur in shipment to or from Buyer or due to

improper installation, maintenance, misuse, neglect or any cause other than ordinary commercial or

industrial applications. In particular, BradControl™ makes no warranties whatsoever with respect to implied

warranties of merchantability or fitness for any particular purpose. All such warranties are hereby expressly

disclaimed. No oral or written information or advice given by BradControl™ or BradControl's representative

shall create a warranty or in any way increase the scope of this warranty. This limited warranty is in lieu of all

other warranties whether oral or written, expressed or implied. BradControl’s liability shall not exceed the

price of the individual units, which are the basis of the claim. In no event shall BradControl™ be liable for any

loss of profits, loss of use of facilities or device, or other indirect, incidental or consequential damages.

Although every effort has been made to ensure the accuracy of this document, all information is subject to

change without any notice. BradControl™ takes no liability for any errors in this document or for direct,

indirect, or consequential damage resulting from the use of this manual.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many

variables and requirements associated with any particular installation, BradControl™ cannot assume

responsibility or liability for actual use based on the examples and diagrams.

COPYRIGHTS and TRADEMARKS

Reproduction of the contents of this manual, in whole or in part, without written permission of BradControl™

is prohibited.

Mini-Change®, Ultra-Lock™, BradControl™ are all registered trademarks of Molex, Inc.

All other products or trademarks are the property of their respective owners.