3

OPERATION - PRIMING THE PUMP

WARNING: DO NOT RUN THE PUMP BEFORE PRIMING IT, SINCE THE SEAL AND IMPELLER COULD BE

PERMANENTLY DAMAGED.

MAINTENANCE

WARNING - ELECTRICAL PRECAUTIONS

All wiring, electrical connections, and system grounding

must comply with the National Electrical Code (NEC) and

with any local codes and ordinances. Employ a licensed

electrician.

WARNING - RISK OF ELECTRICAL SHOCK

Before servicing motor operated equipment, shut off the power at

the main electrical panel and disconnect the power supply from the

motor and the accessories. Use safe working practices during

servicing of equipment.

a) Lubrication: The pump requires none. Refer to motor manufactur-

ers instructions for motor lubrication.

b) Cleanout plug: For applications where clogging is a problem, a

1/4" NPT plug has been provided for access to clean the nozzle/

venturi. This plug is located directly below the suction opening in the

front of the casing. IMPORTANT! Before removing the cleanout

plug, shut off the power to the pump at the main electrical panel.

Open a tap in the water system to release the pressure.

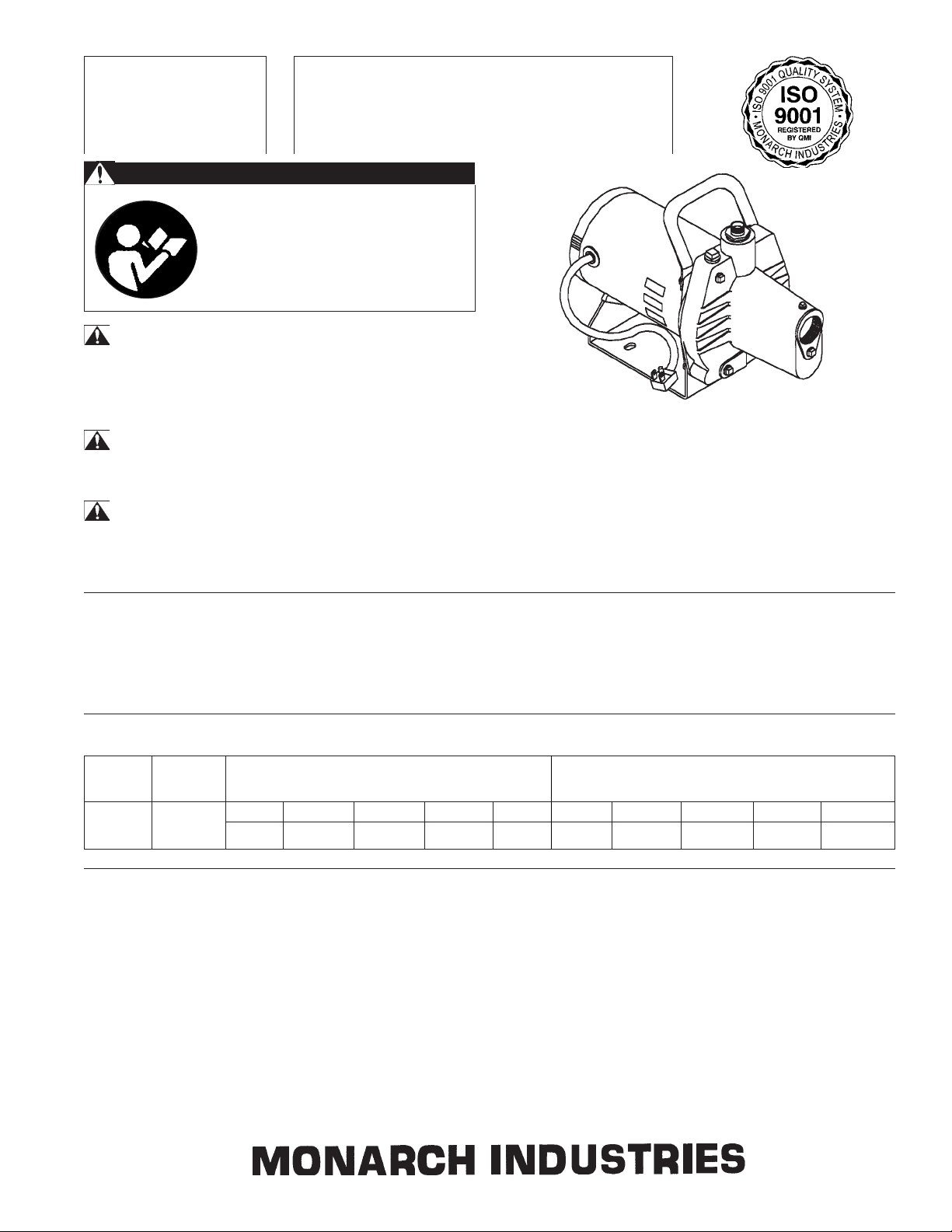

c) Replacing Mechanical Seal: (See Fig. 2)

Disassembly

1) Shut off the power to the pump at the main sevice panel.

2) Open a tap in the water system to release the pressure.

3) Remove the drain (12) and prime plugs to allow the pump to

drain.

4) Remove the 4 bolts (1) and remove casing (2).

5) Pry the diffuser (4) out of the casing using 2 slotted screwdriv-

ers for leverage.

6) Remove cap (5) and insert a screwdriver to prevent the shaft

from turning while unscrewing the impeller (6)(GE m o -

tors). For A.O. Smith motors, remove rear cover and hold the

shaft using a flat wrench inserted from the side, through the

opening in the end of the housing. If the impeller cannot be

turned by hand, insert a flat object into the impeller vane.

7) Slip the rotating seal (7) off the shaft and remove the seal plate

(8).

8) Remove the ceramic seal seat (9) from the seal plate. Fig.2

Reassembly

1) Clean all the parts thoroughly before assembling.

2) Push ceramic seal (9) it into the seal plate using thumbs only.

Make sure the smooth surface of the ceramic seat faces

outwards.

3) Put the seal plate back on the motor.

4) Slip on rotating seal (7) to the shaft with the 'carbon' ring

towards the ceramic seat.

5) Replace the impeller (6) and the diffuser (4).

6) Replace the casing (2) making sure that the venturi is properly

seated, and that the gasket is not damaged and is in place.

7) Reinstall the drain plugs.

8) Reconnect the power.

9) Prime pump, start, check for leaks.

a) Priming: Do not run the pump before priming it, since the seal and impeller

could be permanently damaged. Remove the plug from the street tee and

pour clean water into the unit until casing and suction line are completely

filled. Replace the priming plug and start the motor. If the unit is properly

primed, it should pump almost immediately. If not, repeat the priming

procedure until all the air has been eliminated from the suction line. If an

in-line check valve is used in place of a foot valve, the initial priming time

may take 5 to 15 minutes depending on the suction lift, (higher suction lift

requires longer priming times). At 10 feet or greater suction lifts, water

should be added to the casing approximately every 3 min-

utes until primed. If the pump does not prime within 25

minutes, stop the pump and check for suction leaks.

b) Draining: Should the unit be subject to freezing, it will be

necessary to drain the pump and tank. To do this, shut off the

power to the pump at the main electrical service panel. Open

a valve in the system to release the pressure. Remove drain

and priming plugs from the casing. Allow ample time for

system to drain before reinstalling the plugs!