SETUP MODE

Prior to entering setup mode of the Monit Brake Dial:

• Decide whether to view the Brake Bias dial setting relative to the; FRONT, or

the REAR, or to view in ABSOLUTE.

This decision is down to driver preference. It is recommended to view

relative to FRONT if the driver preference is unknown/unsure.

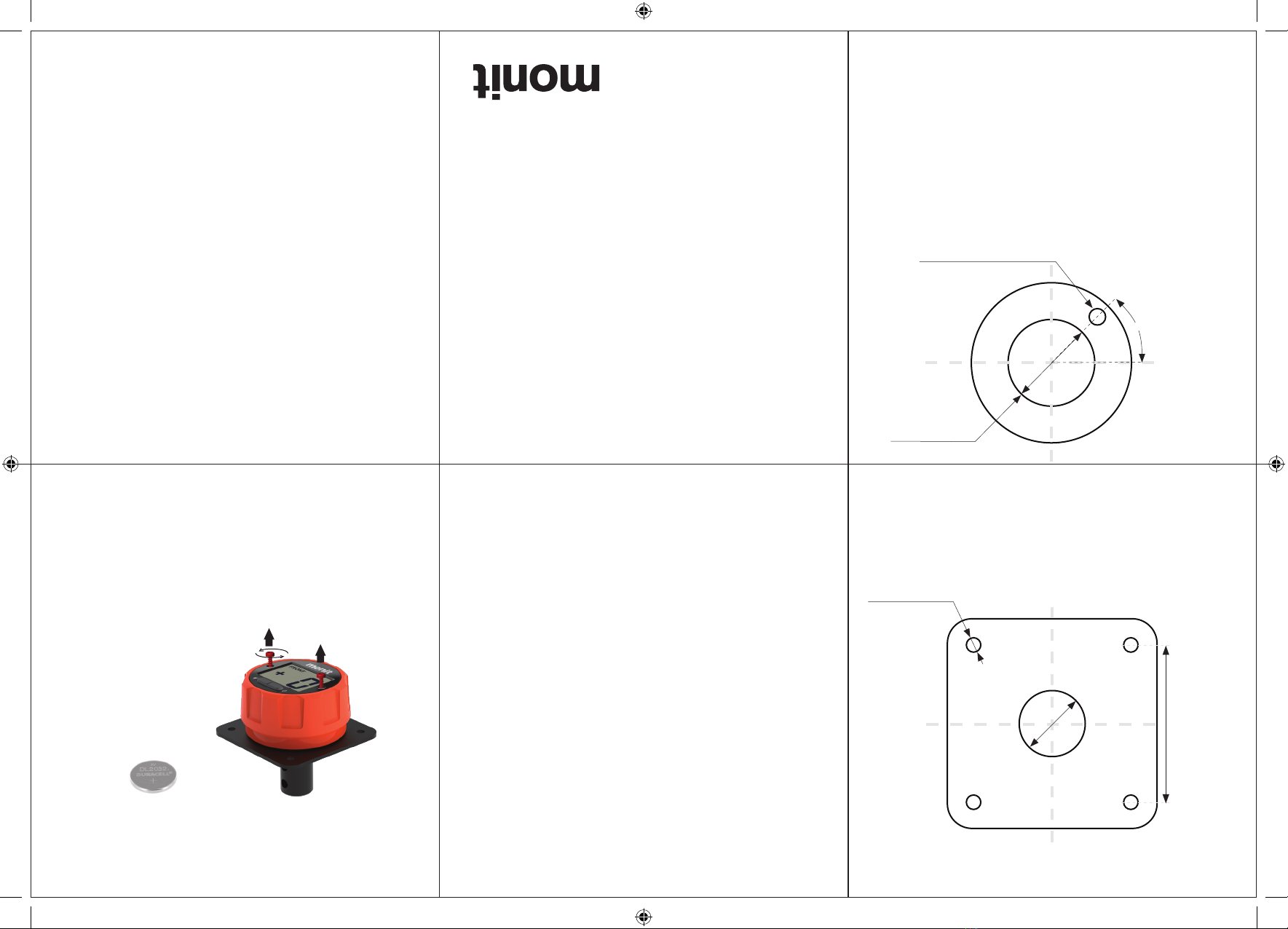

• Check and determine if the front braking force is increased when the

vehicles balance bar is rotated clockwise. Whether it increases or it

decreases will be determined by the vehicles physical pedal box/balance

bar layout relative to the brake master cylinders. This information will be

used in Step 3 below

Press and hold down both the and “”

buttons for 5 seconds.

This will change to Set-up Mode and display the

“” (Clockwise) abbreviation. (The Brake Dial

will return to operation mode if no buttons are

pressed after 30 seconds)

Pressing the button will toggle between “ ” and “ “.

This setting determines what turning the dial clockwise will indicate.

Once preferred options have been set, hold down and “” for 3

seconds to save these settings and return to Operation Mode.

Pressing the “ ” button will toggle between FRONT, REAR, and

Absolute display options. Ensure this preference is chosen prior to

Step 3.

FRONT DISPLAY REAR DISPLAY ABSOLUTE DISPLAY

OPERATION MODE

OPERATION MODE

>

9

0

m

m

r

a

d

i

u

s

.

0.5-1.0Nm

Press and hold for 5 seconds

Press and hold for 3 seconds

Press

Press

Press

Set to “ ” the display

will make a positive

increment (+1) with each

clockwise ¼ turn.

Set to “ ” the display will

make a negative change

(-1 from the dispayed count)

with each clockwise ¼ turn.

Long Press (2.5 seconds)

the “ ” button will reset the

count to zero

Short Press of the

button will illuminate the

display screen for 5 seconds

Long Press (5 seconds) of the button will toggle

between ‘A’ and ‘B’ driver zero settings. The ‘B’ driver

count is separate and can be zeroed independently to the

main driver zero setting.

Rotation of the dial will

change the count displayed

with reference to the settings

saved.

Press and hold

for 5 seconds

CABLE INSTALLATION

Note: It is possible to use an existing cable and adaptor setup to connect

the Brake Dial to the balance bar if the diameter of the cable is less than

Ø3.95mm. If using the existing cable, ensure there is sufficient cable inner

exposed to locate and secure into the rear cable hole on the Monit Brake Dial.

1) Choose a suitable location for mounting the Brake Dial. Trial fit the cable

routing from this location to the balance bar on the brake pedal to point out

any potential obstructions.

2) For optimum performance it is recommended to have fewer and larger

bends in the cable with the shortest most direct route from dial to balance

bar.

3) Based on the routing the cable length may need to be shortened. With the

cable in position mark where it needs to be cut. Remove assembly from

the vehicle onto a workbench for cutting. Braze the inner cable at the cut

mark to avoid fraying when cutting. (Remove the inner cable from the outer

cable to avoid melting).

4) Cut the cable outer 20mm shorter than the finished inner cable length.

5) Once the mounting location and cable routing has been determined, fix the

cable to your vehicle using the cable clamps supplied. To ensure optimum

performance of the cable and dial ensure to use all the clamps provided.

6) Insert the cable inner into the

appropriate balance bar adaptor

(3/8” or 7/16” depending on

balance bar thread) and secure by

tightening the M4 grub screw to a

recommended torque of 0.5-1.0Nm.

Use this same torque setting for the

end of the cable that is inserted into

the back of the Brake Dial.

7) Secure the balance bar adaptor by

tightening the jam nut against it to

the recommended torque settings

from your balance bar manufacturer.

8) Observe the effect that rotating the

dial clockwise has on the brake

bias and apply the relevant rotation

direction label to reflect this.

Note: Route cable as to not obstruct

driver’s feet. Ensure any bends in

the cable layout are no tighter than

90mm radius.