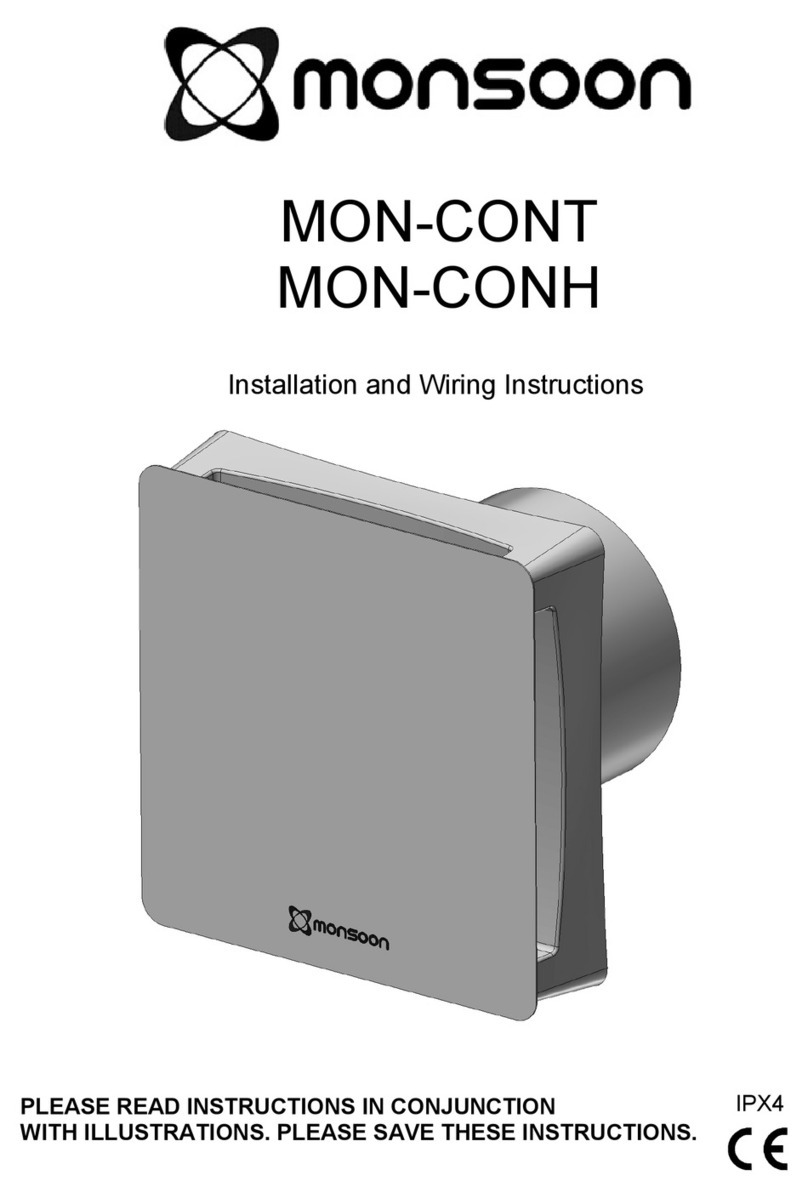

A. INSTALLATION

PANEL/CEILING/ INTERIOR WALL MOUNTING

1. Cut a 107mm diameter hole for 100mm fans or a 130mm hole for 125mm fans.

Note: The 100mm and 125mm fans have outer product diameters of 190mm

and 220mm respectively, when positioning the fan, please provide at least 10cm

between any adjacent walls or ceilings and the fan.

2. Remove the tile front by rotating counter clockwise.

3. Loosen the 3 grille screws to remove inner grille.

4. Mark the screw centres through the holes in the fan back plate. Drill, plug and

screw into position. Attach ducting as required for the installation – (Please see

Condensation section below).

5. Wire the fan as described in Section B-Wiring. Adjust any settings as required

(see Section C-Setup).

6. After installation, ensure impeller rotates freely.

7. Replace the inner grille and tighten the retaining screws. Place tile front onto the

inner grille by aligning and rotating clockwise until fixed.

CONDENSATION BUILD UP

Where ducted Fans are used to handle moisture-laden air, insulated ducting or

a condensation trap should be fitted to prevent water regularly draining onto the

building structure/plasterboard and/or the fan. Horizontal ducts should be

arranged to slope slightly downwards away from the Fan.

EXTERIOR WALL MOUNTING

1. For wall mounting cut a 117mm diameter hole (100mm fans) or a 140mm hole

(125mm fans) through the wall and insert the wall sleeve. Slope the sleeve

slightly downwards away from the fan. Where necessary cut to length and

cement both ends into position flush with the wall faces. The 100mm and

125mm fans have outer product diameters of 190mm and 220mm respectively,

when positioning the fan, please provide at least 10cm between any adjacent

walls or ceilings and the fan.

2. Fix exterior grille into position with the louvres positioned downwards.

3. Remove the tile front by rotating counter clockwise.

4. Loosen the 3 grille screws to remove inner grille.

5. Mark the screw centres through the holes in the fan back plate. Drill, plug and

screw into position. Attach ducting as required for the installation.

6. Wire the fan as described in Section B-Wiring. Adjust any settings as required

(see Section C-Setup).

7. After installation, ensure impeller rotates freely.

8. Replace the inner grille and tighten the retaining screws. Place tile front onto the

inner grille by aligning and rotating clockwise until fixed.