PVVEX58-300 & PVVEX510-300 Horizontal Power Vent

Page 10 XG0518 - 070714

* Based on CGA B149.1 Natural Gas and Propane installation code. Local codes may vary, please check with local regulatory agency.

** Based on ANSI Z223.1/NFPA 54 National Fuel Gas Code. Local codes may vary, please check with local regulatory agency.

+ A vent shall not terminate directly above a sidewalk or paved driveway which is located between two single family dwellings and serve both dwellings.

++ Only permitted if veranda, porch, deck, or balcony is fully open on a minimum of two sides beneath the oor.

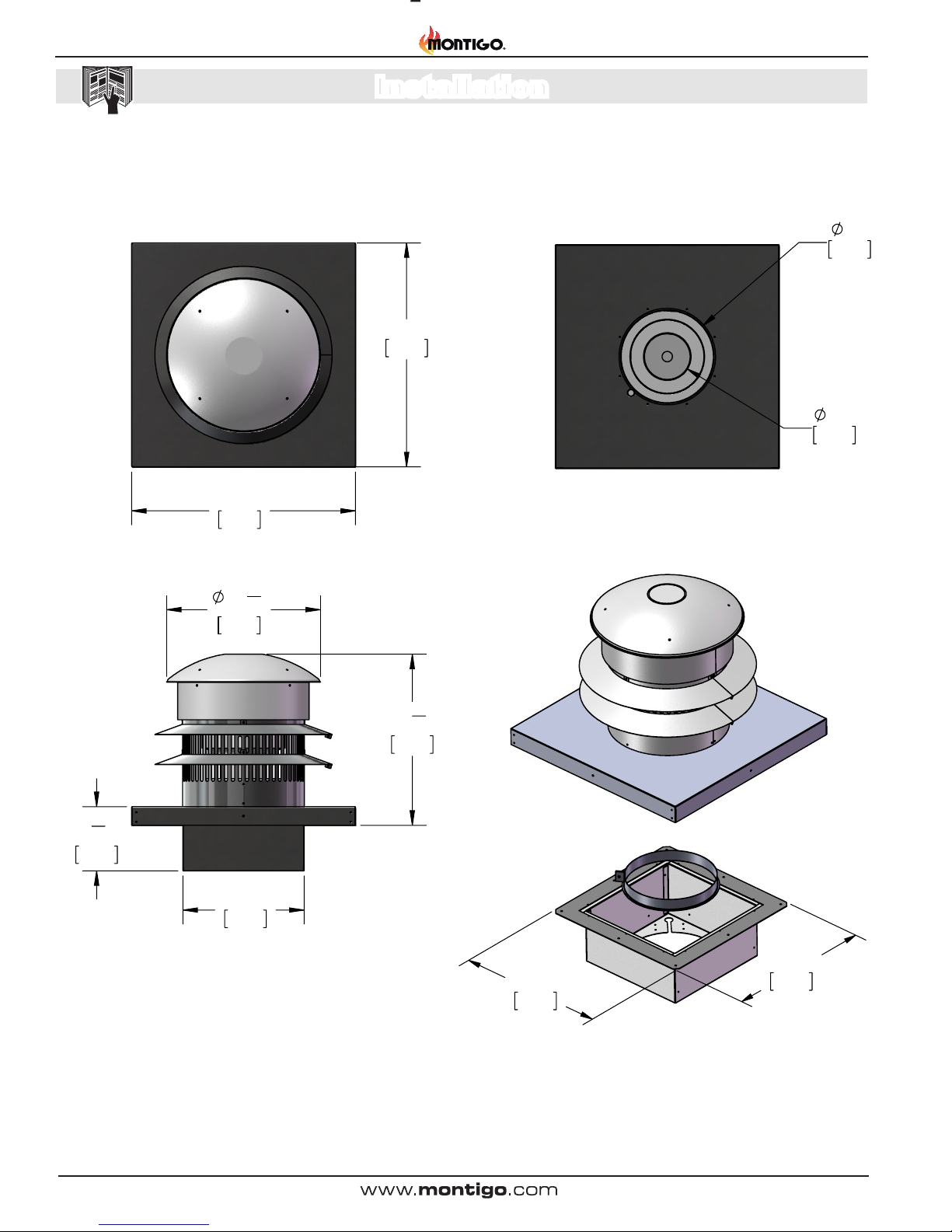

V

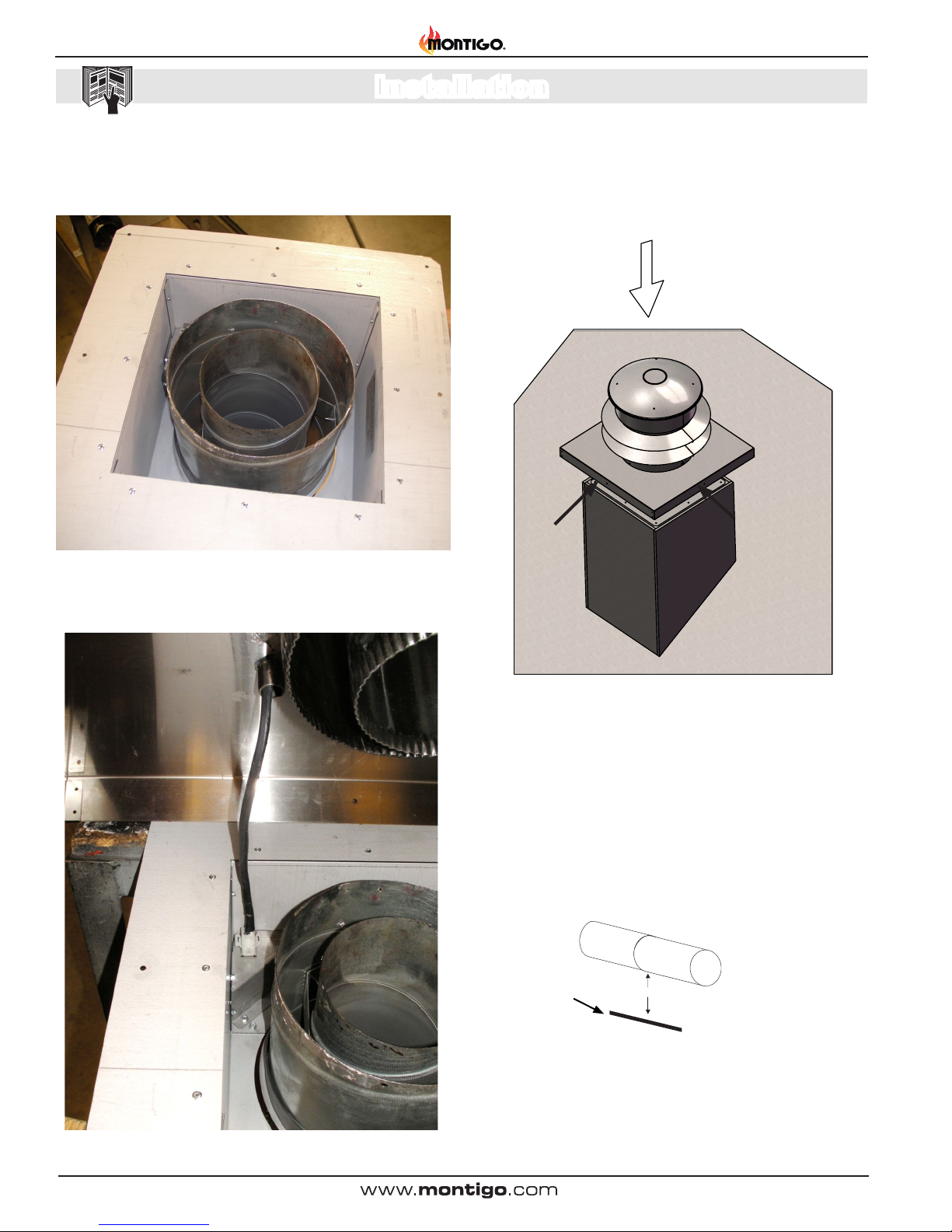

Vertical Detail

Horizontal

Detail

Location Canada* USA**

Aclearance to the termination frame above grade, veranda, porch, deck, or balcony 30 inches 30 inches

Bclearance to top of doors or operable windows 12 inches 12 inches

Cclearance to sides or bottom of door or operable windows 4 feet 4 feet

Dclearance to permanently closed window when installed with approved glass penetration termination 0 0

Eclearance to permanently closed window Recommended to prevent condensation 30 inches 30 inches

Fclearance to ventilated soft located within a horizontal distance to 24 inches from centerline

of termination

22 inches 22 inches

Gclearance to unventilated soft 30 inches 30 inches

Hclearance to outside corner 30 inches 30 inches

Iclearance to inside corner 30 inches 30 inches

Jclearance to each side of the vertical centerline of a metre or regulatory assembly to a maximum

vertical distance of 15ft

3 feet 3 feet

Kclearance to service regulator vent outlet 3 feet 3 feet

Lclearance to non mechanical air supply inlet to the building or combustion air inlet to other

appliance for appliance <= 100.000 BTU/H (30 KW)

12 inches 4 feet

Lclearance to non mechanical air supply inlet to the building or combustion air inlet to other

appliance for appliance > 100.000 BTU/H (30 KW)

6 feet 4 feet

Mclearance to forced air supply inlet 6 feet 3 feet above air inlet

N+ clearance above paved sidewalk or paved driveway located on public property 7 feet 7 feet

P++ clearance under veranda, porch, deck, or balcony 30 inches 30 inches

Qclearance above roof See Fireplace Installation Guide See Fireplace Installation Guide

Rclearance to adjacent walls and neighboring buildings See Fireplace Installation Guide See Fireplace Installation Guide

Sclearance from corner in recessed location 30 inches 30 inches

TMaximum depth of recessed location 48 inches 48 inches

UMaximum width for back wall of recessed location 60 inches 60 inches

VHorizontal clearance between two terminations that are level See Fireplace Installation Guide See Fireplace Installation Guide

WHorizontal clearance (centre to centre) between two terminations that are not level 30 inches 30 inches

Power Vent Locations

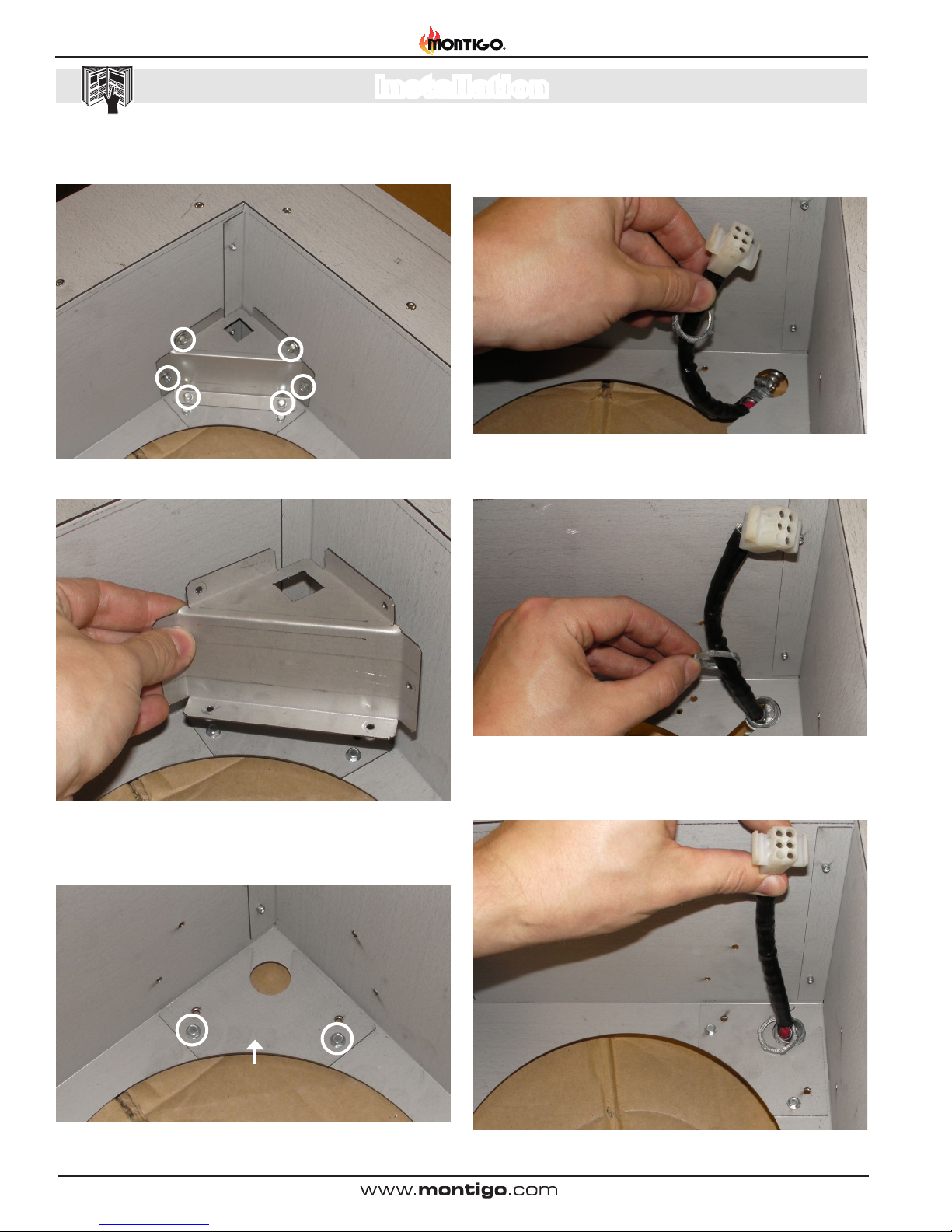

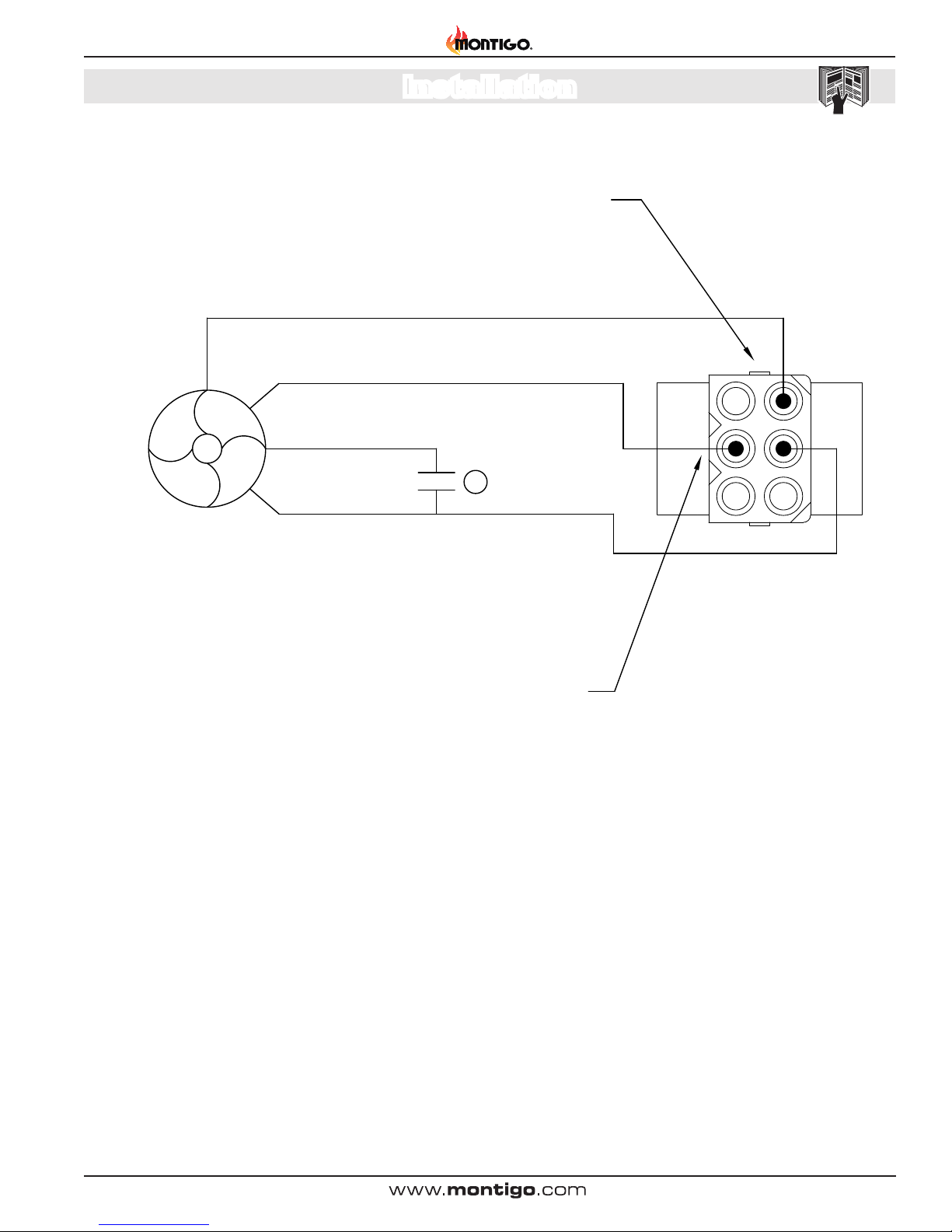

Installation