2

STAC6-Q-H Hardware manual

920-0109 Rev C

4/18/2023

Contents

Safety Instructions ..............................................................................................................................5

Over-Current Protection ...................................................................................................................7

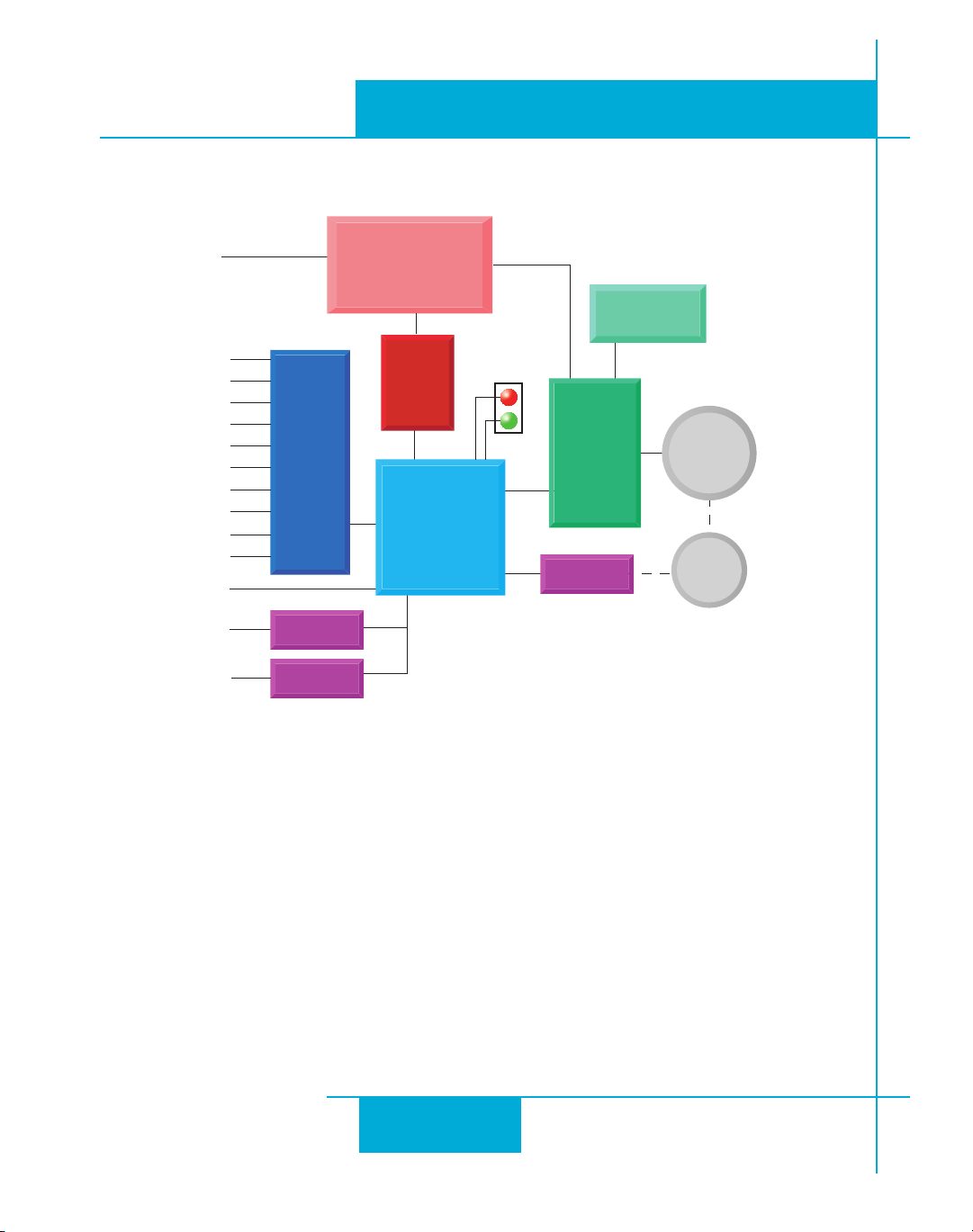

Block Diagram - STAC6-Q-H .................................................................................................................................................8

Motion Control Options....................................................................................................................9

STAC6-H Control Options......................................................................................................................................................9

Getting Started.................................................................................................................................. 10

Connecting to the PC using RS-232........................................................................................... 11

Connecting to the PC using RS-485........................................................................................... 12

Converting USB to RS-485 .................................................................................................................................................13

USB-COMi-M Switch Settings...........................................................................................................................................13

Assigning Addresses in Multi-axis Systems.................................................................................................................13

Connecting AC Power..................................................................................................................... 14

Fusing........................................................................................................................................................................................ 14

Line Filter.................................................................................................................................................................................. 14

Connecting the Motor.................................................................................................................... 15

Connecting an Encoder ................................................................................................................ 17

Encoder Feedback Options ............................................................................................................................................... 18

Wiring Inputs and Outputs ........................................................................................................... 19

Connecting Digital Inputs on the IN/OUT1 connector....................................................... 20

High Speed Digital Inputs.................................................................................................................................................. 20

Using High Speed Inputs with 12-24 Volt Signals..................................................................................................... 22

Standard Digital Inputs.......................................................................................................................................................23

Single Ended Inputs.............................................................................................................................................................23

What is COM? .........................................................................................................................................................................24

Digital Input Connection Examples ...............................................................................................................................24

Connecting Limit switches to the STAC6 Drive.......................................................................................................... 26

Wiring a Mechanical Limit Switch...................................................................................................................................26

Wiring a Limit Sensor........................................................................................................................................................... 27

Connecting Digital Outputs on the IN/OUT1 connector ................................................... 28

Connecting Analog Inputs on the IN/OUT1 connector...................................................... 30

Basic Specications: .............................................................................................................................................................31

Connecting an Analog Input to a Potentiometer or Joystick ............................................................................... 31

Dierential Inputs ................................................................................................................................................................32

Mounting the Drive ......................................................................................................................... 34

Schedule of Limitations:.....................................................................................................................................................34

Electrical Ratings:..................................................................................................................................................................35

Markings: .................................................................................................................................................................................35

Mechanical Outline.......................................................................................................................... 36