Gason 235848 Programming manual

COPYRIGHT

Neither this manual or part thereof may be reproduced or published

without the prior permission of AF Gason Pty Ltd

Operators & Parts

Manual

GPN 235883 REV* 07/01/2021

OH&S Compliance Certification

Company Name A.F. GASON PTY LTD

A hazard identification, risk assessment and risk control procedure has been carried out on a representative example of the under men-

tioned product(s) in accordance with the Occupational Health and Safety requirements of all states and territories of Australia and where

found necessary the appropriate risk control measures have been incorporated in the product specifications.

The operator’s manual contains the necessary health and safety information and safety warnings are applied to the product where neces-

sary.

Product Description PARALLELOGRAM PRESSWHEEL

Models No. or No.’s 235848

Signed on behalf of the above named company

Name (printed) Tom Mccluskey

Position Design Engineer

Date --/--/2021

Details of the Unit Assessed for the Purpose of Compliance

Model No. PARALLELOGRAM PRESSWHEEL

Serial No. 235848-000100

Date of Inspection --/--/2021

Location of Inspection ARARAT, VICTORIA

Contents

Safety ......................................................................................................................................................2

Installation ..............................................................................................................................................3

Torque Specifications..............................................................................................................................3

Set-up......................................................................................................................................................4

Operation................................................................................................................................................4

Maintenance...........................................................................................................................................4

10 hours (Daily)...................................................................................................................................4

100 hours (Weekly).............................................................................................................................4

Bush Replacement..............................................................................................................................5

Tyre/Bearing Replacement.................................................................................................................5

Spare Parts..............................................................................................................................................6

Base Parts Assembly –GPN 235677....................................................................................................7

Shank Options .....................................................................................................................................8

Presswheel Assembly –GPN 235804 ..................................................................................................9

Optional Mud-Scraper –GPN 235809...............................................................................................10

Introduction

1

AF Gason Pty Ltd (Gason) is an Australian

owned family business operating from within

rural Victoria. The Gason Company has been

servicing the needs of rural Australians for

over 75 years. We operate through a local

dealer support network that spans the coun-

try. Gason would like to thank you for pur-

chasing your Australian made tillage attach-

ment, and trust that you will have many years

of trouble free service.

The Gason Parallelogram Presswheels are a till-

age implement attachment that offers inframe

mounting of presswheels to individual tines for

improved seed placement, seed/fertilizer sep-

aration and seed to soil contact.

Some features of the Gason Parallelogram

Presswheel include:

▪Mounts direct to Gason HydraTILL tine.

▪Height setting variable for large range of

under frame clearances.

▪All pivot points use greaseable hardened

bushes.

▪Aluminium split rim that allows fitment

of different tyres, varying in tyre width,

profile and construction.

▪Adjustable tyre down-force.

▪Optional adjustable mud scraper.

▪Adjustable Sowing Boot.

Field experience has shown that a good under-

standing of the implement and its attachments

greatly reduces problems in the field.

Prior to use, please ensure the manual has

been read and understood.

This presswheel may not be suitable for all soil

conditions throughout Australia. When pur-

chasing these attachments please conduct suf-

ficient research to ensure correct operation in

your local conditions. Presswheels of any de-

scription will have an adverse effect on trash

flow. Stubble management at harvest is im-

portant for successful operation of press-

wheels at seeding.

Only the primary shank of the Parallelogram

Presswheel is to be used for engaging un-

worked ground. The Parallelogram Presswheel

sowing boot has been designed to be a sec-

ondary seeding device, it should be adjusted

high enough that it only engages loose soil. If

not, premature wear or failure could occur.

The Parallelogram Presswheel should not be

worked in rocky ground.

Important: Warranty will be void if working in

rocky ground.

Safety

2

Safety

Gason rate operator Safety as one of the high-

est priorities when designing new features and

machines. Every effort is taken to consider the

end user and the safety risks they may face.

Accidents can disable & kill

Accidents are costly

Accidents can be avoided

General Safety

Whilst great care and every effort have been

made by Gason to provide a machine to the

highest possible safety standards, tillage ma-

chinery by nature is potentially dangerous.

Read and understand this manual and the man-

ual of the tractor. Know your machine and its

limits and operate within them. If in doubt, ASK!

Be Prepared

In the event of an emergency it is best to be

prepared. Gason recommend whilst operating

machinery, a fire extinguisher and first aid kit

should be readily available in the event that

they might be required.

Safety Rules

Danger: Stand well clear when the at-

tached machine is in operation, including folding

or unfolding wings.

Danger: Do not work under an unsup-

ported implement.

Danger: Do not work on or make adjust-

ments to the presswheels unless the tractor is

turned off, handbrake applied and key removed.

Caution: Check that all hardware is tight

and properly installed. Refer Assembly Torque

table.

Caution: Where possible, it is good prac-

tice to always keep a mobile phone on your per-

son whilst working alone.

Caution: Be aware of protruding sharp

ground engaging tools whilst in the vicinity of

the machinery.

Disclaimer

Gason accepts no responsibility or liability for any losses, injuries or damages

that may result from failing to observe these safety rules.

Installation

3

Installation

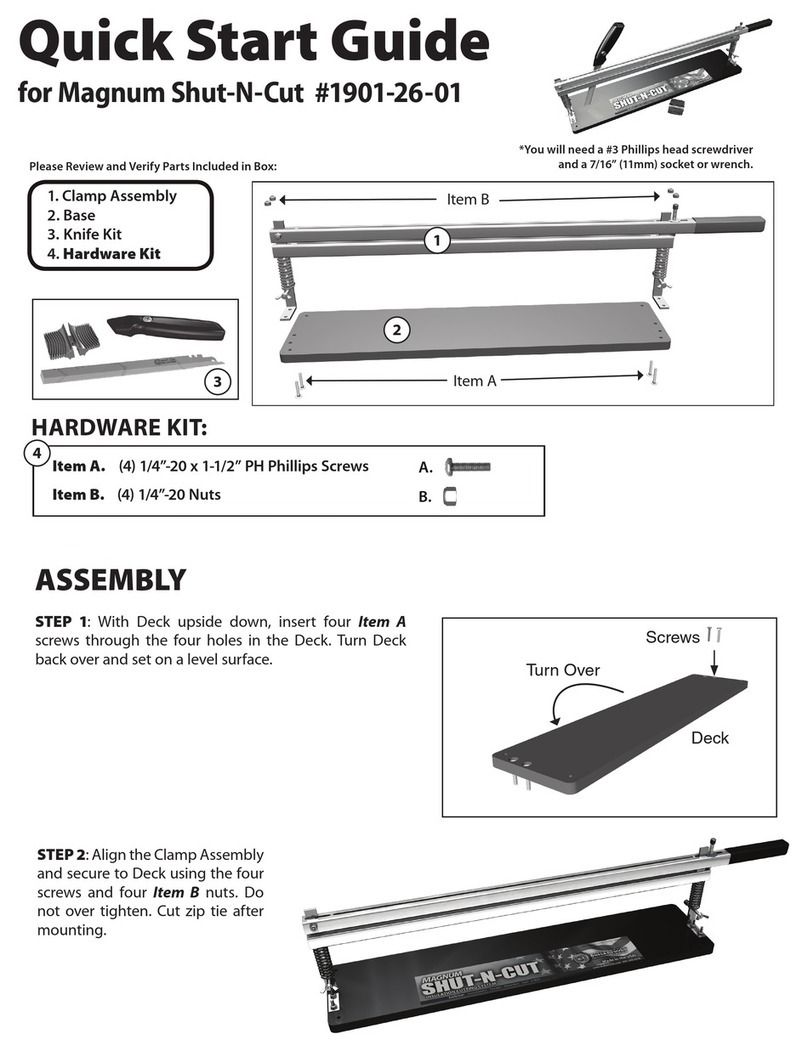

The Parallelogram Presswheel has been de-

signed to fit into a Gason HydraTILL tine.

First, fully raise the implement. The assembly

is installed by pinning though the shank and

cast pivot bracket then tightening and lock-

ing the two M20 set screws. From factory the

pin will be installed in the middle hole in both

the pivot bracket and the shank and the set

screws will be locked loose (for ease of ad-

justment). The mid position will give approx-

imately 750mm under-frame clearance

(UFC), depending on the point used. The UFC

can be adjusted in 12.5mm (1/2”) incre-

ments.

HydraTILL tine with Parallelogram

Presswheel installed in middle position.

Care should be taken to ensure each

Parallelogram is set in the same holes

(same UFC).

Ensure the two M20 set screws are

tightened hard against the shank and

locked with the nut prior to use.

Torque Specifications

Caution: Torque values listed on the

following page should be used as a guide

only. If a different torque value or tighten-

ing procedure is specified for a specific ap-

plication, do not use these values.

Refer to the Parts section for proper grade

and length of bolts for replacement parts.

Do not replace Nyloc nuts with nuts and

spring washers. Replace all parts with origi-

nal specified parts only (note fastener

grades).

The following torque figures are those rec-

ommended for zinc plated, lightly oiled

bolts. Recommended assembly torques may

be obtained by multiplying the torque fig-

ures in the table below by:

0.78 –for degreased zinc plated bolts.

1.10 –for black oxide finished bolts

lbf.ft Nm lbf.ft Nm lbf.ft Nm

7/16 UNF 43 59 60 82 - -

7/16 UNC 39 53 54 74 - -

1/2 UNF 67 91 94 128 - -

1/2 UNC 59 81 83 113 - -

5/8 UNF 135 184 186 253 - -

5/8 UNC 117 159 165 224 - -

3/4 UNF 235 319 325 441 - -

3/4 UNC 210 285 290 394 - -

7/8 UNF 370 502 520 706 - -

7/8 UNC 335 455 470 638 - -

1UNF 550 746 775 1052 - -

1UNC 505 685 710 963 - -

M10 1.5 29 40 41 56 - -

M12 1.75 51 70 73 100 - -

M16 - - - - - 170 231

M16 2.0 126 171 180 245 - -

M18 1.5 - - - - 254 345

M20 1.5 - - - - 376 510

M20 2.5 247 335 351 477 - -

M22 1.5 - - - - 475 645

M24 - - - - - 500 679

M24 3.0 425 577 608 825 - -

Head Markings

(Manufacturers marks

mayvary)

Recommended Assembly Torque

8.8

10.9

Wheel Stud

Metric Grade Number

S.A.E Grade Number

5

8

Size

Thread

Pitch

Wheel Stud

Head Markings

(Manufacturers marks

mayvary)

Operation

4

Set-up

1. Before making any adjustments to the Par-

allelogram Presswheels read and under-

stand the operating instructions for your

implement.

2. Set the desired packing force on the

presswheel tyre by changing the positions

of the extension spring retainers. Moving

the spring retainer rearwards increases

packing force.

3. Initially set the sowing boot depth to posi-

tion “F”. If noted from previous use set

the sowing boot depth to the correct posi-

tion.

4. If installed, the mudscraper should have

approximately 3mm clearance on the

tyre.

5. Set the implement depth stops to achieve

desired digging depth (and fertiliser

depth).

6. Sow at least 50 metres with the implement

and the Parallelogram Presswheels at the

desired sowing speed with product flowing

at desired rates.

7. Stop the machine. Check sowing depth and

adjust sowing boot as necessary. Sowing

boot adjusts in 5mm increments. Repeat

steps 6 and 7 until desired sowing depth is

consistently achieved.

Note: For best results, the sowing boot needs

to be adjusted on commencement of each job

when the machine is at working depth in the

soil to obtain optimum seed placement. Check

and re-check during operation.

Caution: there is a limitation to maxi-

mum depth obtained with the sowing boot.

Depth will varywith soil type, moisture content

of soil, speed of travel and type of digging

point. Never adjust sowing boot depth below

the primary digging tool!

Operation

When working with your frame mounted

presswheels, follow all operating guidelines in

the Implement manual and regularly check for:

▪Blockages due to mud, stubble, etc.

▪Wheels can freely rotate.

▪Even tyre wear and/or damage.

▪All hardware in place and tight.

▪Kinks/blockages in sowing tubes

▪Point, boot & mud scraper wear

Be safety conscious during every operation

with your machine. Ensure bystanders are not

too close or riding on the implement when

working, raising or lowering machine.

Maintenance

10 hours (Daily)

Check for uneven tyre wear or damage, ensure

there is no material build-up on presswheels,

arms, sowing boots or mud-scrapers.

Check for kinks or blockages in sowing tubes,

manually run product through the distribution

system whilst stationary and ensure product is

being dispensed from each sowing boot.

100 hours (Weekly)

Grease the four hardened steel pivots. In ex-

treme dusty conditions pivots should be

greased at 50 hours or twice weekly. Use any

lithium based, extreme pressure general pur-

pose grease containing approximately 10%

weight of molybdenum disulphide.

Check wheels can freely rotate, observe wear

on point, sowing boot & mud scraper and re-

place as necessary. Check all hardware is in

place and tight.

Operation

5

Bush Replacement

For pivots using hardened steel pins and

bushes, follow the procedure below:

Removal and installation of the bush must be

done as follows:

1. Remove worn bush from its housing.

2. Check for damage, clean and degrease

the housing internal diameter and the new

bush external diameter with a contact cleaner

or Loctite 770.

3. Allow to dry.

4. Apply a light coating of Loctite 620 or similar

retaining compound to the leading chamfered

edge of the replacement bush external diame-

ter only.

5. Press fit into housing until flush.

Important: Take extreme care not to damage

or remove the inner surface of the bush. En-

sure no adhesive contacts the bush’s inner

surface.

Tyre/Bearing Replacement

The Manutec presswheel fitted to the Paral-

lelogram consists of a split aluminium rim, a

rubber tyre, two sealed deep groove ball

bearings, steel seals, bushings and fasteners.

A long service life, without the need for relu-

brication, adjustment or any other mainte-

nance can be expected. In the event that a

failure occurs, follow the following instruc-

tions for replacement of the bearings or press-

wheel tyre.

Disassembly instructions

1. Remove wheel/tyre assembly from the

Parallelogram by removing the M16 axle

bolt.

2. Remove the M10 fasteners holding the

two halves of the aluminium rim together.

3. Disassemble the two rim halves and the

tyre.

4. Sitting the rim halves on two blocks of

wood, inside facing upwards, use a punch

on the bearings outer race to remove the

bearings, seals and bushings if required.

5. Inspect all components and replace as nec-

essary.

Assembly instructions

1. Placing the rim halves inside down on a flat

surface, use a suitable tool to press/punch

in the bearing by its outer race.

2. Fit flat washer and steel bush.

3. Use a suitable tool to press/punch in the

metal seal.

4. With the presswheel tyre between the two

rim halves, torque M10 fasteners to

60N.m.

5. Replace assembly and secure M16 axle

bolt tightening only enough to prevent ro-

tation.

6

Spare Parts

Parallelogram Presswheel

Spare Parts

7

Base Parts Assembly –GPN 235677

ITEM

PART No.

DESCRIPTION

QTY

1

209191

CLIP GRIP 3MM

1

2

REF.

SHANK ASSEMBLY AS CONFIGURED

1

3

214877

SPRING EXTENSION

2

4

235671

LINKAGE PLATE UPPER

2

5

235672

LINKAGE PLATE LOWER

2

6

235673

SPRING RETAINER

2

7

235674

PARALELLOGRAM WELDMENT

1

8

235675

PIN

1

9

236570

SOWING TUBE PARALLELOGRAM

1

10

235804

PRESSWHEEL ASSY

1

11

235809

MUDSCRAPER KIT

1

12

900824

PIVOT BUSH

4

13

903406

NUT NYLOC M10 CL8 AS1285

1

14

903930

NUT NYLOC M16 CL8

5

15

913421

BOLT M10x75x1.5P GR8.8 HEX Z/P

1

16

913670

BOLT M16x130 GR8.8 HEX ZP

5

17

235853

DECAL –SOWING TUBE

1

Spare Parts

8

Shank Options

ITEM

PART No.

DESCRIPTION

QTY

1

209644

CLAMP

1

2

214750

SHANK ASSEMBLY - KEECH FEMALE

1

3

214913

SHANK ASSEMBLY - DOUBLE BOLT

1

4

214914

SOWING BOOT ASSEMBLY

1

5

237124

POINT HMA 1051XP

1

6

903205

NUT M5 WHIZ LOCK FLANGE - CL10

1

7

903302

NUT NYLOC M8

1

8

917311

SCREW SET M8 x 40 x 1.25P

1

9

922329

SCREW CAP M5 x 15

1

10

206036

PIVOT BUSH FOR REF. INCLUDED IN SHANK ASSEMBLIES

REF.

ASSEMBLY NOTE: APPLY THREAD

LOCKING ADHESIVE TO ITEM ⑨.

Spare Parts

9

Presswheel Assembly –GPN 235804

ITEM

PART No.

DESCRIPTION

QTY

1

201256

6205-2RS DEEP GROVE BALL BEARING

2

2

207181

TYRE PRESSWHEEL –55 WEDGE SOLID

1

207183

TYRE PRESSWHEEL –80 WEDGE SOLID

210381

TYRE PRESSWHEEL –55 WEDGE SP

210384

TYRE PRESSWHEEL –80 WEDGE SP

3

235803

PRESSWHEEL RIM (PAIR)

1

4

235805

METAL SEAL 25 X 52

2

5

235806

WASHER 34 X 51.8 X 2.8

2

6

235807

STEEL BUSH SHORT

1

7

235808

STEEL BUSH LONG

1

8

902205

NUT LOCK M12 x 1.75P HEX ZP

3

9

917601

SCREW SET M12 x 25

3

ASSEMBLY INSTRUCTIONS ON PAGE 5.

Spare Parts

10

Optional Mud-Scraper –GPN 235809

ITEM

PART No.

DESCRIPTION

QTY

1

237745

MUDSCRAPER - PAINTED

1

2

917335

SCREW SET M8 x 20 FLANGED SERRATED

2

ASSEMBLY NOTE: APPLY THREAD

LOCKING ADHESIVE TO ITEM ②.

Table of contents

Popular Industrial Equipment manuals by other brands

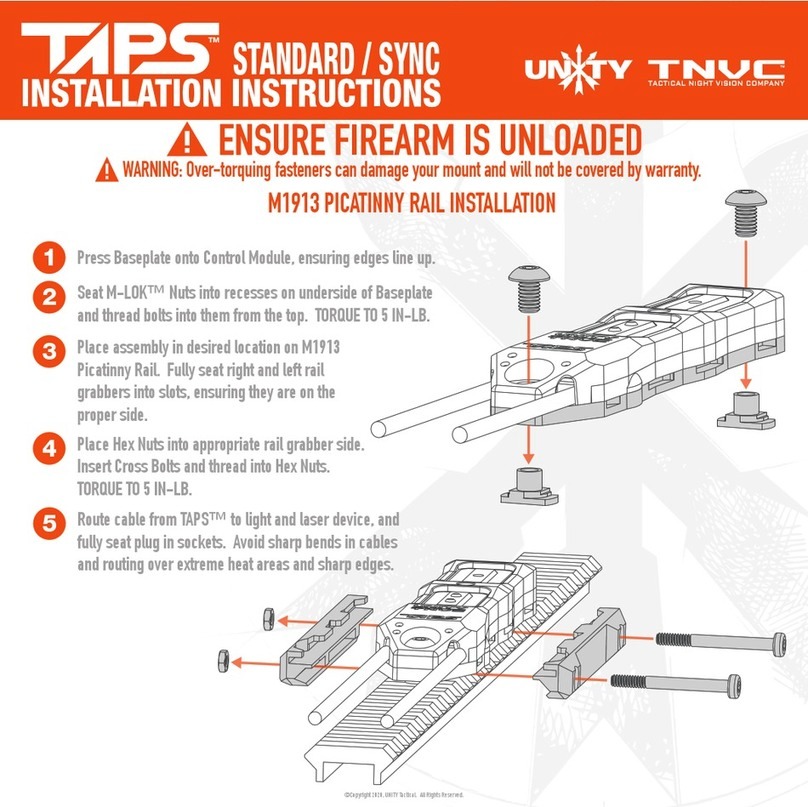

Unity

Unity M1913 installation instructions

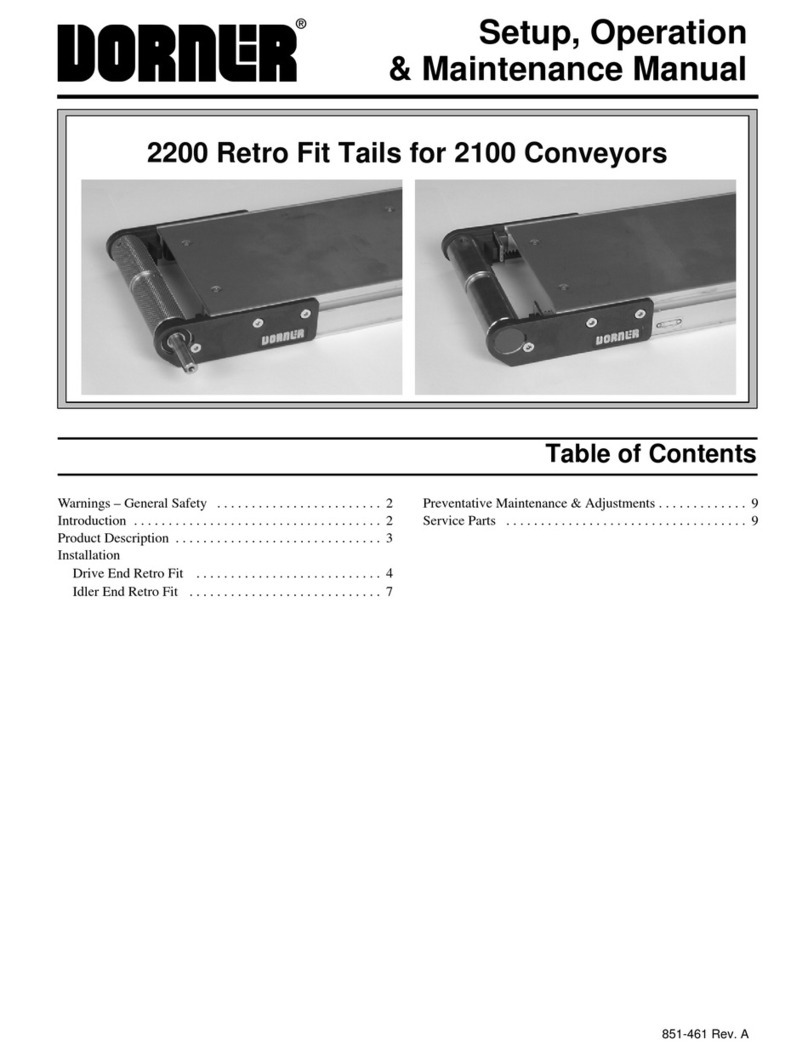

Dorner

Dorner 2200 series Safety, Setup, Operation & Maintenance Manual

PennBarry

PennBarry Domex Operation & maintenance manual

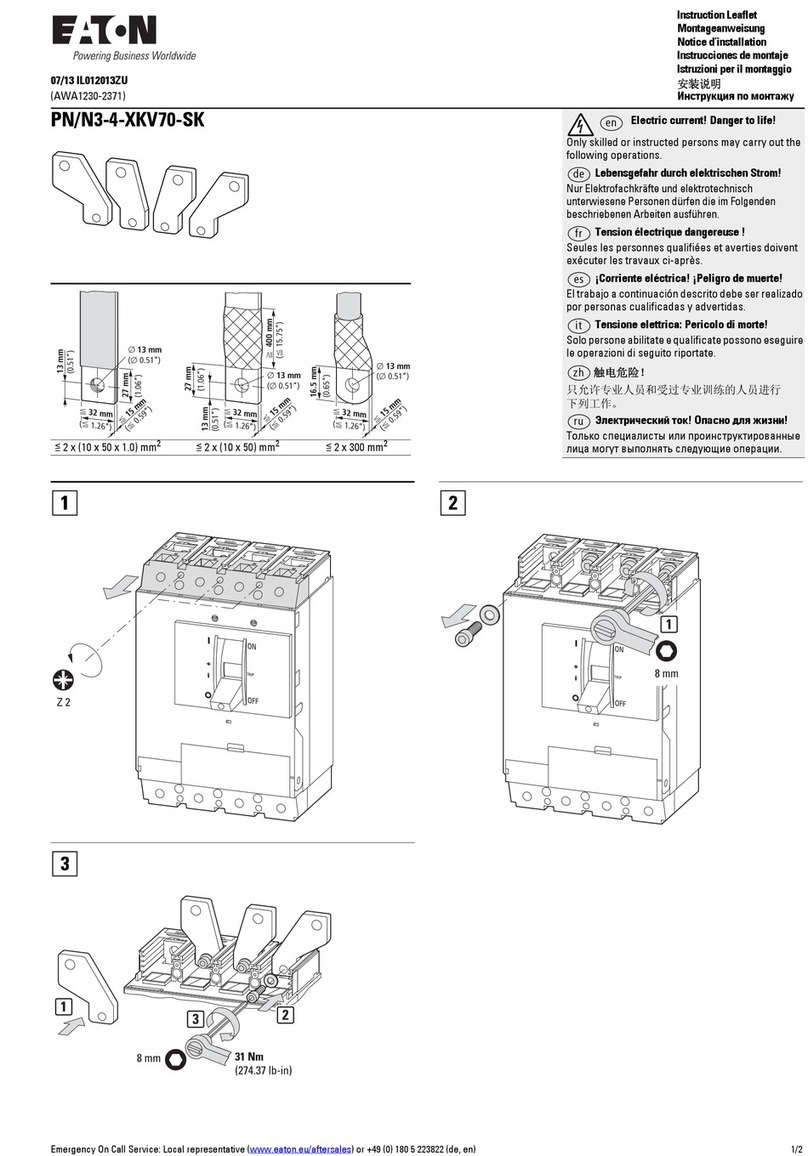

Eaton

Eaton PN/N3-4-XKV70-SK Instruction leaflet

Endura

Endura XL100 Installation operation & maintenance

ALLSPEEDS

ALLSPEEDS Webtool HCV270 instruction manual