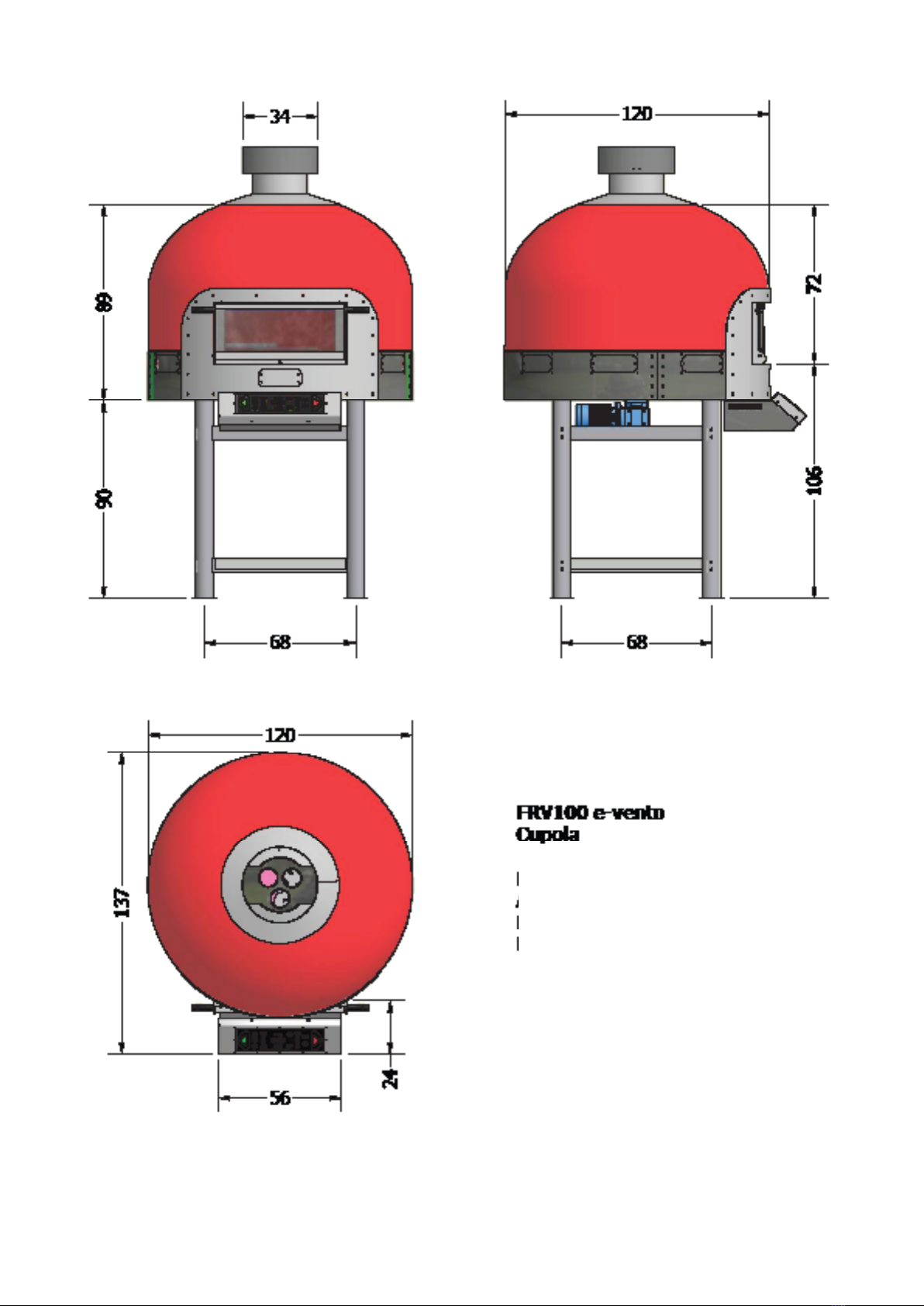

RANGE FRV100 MORELLO FORNI S. A. S.

4

Chapter 1. General contents

1.1 TESTING AND WARRANTY

The unit has been tested in the manufacturer’s plant in compliance with current laws and regulations and is

supplied ready to use.

The warranty is valid 12 months from the date of delivery of the oven and covers the reparation of all

defective parts. Visible defects and dissimilarities in the order, if existing, must be reported to the manufac-

turer within 5 days from the date of receipt of the oven in order to be accepted.

All other defects that become evident after the receipt of the oven must be reported within ve days from

the date of occurrence or, at any rate, within a maximum of 6 months as stated in the warranty. The

purchaser shall be entitled to claim for the reparation or the replacement of the defective parts only, as the

warranty does not cover any whatsoever direct or indirect damage.

However, the reparation or replacement of defective parts must be requested within the maximum limit sta-

ted in the warranty, unless otherwise provided for in applicable laws and regulations.

Defective materials shall be repaired or replaced in the manufacturer’s plant. Therefore, the purchaser shall

return said materials carriage free to the manufacturer, who shall in turn return them carriage forward to the

customer.

1.2 PREMISE

This manual is supplied in order to provide all the instructions for a correct use and maintenance of the

oven, and the maximum safety of users.

The description of the following professional qualications and related duties are provided for further

clarication.

Installer: qualied technician in charge of the installation and commissioning of the oven in

accordance with the instructions of this manual.

User: any person who is familiar with the content of the manual and who uses the oven for the intended

use and in accordance with the instructions provided. Users are always expected to carefully read and

consult the manual. Users are recommended to specically and frequently read and refer to paragraph 1.5

Safety Precautions.

Technician responsible for ordinary maintenance: qualied technician trained to perform ordinary

maintenance operations in accordance with the instructions of this manual.

Technician responsible for extraordinary maintenance: qualied technician trained to perform

extraordinary maintenance on the unit.

The manufacturer disclaims all responsibility for damages originating from the improper and incorrect use of

the oven or from the failure to comply with the instructions of this manual.

This manual should be stored in an accessible location that is known to all users (installer and technicians

responsible for ordinary and extraordinary maintenance).

This manual cannot be reproduced and/or transmitted, in whole or in part, with any whatsoever means or

media.

1.3 CUSTOMER’S DUTIES

The customer shall be responsible for the following:

- Correct and safe installation of the oven received

- Power supply

- Connection to the ue

- Consumables for cleaning

- Ordinary maintenance

The symbol , which is present in some parts of this manual, highlights an

important warning that should be followed for safety purpose.