BARTELL MORRISON INC. BARTELL MORRISON (USA) LLC

375 ANNAGEM BLVD, MISSISSAUGA, ONTARIO, CANADA, L5T 3A7, 905-364-4200 FA 905-364-4201

25 INDUSTRIAL DRIVE, KEYPORT, NEW JERSEY, USA, 07735, 732-566-5400 FA 732-566-5444

Created 07/04

Revised 05/11

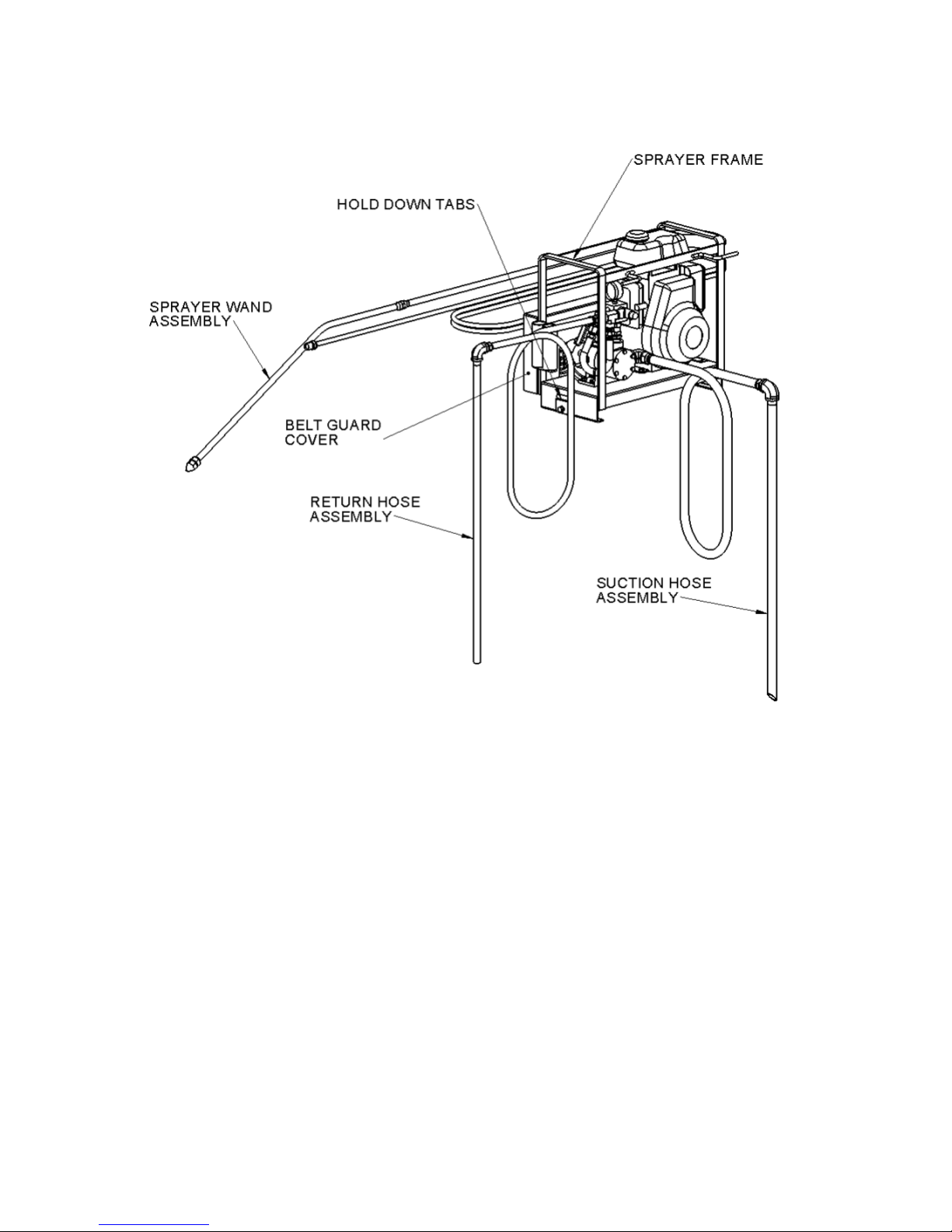

• NEVER leave the power sprayer unattended while running.

• Children and small animals should NEVER be present in the work area during

operation of the power sprayer.

• ALWAYS check your power sprayer for loose or missing nuts

and bolts before starting. Tighten any loose fasteners and replace

missing or broken parts.

• Perform all routine maintenance as described within this manual. Failure to do

so will void your warranty and will eventually result in premature equipment

failure.

• NEVER perform maintenance on a running piece of equipment. Shut down the

engine and allow it to cool before servicing the power sprayer, including

mechanical work or lubrication.

• ALWAYS replace missing, damaged or unclear safety

labels to ensure operator awareness and safety.

• NEVER operate the power sprayer with missing or

damaged safety guards. Replace immediately with

appropriate Morrison parts.

• NEVER put hands, feet, or other appendages inside the

belt guard while the engine is running, even at idle or

with protective clothing, as serious injury may result.

• NEVER wear loose fitting clothing or jewelry around rotating equipment such

as the power sprayer as it may become entangled in the machinery, resulting

in serious injury.

• ALWAYS refuel the power sprayer in a well-ventilated area,

away from ignition sources such as sparks, flames, and lit

cigarettes. Smoking while fuelling the equipment may result in

explosion.

• Ensure the engine has cooled sufficiently before refueling to

avoid igniting gasoline fumes.

• NEVER operate the power sprayer in explosive environments

such as paint fumes, methane, natural gas, fine particulate,

aerosol propellant, or solvent fumes.

• NEVER smoke near the power sprayer as stray gasoline fumes

may ignite. Operating the power sprayer around an open flame

may also result in explosion.

• ALWAYS shut down the engine and allow it to cool off before lifting or

transporting the power sprayer.

• ALWAYS tie down the power sprayer when being transported in a truck or on

a flatbed. Empty the fuel tank if transporting it over long distances.