311822

3

Engine Radiator ............................................24

Recommended Spare Parts...........................25

Replacement Parts.........................................26

Compressor Replacement Parts ....................27

Troubleshooting ................................28

Overview .......................................................28

Machine Will Not Crank..................................28

Machine Cranks But Will Not Start.................28

Machine Shuts Down With Air Demand

Present...........................................................28

Machine Will Not Build Pressure....................28

With No Demand, Machine Builds Excessive

Pressure ........................................................28

Insufficient Air Delivery...................................28

Engine Fan.....................................................29

Radiator Pressure Cap..................................29

Unplanned Shutdown.....................................29

Improper Discharge Pressure .......................29

Engine Overheating ......................................29

Compressor....................................................29

Insufficient Air Delivery ..................................30

High Compressor Discharge Temp................30

Separator Plugging .......................................30

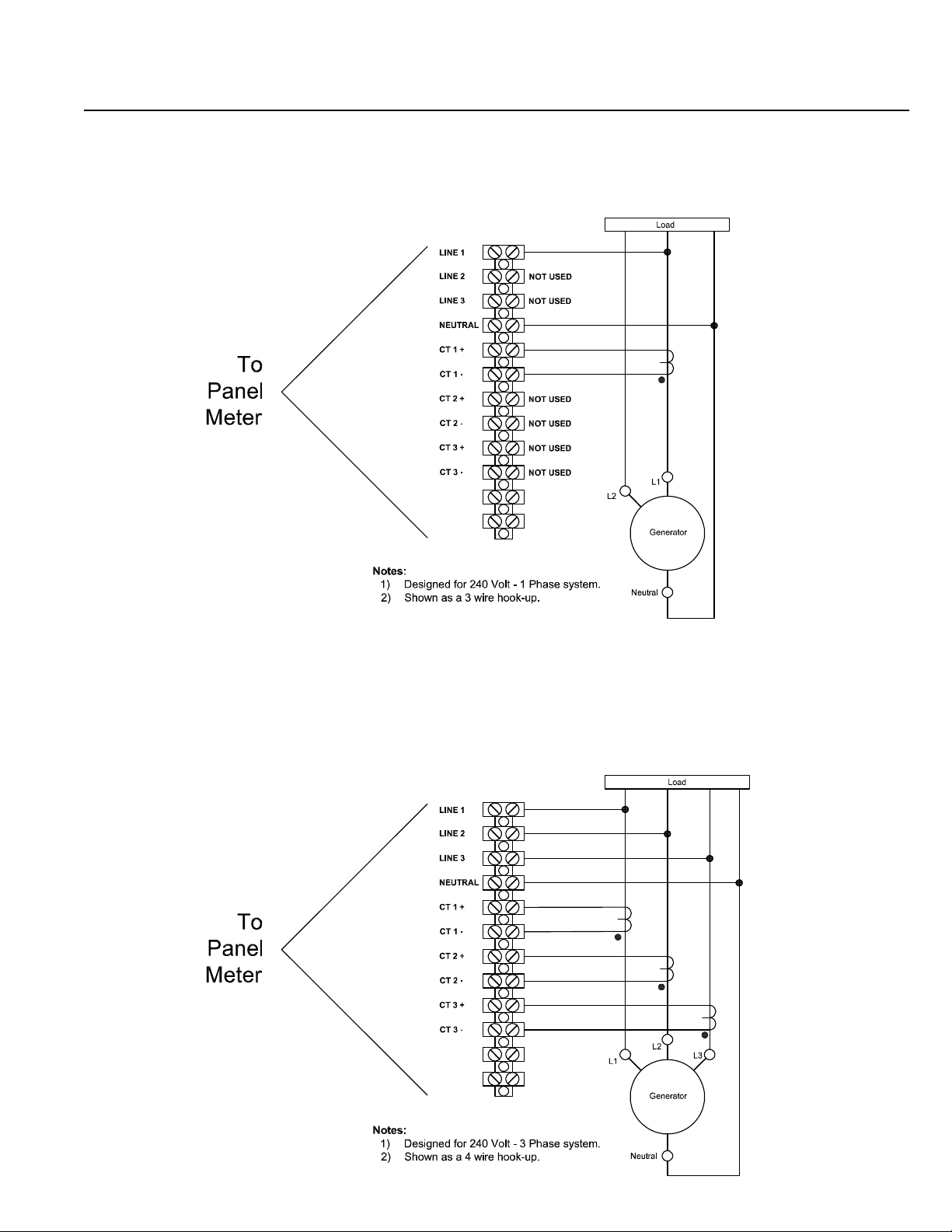

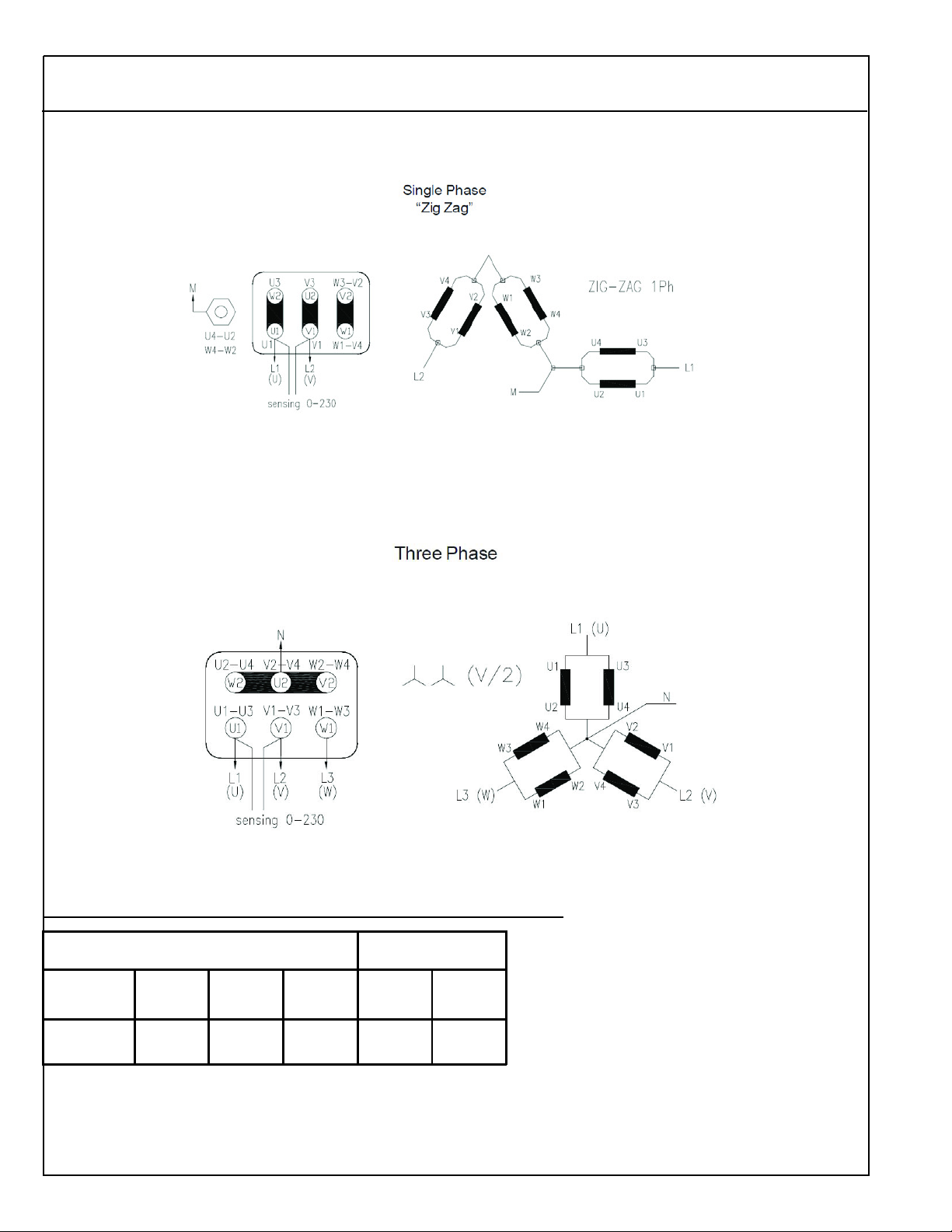

Generator Troubleshooting..............31

Generator Not Working .................................31

Generator Shuts Down..................................31

Generator Overheats ....................................31

Generator Blowing Fuses..............................31

Generator Has Low Voltage at No Load........31

Generator Has High Voltage at No Load.......31

Generator Is Noisy ........................................32

Generator Has Low Voltage at Full Load ......32

Generator Unstable Voltage..........................32

Generator Has Dirty Windings ......................32

Generator - Improper Speed..........................32

Warranties..........................................33

Welcome

............................................................4

General information................................................4

Safety

...................................................................5

Safety Precautions .................................................5

Safety Rules...........................................................6

Installation ...............................................7

General Description ...............................10

Hazards and Warnings ...........................11

Electrical Shock Hazards .....................................11

Fire Hazards.........................................................11

Explosion Hazards ..............................................11

Warnings ..............................................................11

Operation.................................................12

Initial Startup Preparation ...................................12

Pre-Start-up Inspection Checks ...........................12

Operation Procedure...........................................12

Shutdown Procedure ..........................................12

Operating Conditions ...........................................12

Display Panel ..........................................13

Specifications .........................................16

Compressor Lubrication and

Maintenance............................................18

Draining Water From Compressor Oil.................19

Lubrication Recommendations............................19

Application Guide................................................20

Compressor Oil Level .........................................20

Maintenance...........................................21

Compressor Oil Sump Fill, Level, Drain ..............22

Air/Oil Coalescer .................................................22

Oil Filter ..............................................................23

Belt Tensioning Procedure ..................................23

Belt Replacement Procedure ..............................23

Engine Cooling System........................................24

Engine Coolant.....................................................24

Coolant Level .......................................................24

Table of Contents