INFORMATION

Dear Customer,

We wish to thank you for having bought from

MOSA a high quality set.

Our sections for Technical Service and Spare

Parts will work at best to help you if it were

necessary.

To this purpose we advise you, for all control and

overhaul operations, to turn to the nearest

authorized Service Centre, where you will obtain

a prompt and specialized intervention.

☞In case you do not profit on these Services and

some parts are replaced, please ask and be

sure that are used exclusively original MOSA

parts; this to guarantee that the performances

and the initial safety prescribed by the norms in

force are re-established.

☞Theuseof non original spare parts will cancel

immediately anyguarantee andTechnicalSer-

vice obligation from MOSA.

NOTES ABOUT THE MANUAL

Before actioning the machine please read this

manual attentively. Follow the instructions

contained in it, in this way you will avoid

inconveniences due to negligence, mistakes or

incorrectmaintenance. The manualis for qualified

personnel, who knows the rules: about safety and

health, installation and use of sets movable as

well as fixed.

You must remember that, in case you have

difficulties for use or installation or others, our

Technical Service is always at your disposal for

explanations or interventions.

Themanual for UseMaintenance and SpareParts

is an integrant part of the product. It must be kept

with care during all the life of the product.

In case the machine and/or the set should be

yielded to another user, this manual must also

given to him.

Do not damage it, do not take parts away, do not

tear pages and keep it in places protected from

dampness and heat.

You must take into account that some figures

contained in it want only to identify the described

parts and therefore might not correspond to the

machine in your possession.

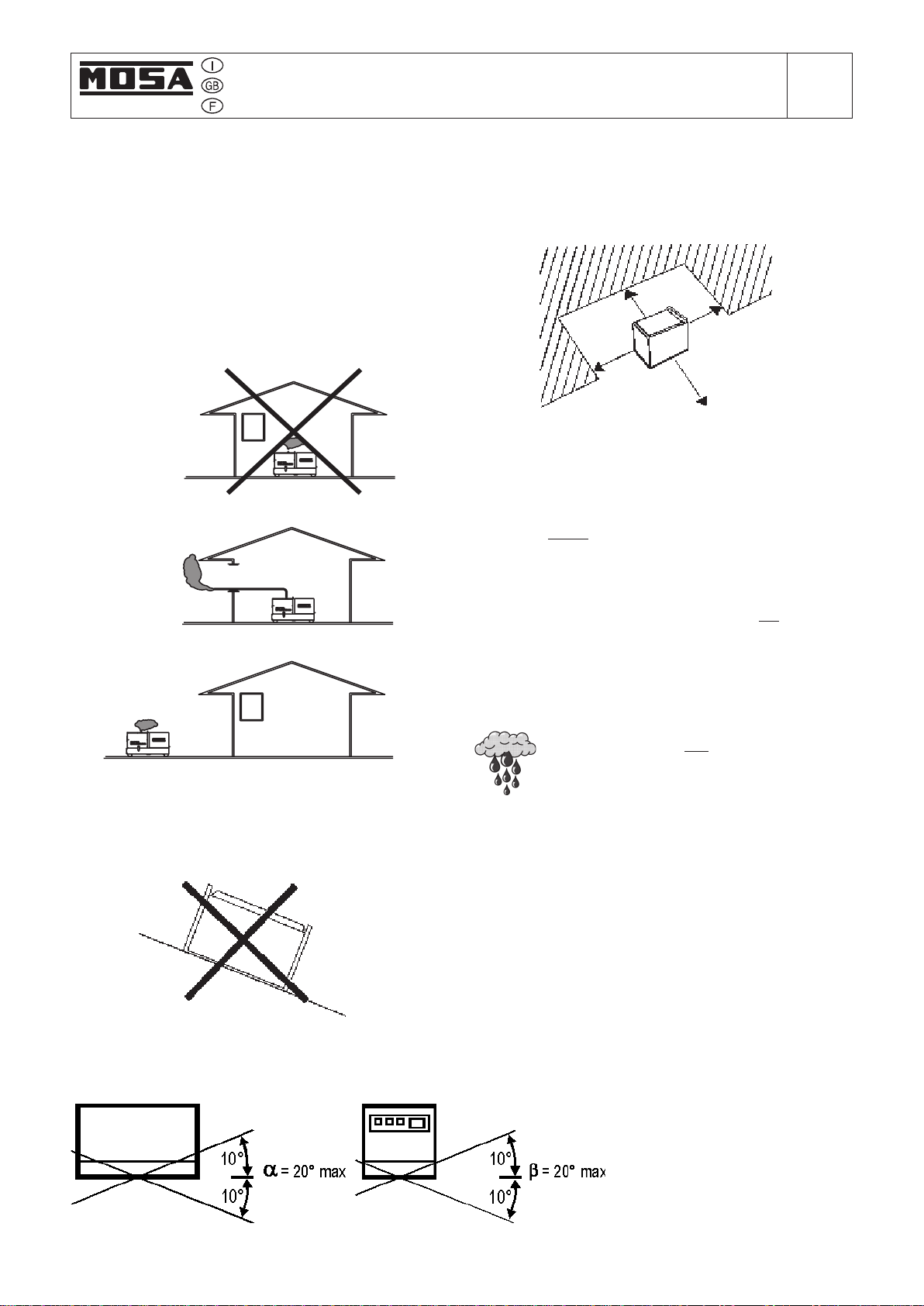

INFORMATION OF GENERAL TYPE

In the envelope given together with the machine

and/or set you will find: the manual for Use

Maintenance and Spare Parts, the manual for

use of the engine and the tools (if included in the

equipment),the guarantee (inthe countries where

it is prescribed by law).

Our products have been designed for the use of

generation for welding, electric and hydraulic

system; ANY OTHER DIFFERENT USE NOT

INCLUDED IN THE ONE INDICATED, relieves

MOSA from the risks which could happen or,

anyway, from that which was agreed when selling

the machine; MOSA excludes any responsibility

for damages to the machine, to the things or to

persons in this case.

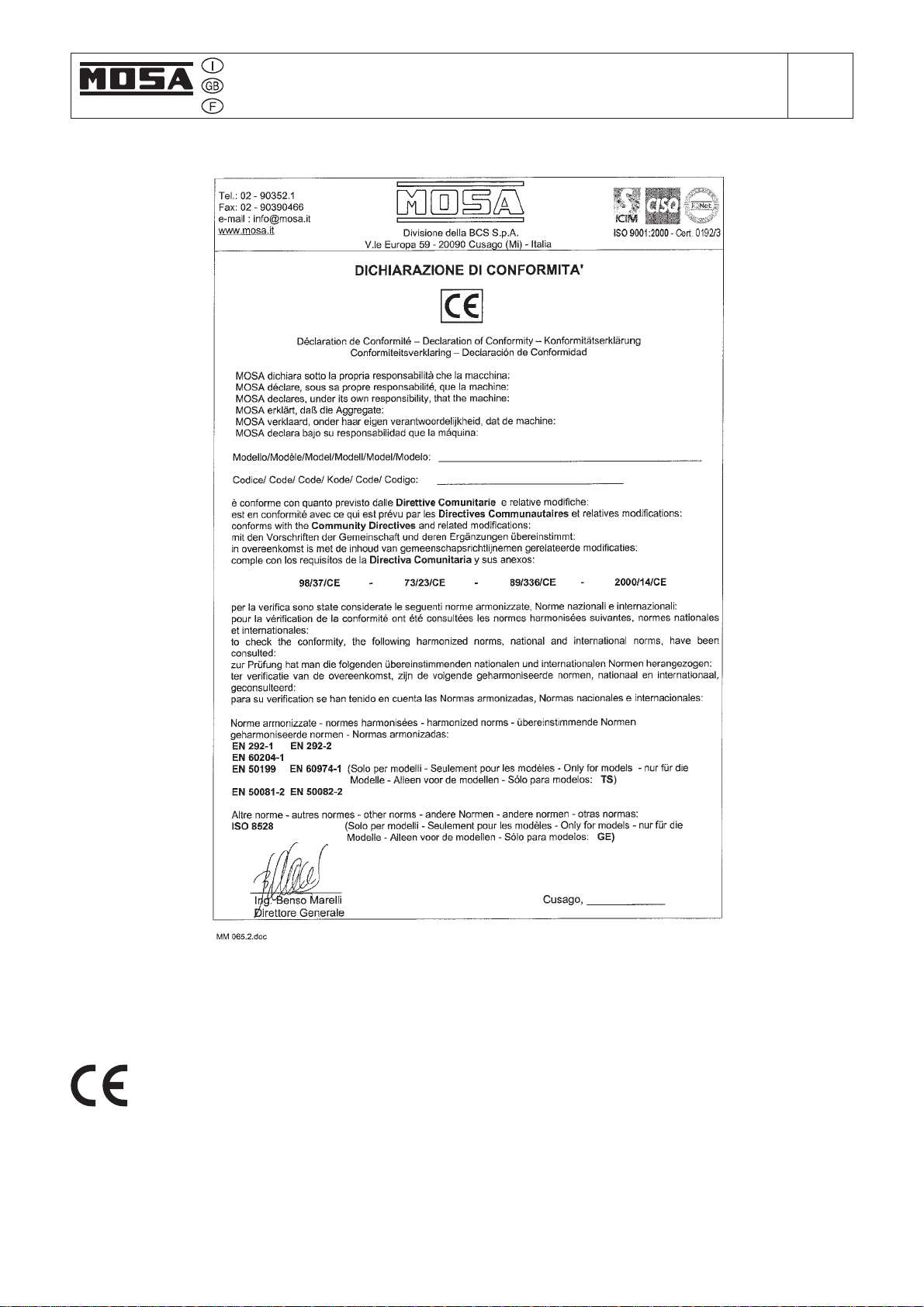

Our products are made in conformity with the

safety norms in force, for which it is advisable to

use all these devices or information so that the

use does not bring damage to persons or things.

While working it is advisable to keep to the

personal safety norms in force in the countries to

whichthe productis destined (clothing,work tools,

etc.).

Donot modify for any motive parts of the machine

(fastenings,holes, electric ormechanicaldevices,

others..)if not dulyauthorized in writing byMOSA:

the responsibility coming from any potential

intervention will fall on the executioner as in fact

he becomes maker of the machine.

Notes GE_, MS_, TS_, EAS_

M

1-1

© MOSA 1.0-10/02

☞Notice: thismanual does not engage MOSA,

who keeps the faculty, apart the essential

characteristicsof the model heredescribed and

illustrated,tobringbettermentsandmodifications

to parts and accessories, without putting this

manualuptodate immediately.

10/10/02 M 1-1 GB