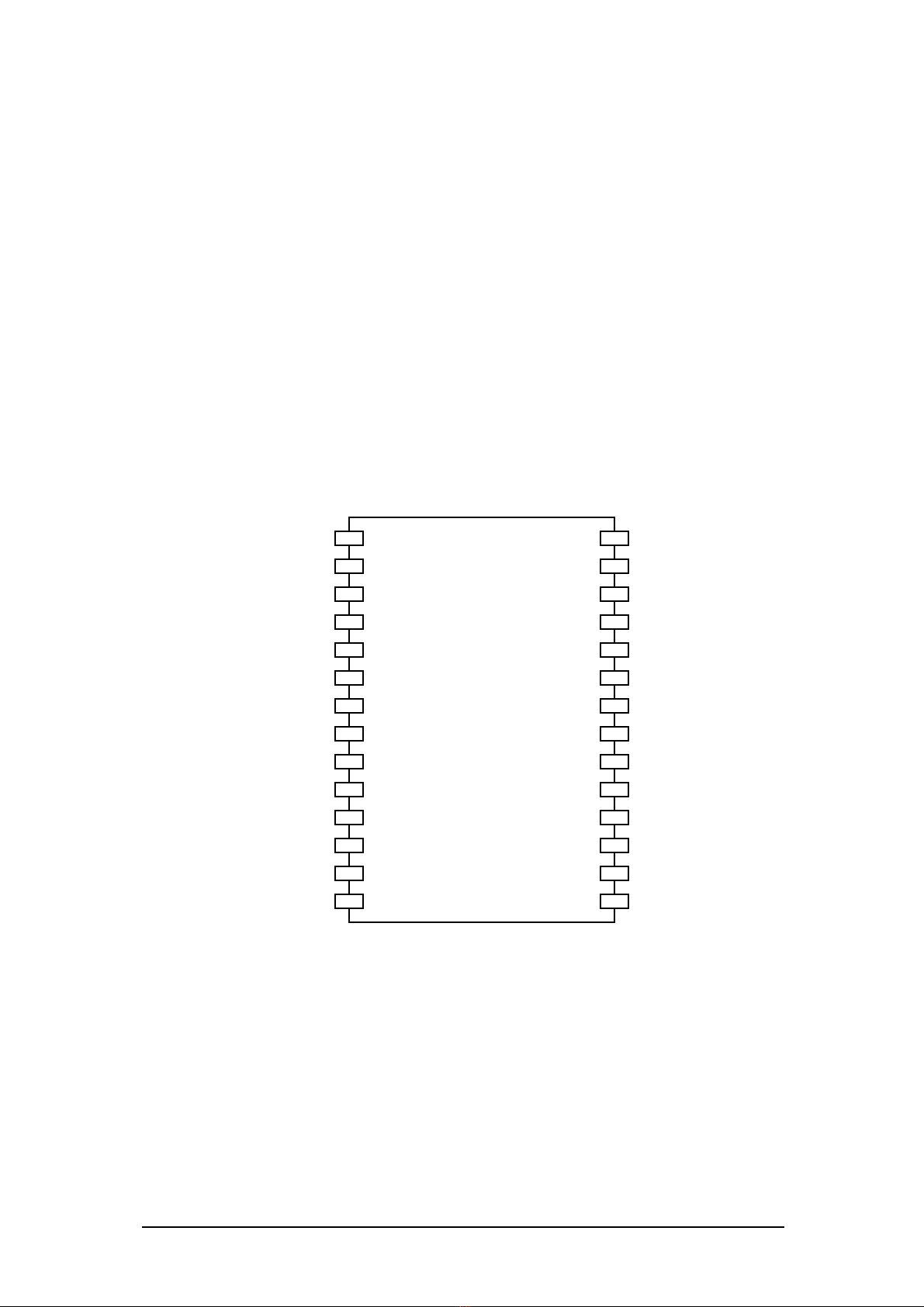

9

Pins Pin Name Type

1

I/O Level

23

Function

1 +5V P - +5V supply

2 A-CHA I FT Axis A encoder input CHA

3 A-CHB I FT Axis A encoder input CHB

4 A-HM I FT,AL Axis A home indicator input

5 A-FL I FT,AL Axis A forward limit input

6 A-RL I FT,AL Axis A reverse limit input

7 A-DIR O FT Axis A direction output

8 A-PWM O FT Axis A PWM output

9 STEPPER A I FT,AL Axis A Stepper select

10 STEPPER B I FT,AL Axis A Stepper select

11 Reserved - - Reserved. Do not use.

12 Reserved - - Reserved. Do not use.

13 Reserved - - Reserved. Do not use.

14 Gnd P - Ground

15 Gnd P - Ground

16 Reserved - - Reserved. Do not use.

17 Reserved - - Reserved. Do not use.

18 Reserved - - Reserved. Do not use.

19 Rx - - UART Receive

20 Tx - - UART Transmit

21 B-PWM O FT Axis B PWM output

22 B-DIR O FT Axis B direction output

23 B-RL I FT,AL Axis B reverse limit input

24 B-FL I FT,AL Axis B forward limit input

25 B-HM I FT,AL Axis B home indicator input

26 B-CHB I FT Axis B encoder input CHB

27 B-CHA I FT Axis B encoder input CHA

28 +5V P - +5V supply

Table 1 – MK-200 pin definitions

1

P = Power, I = Input, O = Output

2

FT = Five voltage Tolerant

3

AL = Active Low