Motomaster ELIMINATOR 140-0050-6 User manual

IMPORTANT:

Please read this manual carefully before using this winch and save it

for reference. Keep this instruction manual for future use. Should this

product be passed on to a third party, this instruction manual must be

included.

model no. 140-0050-6

INSTRUCTION

MANUAL

ATV WINCH KIT

4700 lb (2132 kg)

model no. 140-0050-6 | contact us 1-888-942-6686

2

SERVICE INFORMATION

For customer assistance please call

TABLE OF CONTENTS

3

TABLE OF CONTENTS

Service Information 2

Introduction 4

Safety Definitions 4

Important Safety Instructions 5

Safety Symbols 7

Operation Symbols 7

Key Parts Diagram 8

Key Parts List 10

Assembly 11

Mounting the Winch 11

Solenoid/Contactor Location 13

Installing the Mini-rocker Switch 14

Wiring the Winch 15

Wiring Diagram 17

Switch Wiring Diagram 18

Operation 19

General Tips for Safe Operation 19

Self Recovery 20

Synthetic Rope Abrasion Sleeve 21

Winching Techniques A-Z 22

Maintenance 24

Lubrication 25

Synthetic Rope Replacement 25

Specifications 28

Performance Specifications 28

Troubleshooting 29

Warranty 30

Parts Diagram 32

Parts List 33

Motor Parts Diagram 36

Motor Parts List 37

4

INTRODUCTION

model no. 140-0050-6 | contact us 1-888-942-6686

INTRODUCTION

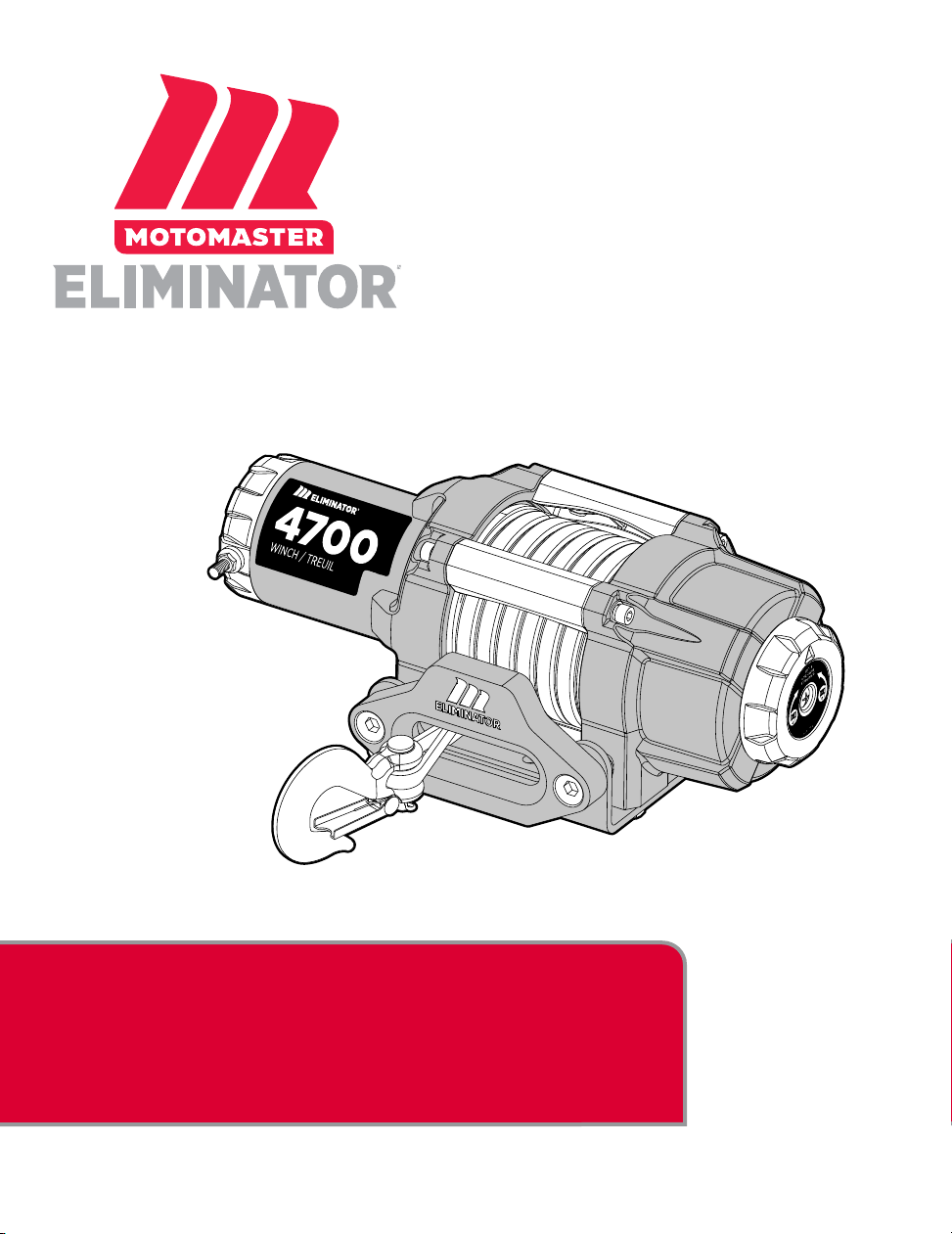

This MotoMaster®Eliminator ATV Winch Kit

includes everything you need to start winching,

including cables, contactor, mounting channel,

aluminum hawse, a wiring kit and mini-rocker

switch. This winch kit is the perfect combination

of power and performance to use with your ATV,

trailer, boat or snowmobile.

This manual will explain how to use the winch

safely and effectively. Please read and follow

these instructions and precautions carefully.

SAFETY DEFINITIONS

The purpose of safety symbols is to attract

your attention to possible dangers. The safety

symbols, and their explanations, deserve your

careful attention and understanding. The safety

warnings do not by themselves eliminate any

danger. The instructions or warnings they give

are not substitutes for proper accident prevention

measures.

DANGER

DANGER indicates a hazardous situation which, if not

avoided, will result in death or serious injury.

WARNING

WARNING indicates a hazardous situation which, if

not avoided, could result in death or serious injury.

CAUTION

CAUTION indicates a hazardous situation which, if not

avoided, could result in minor or moderate injury.

NOTICE

NOTICE indicates information considered important,

but not hazard-related (e.g., messages relating to

property damage).

5

IMPORTANT SAFETY INSTRUCTIONS

WARNING!

• Never use winch to lift or move persons or animals.

• Never use winch as a hoist or to suspend a load.

• Never step over the cable/rope when operating under load.

• Never operate winch with less than 5 wraps of rope around the drum. Rope could come loose from the

drum as the rope attachment to the drum is not designed to hold a load.

WARNING!

• Never exceed the rated capacity. Be aware that the cable/rope may break before the motor stalls.

• For heavy loads at or near rated capacity, always use a snatch block to reduce the load on the cable/rope.

WARNING!

• Do not use the winch to secure or hold a vehicle for an extended period of time.

• Always apply stop blocks to the wheels of the vehicle when on an incline.

• Do not use the winch to secure a vehicle for transporting purposes.

• Never move the vehicle to pull a load (towing) when operating the winch cable/rope.

• Never release the free-spool clutch when there is a load on the winch.

WARNING!

Disconnect the mini-rocker switch and battery leads when not in use.

WARNING!

Avoid “shock loads” by using the control switch intermittently to take up the slack in the cable/rope.

“Shock loads” can exceed the rated capacity of the cable/rope and drum.

WARNING!

When re-spooling the cable/rope, ensure that it spools in the under-wind position with the cable/rope

entering the drum from the bottom, not the top.

To re-spool correctly, and while wearing gloves, keep a slight load on the cable/rope while pushing the

mini-rocker switch button to draw in the cable/rope. Walk toward the winch not allowing the cable/rope

to slide through your hands. Do not let your hands get within 12" (30 cm) of the winch while re-spooling.

Turn off the winch and repeat the procedure until a few feet of cable/rope are left. Disconnect the mini-

rocker switch and finish spooling by rotating the drum by hand with the clutch disengaged. Keep hands

clear of the fairlead and drum while the winch is under power.

IMPORTANT SAFETY INSTRUCTIONS

model no. 140-0050-6 | contact us 1-888-942-6686

6

IMPORTANT SAFETY INSTRUCTIONS

WARNING!

• Always use extreme caution when handling hook and cable/rope during spooling operations.

• Always use supplied hand strap whenever spooling rope in or out, during installation and during operation.

WARNING!

Always wear heavy leather gloves when handling cable/rope.

CAUTION!

Do not wrap the cable/rope around any object and hook it back onto itself.

CAUTION!

Duration of winching pulls should be kept as short as possible.

If the motor becomes excessively hot to the touch, stop winching immediately and let it cool down for 5

minutes. Do not pull for more than one minute at or near the rated load.

CAUTION!

If the motor stalls, do not maintain power to the winch.

Electric winches are designed and made for intermittent use and should not be used in constant duty

applications.

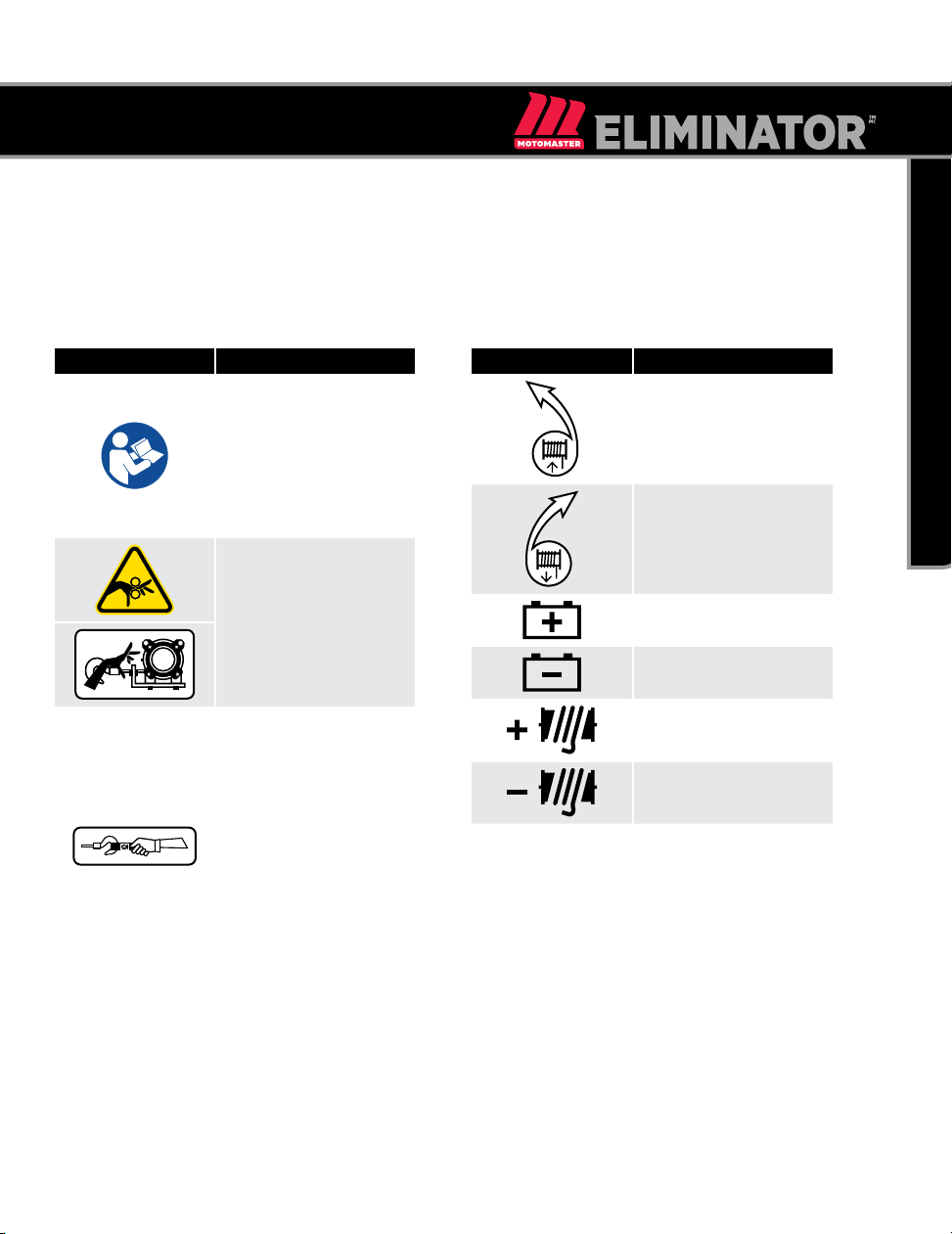

SAFETY SYMBOLS

7

SAFETY SYMBOLS

Some of the following symbols may be used on

this product. Please study them and learn their

meaning. Proper interpretation of these symbols

will allow you to more safely operate the product.

SYMBOL MEANING

Read and understand

this instruction manual

thoroughly before using

the product. It contains

important information

for your safety as well as

operating and maintenance

advice.

Always keep hands clear of

cable/rope, hook loop, hook

and hawse fairlead opening

during installation, operation

and when spooling in or out.

• Always use extreme

caution when handling

hook and cable/

rope during spooling

operations.

• Always use supplied hand

strap whenever spooling

rope in or out, during

installation and during

operation.

• Always wear heavy leather

gloves when handling

cable/rope.

OPERATION SYMBOLS

Some of the following symbols may be used on

this product. Please study them and learn their

meaning. Proper interpretation of these symbols

will allow you to more safely operate the product.

SYMBOL MEANING

Turn the clutch to the “IN”

position to retract the rope.

Turn the clutch to the “OUT”

position to release the rope.

Positive battery terminal

Negative battery terminal

Positive winch terminal

Negative winch terminal

model no. 140-0050-6 | contact us 1-888-942-6686

8

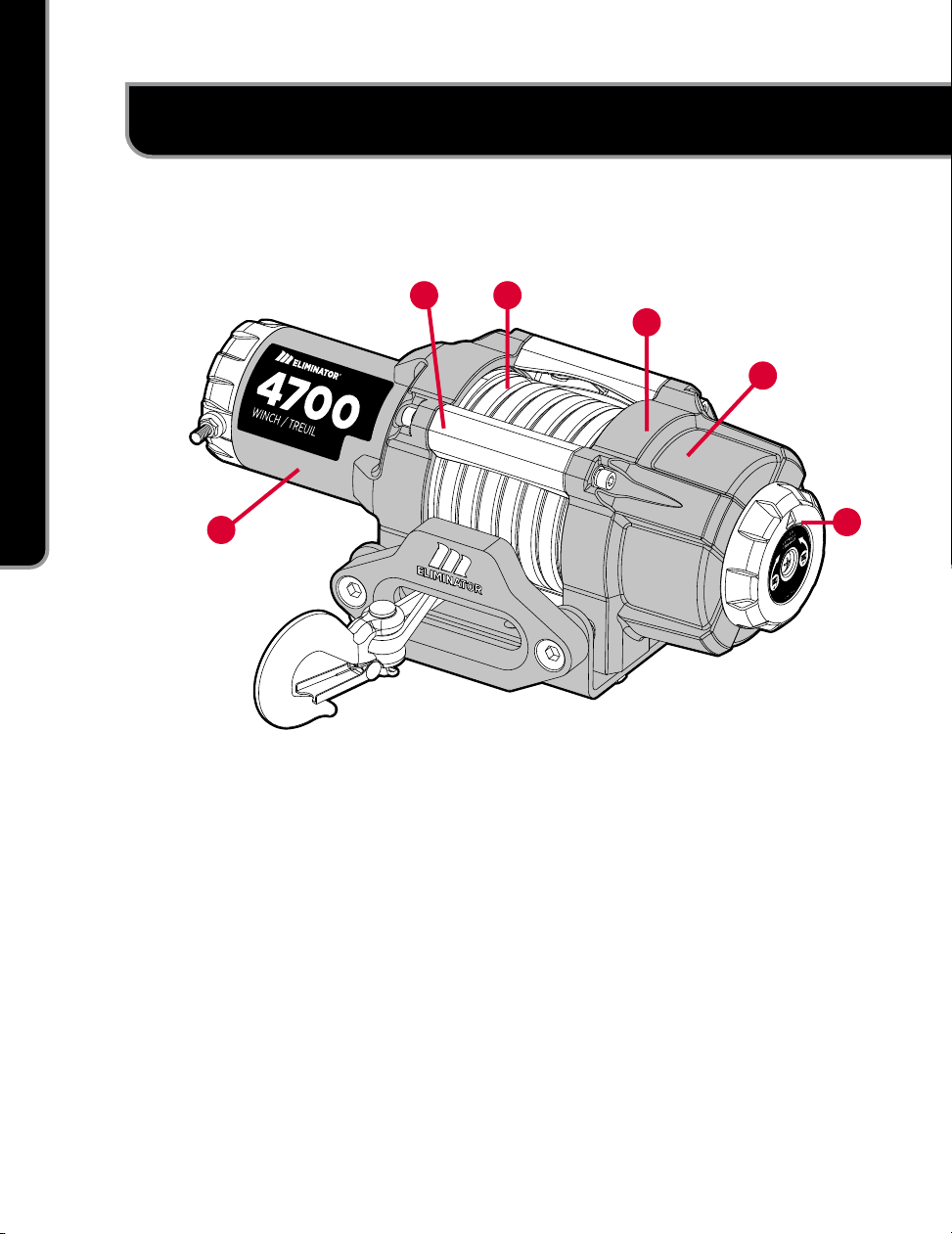

KEY PARTS DIAGRAM

KEY PARTS DIAGRAM

1. Motor – 1.6 HP (1.2 kW) 12V DC motor

provides power to the planetary gear

mechanism.

2. Tie Bars – Durable all-metal construction tie

bars for increased structural rigidity.

3. Winch Drum – The winch drum is the

cylinder on which the synthetic rope

is stored. It can feed or wind the rope

depending on the remote winch switch.

4. Braking System – Braking action is

automatically applied to the winch drum

when the winch motor is stopped and there

is a load on the synthetic rope.

5. Planetary Gear System – The reduction

gears convert the winch motor power into

extreme pulling forces. This system allows

high torque while maintaining compact size

and light weight.

6. Clutch – The clutch allows the operator to

manually disengage (“Out”) the spooling

drum from the gear train, free spool.

Engaging the clutch (“In”) locks the winch

into the gear system.

2

16

3

4

5

9

KEY PARTS DIAGRAM

7. Hand Strap – Used to assist synthetic rope

feed.

8. Aluminum Hawse – When using the winch

at an angle the hawse acts to guide the

synthetic rope onto the drum and minimizes

damage to the synthetic rope from abrasion

on the winch mount or bumper.

9. Mini-rocker Switch – Rocker switch with

handlebar mount for powering the synthetic

rope in or out of your winch drum.

10. Solenoid/Contactor – Power from the

vehicle battery flows through the weather

sealed contactor before being directed to the

winch motor.

11. Mounting Channel – Winch mount to attach

the winch to your vehicle.

12. Winch Connection Cables – Used to

connect the contactor to the winch motor and

the contactor to the vehicle battery.

8

9

10

11

12

13

15

14

16

7

13. Synthetic Rope – 38' x 15/64"

(11.6 m x 6 mm) Synthetic rope designed

specifically for load capacity of 4,700 lb

(2,132 kg). The synthetic rope feeds onto the

drum in the “under wind” position through

the aluminum hawse and is looped at the

end to accept the clevis hook pin.

14. Clevis Hook – Provides a means for

connecting the looped ends of cables to an

anchor.

15. Wire Tap – Allows the ability to splice the

end of the red wire on the mini-rocker switch

to an ignition or keyed controlled power

source.

16. Cable Ties – Attaches the mini-rocker

switch cable to the chassis of your vehicle.

model no. 140-0050-6 | contact us 1-888-942-6686

10

KEY PARTS LIST

KEY PARTS LIST

PART PART

QTY. HARDWARE HARDWARE

QTY. TOOL(S) NEEDED

TORQUE

lbf-ft

(Nm)

Winch Body 1

Hexagon Head Bolt M8 x 25 4 1x 13 mm wrench 6.1–7

(8.2–9.5)

Flat Washer Ø8 4

Flat Washer Ø8 4

Mounting

Channel 1

Aluminum Hawse 1

Hexagon Socket Set Screw

M10 x 25 2 1x 8 mm wrench 11.8–12.6

(16–17.1)

Lock Nut M10 2 1x 16 mm wrench

Mini-rocker

Switch 1

Hexagon Socket Head

Screw M5 x 18 1 1x 4 mm wrench 2.2–3

(3–4)

Hexagon Socket Head

Screw M5 x 25 2 1x 4 mm wrench

Flat Washer Ø5 3

Nut M5 3 1x 8 mm wrench

Wire Tap 1

Contactor 1

Hexagon Head Bolt M6 x 25 4 1x 10 mm wrench 4.1–4.9

(5.6–6.6)

Flat Washer Ø6 4

Lock washer Ø6 4

Lock Nut M6 4 1x 10 mm wrench

Battery Wire —

Red 1

Battery Wire —

Black 1

Winch Wire —

Yellow 1

Winch Wire —

Blue 1

Clevis Hook 1 Needle nose pliers

Hand Strap 1

ASSEMBLY

11

ASSEMBLY

MOUNTING THE WINCH

The MotoMaster®Eliminator ATV Winch Kit is designed with a bolt pattern that is standard in this class of

winch. Many winch mounting kits are available that utilize this bolt pattern for the most popular trucks,

SUVs and ATVs.

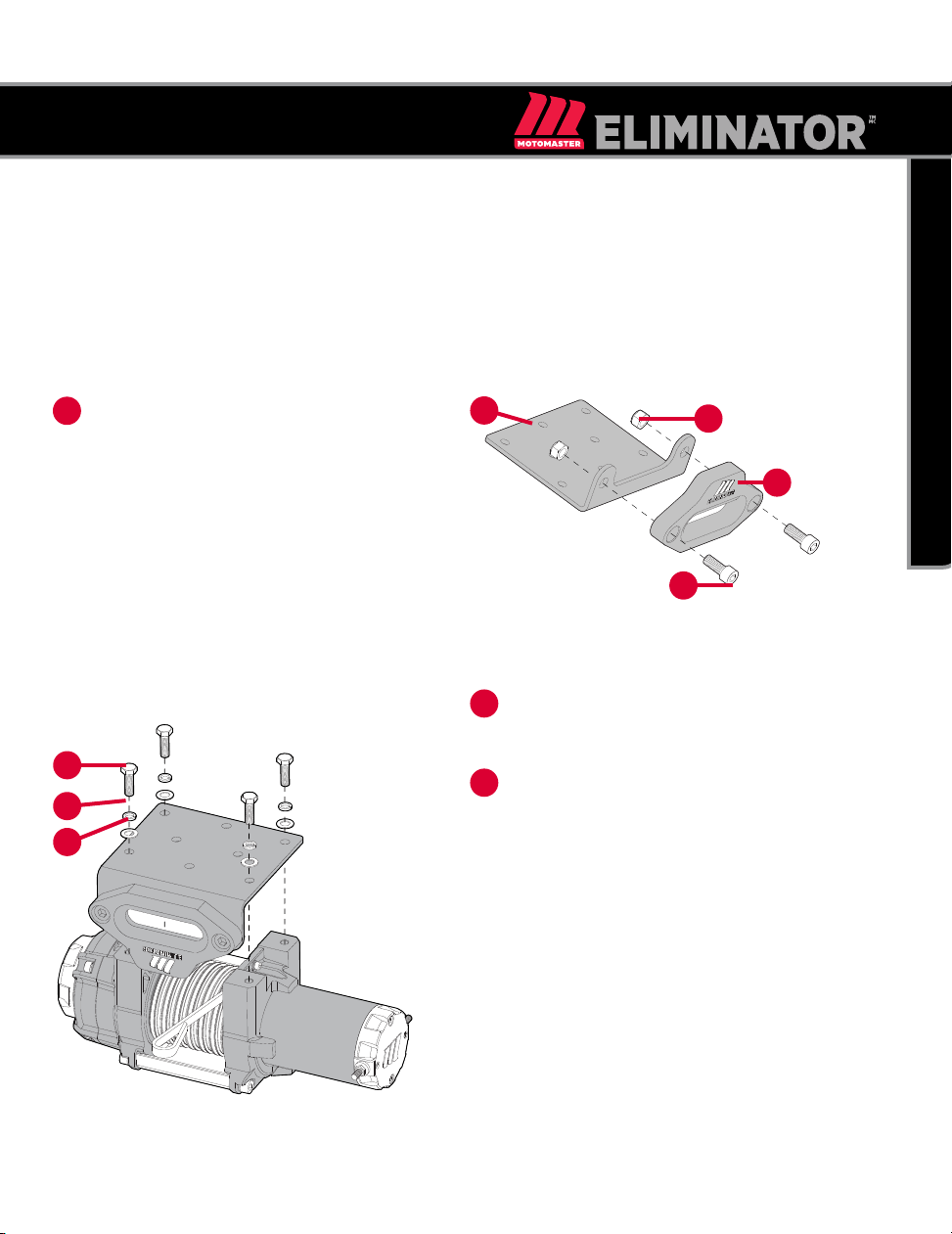

Insert M10×25 (A) bolts through the

mounting channel (B) holes and attach the

aluminum hawse (C) to the mounting channel

with the M10 lock nuts (D) provided.

1

2

3

B

G

F

E

A

D

C

Turn the winch upside down. Place the

mounting channel on the winch, making sure

the winch is centred in the middle of it.

Thread the M8×25 (E) bolts through the Ø8

lock (F) and flat washers (G), and then thread

through the mounting channel. Tighten the

bolts. DO NOT overtighten.

model no. 140-0050-6 | contact us 1-888-942-6686

12

ASSEMBLY

4Turn winch right side up. Disengage the

clutch by moving the clutch to the “Out”

position — the arrow will be to the back of

the winch as shown. Release the synthetic

rope and pull through the aluminum hawse.

CAUTION!

See Key Parts List section for torque ratings. Mounting bolts must be SAE grade 5 or better and torqued to

34 lbf-ft (46 Nm).

CAUTION!

If utilizing a mounting plate, ensure that the three major sections (motor, drum and gear housing) are

properly aligned. Proper alignment of the winch will allow for even distribution of the full rated load.

The type of vehicle to which the winch and mounting channel will be applied, will dictate the type of

mounting kit that should be used.

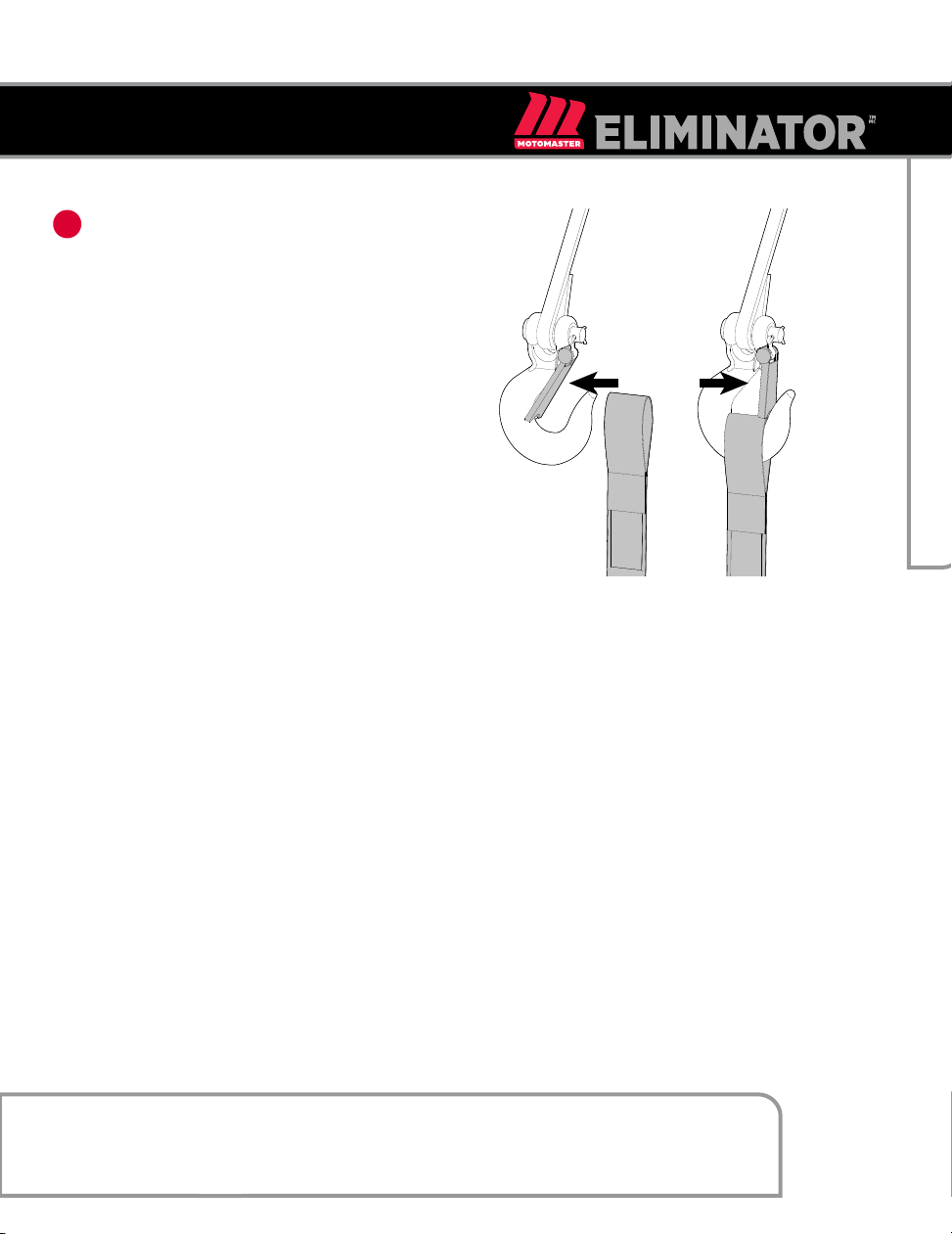

5Attach the clevis hook to the synthetic rope

by removing cotter pin and pin, then thread

through and reattach the pin and cotter pin.

CLUTCH

OUT

13

ASSEMBLY

6Add hand strap to the clevis hook.

SOLENOID/CONTACTOR LOCATION

Find a location for the solenoid/contactor. It is recommended that the solenoid/contactor be mounted close

to the battery in a clean, dry location. Make sure the location chosen allows for sufficient clearance from all

metal components. Drill mounting holes if required. Once a location is found, DO NOT install the unit until all

wiring is completed (see wiring section).

NOTICE:

Terminals coming in contact with metal will cause a direct short, possibly causing solenoid/contactor and/

or battery damage.

model no. 140-0050-6 | contact us 1-888-942-6686

14

ASSEMBLY

1

2

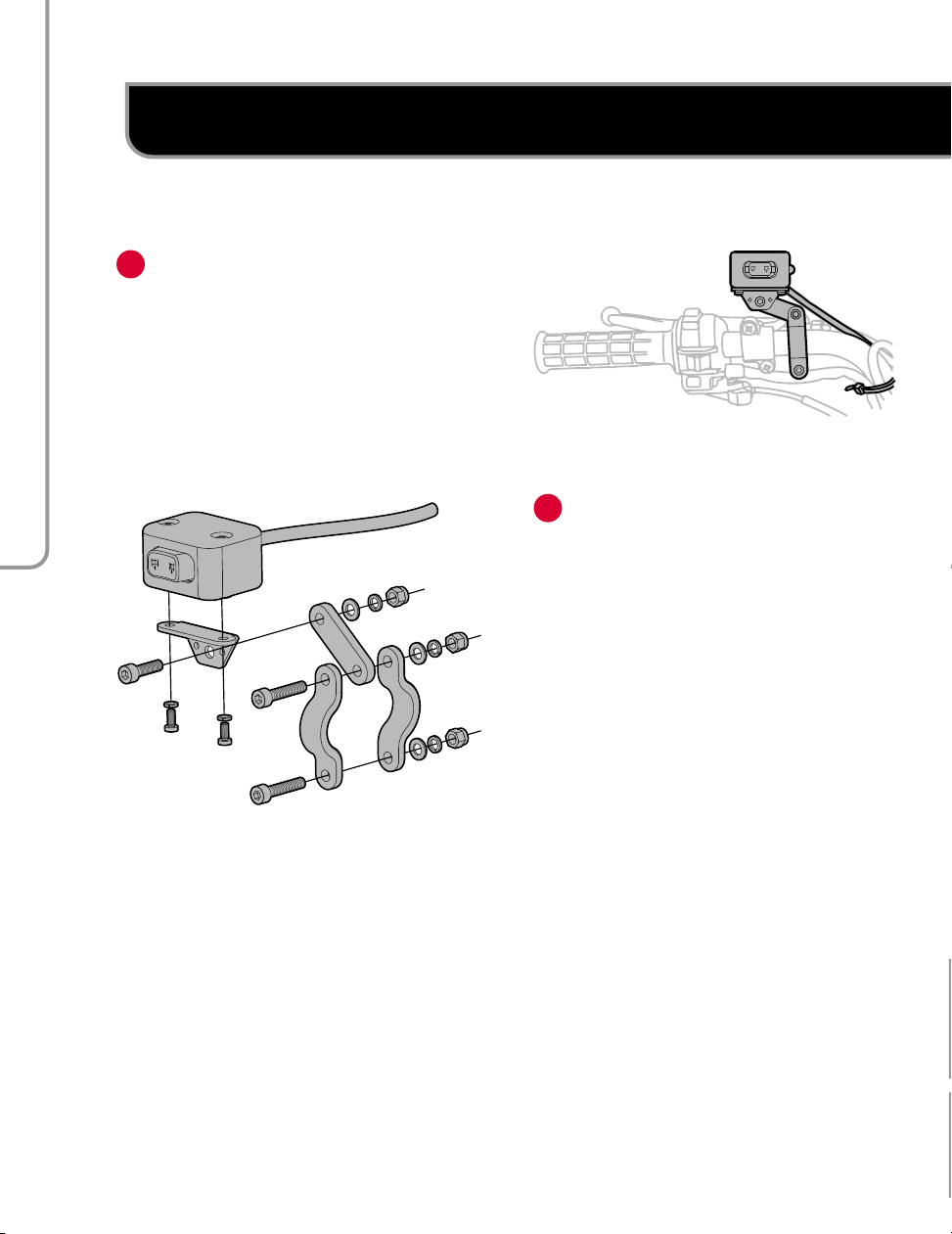

INSTALLING THE MINI-ROCKER SWITCH

Decide which handlebar the mini-rocker

switch will be mounted on. The mini-

rocker switch is usually installed on the left

handlebar.

Use a piece of electrical tape (not provided)

around the handlebar to help prevent rotation

of the mount.

Loosen the hardware and mount to the

handlebar.

Tighten the mini-rocker switch in place. DO

NOT overtighten or tighten/clamp over any

hoses or cables.

Once the mini-rocker switch is mounted,

the wires can be routed back to where the

solenoid/contactor is located.

Make sure the handlebars have full range

of motion and then secure the mini-rocker

switch’s cable with the supplied cable ties.

15

ASSEMBLY

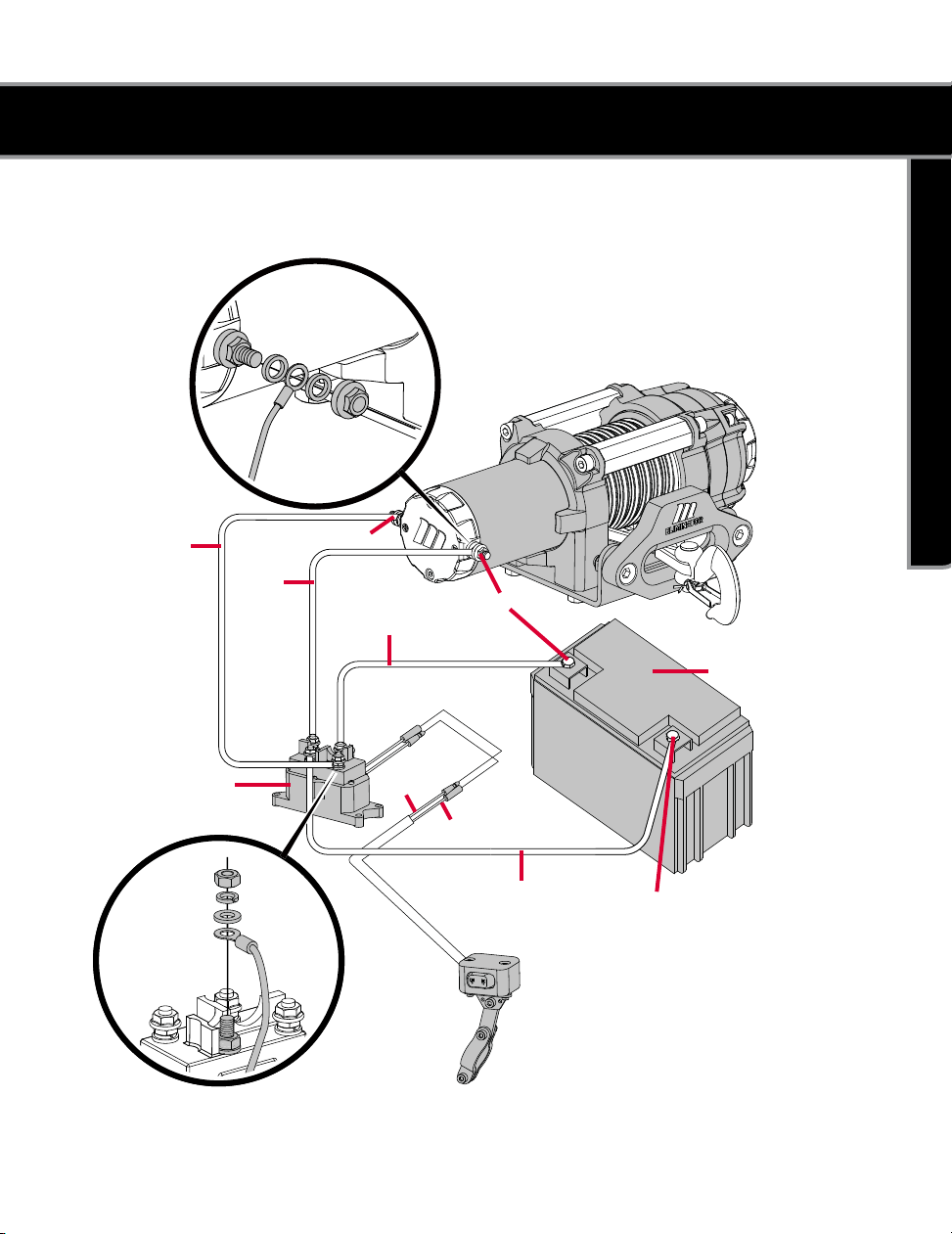

WIRING THE WINCH

See the wiring diagram on the following page for

these following steps

Connect the yellow and blue cables to the

motor terminals on the winch (yellow to

the positive (+) terminal of the motor; blue

to the negative (-) terminal of the motor).

Tighten the terminal nuts on the motor. DO

NOT overtighten. Route the other ends to the

solenoid/contactor location.

Connect the yellow and blue cables to the

solenoid/contactor (yellow to yellow and blue

to blue). DO NOT tighten nuts.

Connect the red and black cables to the

solenoid/contactor (red to red and black to

black). DO NOT tighten nuts. Route the other

ends to the vehicle’s battery.

1

2

3

4

9

5

6

7

8

CAUTION!

NEVER route electrical cables across any sharp edges, through and/or near moving parts, or near parts

that may become hot.

Battery cables should NOT be drawn tight. Leave some slack for cable movement.

NOTICE:

You may need to use a test light to locate a suitable wire. The wire should only have power when the key

is in the ON position.

Connect the red lead to the positive (+)

terminal of the vehicle’s 12V battery.

Connect the mini-rocker switch to the

solenoid/contactor (black to black and green

to green).

Splice the end of the red wire on the mini-

rocker switch to an ignition (keyed) controlled

power source using the supplied wire tap.

Once all wiring is connected to the solenoid/

contactor, it can then be mounted using the

supplied M6 hardware.

Tighten the solenoid/contactor terminal nuts.

DO NOT overtighten.

Connect the black lead to the negative (-)

terminal of the vehicle’s 12V battery.

Place all terminal boots over terminals and

secure all cables with cable ties or electrical

tape (not included).

10

model no. 140-0050-6 | contact us 1-888-942-6686

16

ASSEMBLY

NOTICE:

Depending on the location of the solenoid/contactor, you may need to use the black and red cables in

place of the yellow and blue, and the yellow and blue in place of the red and black.

Check for proper drum rotation. Turn the clutch to the “Out” position (free spooling). Pull out some

cable from the drum, and then turn the clutch to the “In” position to engage the gears.

11

12

CLUTCH

OUT

OUT IN

IN

Press the “Out” button on the mini-rocker switch. If the drum is turning and releasing more cable/rope,

then your connections are accurate. If the drum is turning and collecting more cable/rope then reverse

the leads on the motor. Repeat and check rotation. Press the “In” button on the mini-rocker switch as a

final test.

WIRING DIAGRAM

17

WIRING DIAGRAM

POSITIVE (+)

YELLOW

SOLENOID/CONTACTOR

BLACK

RED POSITIVE (+)

+

BATTERY

GREEN

BLACK

BLUE

NEGATIVE (–)

–

model no. 140-0050-6 | contact us 1-888-942-6686

18

SWITCH WIRING DIAGRAM

SWITCH WIRING DIAGRAM

GREEN

IGNITION WIRE

RED

BLACK

OPERATION

19

OPERATION

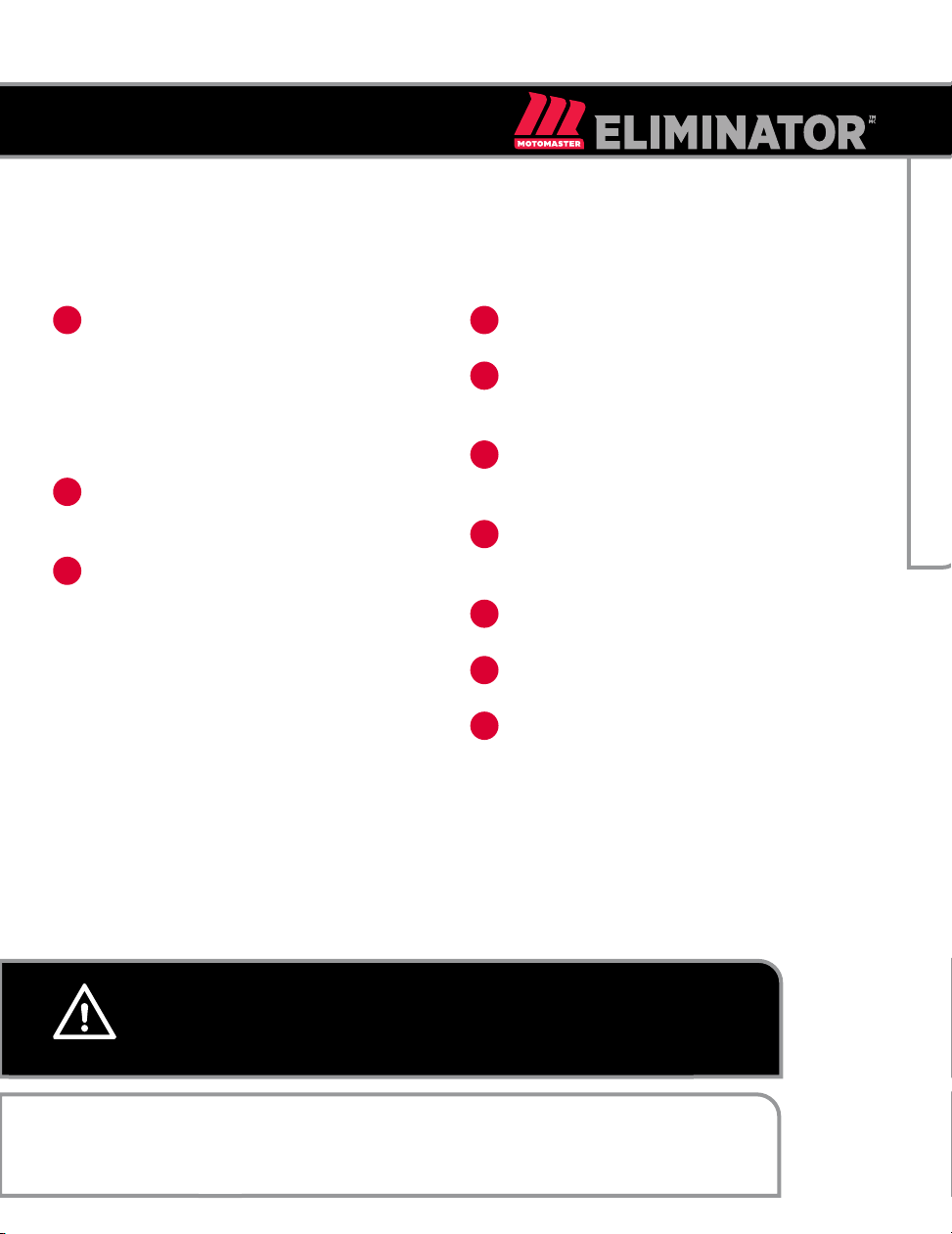

GENERAL TIPS FOR SAFE OPERATION

Your winch is rated at a 4,700 lb (2,132 kg)

capacity in first layer (max.) when spooling

the first rope layer on the drum. Overloads can

damage the winch, motor and/or synthetic

rope. For loads over 2,350 lb (1,066 kg), we

recommend the use of the pulley block/snatch

block to double the synthetic rope line. This will

aid in two ways:

• Reduce the number or rope layers on the

drum; as well as

• Reduce the load on the rope by as much as

50%.

When doubling the line back to the vehicle, attach

to the tow hook, frame or other load-bearing part.

The vehicle engine should be kept running during

operation of the winch to minimize battery drain

and maximize power and speed of the winch. If

the winch is used for a considerable time with the

engine off, the battery may be drained and too

weak to restart the motor.

Get to know your winch before you actually

need to use it. We recommend that you set up a

few test runs to familiarize yourself with rigging

techniques, the sounds your winch makes under

various loads, the way the cable/rope spools on

the drum, etc.

Inspect the synthetic rope and equipment before

each use. A frayed or damaged cable/rope must

be replaced immediately. Use only manufacturer’s

identical replacement rope with the exact

specifications.

Always inspect the winch installation and bolts

to ensure that all bolts are tight before each

operation.

Any winch that appears to be damaged in

any way, or operates abnormally MUST BE

REMOVED FROM SERVICE UNTIL REPAIRED. It

is recommended that the necessary repairs be

made by a manufacturer’s authorized repair

facility.

Pull only on areas of the vehicle as specified by

the vehicle manufacturer.

model no. 140-0050-6 | contact us 1-888-942-6686

20

OPERATION

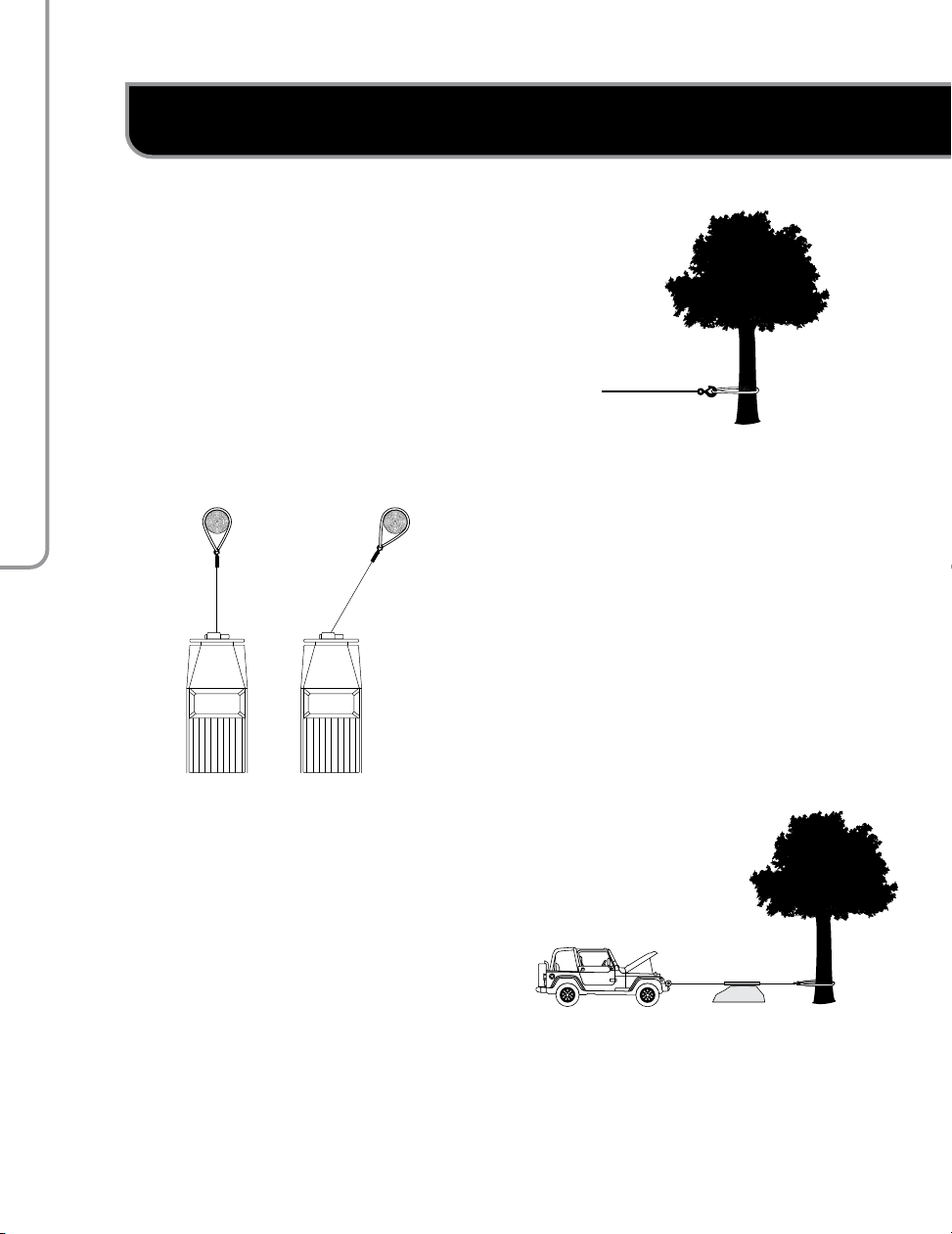

SELF RECOVERY

Locate a suitable anchor such as a strong tree

trunk or boulder. Always use a sling as an anchor

point.

Your winch is equipped with a aluminum hawse

to help guide the synthetic rope and to reduce

binding on short side pulls. Do not winch from an

acute angle as the synthetic rope will pile up on

one side of the drum causing damage to synthetic

rope and the winch.

Short pulls from an angle can be used to

straighten the vehicle. Long pulls should be done

with the synthetic rope at a 90° angle to the

winch/vehicle. When pulling a heavy load, place

a blanket or jacket over the synthetic rope 5 – 6’

(1.5 – 1.8 m) from the hook.

In the event of a broken cable/rope it will dampen

the snap back.

CORRECT INCORRECT

Table of contents

Popular Winch manuals by other brands

Come.up Winch

Come.up Winch 295750 12V manual

AWD

AWD AWD0907A instruction manual

Kolpin Outdoors

Kolpin Outdoors KAWASAKI MULE PRO-FX Assembly & owners manual

Keeper

Keeper Trakker KT2500 Assembly & operating instructions

Berger & Schroter

Berger & Schroter 31593 Instructions for use

Ronstan

Ronstan Andersen 28ST FS product manual

Westfalia

Westfalia 32 15 21 instruction manual

Tractel

Tractel caRol TR Operation and maintenance manual

Antal

Antal XT66EH installation manual

Startax

Startax 9201-10000-T User instructions

Comeup

Comeup Blazer M2 instruction manual

Ingersoll-Rand

Ingersoll-Rand force 5 Man-Rider FA2.5MRA Parts, operation and maintenance manual