Section 1 Safety procedures 8

The Quality is Transparent

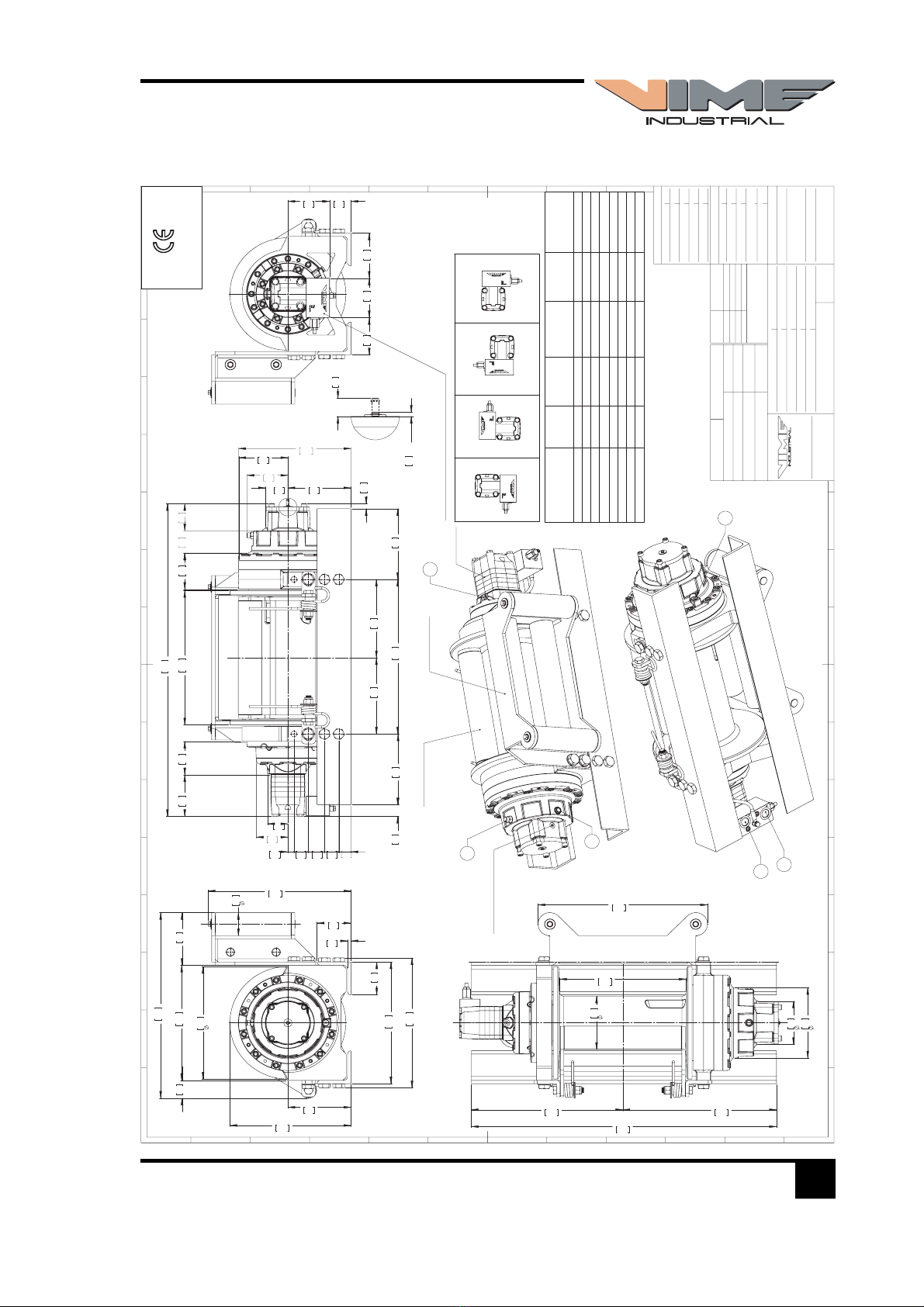

1.4.3 EPHL 100 FN CE TECHNICAL DATA

1.4.4 EPHL 100 FN CE WINCH PERFORMANCE CHARTS AT THE 1ST LAYER

0

2.000

4.000

6.000

8.000

10.000

12.000

50 100 150 200

PRESSIONE DI LAVORO [Bar]

0,00

2,00

4,00

6,00

8,00

10,00

12,00

20 40 60 75

ALIMENTAZIONE OLIO [litri/min]

RATIO LAYER LINE PULL ON [KGF]

ROPE 15 MM

1/22,69

1 10.000

2 8.550

3 7.460

4 6.600

5 5.900

ROPE 16 MM

1/22,69

1 10.000

2 8.470

3 7.350

4 6.490

5 5.800

LINE PULL [KGF]

LINE SPEED [MT/MIN]

OIL

SUPPLY

[LT/MIN]

DRUM

REVOLUTION

[RPM]

LINE SPEED PER LAYER [MT/MIN]

1 2 3 4 5

ROPE 15 MM

40 10,0 5,6 6,5 7,4 8,3 9,1

60 15,7 8,8 10,1 11,7 13 14,5

75 20,0 11,1 13 15 16,7 18,6

40 10,0 5,6 6,6 7,6 8,6 9,6

60 15,7 8,8 10,3 11,9 13,5 15,1

75 20,0 11,1 13,2 15,2 17,2 19,2

ROPE 16 MM

WIRE ROPE QUANTITY ON LAYER (DRUM LENGTH EPHL FN= 373 MM)

LAYER

DRUM

DIAMETER

[MM]

WIRE ROPE

ON LAYER

[MT]

WIRE ROPE

QUANTITY

[MT]

15 MM 16 MM 15 MM 16 MM 15 MM 16 MM

6 327 338 24,5 23,7 113,4 108,5

5 297 306 22,3 21,4 88,9 84,8

4 267 274 20,0 19,2 66,6 63,4

3 237 242 17,8 17,0 46,6 44,2

2 207 210 15,5 14,7 28,8 27,2

1 177 178 13,3 12,5 13,3 12,5

0 162 162 - - - -

LINE SPEED [MT/MIN]

WORKING PRESSURE [BAR] OIL SUPPLY [LT/MIN]

LINE PULL FIRST LAYER [KG]

Ø 162

LAYER

Ø 342

FEATURES EPHL 100 FN CE (160 cc.)

LINE PULL FIRST LAYER 10.000 KGF

LINE SPEED FIRST LAYER 11,1 MT/MIN.

MAX. WORKING PRESSURE 200 BAR

MAX. OIL SUPPLY 75 LT/MIN

MIN. OIL SUPPLY 20 LT/MIN

WIRE ROPE SIZE (EN 14492-1) *15/16 MM

WIRE ROPE MINIMUN BREAKING ROPE (EN 14492-1) 20.000 KG

MAX. WIRE ROPE CAPACITY (EN 14492-1) **80/60 MT

NOTE

Specifications are subject to change without notification and without incurring obliga-

tion. Specifications in this publication are theoretical and may vary depending on hy-

draulic system, environment, etc.

*Wire rope size must be respected. Recommended wire rope min. tensile strength 2160

N/mm². Wire rope minimum breaking load must be at least double of winch max.

pulling capacity.

** Max. wire rope capacity according with EN 14492-1.

WINCH (WITHOUT CABLE) 200

ACCESSORY : ROLLERFAIRLEAD 35

ACCESSORY : CABLE TENSIONER 10

WEIGHT [KG]