© Motor City Wash Works, Inc. 48285 Frank, Wixom Michigan 48393 U.S.A. Phone: 248.313.0272 ▪ Fax: 248. 313.0271

8MANULALTINS001 10-15-2020 www.motorcitywashworks.com 2

Installation Procedures:

Upon receiving your MCWW Alternator Enclosure, open the box and verify that you have all the

required components as well as there are no damages to the equipment. Verify also that you have

all your installation material.

Mount the Control Panel in the mechanical room or on any wall in a CLEAN, DRY AREA.

Secure the panel to the wall using the 1/4” mounting hole in the four mounting brackets.

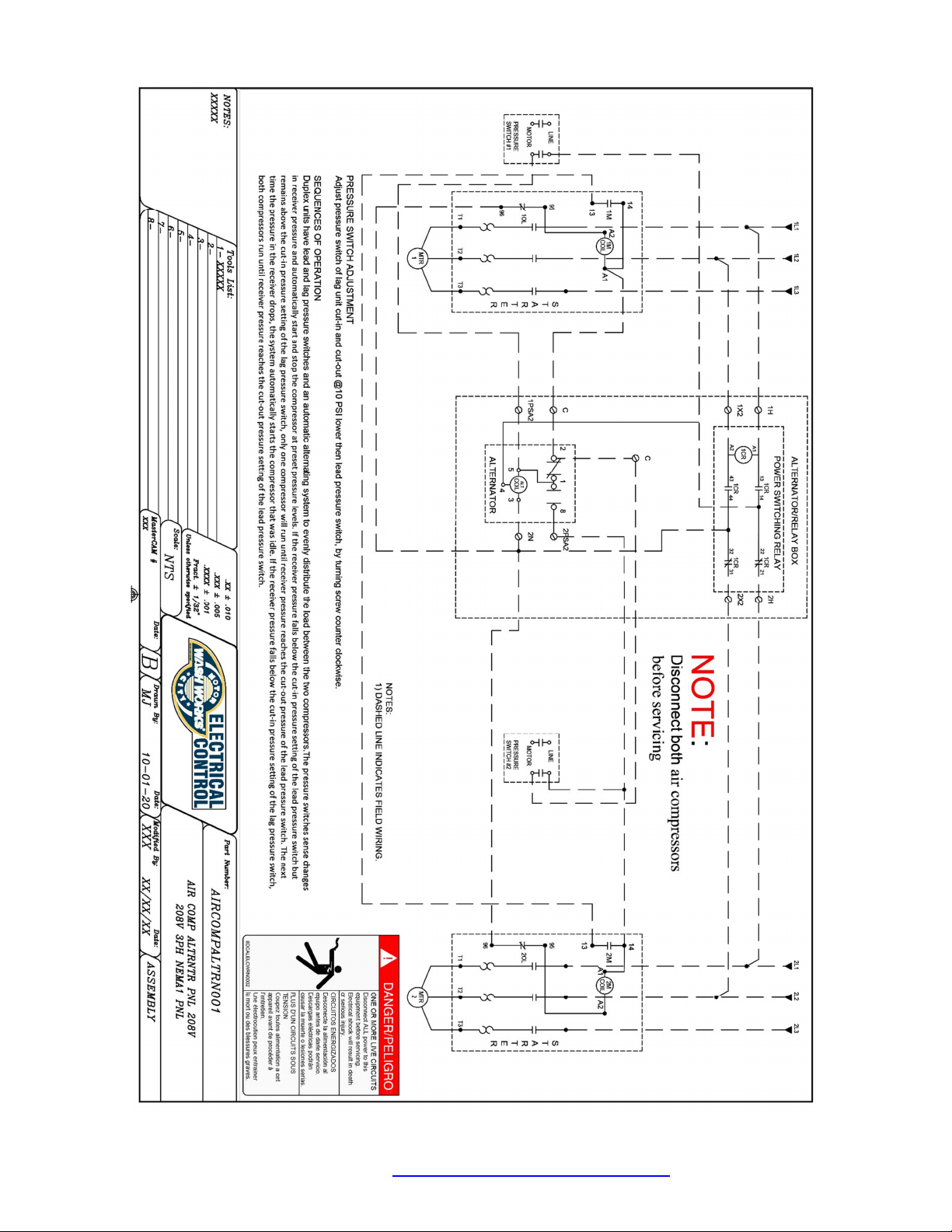

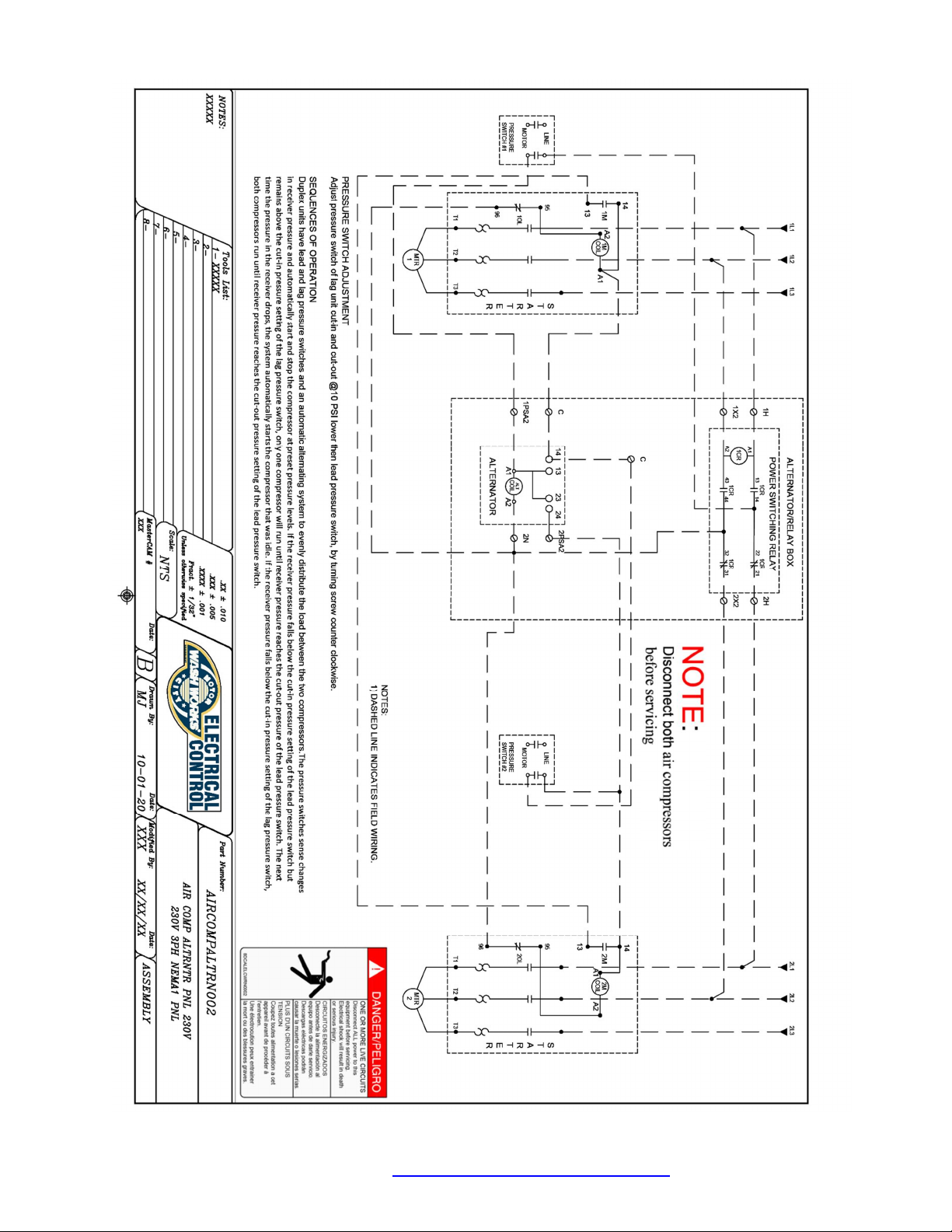

Pull and connect field installed wiring from the L1 and L2 legs of power from each compressor

to alternator enclosure as shown in drawing below.

Pull and connect field installed wiring from both compressors to alternator unit within enclosure

as shown in drawing below.

Pull and connect field installed wiring in-between both compressors as shown in drawing below.

Set pressure switch ON/OFF on Load 2 (Compressor 2) to 10 PSI lower than Load 1 (Compressor

1). For example: Compressor 1 is set to 140/110PSI for ON/OFF, Compressor 2 should be set

to 130/100PSI.

Start-Up Procedures:

Turn ON power to compressors and alternator enclosure. Verify alternator has power and that

Load 1 (Compressor 1) is on. Compressor 1 must be wired to Load 1.

Once Load 1 (Compressor 1) is running and hits its high limit (in this case 140PSI) it will turn

OFF. The next time pressure drops, it will turn ON the idle compressor (Load 2, Compressor 2).

Load 2 (Compressor 2) will run until the high limit of the lead pressure switch is reached again.

If the pressure drops below the lag pressure switch low limit (in this case 100PSI), both Load 1

& Load 2 (Compressors 1 & 2) will turn on to bring pressure back into range. This process will

continue to go back and forth reaching the lead pressure switch’s high limit.

Note: Both compressors will never be on at the SAME TIME unless Load 2 (Compressor

2) pressure switch has hit its LOW limit, in which case both Loads (Compressors) will turn

on to compensate and try to bring pressure back up into range.