DUET AD Installation Guide Pag. 2

1Index

1Index .......................................................................................................................................... 2

2About this document .................................................................................................................... 4

3General Description ...................................................................................................................... 4

3.1 DUET AD .............................................................................................................................. 4

3.2 Proper use ............................................................................................................................ 5

3.3 Standards and guidelines ....................................................................................................... 5

4Safety instructions........................................................................................................................ 6

5Technical data, accessories ........................................................................................................... 7

5.1 Electrical data........................................................................................................................ 7

5.2 Mechanical data .................................................................................................................... 7

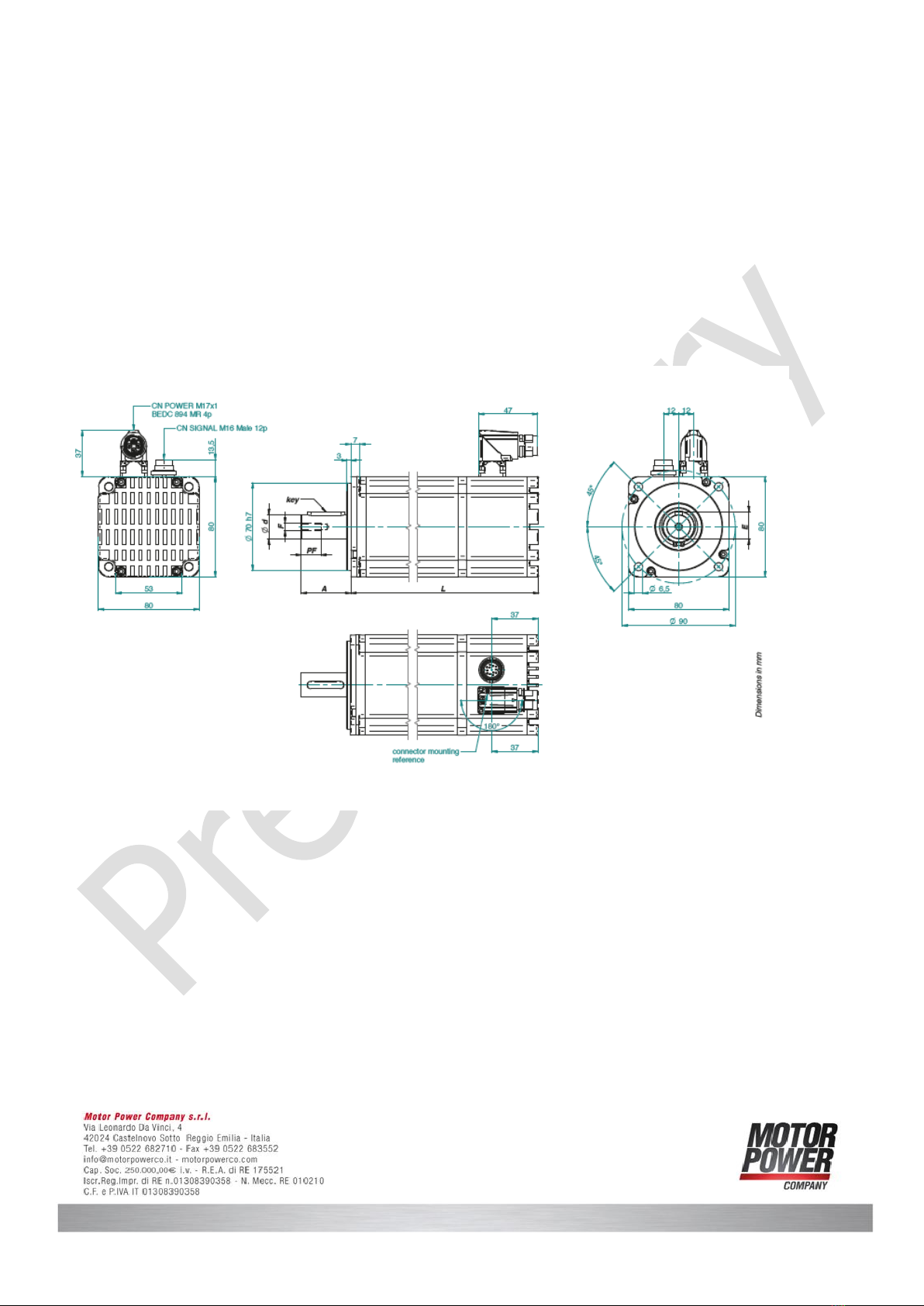

5.3 Dimensions ........................................................................................................................... 8

5.4 DUET AD 1,5 03 .................................................................................................................... 8

5.5DUET AD 2,8 02 .................................................................................................................... 9

5.6 Accessories ........................................................................................................................... 9

6Protective functions.................................................................................................................... 10

6.1 Ballast circuit....................................................................................................................... 10

6.2 Current limitation................................................................................................................. 10

7Installation ................................................................................................................................ 11

8Mechanical assembly .................................................................................................................. 11

8.1 EMI compatibility................................................................................................................. 11

8.2 Ground wire ........................................................................................................................ 12

8.3 Motor power supply ............................................................................................................. 13

8.4 Signal interface supply ......................................................................................................... 15

8.5 Schematic circuit of the digital inputs .................................................................................... 16

8.6 Schematic circuit of the digital outputs .................................................................................. 17

8.7 Maximum cable length and power supply............................................................................... 18

9Connection schematic................................................................................................................. 18

9.1 Schematic circuit for power supply controller ......................................................................... 19

9.2 Connection motor power supply............................................................................................ 20