4EN

persons without any knowledge of the product, provided that

these are supervision and instructions given by persons with

experienced in terms of usage of the product in a safe manner

and who understands the risks and dangers involved.

•Children shouldn’t play with the product or opening devices

to avoid the motorized door or gate from being triggered

involuntarily.

WARNINGS FOR TECHNICIANS

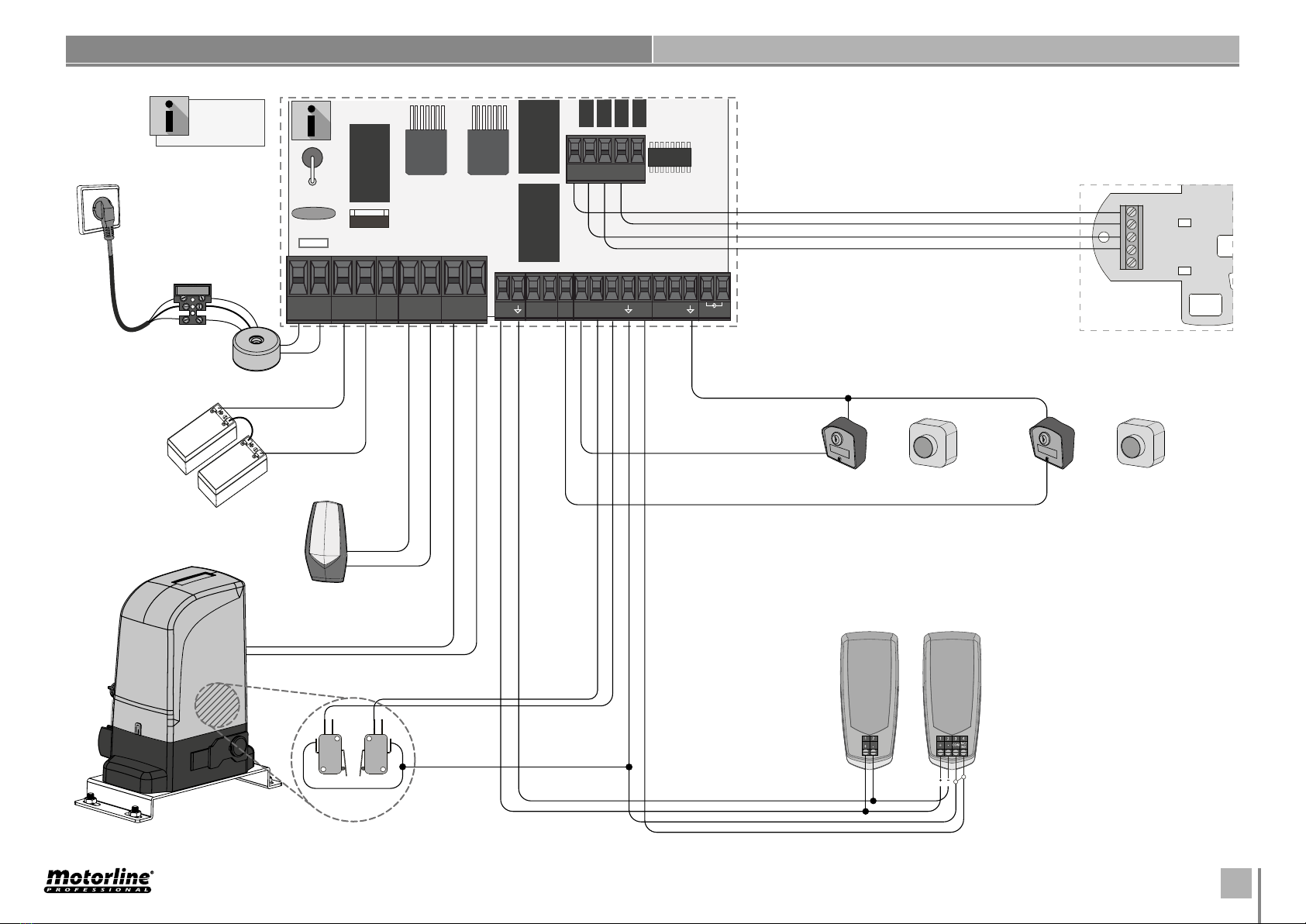

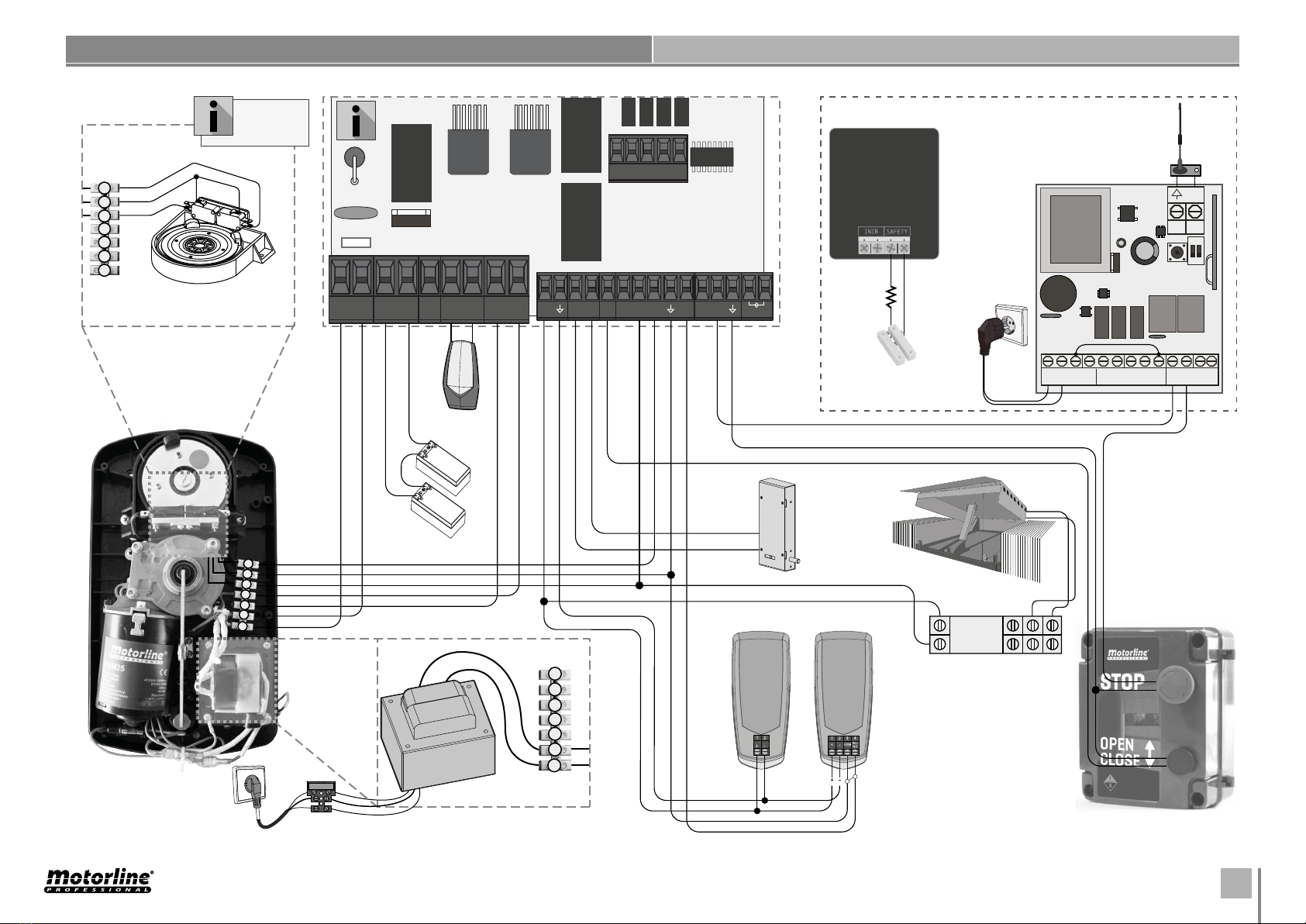

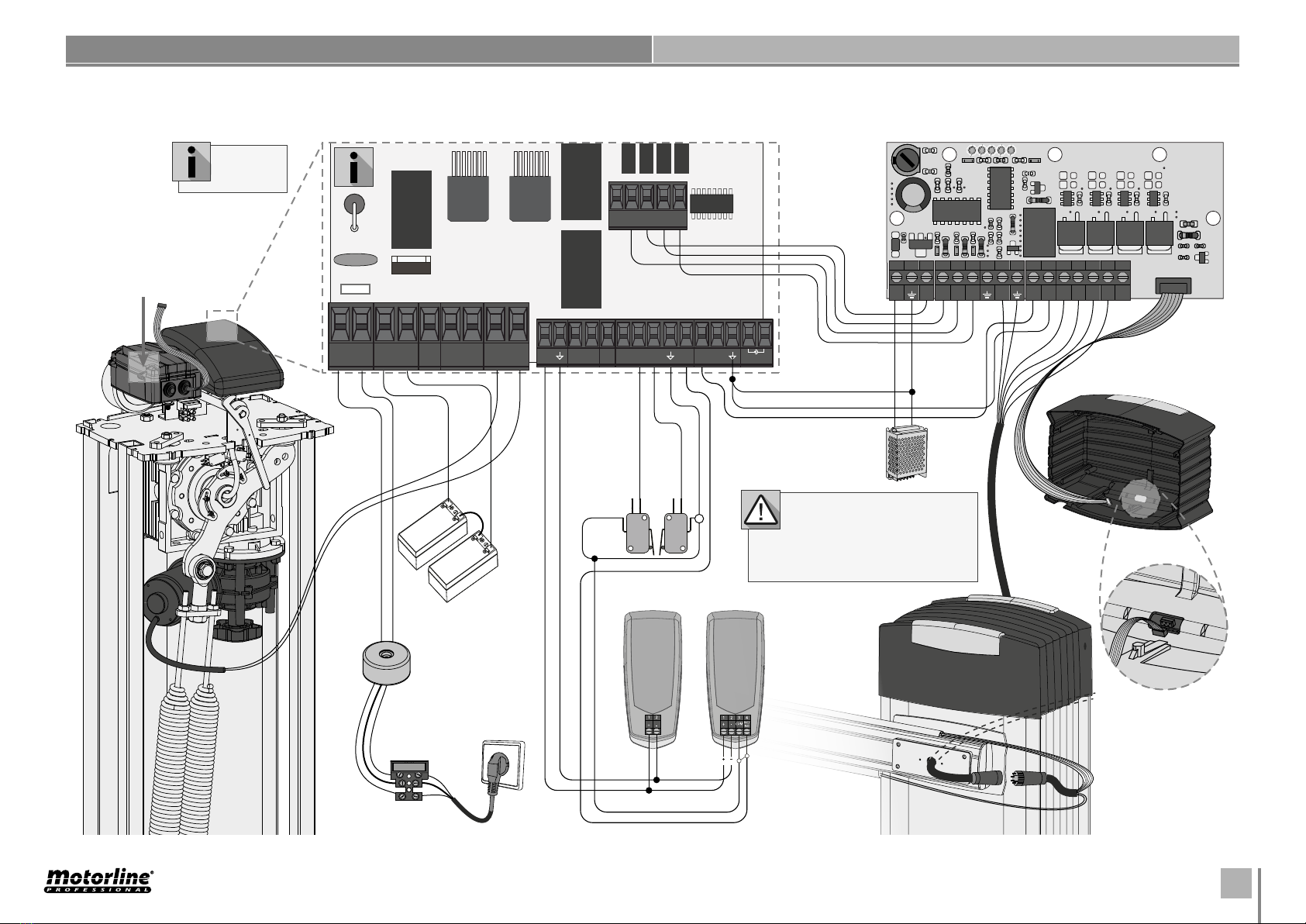

•Before beginning the installation procedures, make sure that

you have all the devices and materials necessary to complete

the installation of the product.

•You should note your Protection Index (IP) and operating

temperature to ensure that is suitable for the installation site.

•Provide the manual of the product to the user and let them know

how to handle it in an emergency.

•If the automatism is installed on a gate with a pedestrian door,

a door locking mechanism must be installed while the gate is in

motion.

•Do not install the product “upside down” or supported by

elements do not support its weight. If necessary, add brackets

at strategic points to ensure the safety of the automatism.

•Do not install the product in explosive site.

•Safety devices must protect the possible crushing, cutting,

transport and danger areas of the motorized door or gate.

•Verify that the elements to be automated (gates, door, windows,

blinds, etc.) are in perfect function, aligned and level. Also verify

if the necessary mechanical stops are in the appropriate places.

•The central must be installed on a safe place of any fluid (rain,

moisture, etc.), dust and pests.

•You must route the various electrical cables through protective

tubes, to protect them against mechanical exertions, essentially

on the power supply cable. Please note that all the cables must

enter the central from the bottom.

•If the automatism is to be installed at a height of more than 2,5m

from the ground or other level of access, the minimum safety

and health requirements for the use of work equipment workers

at the work of Directive 2009/104/CE of European Parliament

and of the Council of 16 September 2009.

•Attach the permanent label for the manual release as close as

possible to the release mechanism.

•Disconnect means, such as a switch or circuit breaker on the

electrical panel, must be provided on the product’s fixed power

supply leads in accordance with the installation rules.

•If the product to be installed requires power supply of 230Vac

or 110Vac, ensure that connection is to an electrical panel with

ground connection.

•The product is only powered by low voltage satefy with central

(only at 24V motors)

WARNINGS FOR USERS

•Keep this manual in a safe place to be consulted whenever

necessary.

•If the product has contact with fluids without being prepared,

it must immediately disconnect from the power supply to avoid

short circuits, and consult a specialized technician.

•Ensure that technician has provided you the product manual

and informed you how to handle the product in an emergency.

•If the system requires any repair or modification, unlock the

automatism, turn off the power and do not use it until all safety

conditions have been met.

•In the event of tripping of circuits breakers of fuse failure, locate

the malfunction and solve it before resetting the circuit breaker

or replacing the fuse. If the malfunction is not repairable by

. SAFETY INSTRUCTIONS . SAFETY INSTRUCTIONS