Pag.

10 - Manual code:

119E7051G B ver.

4 08/2013 - The data and information in this manual are subject to change at any time.

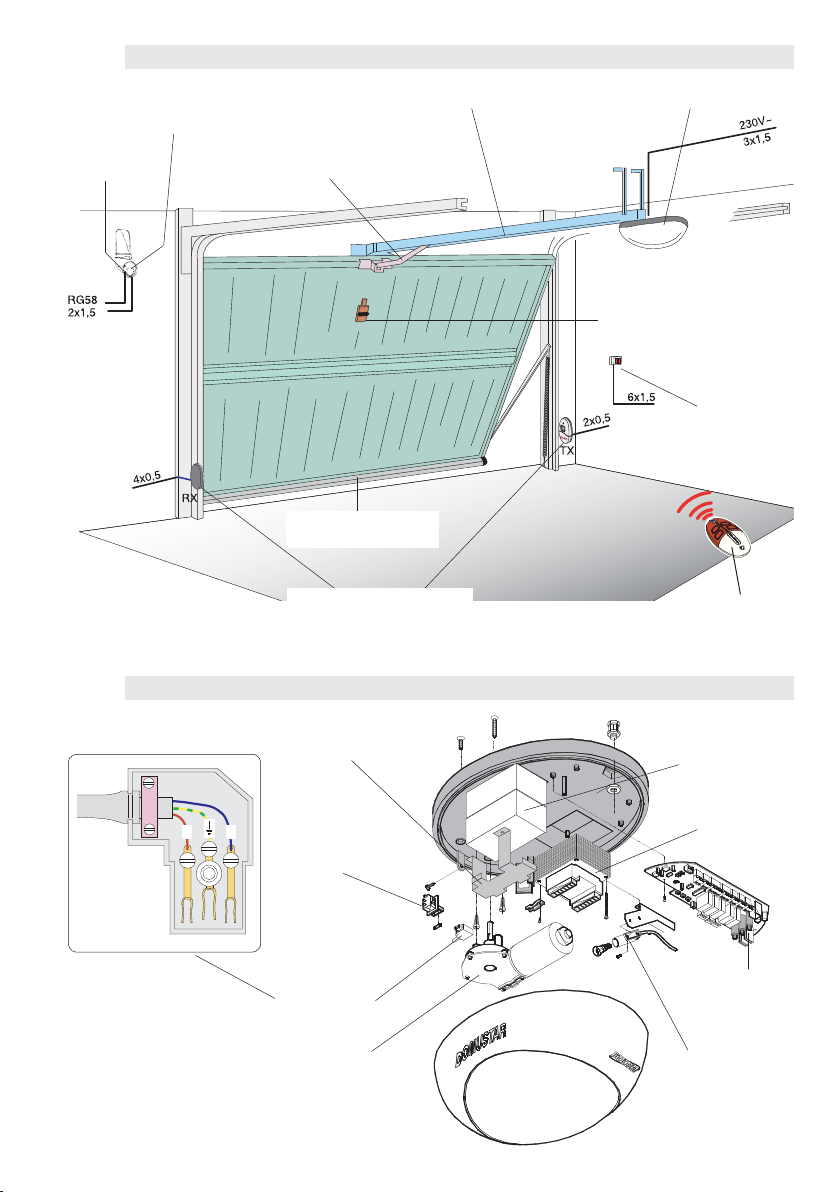

5.1 CONTROL BOARD DESCRIPTION

The board is powered by a power supply

socket (230V AC) and is protected in input

by a 1.6A mains fuse. The control devices

are low-voltage and protected by a 3.15A

fuse. The overall rated power of the 24V

accessories, protected by 3.15A fuse, must

not exceed 40W.

Work time set at 80 seconds.

Commands

- Total stop, pushbutton connected to

the ST-G terminals, stop of the overhead

door with exclusion of the automatic

closing cycle; to resume movement, the

pushbuttons or radio-controls must be

used;

- Opening-closing, pushbutton connected

to G-Ps or by radio-control, see page 14,

function selections;

Safety

- Re-opening during closure, see function

selections;

- Photoelectric cell test. Function selections

dip switch 9 ON;

- Amperometric device : see NOTE.

Other functions

- Automatic closure, see function

selections;

- Obstacle detection , see function

selections;

- Pre-flashing, see function selections;

Connected accessories

- Courtesy light (24V-25W). Lamp that lights

up the manoeuvre zone after an opening

command; it remains on for a set time of 2

mins. 30 secs.

Optional accessories

- 2acourtesy light (24V-25W), connected to

the 20-K3 terminals.

-Flashing light indicating movement

(24V-25W max.), connected to the 20-K1

terminals;

- Board for supplying power by battery

that, in the event of blackout, intervenes

automatically. When mains comes back on,

it recharges the batteries;

- Radiofrequency board for remote control.

Adjiustments

- Adjustment of automatic closing time;

- Adjustment of amperometric sensitivity.

Important: after supplying electricity to

the system, the 1st manoeuvre is always

an opening one. During this phase, it is not

possible to close the door, but it is possible

to close it again after the complete opening

manoeuvre.

Important! Shut off the mains power

before servicing the inside of the unit.

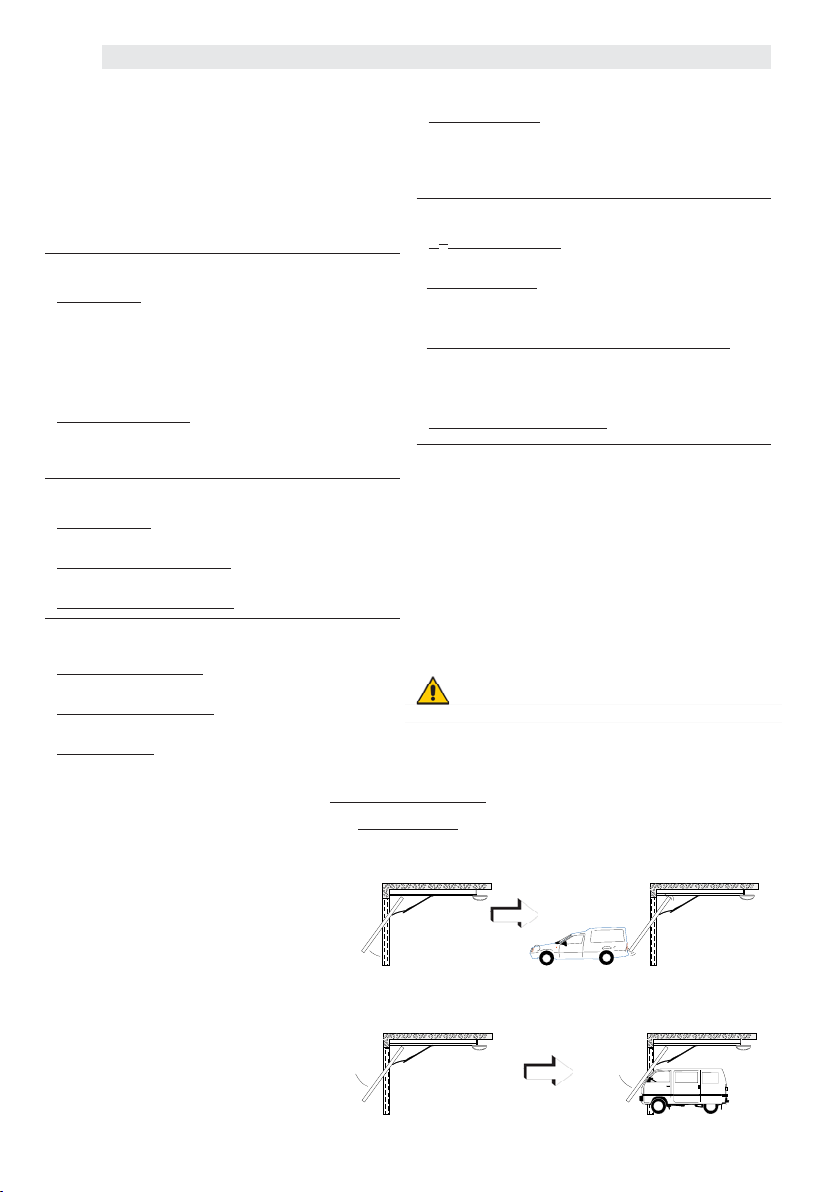

N.B.: In situation (b), if an obstacle is

detected three times, the door wing

stops during aperture, and auto-

matic closure is disactivated.

Use the keyboard or the radio trans-

mitter to resume movement of the

bar.

In the presence of an obstacle, the

amperometric device:

a) completely stops the door during

opening and subsequently closes it

automatically (if activated);

b) if in the closure phase, the move-

ment of the door is reversed.

NOTE