BY12512d_e.doc / Mai-08 Page 3 / 52

Table of Contents

1. Introduction....................................................................................................................4

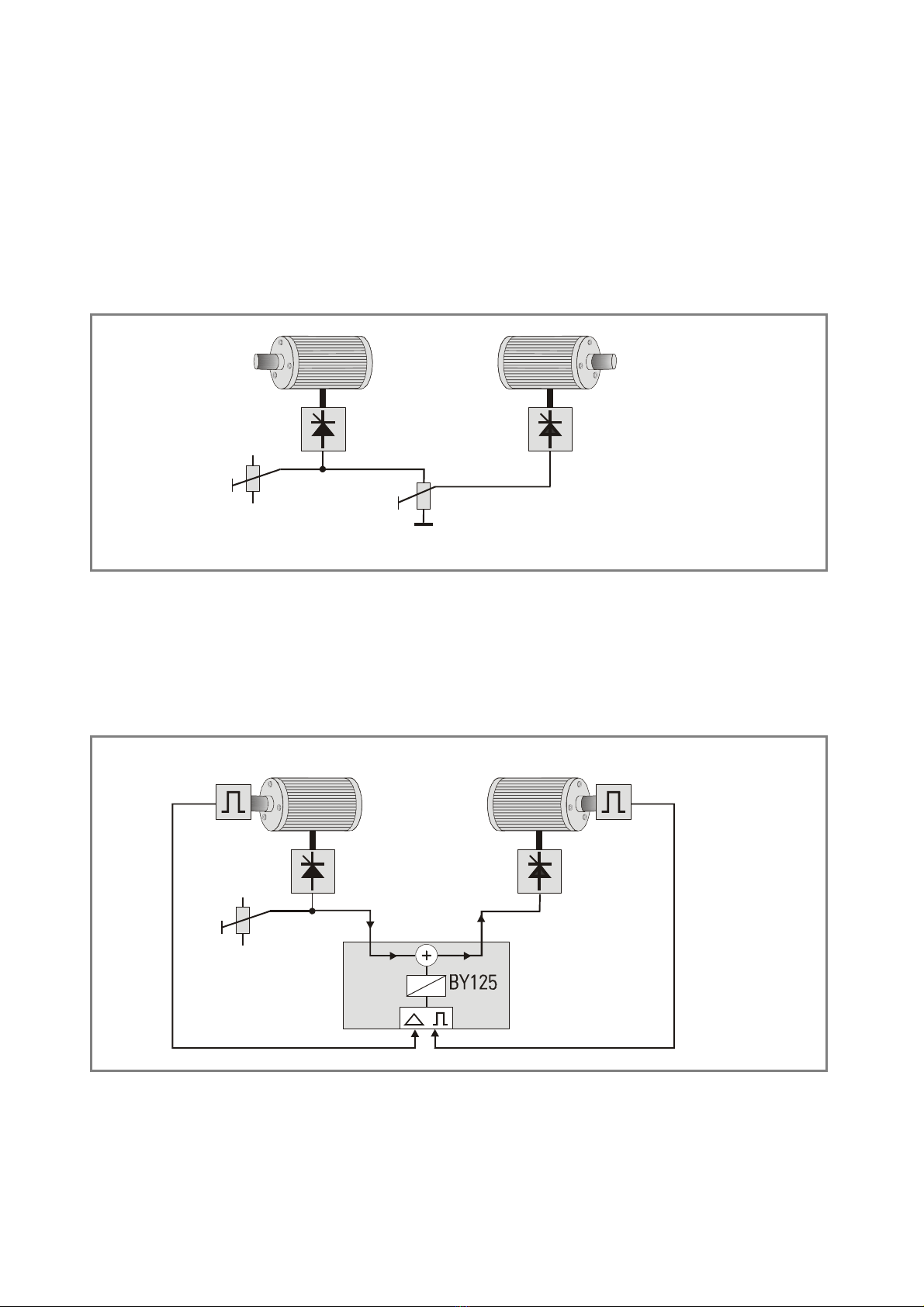

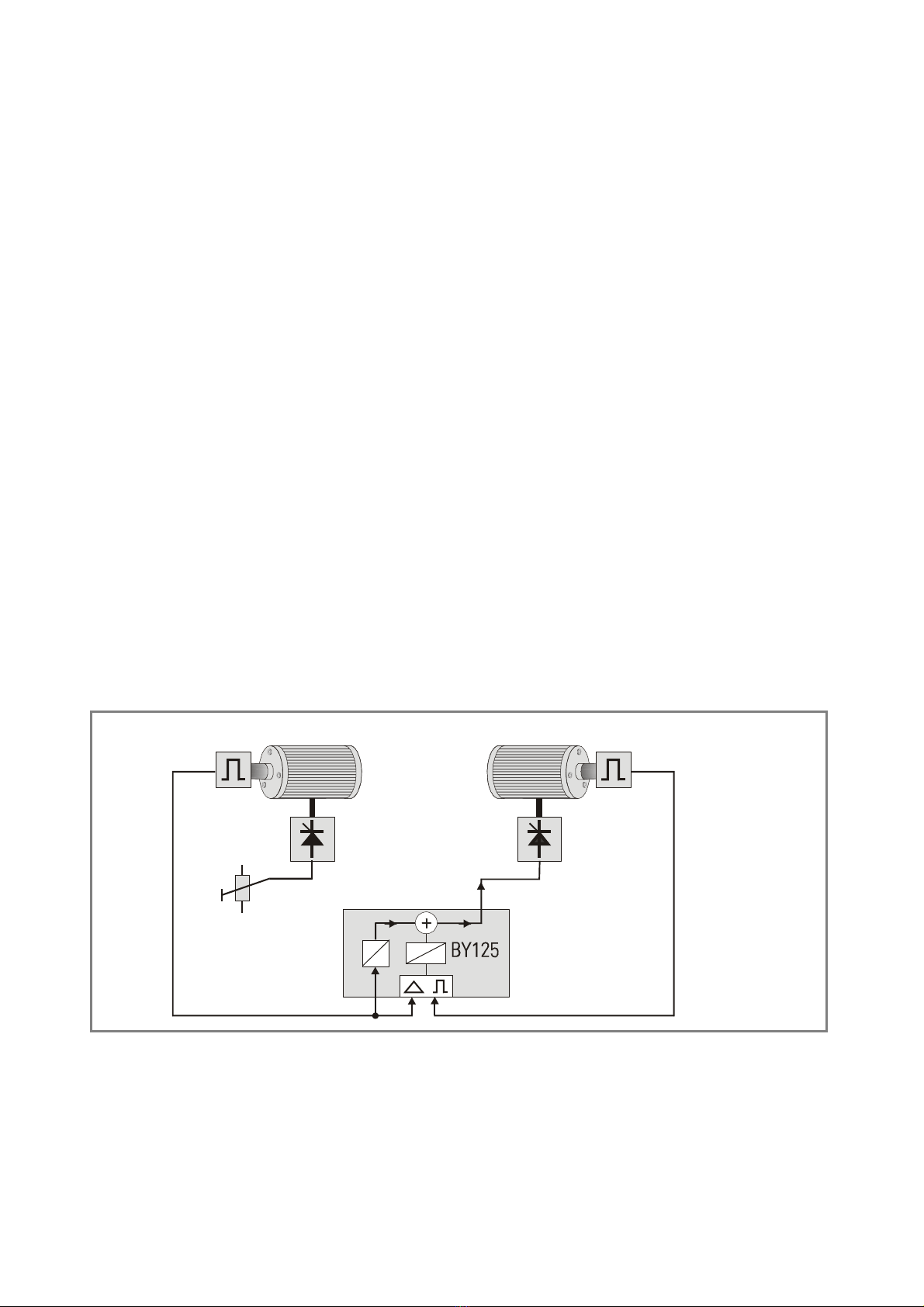

2. Principle of operation..................................................................................................... 6

3. Impulse Scaling.............................................................................................................. 9

4. Ratio Change during Operation.....................................................................................12

5. Change of Phase and Relative Position.........................................................................13

5.1. Timer Trimming (Modes 1 - 4 and 8)..........................................................................................13

5.2. Impulse Trimming (Modes 5 and 6)............................................................................................13

5.3. Phase Offset Operation (Mode3)................................................................................................13

6. Index Control (Modes 2, 6 and 8) ..................................................................................14

7. Connections and Hardware Settings.............................................................................16

7.1. Power Supply..............................................................................................................................17

7.2. Encoders......................................................................................................................................17

7.3. Analogue Input and Output ........................................................................................................19

7.4. The Serial Ports ..........................................................................................................................19

7.5. Control Inputs and Outputs ........................................................................................................21

8. Register List and Clarification.......................................................................................24

8.1. General Parameters....................................................................................................................25

8.2. Setup Registers ..........................................................................................................................29

9. The Front LED................................................................................................................33

10. Remarks about Drives, Encoders, Cables etc. ...............................................................34

10.1. Drives ..........................................................................................................................................34

10.2. Encoders......................................................................................................................................34

10.3. Screening....................................................................................................................................35

10.4. Cables .........................................................................................................................................37

10.5. Remote Signal Commutation .....................................................................................................37

11. Steps for Commissioning ..............................................................................................38

12. Hints for Final Operation...............................................................................................45

12.1. Integrator ....................................................................................................................................45

12.2. Correction Divider.......................................................................................................................45

12.3. Offset voltage .............................................................................................................................45

12.4. Other settings .............................................................................................................................46

12.5. Oscilloscope Function.................................................................................................................46

13. Serial Codes..................................................................................................................47

14. Master Reset and EEPROM Erasure..............................................................................48

15. Dimensions and Specifications.....................................................................................49

16. Appendix: Option UP125 ...............................................................................................50