ZU25102A_e.DOC / Mrz-08 Page 3 / 26

Table of Contents

1. Introduction....................................................................................................4

2. Applicable encoders and sensors ..................................................................5

3. Terminal Assignment .....................................................................................6

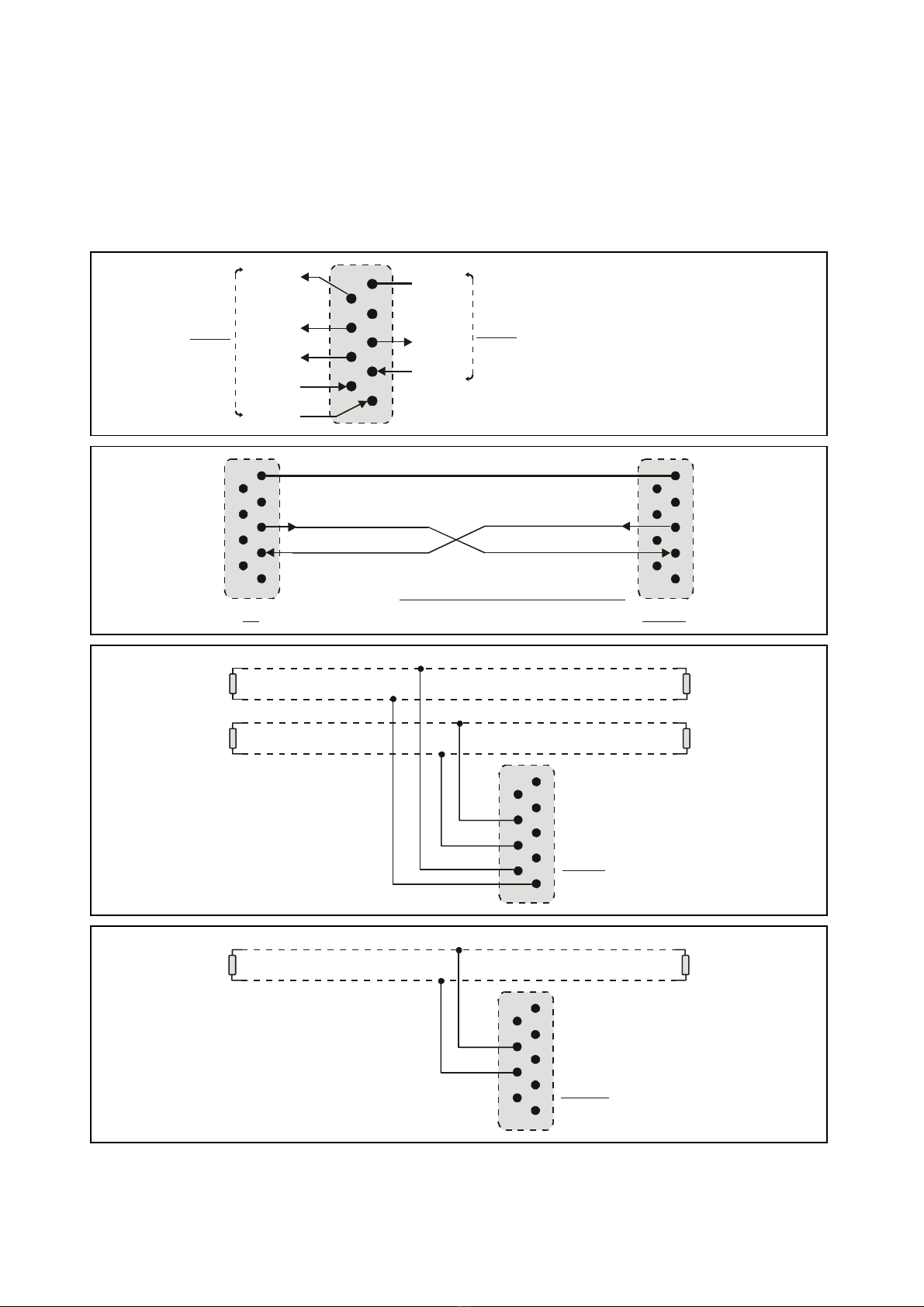

3.1. Incremental encoders TTL / RS 422 ......................................................................6

3.2. Incremental encoder HTL / 12-30V .......................................................................7

3.3. Proximity switches, photocells etc........................................................................7

3.4. Analogue outputs ..................................................................................................7

3.5. Serial interfaces ....................................................................................................8

4. DIL switch settings.........................................................................................9

5. Setup Procedure........................................................................................... 11

5.1. Operation as single channel counter (without direction signal)

or as positional counter (with direction signal)...................................................12

5.2. Operation as a summing or differential counter with

two independent impulse inputs (A+B, A-B).......................................................12

6. Readout of the actual counter state by serial communication ..................13

7. PC setup with use of the operator software OS3.x.....................................14

8. Displays and Softkeys..................................................................................15

9. Parameter Settings ......................................................................................16

10. Free Programmable Linearization.................................................................21

11. Test Functions.............................................................................................. 23

12. Dimensions .................................................................................................. 24

13. Technical Specifications ..............................................................................25

14. Parameter List.............................................................................................. 26