Notes on characters and symbols

In the operating instructions, the following terms and symbols are used for particularly important

information.

The associated text describes risks or hazards, the possibilities for preventing these risks and

hazards, and the consequences of failure to observe safety regulations.

This is a warning about a possible risk situation that could

lead to injuries of mild or medium severity, as well as material

damages if the associated safety instructions are not

followed.

BEFORE YOU OPERATE this unit, you must read and understand

this instruction manual. Keep this manual handy. The manual

should be kept in a safe place.

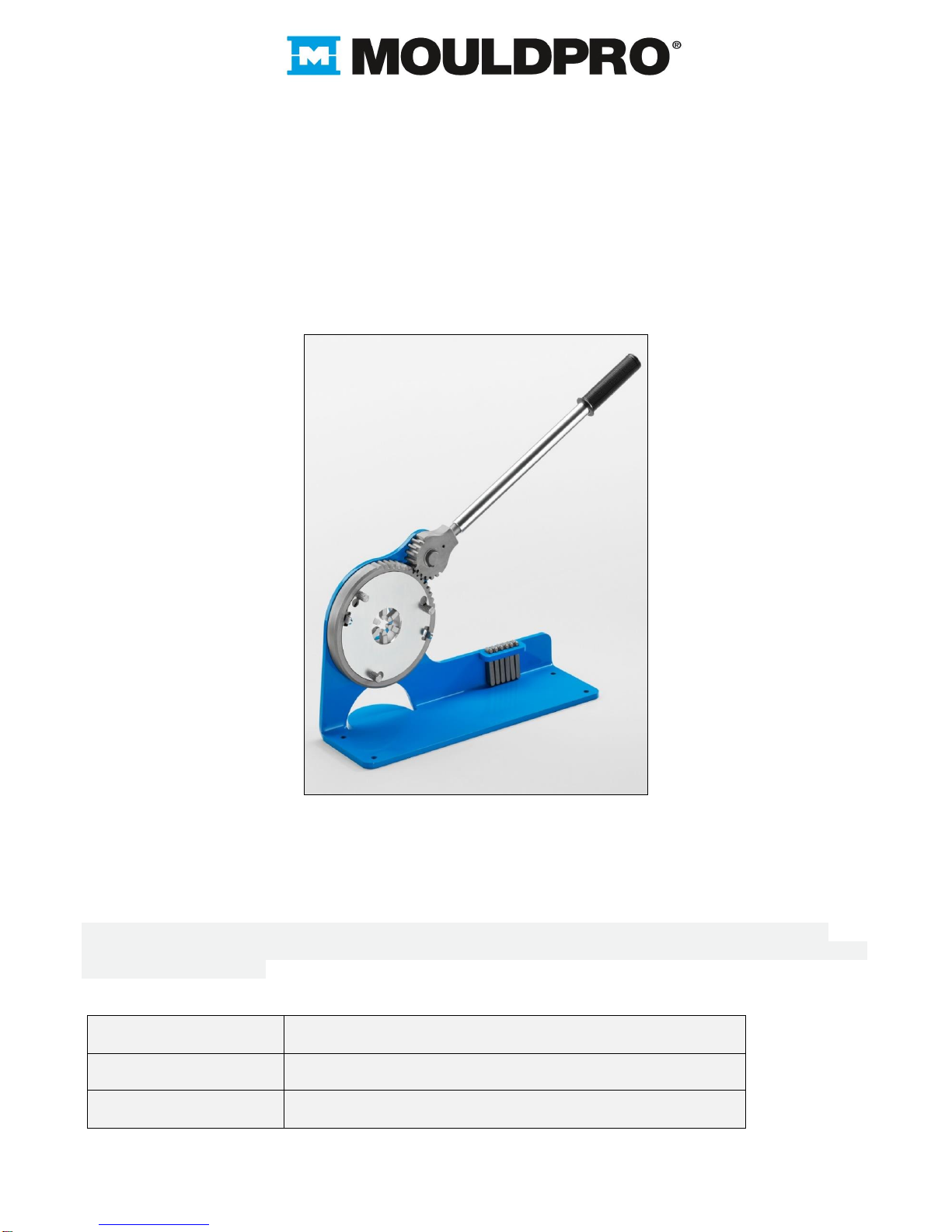

Description of functions

The low-pressure hose crimping tool X100 is manually operated and does not require electricity or

compressed air for its operation.

The working pressure is generated by depressing the hand lever. The necessary force can be applied by any

person of average strength using only one hand.

Instructions for safe transport

When moving the unit, it is necessary to observe the relevant workplace safety regulations! When

transporting the unit, do not walk backwards! Please observe the normal accident prevention

regulations relating to the unit's weight. Make sure that the unit is not subjected to high-force impacts

of any kind: such impacts can cause damage to parts of the unit.

Installation

The low-pressure hose crimper X100 must be bolted in place on a stable, strongly-built, level base.

Always make sure that you have enough space to work and are not hindered or endangered by

adjacent equipment. There must always be good onsite workplace lighting that fulfills the

requirements of any applicable national rules and regulations.