F 002 DG9 A14 2016-07-07| Bosch Limited

8 | NTI 105 | Product descriptionen

4. Commissioning

4.1 Removing the transport packaging

!Dispose the packaging material in accordance with

local regulations. Do not dispose of the packaging

material along with household waste.

4.1.1 Opening the NTI 105

1. Visually, check if there is any damage to the packag-

ing case.

iIf there are signs of damage to the packaging, report

to the transporter immediately. Report the extent of

damage to Bosch Limited immediately.

2. Move the packaging case containing the NTI 105 to

the installation site.

iDispose the packaging material in accordance with

local regulations.

3. Remove the packaging.

4. Check if all the items/accessories listed in the deliv-

ery specification are available with the NTI 105.

iIf any of the items in the scope of delivery are not

delivered, report to Bosch Limited.

4.2 Installation

Requirements for installation:

RPneumatic supply - Pressure input of 8 bar to

16 bar.

RPower supply - 230 VAC +/- 10 %, single phase,

50 Hz

!Cover the NTI 105 such that it is not exposed to rain.

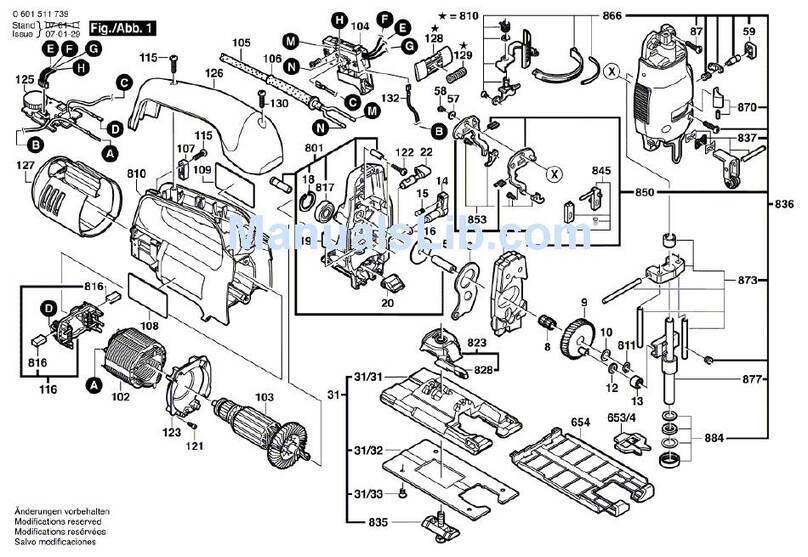

!Do not apply any cleaning agents to the display

(Fig. 1, Pos. 2), keypad (Fig. 1, Pos. 5) or the status

indication LED (Fig. 1, Pos. 9).

iFor optimal operation, ensure that the compressor

pressure is constantly above 10 bar.

iAs a good practice, you can install a 40 micron filter

/ water separator in the supply line from the com-

pressor. The filter should be able to function in the

pressure range of 8 bar to 16 bar. This is to ensure

that the particulate matter and moisture is filtered

from the compressed air even before it reaches

the FRC unit of the NTI 105 which, in turn, leads to

higher longevity of the CMS tanks.

1. Clean the surface of the NTI 105 cabinet with a di-

lute solution of detergent using a soft cloth.

iTo ensure optimum performance, ensure that the

input pressure is 10 bar or above. Also ensure that

the pneumatic connections are leak-proof.

3.4.1 CMS and nitrogen tanks

Two CMS tanks (Fig. 4, Pos. 1) are used to convert air

to nitrogen. The separated nitrogen is collected in a

storage tank (Fig. 1, Pos. 1) for further distribution. The

CMS tanks are firmly fixed and bolted to the cabinet.

3.4.2 Filters for water and oil separation

The input pneumatic line is connected to the Filter Reg-

ulator Combination (FRC) (Fig. 2, Pos. 1) which acts as

an input and filtration device. Air from the compressor

at a minimum pressure of 8 bar is passed through the

FRC where the moisture and dirt are filtered. The col-

lected moisture, dirt or oil can be discharged manually

by opening the drain on the FRC. The regulator is set to

allow a maximum of 10 bar.

!Do not tamper with the regulator setting of the FRC.

3.4.3 Hose for inflation

Air or nitrogen is filled into the vehicle tire via a 8 m

filling hose. A filling nozzle fixed to the hose is used to

connect the filling hose to the vehicle tire.

3.4.4 Keypad, pressure gauge and status indication

LEDs

Selection of air / nitrogen can be done via the toggle

switch (Fig. 1, Pos. 3). The pressure can be set through

the input keys on the keypad. The pressure sensor de-

tects the tire pressure. Based on the set pressure and

mode, the tire is filled with nitrogen or air via solenoid

valves. The result of the operation is displayed on the

LCD screen. A pressure gauge is used for indicating the

pressure in the nitrogen storage tank. Upon completion

of service, the status indication LED (Fig. 1, Pos. 9)

glows.

3.4.5 Power cable and master switch

The NTI 105 is connected to 230 VAC 10%,

50 Hz 1% supply via a power cable. The NTI 105 can

be powered on by turning the master switch in the

clockwise position.