Mountfield IBIZA User manual

IBIZA

Circular and oval swimming pools

INSTALLATION GUIDE

Montageanleitung

für runde und ovale Swimmingpools

IBIZA

Инструкция по монтажу

для круглых и овальных бассейнов

IBIZA

1

IBIZA

Circular and oval swimming pools

INSTALLATION GUIDE

Safety Information

Please read the complete Installation Guide including Safety Guidelines first

and follow them during swimming pool construction and use.

Use appropriate safety devices to prevent uncontrolled access into the pool,

specifically by children under 5 years of age, thereby preventing their

drowning or severe injury.

Non-swimmers and children must be under constant supervision by an experienced person.

Remember that safety guidelines and safety devices cannot substitute personal supervision

by a skilled person, they can only support it.

Read more detailed information starting on page 30.

© 2019 – Mountfield a.s. –05/2019 No. 733B

EN

2

Contents

1 Important comments......................................................................................................................................3

1.1 Swimming pool earthing.........................................................................................................................3

2 Introductory information ...............................................................................................................................3

2.1 Swimming pool parts..............................................................................................................................3

2.2 Swimming pool siting .............................................................................................................................4

2.3 Filter location..........................................................................................................................................4

2.4 Spatial arrangement options ..................................................................................................................4

2.5 Bed preparation......................................................................................................................................5

2.6 Pool liner.................................................................................................................................................5

3 Construction preparation ...............................................................................................................................6

3.1 Pit for a circular swimming pool.............................................................................................................6

3.2 Base slab.................................................................................................................................................6

3.3 Pit for an oval swimming pool................................................................................................................7

4 Swimming pool installation ..........................................................................................................................10

4.1 Circular swimming pool installation .....................................................................................................10

4.2 installation of an oval swimming pool..................................................................................................11

4.3 Steel wall installation............................................................................................................................12

4.4 Processing of the bottom wall edge trims and joining the wall ends with a sliding-in section ...........13

4.5 Preparation of openings for the accessories........................................................................................15

4.6 Laying protective geotextile padding ...................................................................................................19

4.7 Hanging the pool liner and installing the top wall edge trim...............................................................20

4.8 Installing the parts to be built in ..........................................................................................................24

4.9 Complete the technology installation procedures...............................................................................26

5 Dry concrete around the swimming pool.....................................................................................................27

6 Miscellaneous...............................................................................................................................................28

6.1 Water level and skimmer flap ..............................................................................................................28

6.2 Entering the swimming pool.................................................................................................................28

6.3 Advice for using the swimming pool ....................................................................................................29

6.4 Liner repair ...........................................................................................................................................29

6.5 Maintenance.........................................................................................................................................29

6.6 Preparing for the winter season...........................................................................................................30

7 Safety rules ...................................................................................................................................................30

3

1 Important comments

Read all sections of this document

carefully and strictly follow all

instructions.

Illustrations and pictures in this document are partly

symbolic and typical presentations to give the reader

a general idea of the topics described.

Inspect the package(s) delivered before starting the

assembly to make sure that all parts of the swimming

pool have been provided. Inspect all parts to detect

any defect. Mountfield shall not be liable for any

damage arising during the shipment if claimed after

assembling the parts. Mountfield reserves the right to

make changes resulting from technological progress.

Make sure that the steel wall will come in

contact with suitable building materials

only.

For instance, if you intend to use silicone, make

sure that this material contains no acids that may

damage the steel wall's protective coating and

potentially result in corrosion. It may be

necessary to determine if the materials planned

are appropriate with respect to the intended use.

1.1 Swimming pool earthing

The swimming pool wall and all large-area metallic

parts must be bonded in compliance with applicable

local regulations. This is a job for a qualified

electrician.

For this, the steel wall may be drilled through in the

lower part (and then treated with a zinc spray or a

plastic paint) and the earthing cable connected to a

metallic bolt (Fig. 1). The cable is routed from the bolt

to an earthing pole.

Warning: All electrician's work must be

done by a qualified company and in

compliance with applicable electrical

standards (such as DIN VDE 0100 Part

702).

Fig. 1

2 Introductory information

2.1 Swimming pool parts

Fig. 2

The picture above does not show all parts

delivered. The design and colour of the

parts delivered may differ from what is

shown.

The illustrations and pictures reproduced

here may differ from the product actually

delivered. They are only meant to help the

reader understand the text herein.

The manufacturer reserves the right to

make changes without prior notice.

Sliding-in section

for joining the

vertical steel wall

edges

Steel wall

Pool liner

Aluminium top

wall rail

Bottom wall edge

trim

Top wall edge

trim

4

2.2 Swimming pool siting

The swimming pool should stand on a sunny place if

available, not very far from the house. The skimmer

(collecting foreign matter from the pool water surface)

should be located downwind, so any foreign mater

floating on the surface is pushed by wind to the

skimmer. What is more important, however, is that

the skimmer should be installed on the side that is

closer to the filter.

2.3 Filter location

Install the filter system as close to the swimming pool

as possible. Preferably the suction piping (skimmer

piping) should be shorter that the return piping

(nozzle piping).

The filter system can be installed in a shaft, in the

house, in a garden house, etc. If installation in the

house and in a shaft is selected, the floor must be

provided with a drain (sink) in case of water leak.

Water from the back flushing must also be drained,

roughly 200 litres every 1-2 weeks. This can be done

by means of fixed piping or a hose ending in a drain.

If the filter system lies higher that the water level, a

return valve must be installed on the suction side,

that is, on the skimmer piping. This must be installed

1–1.5 m far from the sand filter system and must be

accessible at all times.

The planned water heating method is also an

important factor when selecting the place for the filter

system. If the swimming pool is to be heated by a

dedicated solar system, the filter system should be

installed as close to the solar absorber as feasible.

Even if an air-water heat pump is planned for outdoor

installation, the filter system should preferably also be

installed in the garden. However, if the heat

exchanger is connected to the central heating

system, installation of the filter in the house is virtually

inevitable.

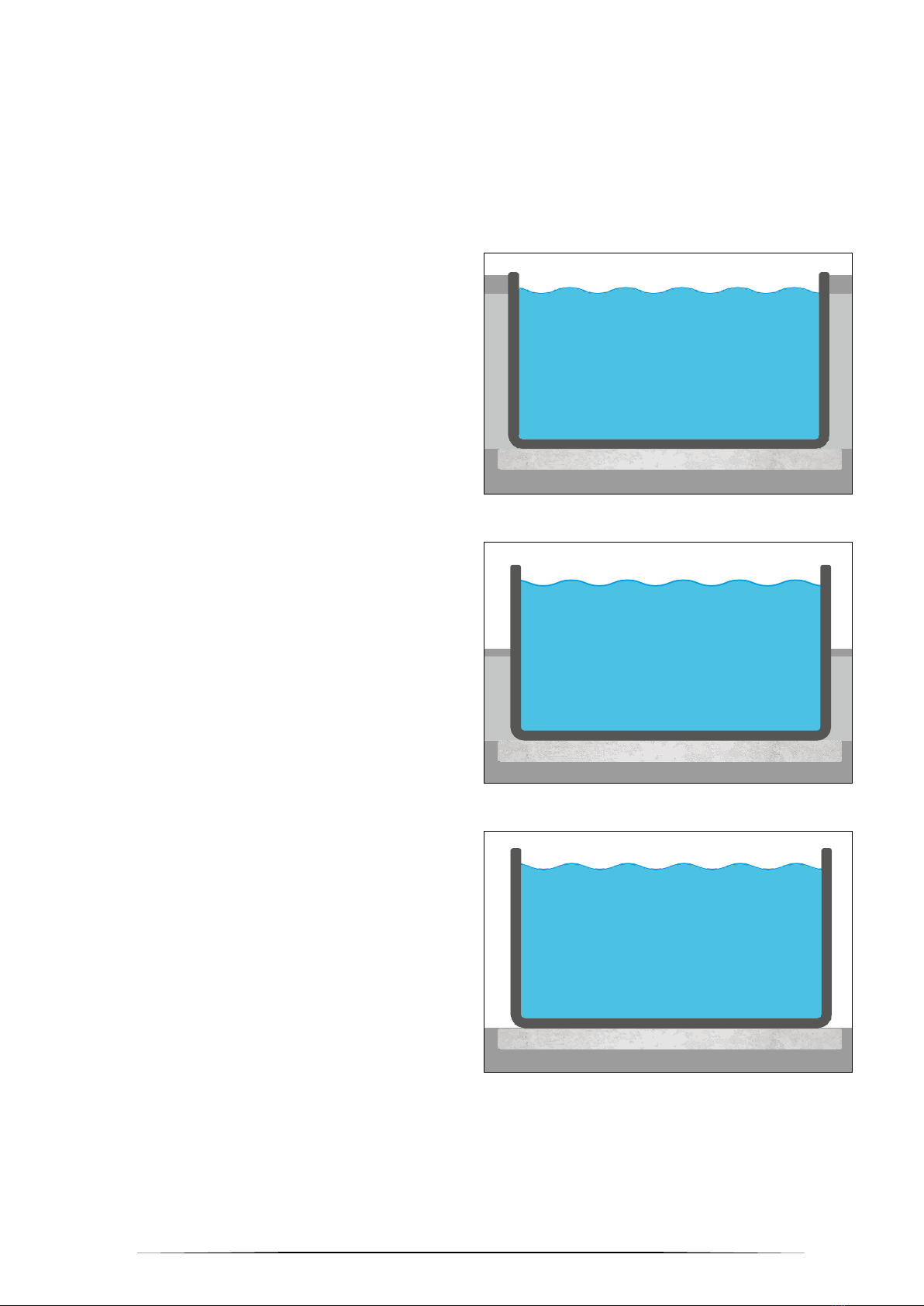

2.4 Spatial arrangement options

2.4.1 Spatial arrangement options –circular

swimming pool

Three different options exist for the installation of a

circular swimming pool irrespective of its depth and

size:

Inground swimming pool

Fig. 3

Semi-inground swimming pool

Fig. 4

Above-ground freestanding swimming pool

Fig. 5

Swimming pools 150 cm deep must always be at

least 60 cm sunk in the ground.

For such swimming pools and for inground and semi-

inground swimming pools the area around the

inground part must always be backfilled with lean

concrete.

5

2.4.2 Spatial arrangement options –oval

swimming pool

Oval swimming pools cannot be installed arbitrarily

and their inground part must encompass least 2/3 of

their total height. The installation site must be

provided with a concrete base slab and with retaining

walls on the long sides, which must be joined with the

base slab by means of steel reinforcement.

Once the construction is complete, the area around

the front sides to the oval swimming pool must be

backfilled with lean concrete or bricked in.

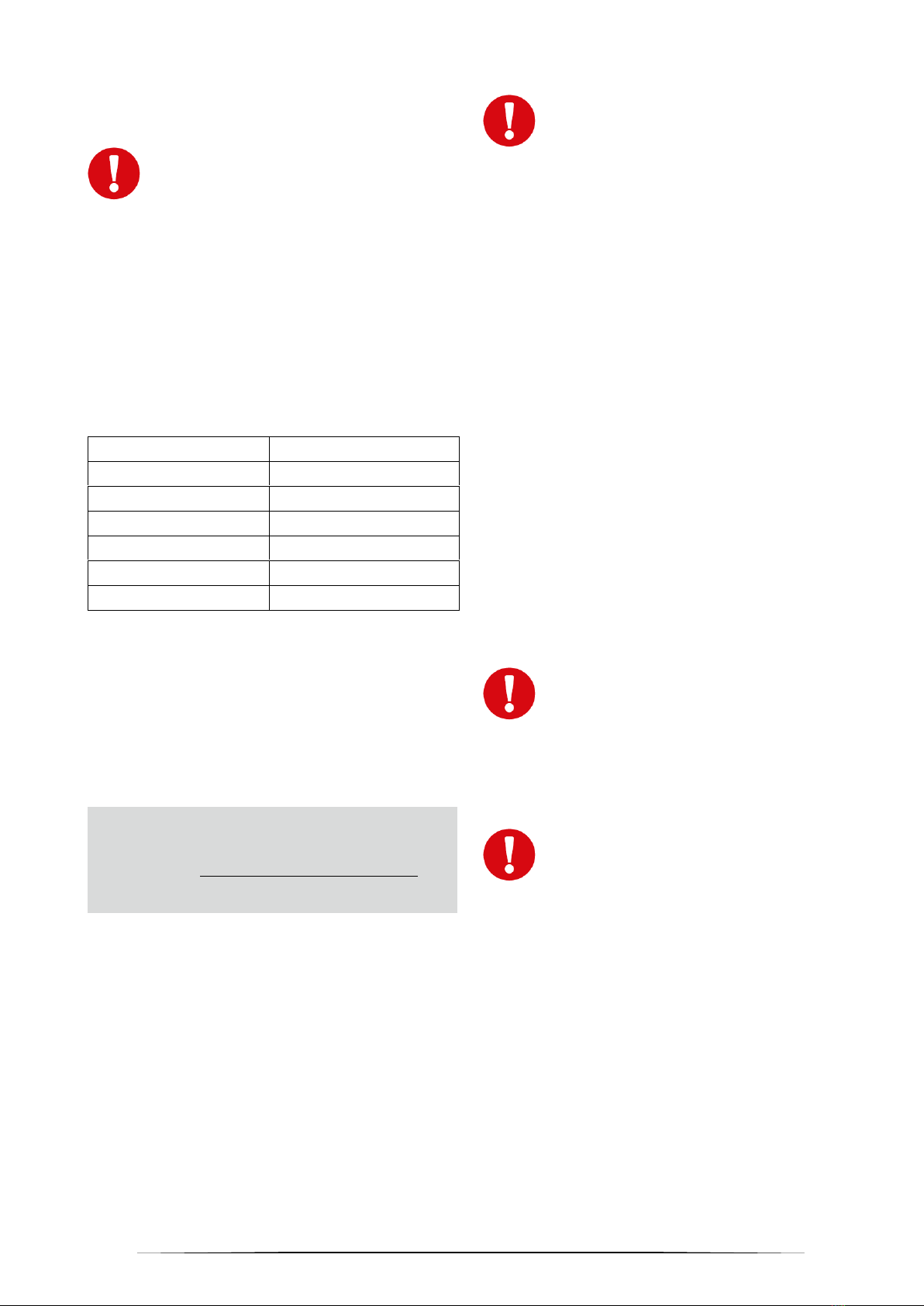

Fig. 6

1) The skimmer/nozzle side

2) Pool stairs

3) Pool lights shedding light away from the

installation site (if any)

4) Pool liner

5) Steel wall

6) Construction sheets + polystyrene

7) Steel wall joining section

8) Retaining wall (reinforced)

9) Reinforced concrete base slab

10) Water draining

11) Gravel (subbase)

2.5 Bed preparation

The swimming pool ground must meet appropriate

static strength requirements and must be solid and

compact. Any inclined surfaces must be eliminated.

Never create any backfill on the slopes! Any slopes

must be supported by retaining walls. Never support

a slope by the swimming pool wall!

The ground for the swimming pool must be natural, it

should not consist of infilling. Any filled-in earth

should be compacted so that the swimming pool

should not sink or else more efforts must be made

when constructing the foundations. If in doubt,

contact a specialized civil engineer or a structural

engineer.

Important when installing the pool into

earth: The swimming pool must not get

into a groundwater area! If groundwater

is encountered during the excavation

work, a civil engineer-specialist must be

contacted and an acceptable solution

must be found!

A reinforced concrete base slab must be used. A

gravel layer is normally used as the subbase. Water

draining piping is generally recommended for

inground swimming pools.

2.6 Pool liner

The pool liner is made of a thermoplastic material.

So, the swimming pool must be mounted at outdoor

temperatures between +15°C and +25°C. Do not

install the liner under strong sunlight, it is better to

wait till the evening.

Because of its material properties, if exposed to low

temperatures, the liner may by about 50 cm shorter

than as required for the swimming pool.

Prevent the swimming pool liner from

getting in contact with any material that

is incompatible with PVC. To this end the

use of protective geotextile padding is

recommended.

6

3 Construction preparation

3.1 Pit for a circular swimming pool

When digging out the ditch for a (nearly)

inground swimming pool, a working area

50 cm wide or wider must be left for later

installation of the swimming pool

structure parts and their connection to

the piping.

If the inground height does not exceed one-half of the

total pool height and the piping should not be buried,

an area 20–30 cm wide will be sufficient.

Remember that the lean concrete backfilling of the

area immediately after the steel walls must be 15–30

cm thick. More information can be found on page 27.

Recommended pit dimensions:

Swimming pool

Pit dimensions

Width x length [m]

Width x length [m]

3.60 diam.

4.60 diam.

4.00 diam.

5.00 diam.

4.60 diam.

5.60 diam.

5.00 diam.

6.00 diam.

6.00 diam.

7.00 diam.

For the sake of simplicity the pit has normally a

rectangular shape, although it can, of course, also be

circular or oval as appropriate, with the required

dimension margins.

The dug-out depth depends on the base slab and

gravel layer thickness as well as on the depth and

height of the swimming pool.

The rule of thumb is:

The base slab is typically 15 cm thick, the gravel

layer is typically about 5 cm thick (the precise

thickness will be determined by the installing

company depending on the bedrock).

Important: If the filter system is not

located immediately at the swimming

pool and the piping is planned to be

buried, then the trenches for the piping

must be excavated simultaneously with

the pit for the pool.

The trenches for the piping must be excavated

simultaneously with the pool pit. They should be

approximately 40–50 cm wide and about 80 cm deep.

If the possibility to completely drain the piping before

the winter season exists, the pipes can be laid higher,

inclined downwards to the (lowest-lying) draining

point.

For this we recommend preparing a large (160 mm in

diameter or larger) plastic or similar pipe at the

appropriate site.

If required, trenches can also be excavated for piping

from the filter system to a solar heating system and

for power supply cables.

3.2 Base slab

Once the pit is dug out and a water draining system

prepared, the concrete base slab (C16/20) reinforced

with a Q 188A construction steel mesh is fabricated.

The recommended base slab thickness is about 15

cm: the actual thickness (and the gravel layer

thickness) should be specified by a specialized civil

engineer.

The base slab should be laid precisely

horizontally, with no gradient, and its

edges should overreach the swimming

pool edges by some 10 cm.

Once again, the base slab can be rectangular or

circular/oval (copying the swimming pool contours).

Warning: Respect the concrete setting

time (typically 28 days). Only a civil

engineer-specialist may decide (on

his/her own responsibility) that this time

can be shortened .

Gravel layer thickness

+concrete slab thickness

+ swimming pool (inground) depth

= digging depth

7

3.3 Pit for an oval swimming pool

3.3.1 Ground plan and size: swimming pool and

retaining wall

Fig. 7

Swimming pool

Retaining wall

Width x

length [m]

A [m]

R [m]

MB [m]

M [m]

3.20 × 5.25

2.05

1.60

3.24

2.25

3.20 × 6.00

2.80

1.60

3.24

3.00

3.50 × 7.00

3.50

1.75

3.54

3.70

4.16 × 8.00

3.84

2.08

4.20

4.04

4.16 × 10.00

5.84

2.08

4.20

6.04

6.00 × 12.00

6.00

3.00

6.04

6.20

3.3.2 The pit

A margin of a minimum of 50 cm must

remain in the rounded swimming pool

segment where the skimmer and nozzles

are to be mounted, to allow the parts to be

built in and interconnected with the piping at

a later stage.

Margins of 30 cm are sufficient on the opposite side

and on the longitudinal sides.

Remember that the space immediately behind the

steel walls (except for the retaining wall segments)

must be backfilled with lean concrete at a 15–30 cm

thickness of bricked in.

Recommended pit dimensions:

Swimming pool

Pit dimensions

Width x length [m]

Width x length [m]

3.20 × 5.25

4.30 × 6.25

3.20 × 6.00

4.30 × 7.00

3.50 × 7.00

4.60 × 8.00

4.16 × 8.00

5.25 × 9.00

4.16 × 10.00

5.25 × 11.00

6.00 × 12.00

7.10 × 13.00

For the sake of simplicity the pit has normally a

rectangular shape, although, of course, it can also be

circular or oval as appropriate, with the required

dimension margins.

The dug-out depth depends on the base slab and

gravel layer thickness as well as on the swimming

pool depth.

The rule of thumb is:

The base slab is typically 15 cm thick, the gravel

layer is typically about 5 cm thick (the precise

thickness will be determined by the installing

company depending on the bedrock).

The above-ground swimming pool height must not

exceed 1/3 of the total swimming pool height.

Typically the swimming pool's top edge is made flush

with the ground and then covered with a rim.

L = Swimming pool length

A

= Swimming pool straight

segment length

MB

= Retaining wall distance

(polystyrene not included)

B = Swimming pool width

R = Swimming pool radius

M = Retaining wall length

Swimming pool contours

L

A

M

MB

B

Gravel layer thickness

+concrete slab thickness

+ swimming pool depth

= digging depth

8

Fig. 8

Important: If the filter system is not

located immediately at the swimming

pool, trenches for the piping must be

excavated simultaneously. The trenches

should be about 40–50 cm wide and

about 100 cm deep. If the option to

completely drain the piping before the

winter season exists, the pipes can be

laid higher, inclined downwards to the

(lowest-lying) draining point.

For this we recommend preparing a large (160 mm in

diameter or larger) plastic or similar pipe at the

appropriate site.

If required, trenches can also be excavated for piping

from the filter system to a solar heating system and

for power supply cables.

3.3.2 Base slab

Fig. 9

Once the earth excavating and water draining (after

gravel layer laying if necessary) operations have

been completed, the concrete base slab (C16/20)

with reinforcement (Q188A construction steel mesh)

is fabricated. The recommended base slab thickness

is about 15 cm: the actual thickness (and the gravel

layer thickness) should be determined by a

specialized civil engineer.

The base slab should be laid precisely

horizontally, with no gradient, and its edges

should overreach the swimming pool edges

by some 10 cm.

Base slab dimensions

Swimming pool

Base slab (minimum)

Width x length [m]

Width x length [m]

3.20 × 5.25

3.90 × 5.50

3.20 × 6.00

3.90 × 6.25

3.50 × 7.00

4.20 × 7.25

4.16 × 8.00

4.86 × 8.25

4.16 × 10.00

4.86 × 10.25

6.00 × 12.00

6.70 × 12.25

Once again, the base slab can be rectangular or

circular/oval (copying the swimming pool shape).

Important: Embedding the steel

reinforcement immediately into the wet

base slab is recommended. The

reinforcement consists of 8mm

construction steel bars with bends, laid

at a spacing of approximately 25 x 50 cm.

Best take one of the hollow blocks to be used for the

retaining wall and imprint the patterns of the later wall

into the wet concrete. Put a bent steel rebar centrally

into each of the now visible internal chambers of the

imprints (Fig. 10).

Fig. 10

Base slab

Gravel layer

Water

draining

Pit

Soil

Wall

Ground level

Swimming pool rim

Mortar / adhesive for tiles

Base slab

Iron rebars

(diam. 8 mm, 25 × 50

cm)

9

3.3.3 Building the retaining walls

Once the base slab can be walked on, the two side

retaining walls should be built. Fill each row of hollow

blocks with concrete (C16/20) and reinforce both

vertically and horizontally with construction steel

rebars (8 mm diam.). While bricklaying, avoid shifting

the joints or disturbing the verticals and straight lines

or the precise parallel orientation of the two retaining

walls.

The retaining wall height depends on the swimming

pool height –see the sketches.

For a safe fastening of the steel wall to the retaining

wall, best make the top 1 to 2 rows by using full

blocks, such as bricks, because (as experience

shows) such blocks will hold the installation screws

better than hollow bocks do. If fastening into filled

hollow blocks is planned, best use very long screws

that will reach the concrete core.

Warning: Consult a civil engineer-

specialist. Mountfield will take no

responsibility for installation errors or

damage resulting from a poorly

constructed retaining wall!

Fig. 11

Fig. 12

Warning: Respect the concrete setting

time (typically 28 days). Only a civil

engineer-specialist may decide (on

his/her own responsibility) that this time

can be shortened .

The wall height (measured from the top edge of the

base slab) must NOT exceed 115 cm / 145 cm for

swimming pool height 120 cm / 150 cm, respectively,

or the top edge trim cannot be installed properly.

Brick

Polystyrene

board 2 cm thick

Hollow block

24 cm high

Vertical and horizontal

steel rebars

Base slab

Brick

Polystyrene board

2 cm thick

Hollow block

24 cm high

Vertical and horizontal

steel rebars

Base slab

112–115 cm

120 cm

142-145 cm

150 cm

Bushing for

technologies

≥80 mm diam.

Bushing for

technologies

≥80 mm diam.

10

Fix the polystyrene boards 20 mm thick to the internal

side of the retaining walls by using an adhesive for

polystyrene. A 25 mm offset above the base slab

must be left free for the bottom edge trims (Fig. 13).

Fig. 13

1) Polystyrene board

2) Bottom edge trim

3) Base slab

Important: If swimming pool lights are

planned to be installed, openings for this

installation must be made/prepared

during the retaining wall building

process. Follow manufacturer's

instructions.

4 Swimming pool installation

4.1 Circular swimming pool installation

Depending on the swimming pool size, its installation

is a job for 3–4 persons and should be made in

windless conditions. The use of gloves during the

steel wall construction is recommended.

First, draw the swimming pool contour on the ground.

This will immensely facilitate the swimming pool siting

and installation procedures . For this, fasten a string

to a nail driven into the centre of the future pool and

measure the radius (= one-half of the diameter). Use

a piece of chalk or a bricklayer's pencil to mark the

radius measured with the string –see Figs. 14 and15:

The bottom and top wall edge trims are provided. You

will find them inside the coiled steel wall.

Fig. 14

Fig. 15

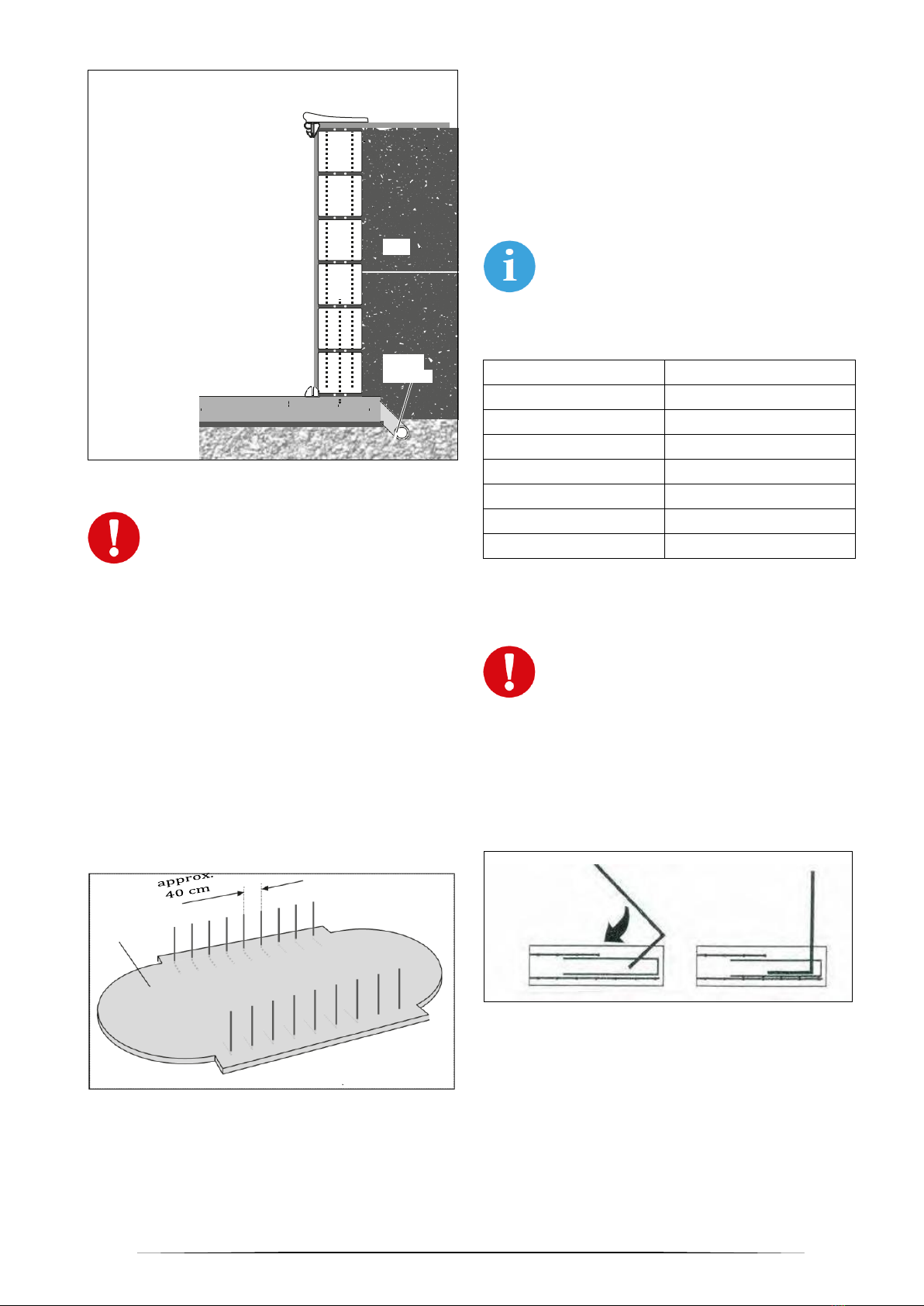

4.1.1 Installation of the bottom wall edge trims

Combine the bottom edge trim segments (approx. 20

mm wide) into one unit by means of the joining tubes

and put the closed swimming pool contours on the

ground. Proceed by following the ground plan.

Check precisely the dimensions and symmetry.

Professional hint for the installation of the

bottom edge trims (and later also the top

edge trims): Combination of the segments

into one unit will be much easier if the pins

are greased.

For this, insert a pin into one segment, grease the still

protruding side (see Fig. 16) and combine the edge

trims (Fig. 17).

11

Professional hint for shortening the bottom

edge trims: First combine all the edge trims

into one and align as appropriate according

to the ground plan. Any overhanging ends

should be shortened only when building the

steel wall because only then the differences

in the dimensions are apparent and can be

trimmed as appropriate.

The precise procedure is shown in Figs. 28-30 on

page 13.

Fig. 16

Fig. 17

Fig. 18

4.2 installation of an oval swimming

pool

First, draw the swimming pool contour on the ground.

The semi-circles of the rounding can be best marked

by means of a string fixed with the nail in the centre

of the future pool. Mark the lines with a bricklayer's

pencil or chalk. The swimming pool dimensions,

including the radius, are shown in Fig. 7 on page 7.

4.2.1 Installation of the bottom edge trims

First slide the straight bottom edge trim segments

(width approx. 20 mm) into one another. Lay the

straight parts of the bottom wall edge trim directly in

front of the brick wall, into the space in the

polystyrene, and centre the edge trims against the

brick wall length. The wall is very slightly longer.

Professional hint for laying the straight edge

trims symmetrically: Measure diagonally the

end points of the edge trims. The

dimensions will be identical if the edge trims

have been laid symmetrically. See

dimension “a” in Fig. 19.

Join the bent bottom edge trim pieces and use them

to fill the rounded segments on the front sides.

Proceed by following the ground plan.

Check precisely the dimensions and symmetry.

Professional hint for shortening the bottom

wall edge trims: First combine all the edge

trims into one and align as appropriate

according to the ground plan. Any

overhanging ends should be shortened only

when building the steel wall because only

then the differences in the dimensions are

apparent and can be trimmed as

appropriate. See section 4.4.

Fig. 19

12

4.3 Steel wall installation

If you want to be able to get into the swimming pool,

you will need swimming pool steps/stairs or a ladder.

Later, when installing the liner, be cautious for the

construction ladder not to damage the liner.

Furthermore, bring the coiled steel wall into the

swimming pool before installing it.

With the assistance of your helpers move the steel

wall roughly to the point where the skimmer (surface

impurity collector) should be installed and put it onto

thick boards and cartons to facilitate its uncoiling (see

Fig. 20). When uncoiling the steel wall, do NOT drag

it over the concrete foundation, it might get damaged.

Fig. 20

The steel wall is coiled inwards in the

factory so the outer side is visible on the

coiled steel wall.

So, uncoil the steel wall in the direction in which it has

been coiled.

In order to prevent injury, wear gloves when uncoiling

and mounting the steel wall and use straps to control

the uncoiling process. (see Fig. 21).

Fig. 21

The recess for the skimmer is normally located at the

beginning of the uncoiling steel wall (approx. 1–2 m

from the front end). If the steel wall is packed in more

than one package, it is shown on the boxes which

steel wall parts (with which recesses for the structure

parts) are included.

Fig. 22

Fig. 23

Uncoil the steel wall and slide it into the edge trims

(see Figs. 22–23). The skimmer recess must be

positioned as required (as close to the filter system

as possible).

The return nozzle is located left of the skimmer

(viewed from outside).

If a joining section is present on one side of the steel

wall, it must be slid out.

Where large swimming pools are concerned, the

steel wall is divided into 2 parts and the joining

procedure using the sliding-in section is performed

twice.

13

Important hint: Some segments of the top

edge trim may be put on for the steel wall to

provisionally keep its shape (see Fig. 24).

Fig. 24

The steel wall of an oval swimming pool may be

provisionally fixed to the retaining walls by using

screw clamps.

Fig. 25

Fig. 26

Always see to it that the steel wall should stand firmly

in the bottom edge trim.

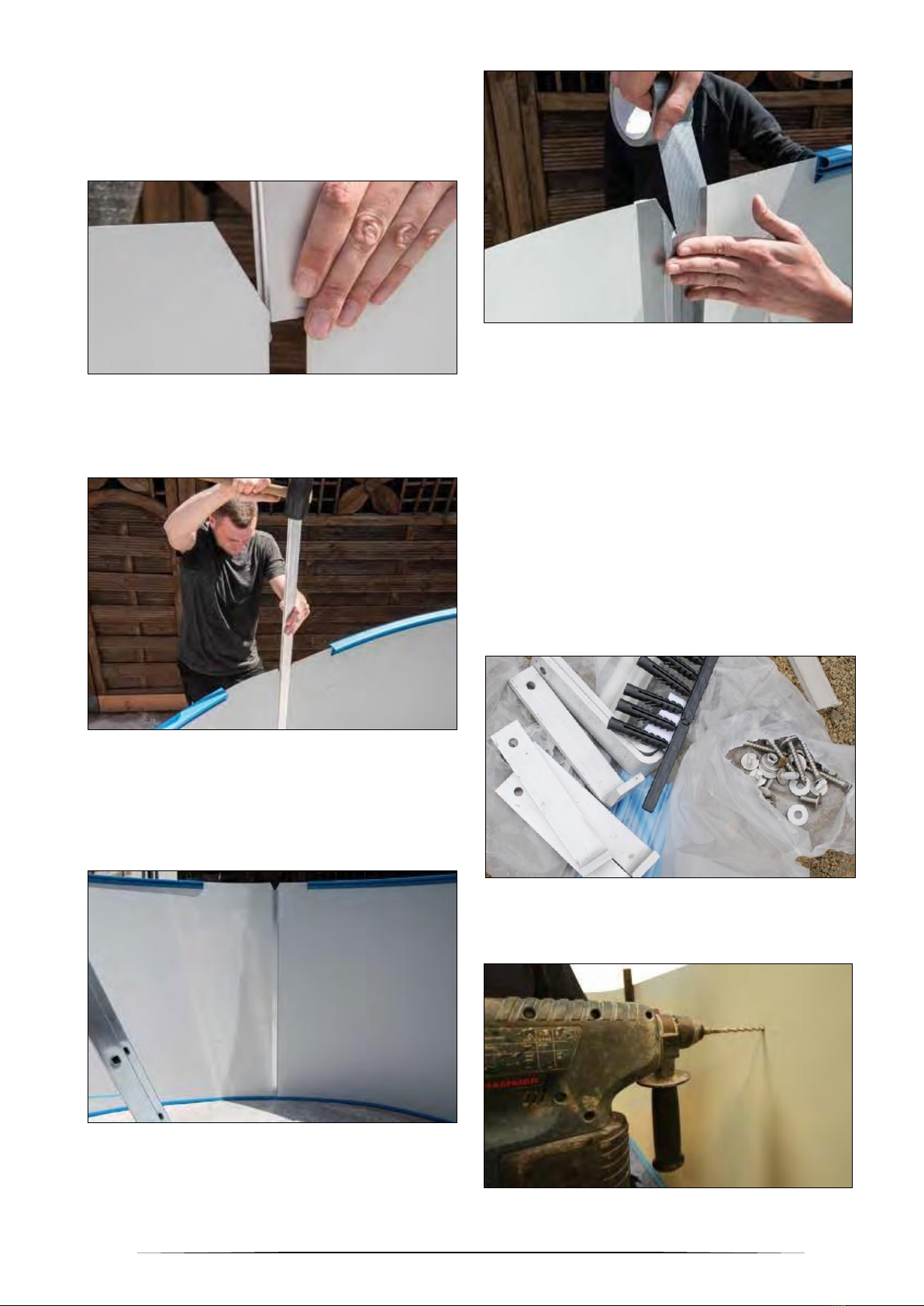

4.4 Processing of the bottom wall edge

trims and joining the wall ends with a

sliding-in section

The gap between the two steel wall ends should be

about 5 mm to enable the sliding-in section to join the

steel wall ends together. This must be taken into

account when shortening the bottom edge trim.

Fig. 27

Shortening the bottom wall edge trim

Uncoil the steel wall and measure any overhang of

the bottom edge trim. Now draw the steel wall by

some 50 cm out of the bottom edge trims and shorten

the bottom edge trim appropriately (remember that a

5mm gap should be left between the steel wall ends

for the sliding-in section –see above).

Important hint: Always shorten the wall edge

trim in the arched segment. If it is shortened

more than 5 cm, then shortening 2 edge

trims is recommended for the sake of arch

symmetry –each arch by one-half of the

total overhang.

Now put the whole steel wall again on and slide the

sliding-in section over (see Figs. 28–30).

Fig. 28

Fig. 29

14

Depending on the swimming pool type the sliding-on

section may have a side bevelled. If this is the case,

put the sliding-in section with the bevelled side

directed inside and upwards. If none of the sides is

bevelled, there is no difference between the

top/bottom sides.

Fig. 30

Facilitate the section installation by moving it slightly

up and down periodically. The use of a rubber

hammer can also be convenient.

Fig. 31

However, if the section is put on incorrectly and/or

driven down with too much force, the steel wall may

get damaged (and the validity of the warranty may be

limited) and the swimming pool stability may be

compromised.

Fig. 32

Fig. 33

Covering the internal sliding-in section surface with

an adhesive tape is recommended in order to protect

the swimming pool liner from damage.

Additional information regarding oval swimming

pools: Steel wall attachment

It is assumed in this explanation that the retaining

wall height is as described on page 9.

In the area of the retaining walls the steel wall must

be fastened to the retaining wall edge with screws (at

a height of 110 cm or 140 cm from the ground for a

swimming pool 120 cm or 150 cm high, respectively).

The fastening must be in a horizontal line. Use the

screws, wall plugs and try squares provided for this

operation (see Fig. 34).

Fig. 34

Drill the holes in the steel wall. Grind the hole edges

smooth and coat with an anticorrosion paint.

Fig. 35

15

Fig. 36

Fig. 37

In this manner the steel wall is fastened directly onto

the retaining wall.

In order to protect the swimming pool liner, cover the

screw heads with an adhesive tape that will not

damage the PVC (with a packaging tape for

instance).

Fig. 38

Caution: Make sure that the swimming

pool stands perfectly horizontally.

Manufacturer's warranty becomes void

and null it the height difference is larger

than 2 cm. If this is the case, identify the

cause a eliminate the problem, e.g. by

improving the base.

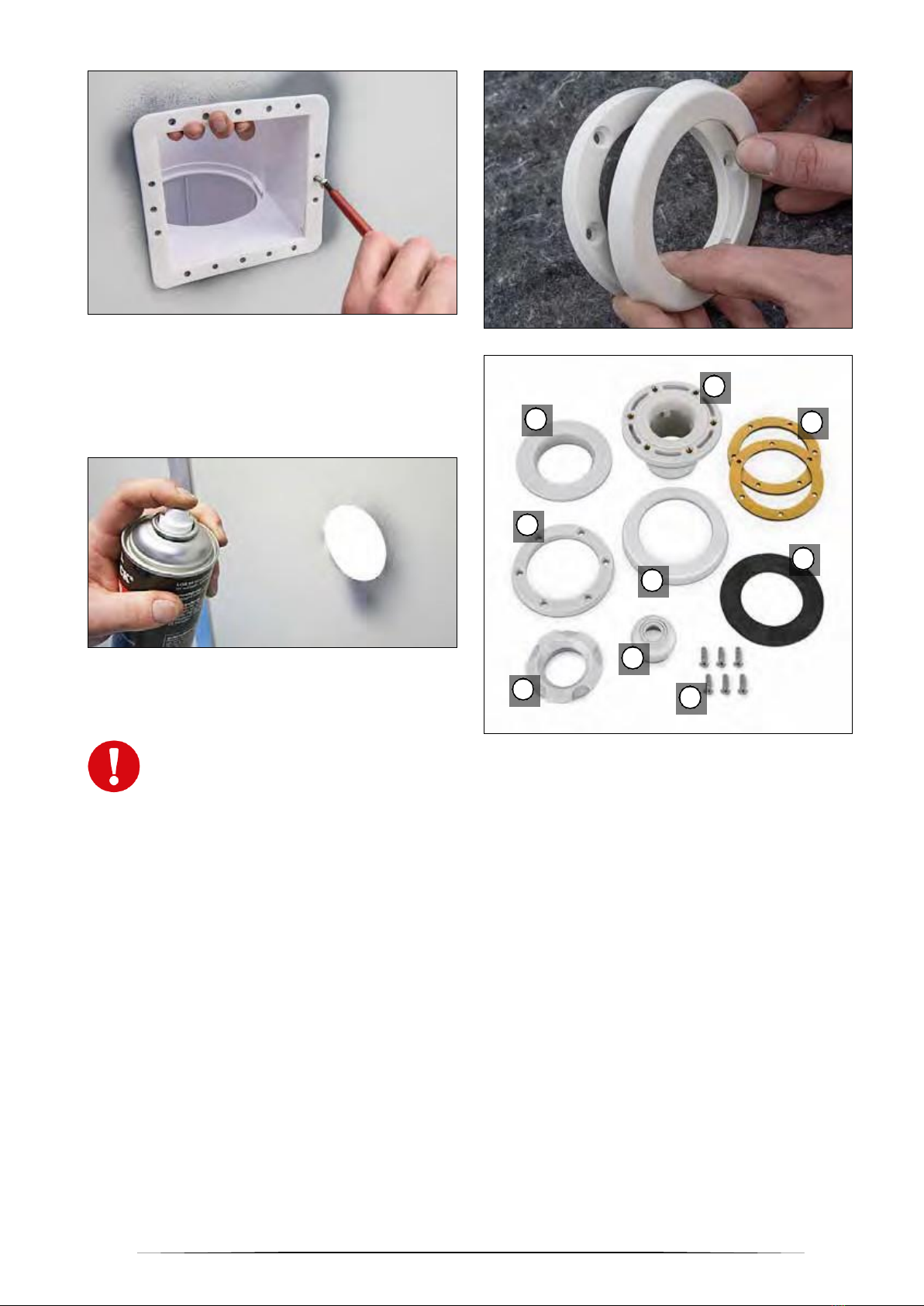

4.5 Preparation of openings for the

accessories

Important: Follow also the accessory manufacturers'

guidelines if attached to the products. If in doubt,

contact your seller.

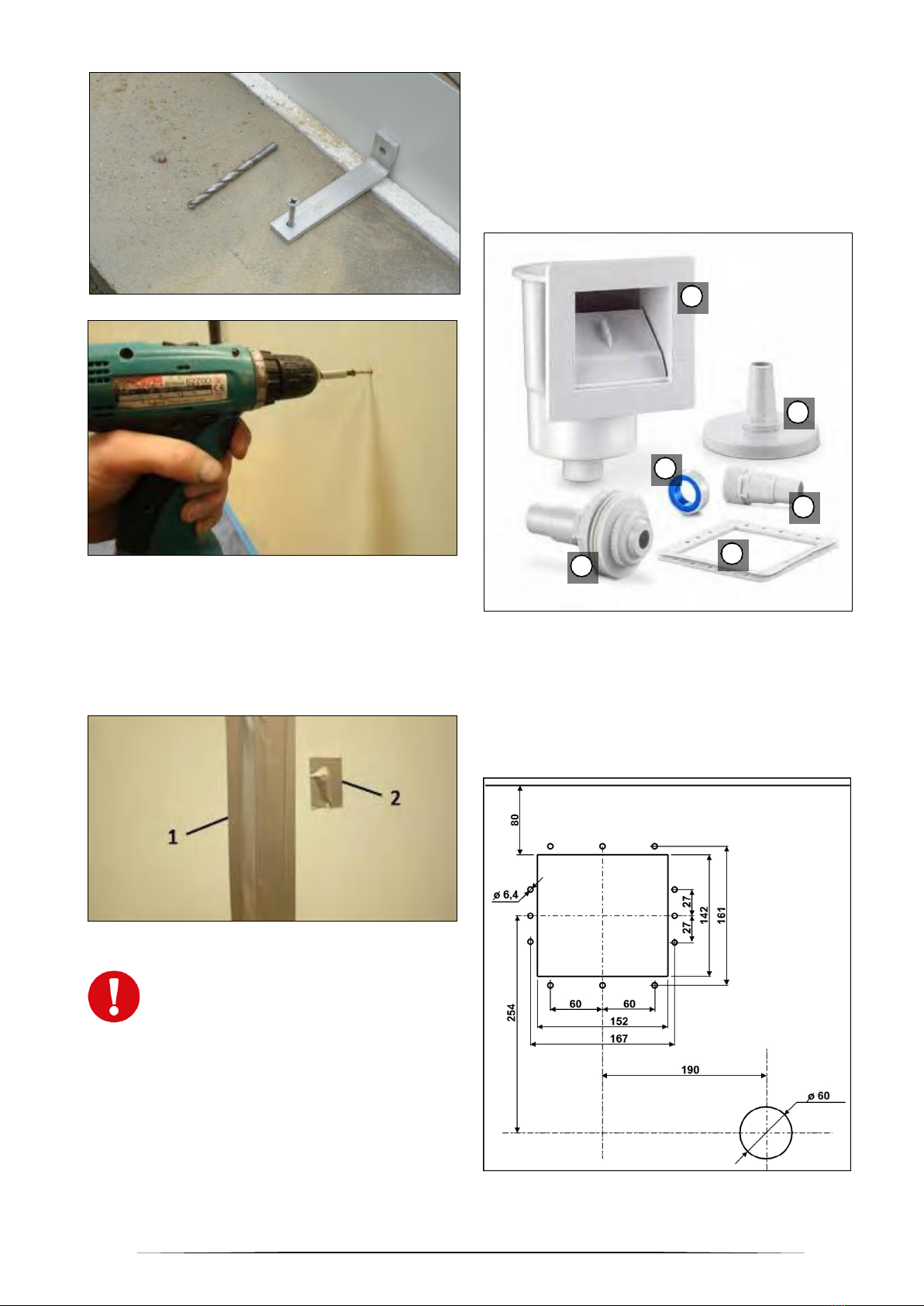

4.5.1 Skimmer (to collect any foreign matter

from the water surface)

Fig. 39

1) Skimmer body 2) Vacuum plate

3) Teflon tape 4) Hose adaptor

5) Double gasket 6) Nozzle

Openings in the swimming pool steel wall for the

skimmer may be present from the factory. If not, they

must be cut out/drilled.

Fig. 40

6

5

4

3

2

1

16

The sketch above shows the dimensions of a

standard skimmer for attachment by using swimming

pool hoses 38 mm in diameter. If a different skimmer

is to be used, an appropriate template / correct

dimensions and spacing must be used.

We recommend that the cutting edges be ground

smooth and treated with an anticorrosion product or

plastic paint prior to the installation.

Fig. 41

If the piping is to be mounted now, installation of the

skimmer at this stage is recommended. For this, put

the double gasket over the steel wall (see Fig. 43),

hold the skimmer at the opening from the outside and

fix it from the inside with rounded head safety screws

(see Fig. 45). If 2 individual gaskets have been

provided in place of the conventional skimmer double

gasket, they must be put on in order: skimmer body –

gasket –steel wall –gasket (–pool liner –skimmer

flange).

This also applies to the return nozzle gasket(s) (for

more information please read page 24, “Internal parts

installation”).

In certain circumstances it may be necessary to

prepare additional holes in the steel wall (and coat

them with an anticorrosion paint) because not always

are the holes for the screws ready.

Fig. 42

If installing the piping later is feasible, the skimmer

can also be installed later along with the installation

of the liner (see page 20).

Fig. 43

Fig. 44

Fig. 45

Flange screw Safety screw

17

Fig. 46

4.5.2 Return nozzle

The IBIZA swimming pools use normally 1 return

nozzle, located next to the skimmer. Here also the

cutting edges should be treated with anticorrosion

coating.

Fig. 47

4.5.2.1 Return nozzles for fixed (buried) piping

Important! The nozzle bodies must be

used now, prior to the installation of the

liner, because they are specific high-

quality return nozzles with a flange on

the swimming pool side, which –in

contrast to conventional nozzles –

facilitate appreciably any later liner

replacement.

The flange is needed for the final nozzle

installation. If the nozzle flange cannot be found

promptly, it is probably inserted into the cover .

Compress/bend the cover slightly to separate the

flange and mount the flange (see Fig. 48).

Fig. 48

Fig. 49

1) Adjusting ring 2) Nozzle eye

3) Nozzle body 4) Safety nut

5) Screws 6) Cover

7) Flange 8) Gasket

9) Hole-less gasket

If the return nozzle is completed with an additional

hole-less gasket , this gasket is not used for

swimming pool with steel walls.

5

1

2

6

9

7

8

4

3

18

Fig. 50

Fix one of the self-sticking gaskets onto the nozzle

body flange frame.

Fig. 51

Fig. 52

Put the nozzle body through the opening in the steel

wall from the inside.

Now put on the safety nut on the nozzle thread from

the back (outer swimming pool side) and screw it on.

Fig. 53

Return nozzles with hose couplings 32/38

mm are installed only simultaneously with

the liner (see page 24).

19

4.6 Laying protective geotextile

padding

The swimming pool should be installed in time or it

may collapse. If fast installation is impossible, e.g.

because of bad weather, we recommend that the

padding should not be used for the time being and

the swimming pool wall should be mechanically

secured against any strong wind.

The use of protective geotextile padding or a

protective paulin is recommended to protect the pool

liner against direct contact with the substrate and any

materials in it that might potentially damage the PVC.

Remember, however, that a protective geotextile pad

can only protect but not make for any surface

unevenness.

The substrate must be cleaned thoroughly before

laying the padding.

In some cases the padding has been cut already to

match that of the swimming pool. If the padding was

delivered in rolls, lay it in strips and fix with an

adhesive tape.

Fig. 54

Fig. 55

Cut the padding approximately 10 longer than the

swimming pool dimension and let it overreach around

the swimming pool wall to a height of some 5 cm.

Cuttings can be used for minor side areas. Draw the

overhanging edges over the bottom wall edge trims

and fix to the steel wall with an adhesive tape.

Fig. 56

Fig. 57

Smooth the padding and join the adjacent strip edges

together also with an adhesive tape.

Table of contents

Languages:

Popular Swimming Pool manuals by other brands

Endless Pools

Endless Pools FASTLANE PRO owner's manual

Doughboy

Doughboy CENTURY Assembly instructions

Outside Living Industries

Outside Living Industries ubbink Ocea 355x550 - H120 cm Note of assembly

Bestway

Bestway FAST SET 257002000451 quick start guide

Bestway

Bestway Hydrium 56586 owner's manual

GRE

GRE PEOV9159 instructions