Part 2: Installation Reference MC-Balance

For more detailed information please consult the User Manual

GENERAL INFORMATION

•Use the equipment only for what it is designed for. The metering of dry additives!

•Before switching on the unit for the first time, ensure that the main power voltage being applied is between 80 and 260Vac.

•Always switch off the Movacolor control cabinet and disconnect from electrical power before performing maintenance.

•The symbol certifies that the machine conforms to the European Union regulations on minimum safety standards.

•Make sure all parts are securely fixed to your extruder or injection molding machine.

LOGIN <menu> supervisor level

The MC-Balance has 3 operation / user levels defined:

User level Default code Access

•Operator 0000 production settings / hopper loader settings / weight check / consumption /

alarm history.

•Tooling 1111 same as operator & additional material calibrations / job functionality.

•Supervisor 2222 same as tooling & additional system configuration / alarm configuration /

file management / load cell calibration.

Password forgotten: Consult user manual.

Entered the wrong password, user level will be set automatically to operator level.

Key lock: The key board can be (un)locked here. User level will be set automatically to operator level.

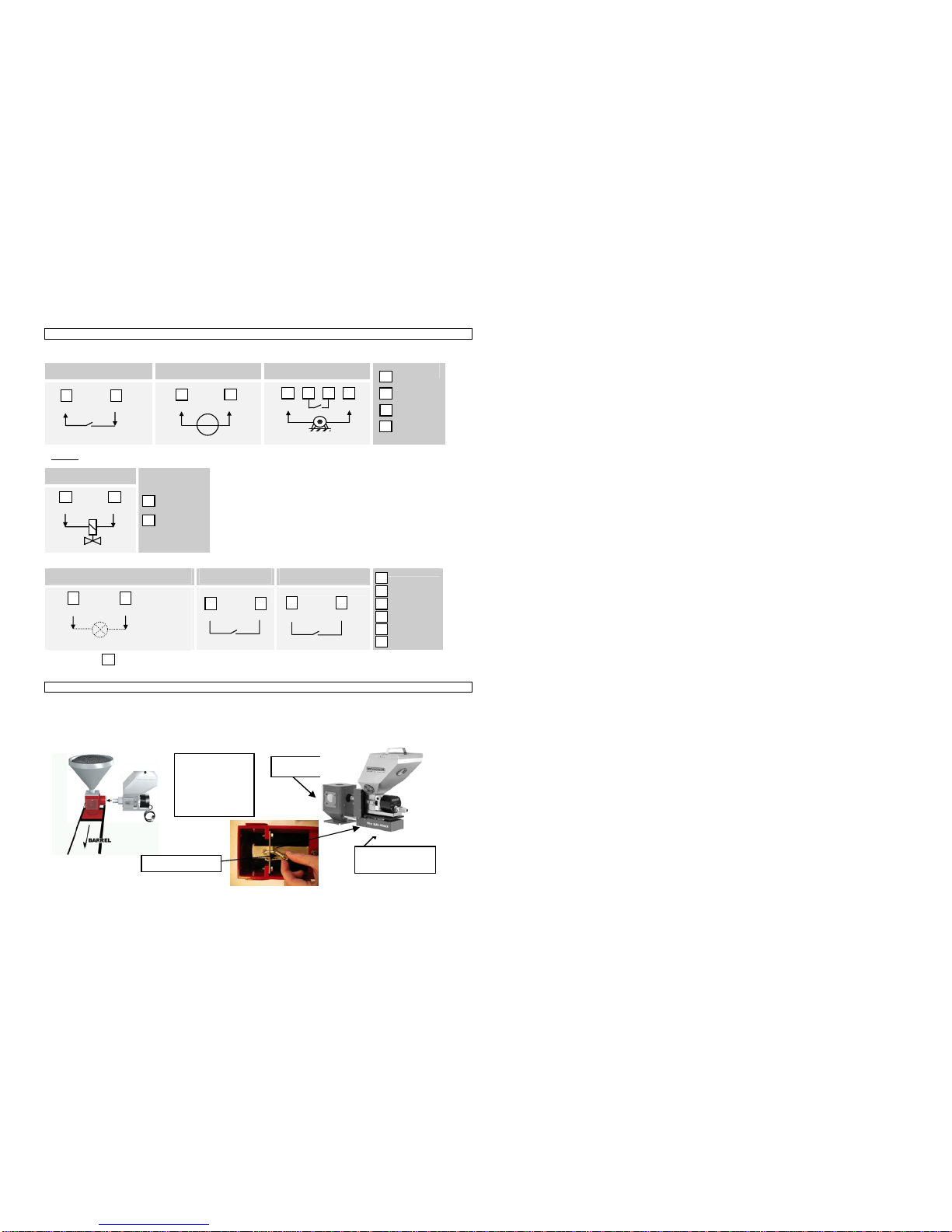

CONFIGURATION <menu> supervisor level

For initial setup the MC-Balance controller needs to be configured in the SYSTEM menu once. Depending on the settings, some

parameters will be (in)visible in case they are not relevant.

Explanation of the parameters:

•Language: Standard language isEnglish. On request also different languages are available.

•Motor type: LT is Low Torque motor and HT is High Torque motor

•Cylinder type: Type of dosing cylinder / feed screw (see manual for all types)

•Material type: Type of material, normal granules (NORMAL) and micro granules (MICRO)

•CAL dev: Calibration deviation, Maximum allowed deviation during material calibration.

•Control mode: Gravimetrical mode (GRAVI) or Rotating mode (RPM)

•Prod. Mode: select, extruder (EXT) or injection molding (INJ)

•Input mode: Type of input signal. Relay, Timer or Tacho (only with extruder)

•Fill. System: Filling system, ME / MV / EX

•Filling start: When the material weight in the hopper is below this value (800gr.), the filling starts

•EX-H level: The filling knife gate valve will close if the weight in the hopper is 2500 grams (default) or more.

•EX-HH level: HH level is High level warning. If the weight in the hopper reaches 3000 grams (default) or more.

•Hopper Empty: When the material weight in the hopper is below this value (700gr.) this alarm appears.

•Deviationalarm: Deviation % setting with reference to the maximum deviation alarm.

•Jobs enabled: Enable / disable production job functionality

•Auto start: Enable / disable auto startup after Voltage dip or main power has been switched OFF.

•Master reset: Reset alarm history (ALARMS) / material calibrations (MATER.) /

production jobs (JOBS) or all of these resets together (ALL)

•IP: IP-address for use in a network environment

•Name: Give a name or figures for individual identification (for use in network)

•Start user: User level to start up with, when switching on the controller’s main power

•Tooling password: Password for Tooling user level, 4 numerals, default 1111

•Supervisor password: Password for Supervisor user level 4 numerals, default 2222

•Conversion: Selevtion of units: Metric [gr/s] / Imp [lbs/hr] / kg/h [instead of gr/s]

•Full scale: Selected loadcell will be shown

•Modbus unit: Unique identity when used in modbus network

•Date: Actual date (dd / mm / yy)

•Time: Actual time (hh / mm / ss)

LOAD CELL <menu> Supervisor level

In this menu it is possible to perform a load cell calibration. (500gr. Calibration weight required)

Always perform a load cell calibration after the machine is installed, with an empty hopper, the motor and hopper lid mounted.

Make sure that the controller is ON for at least 15 minutes and the system must be stable during calibration.

•Go to the LOAD CELL CALIBRATION menu.

•Follow the screens.

WEIGHT CHECK <menu> Tooling / Supervisor level

The following parameters will be shown in this menu:

•Weight: Actual weight on the weighing scale.

•Object: Object weight.

•Zero: Zero YES / NO the object weight.

If the Object weight is not corresponding with the real weight, perform a load cell calibration.

CALIBRATION <menu> Tooling / Supervisor level

The MC-Balance can be started in mainly two ways:

1)Start the unit without pre-calibration of material.

After pressing the START button the unit starts dosing on a speed that is based on default curves which are pre-programmed in the

controller.

2) Start the unit with pre-calibration of material.

After pressing the START button the unit starts dosing on a speed that is based on calibrations made by the user which are stored in the

controller

A material calibration can be made as follows:

AUTOMATIC, Calibration (complete curve) based on the internal reference curves

•Configure the controller in control mode GRAVI.

•Go to the CALIBRATION menu.

•Enter your production parameters, follow the screens and start calibrating.

•It is possible to stop during the calibration (for example to refill the hopper). To continue select YES

and confirm. To stop, select NO and confirm.

•After saving you will automatically go to the PRODUCTION menu and stored calibration is automatically selected.

PRODUCTION <menu> Tooling / Supervisor level

The following EXTRA parameters are displayed in the production screen when logged in as Tooling / supervisor

(depending on configuration):

Extrusion

Ext. cap: Maximum extruder capacity (kg/hr). This value will be coupled to the max. tacho voltage.

Max. tacho: This value (Volts) will be coupled to Ext. cap. (kg/h)

Set tacho: Automatic tacho voltage take over from tacho generator by selecting YES/NO and confirm or

enter tacho voltage manuallyat Max. tacho.

After changing back to operator mode these settings (excl. set tacho) are displayed but can not be changed.

When job function is enabled (in configuration menu) the following parameters will be displayed:

Prod Job: Name of the production Job (For a Job list, press <Enter> for 2 seconds)

Save Job: Save Job into the Job list

Following data will be stored with a JOB, depending on the configuration:

•Configuration settings: Control mode / Prod. mode / Input mode

•Production settings: Job description / Shotwth. / color% / dos.time / Ext. cap. / Max. tacho / RPM

•Material calibration

For a Material calibration list, go to Material and press for 2 seconds. The material descriptions can be made in the tooling or

supervisor level.

Regulation mode: Auto/Manual (this function is only visible when the unit is started)

This function allows to switch from automatic control (Gravimetrical) to manual control (RPM).

Save data (this function is only visible when the unit is started)

With this function the actual data (RPM) can be stored. A material description needs to be entered to store the actual data.

After startup with the stored material description, the unit will run with the stored RPM.