Danfoss EIM 365 User manual

Other Danfoss Controllers manuals

Danfoss

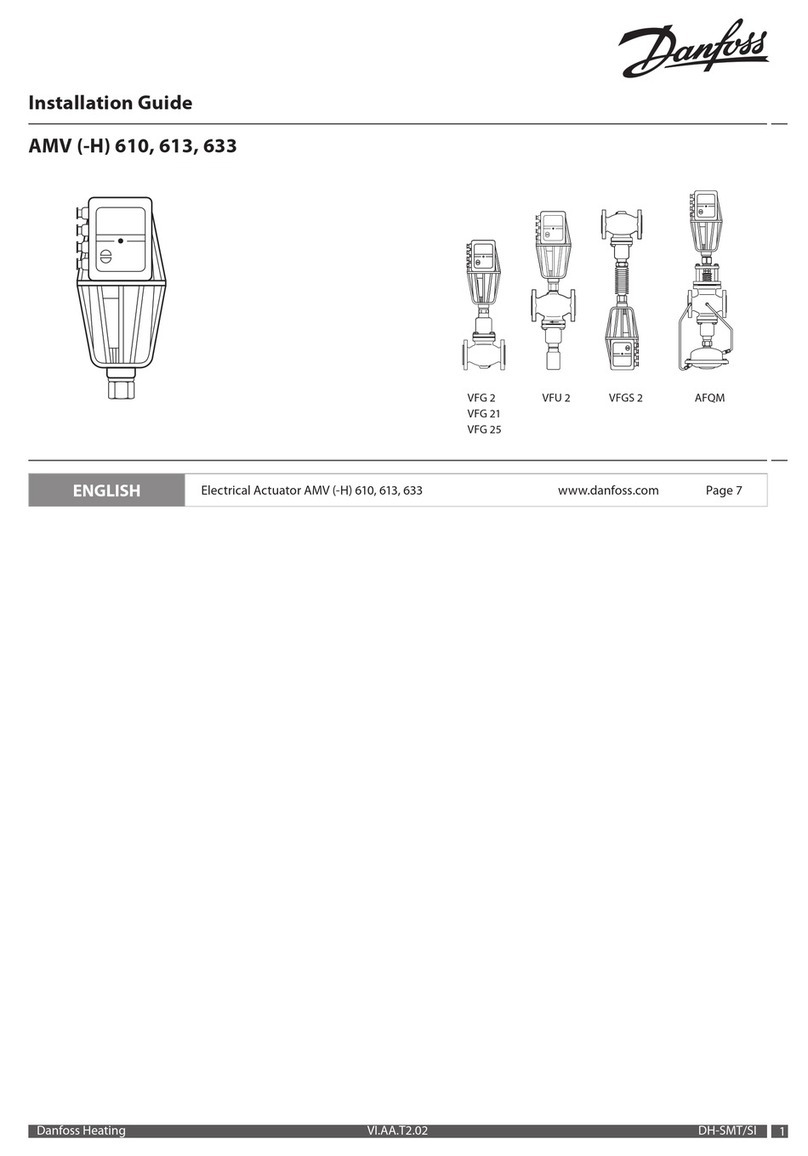

Danfoss AME 55 User manual

Danfoss

Danfoss VLT AQUA Drive FC 200 Operating instructions

Danfoss

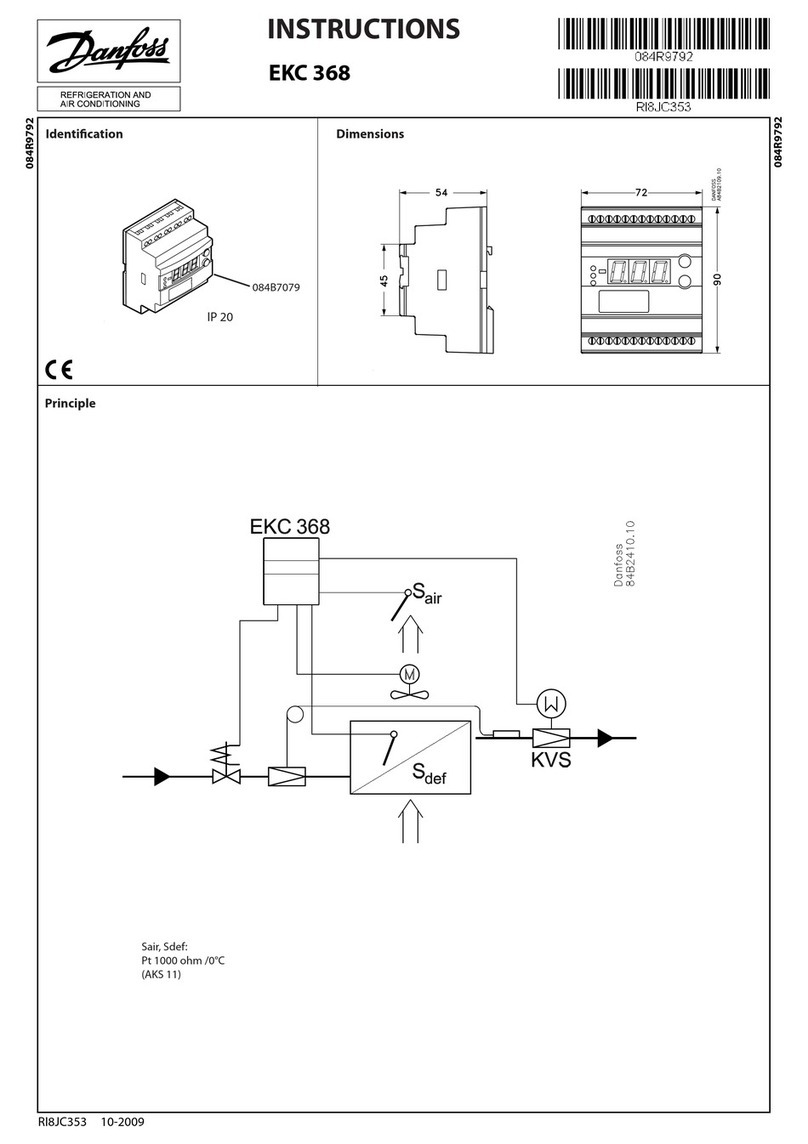

Danfoss EKC 368 User manual

Danfoss

Danfoss AK-SM 800 User manual

Danfoss

Danfoss WP75- RF Assembly Instructions

Danfoss

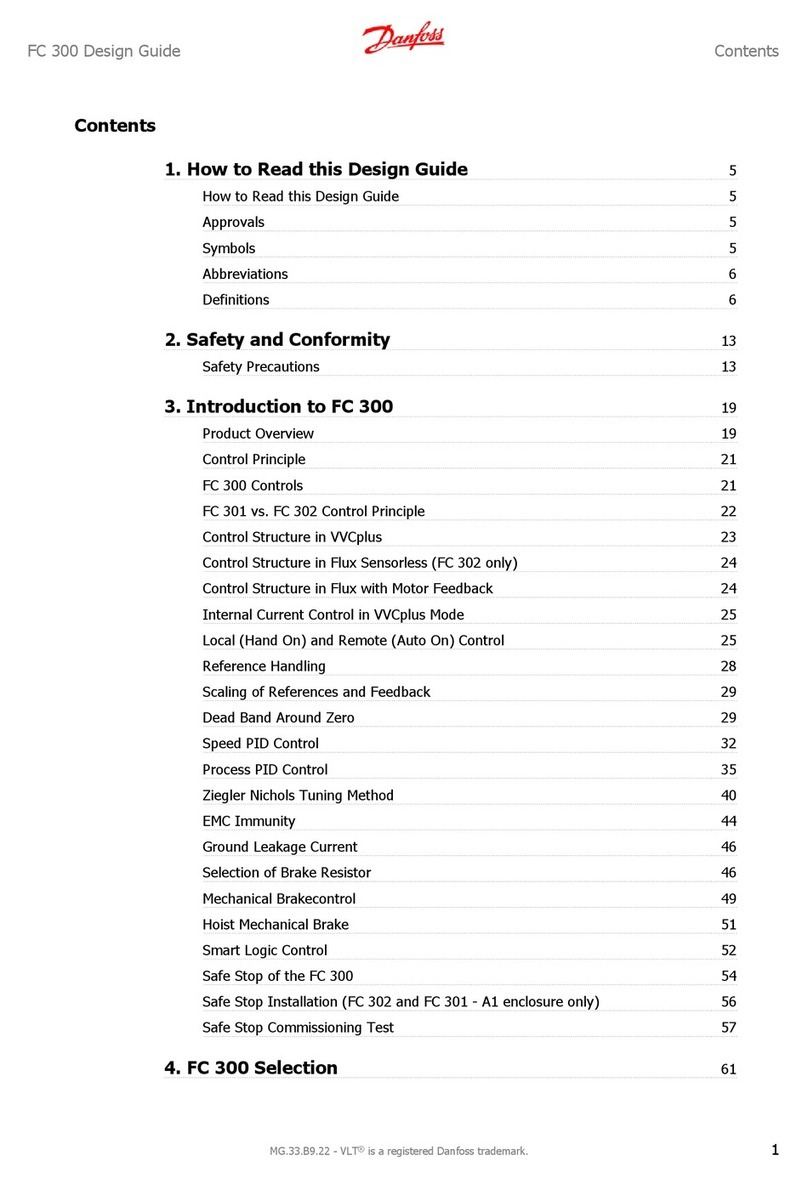

Danfoss FC 300 Guide

Danfoss

Danfoss AME 110 NL User manual

Danfoss

Danfoss DMS 300 User manual

Danfoss

Danfoss MCX08M User manual

Danfoss

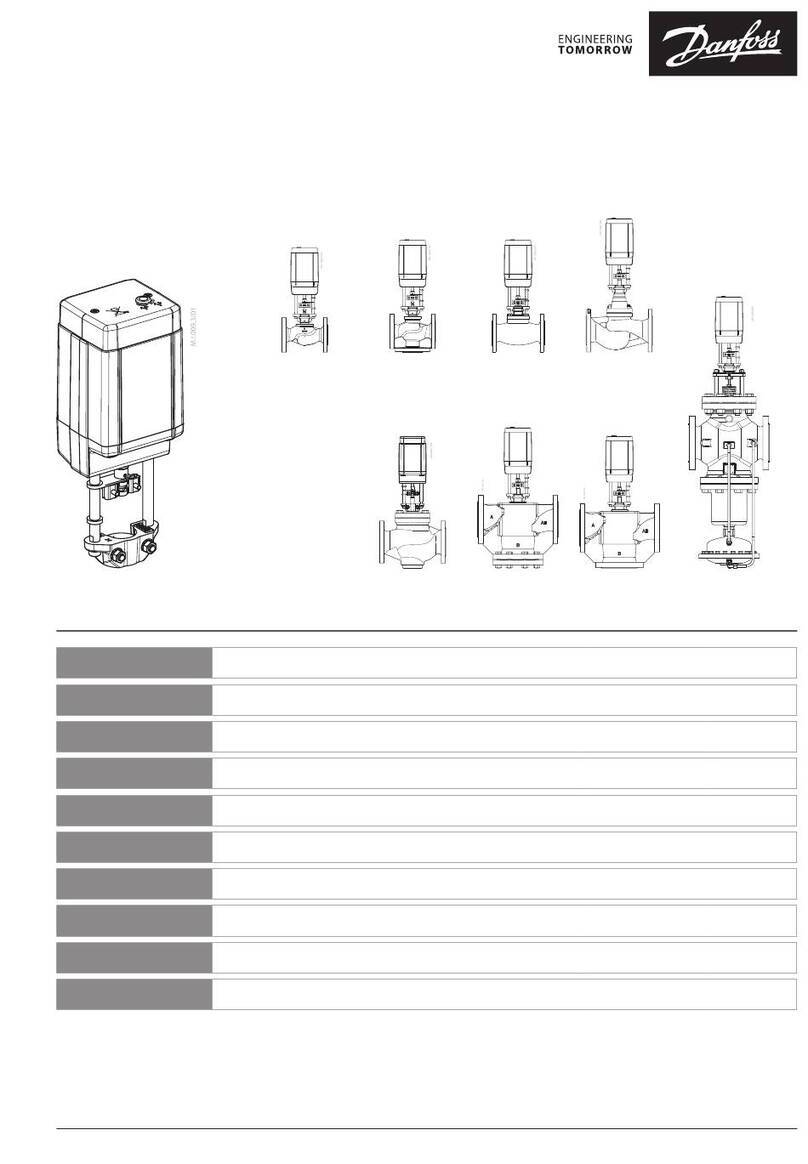

Danfoss AMV 410 User manual

Danfoss

Danfoss AME 110 NL User manual

Danfoss

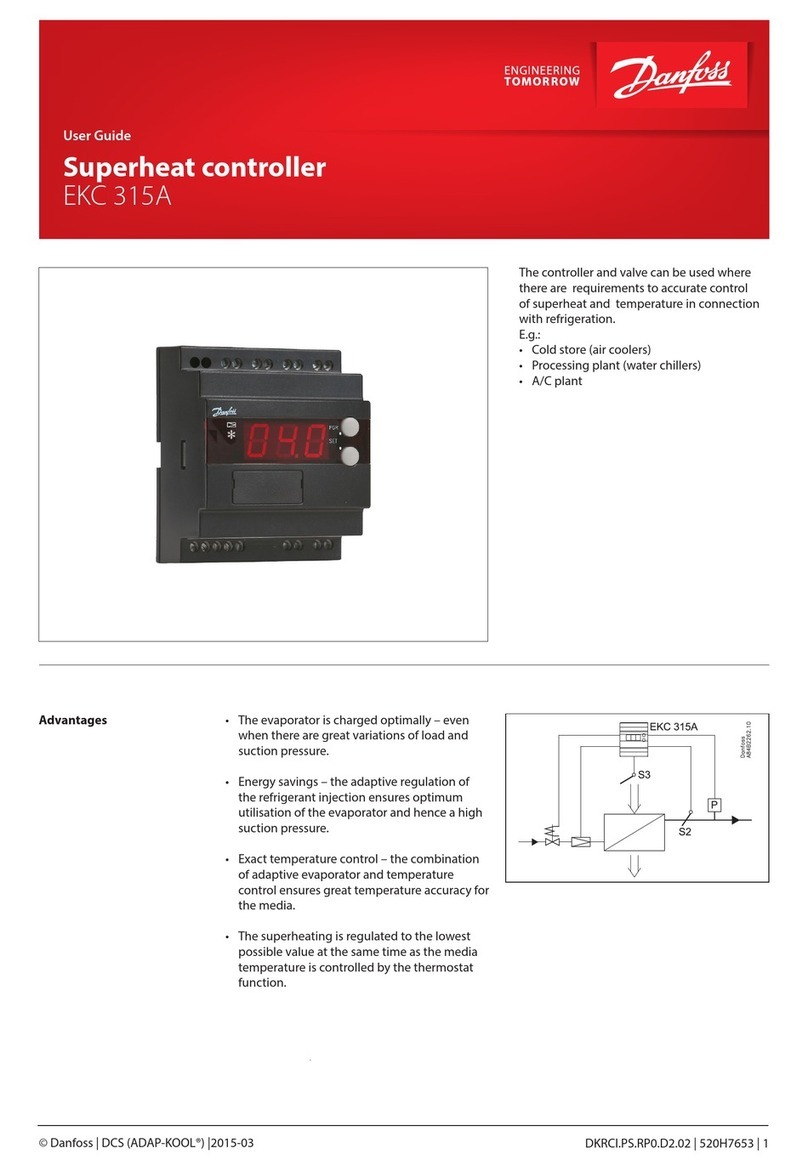

Danfoss EKC 315A User manual

Danfoss

Danfoss VLT AutomationDrive FC 300 User manual

Danfoss

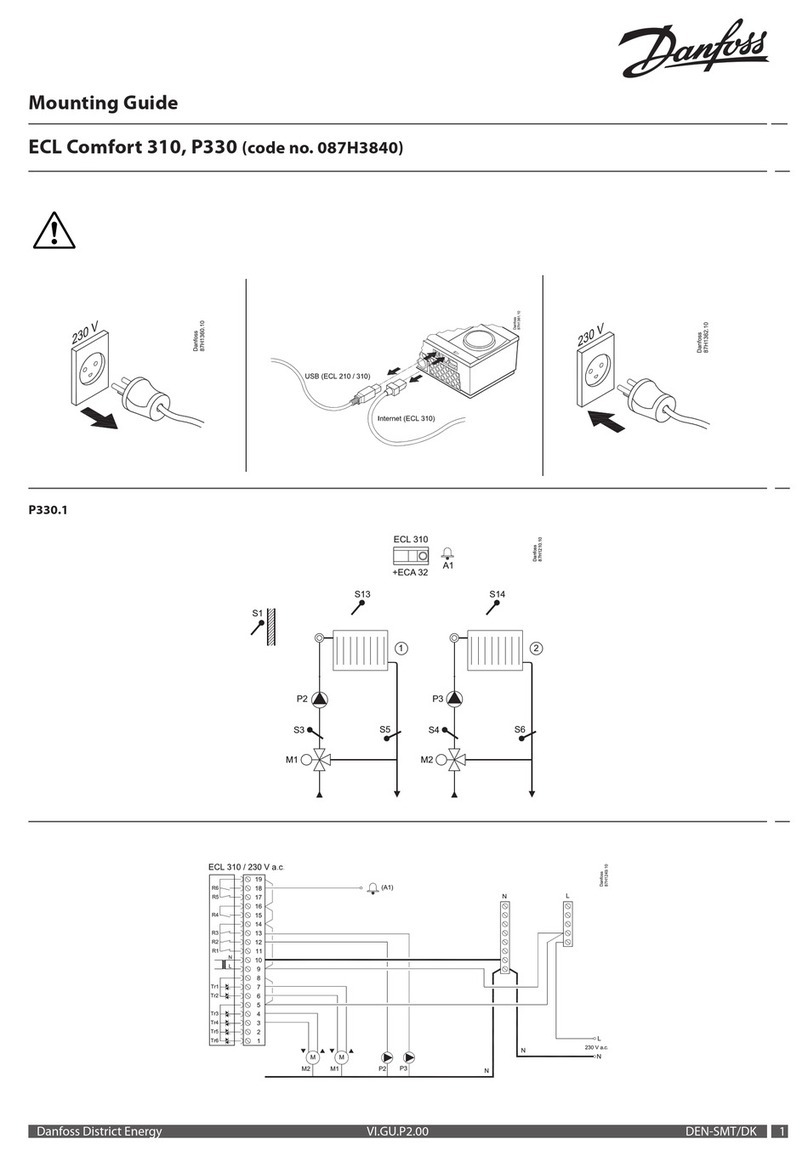

Danfoss ECL Comfort 310 Installation instructions manual

Danfoss

Danfoss VLT Soft Starter MCD 600 User manual

Danfoss

Danfoss VLT FC Series Spare Brake IGBT User manual

Danfoss

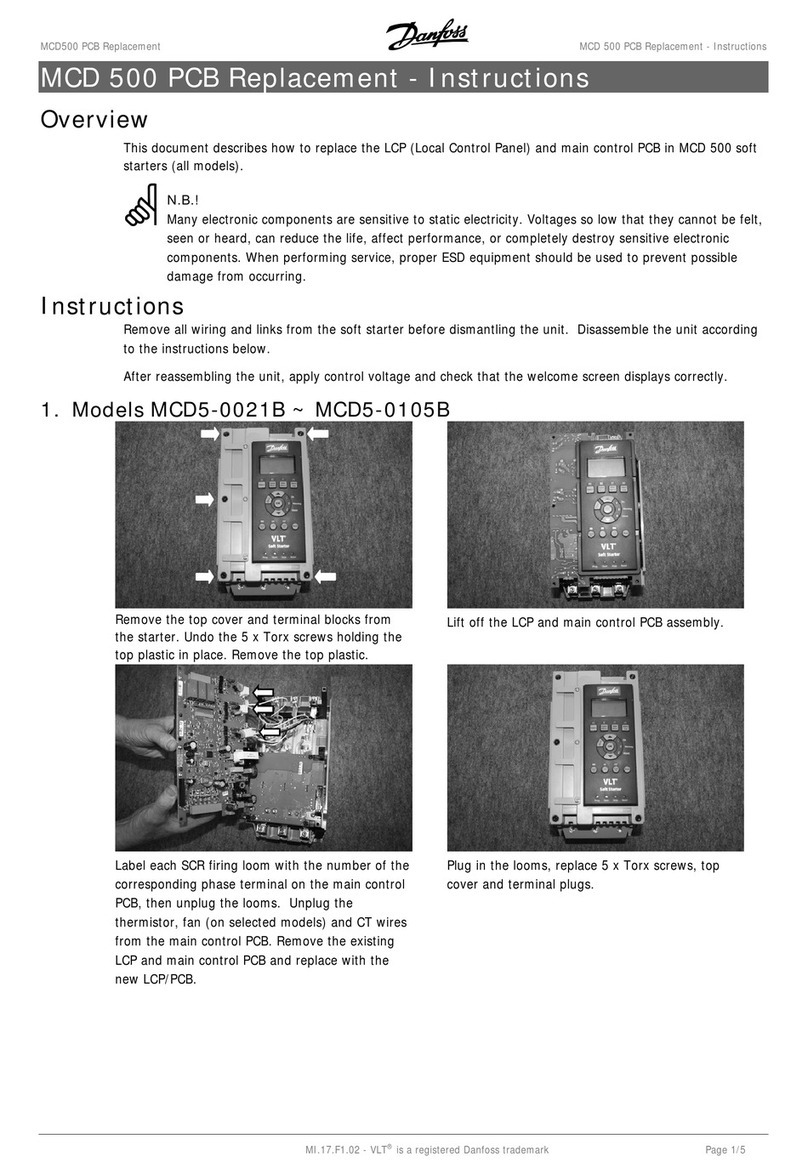

Danfoss MCD 500 Series User manual

Danfoss

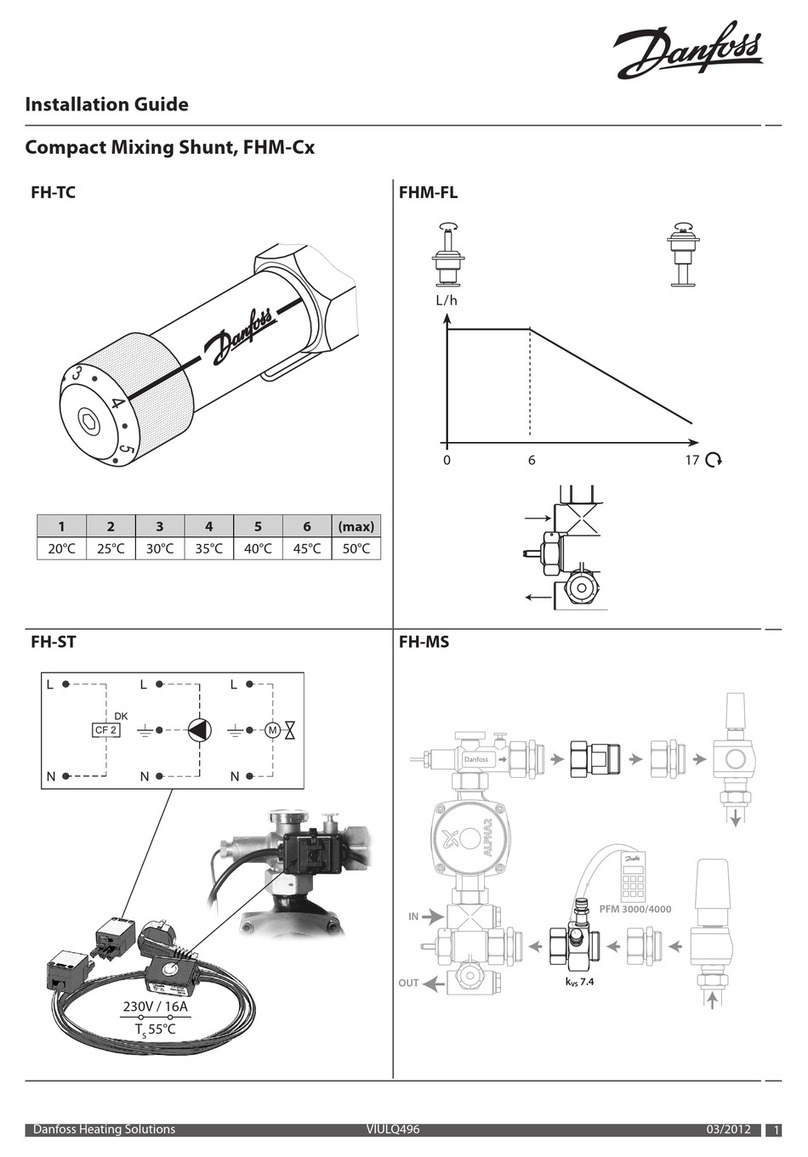

Danfoss FH-TC User manual

Danfoss

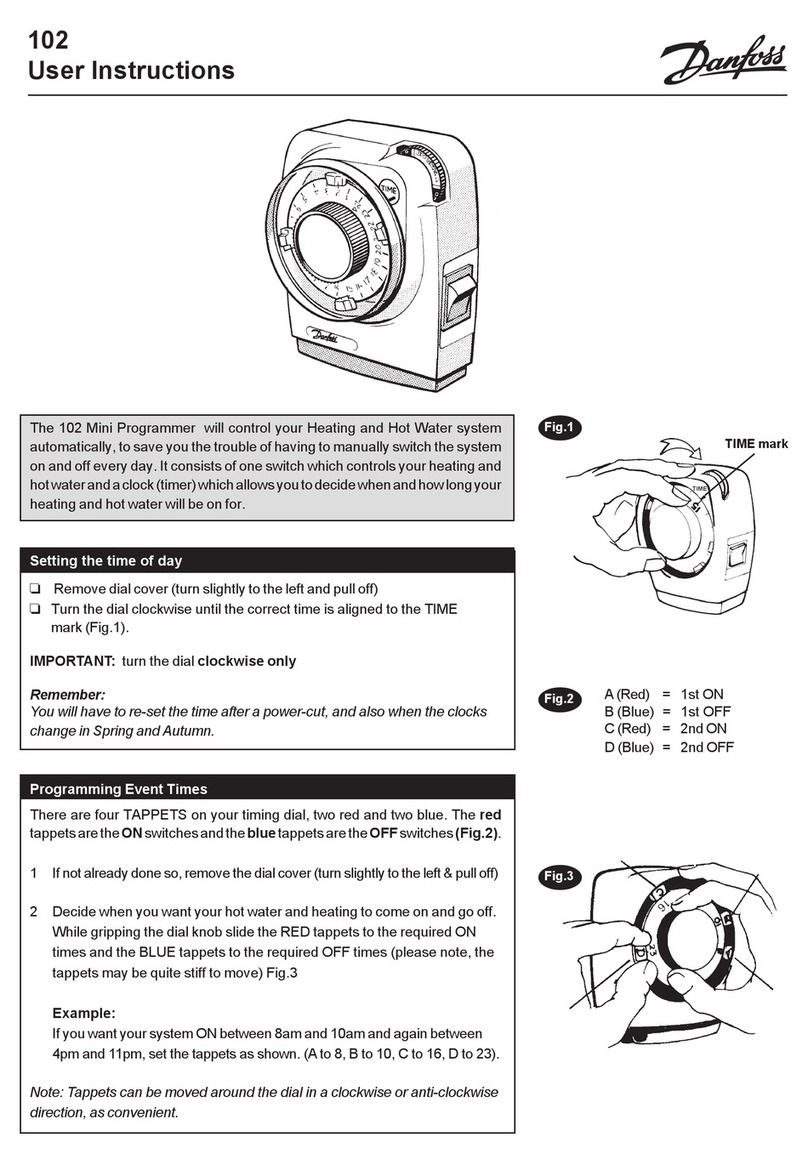

Danfoss 102 User manual

Danfoss

Danfoss EKE 347 User manual

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions