INDEX

1. Introduction ______________________________________________________________________________________________1

1.1 Symbols_______________________________________________________________________________________________1

1.2 Terms ________________________________________________________________________________________________1

2. General in ormation________________________________________________________________________________________2

2.1 Safety ________________________________________________________________________________________________2

2.2 Certification ____________________________________________________________________________________________2

2.3 Operating environmental conditions _________________________________________________________________________2

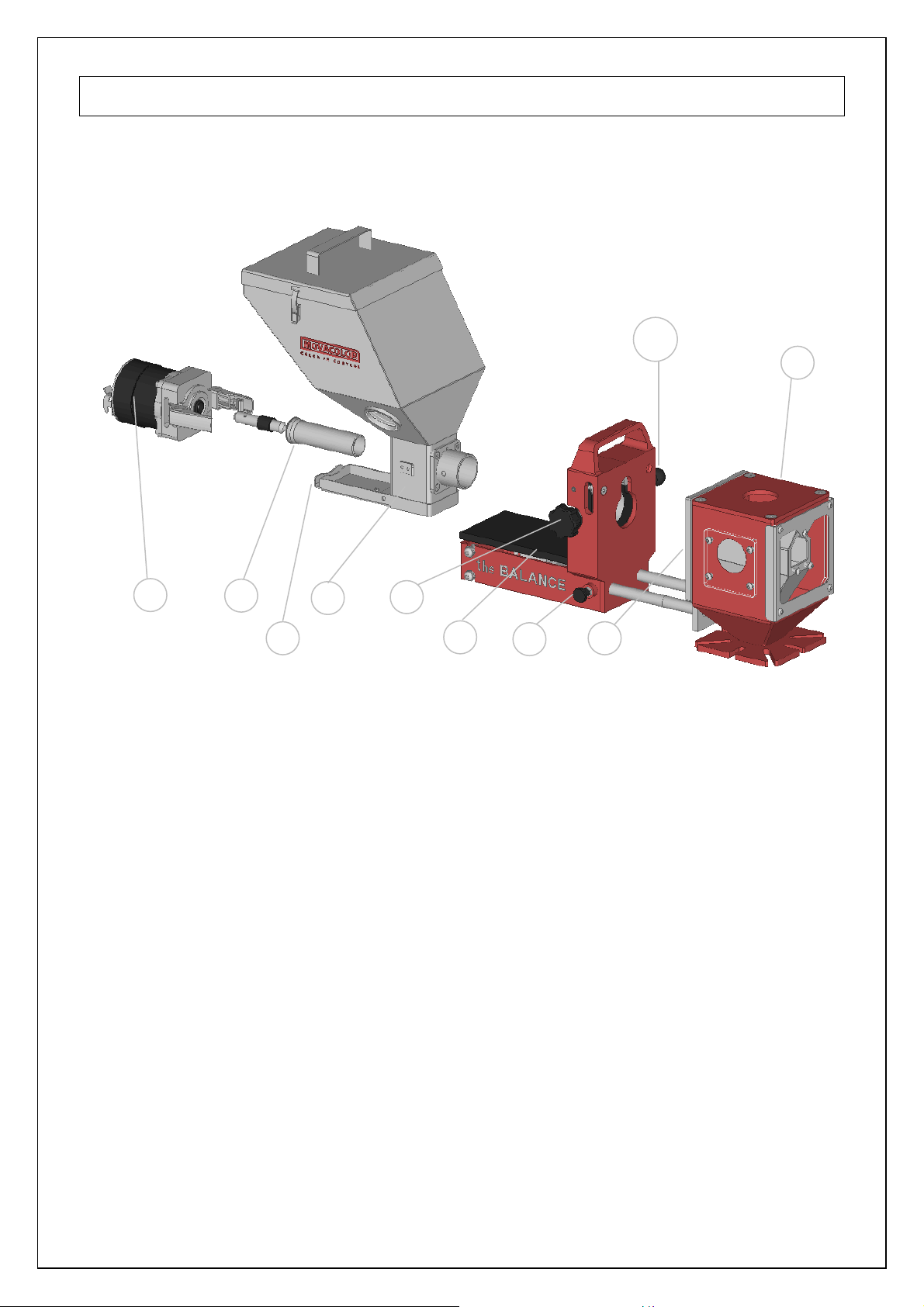

3. Overview Dosing unit ______________________________________________________________________________________3

3.1 MC-Balance Component overvie __________________________________________________________________________3

3.2 Weighing frame _________________________________________________________________________________________4

3.3 Motor and dosing system _________________________________________________________________________________4

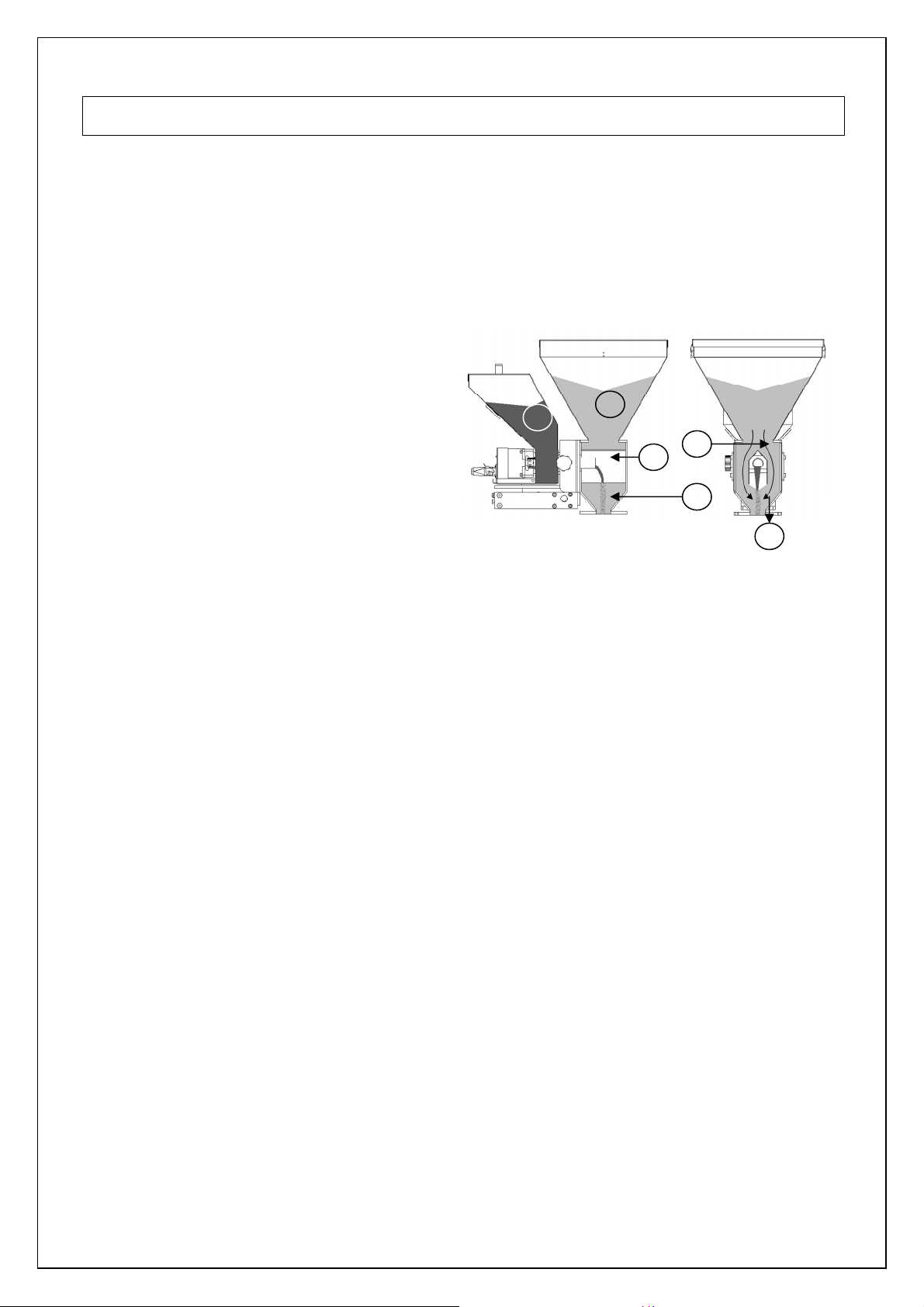

4. Metering principle _________________________________________________________________________________________5

5. Dosing systems / Capacities ________________________________________________________________________________6

6. Installation _______________________________________________________________________________________________8

6.1 Transport ______________________________________________________________________________________________8

6.2 Receipt _______________________________________________________________________________________________8

6.3 Mechanical Installation ___________________________________________________________________________________8

6.4 Changing from Dosing cylinder to Feed scre _________________________________________________________________9

6.5 Electrical installation ____________________________________________________________________________________10

7. Operation _______________________________________________________________________________________________12

7.1 Navigation ____________________________________________________________________________________________12

7.2 Start up & Login________________________________________________________________________________________13

7.3 Keyboard lock _________________________________________________________________________________________14

7.4 Configuration__________________________________________________________________________________________15

7.5 Loadcell calibration _____________________________________________________________________________________21

7.6 Material Pre-calibration __________________________________________________________________________________22

7.7 Production ____________________________________________________________________________________________24

7.8 Auto/Manual regulation mode & Save data function ____________________________________________________________27

7.9 Production JOB ________________________________________________________________________________________28

7.10 Filling the hopper. _____________________________________________________________________________________29

7.11 Consumption _________________________________________________________________________________________33

7.12 Alarms ______________________________________________________________________________________________34

7.13 Files________________________________________________________________________________________________36

7.14 Event LOG___________________________________________________________________________________________37

8. System per ormance ______________________________________________________________________________________38

8.1 Reset regulation _______________________________________________________________________________________38

9. Trouble shooting _________________________________________________________________________________________39

APPENDIX A: MC-Bal. Print view __________________________________________________________________________40

APPENDIX B: MC-Bal. Wiring Diagram _____________________________________________________________________41

APPENDIX C: MC-Bal. Technical Speci ications ______________________________________________________________42

APPENDIX D: MC-Bal. Drawings General Dimensions _________________________________________________________43

APPENDIX E: MC-Bal. Decl. o Con ormity __________________________________________________________________47