moyno Version 3 User manual

SERVICE MANUAL

MOYNO®

Annihilator™

Series 3

Table of Contents

1-1. INTRODUCTION..................................................................................................................................1

1-2. GENERAL.............................................................................................................................1

1-3. NAMEPLATE DATA..............................................................................................................1

1-4. Model Number............................................................................................................1

1-5. Frame Designation .....................................................................................................1

1-6. Trim Code...................................................................................................................2

1-7. Equipment Description................................................................................................2

1-8. Grinder Unit................................................................................................................2

1-9. Motor ..........................................................................................................................2

1-10. Reducer......................................................................................................................2

2-1. INSTALLATION...................................................................................................................................2

2-2. GENERAL.............................................................................................................................2

2-3. Piping ...................................................................................................................................2

2-4. Foundation ............................................................................................................................2

2-5. Motor Controls ......................................................................................................................2

3-1. OPERATION ...................................................................................................................................3

3-2. INITIAL CHECK/START-UP..................................................................................................3

4.1. MAINTENANCE ...................................................................................................................................3

4-2. LUBRICATION......................................................................................................................3

4-3. Motor Bearings.............................................................................................................3

4-4. Gear Reducer...............................................................................................................3

4-5. Cartridge Assembly......................................................................................................3

4-6. DISASSEMBLY...................................................................................................................3

4-7. Disconnect Grinder.....................................................................................................3

4-8. Cartridge Replacement...............................................................................................4

4-9. Motor Removal………………………………………………………………………………4

4-10. Gear Reducer Removal..............................................................................................4

4-11. Cartridge Disassembly................................................................................................4

4-12. INSPECTION.......................................................................................................................4

4-13. ASSEMBLY.........................................................................................................................5

4-14. Seal Assembly............................................................................................................5

4-15. Cartridge Assembly………………………………………………………………………….5

4-16. Reducer/Motor Assembly...........................................................................................6

4-17. Torque Guidelines Chart ............................................................................................6

4-18. STORAGE...........................................................................................................................7

4-19. Short-Term Storage....................................................................................................7

4-20. Long-Term Storage ....................................................................................................7

4-21. Hardware List......................................................................................................................8

4-22. Parts List .............................................................................................................................9

Parts List continued………………………………………………………………………………..10

Flanged Reference ………………………………………………………………………………..11

Exploded View...................................................................................................................12 & 13

SERVICE MANUAL

Moyno®Annihilator™

Series 3

1-1. INTRODUCTION

1-2. GENERAL

The Moyno®Annihilator, twin shaft grinder, is a rugged and

reliable grinder designed to efficiently reduce the size of large

solids typically encountered in raw wastewater, primary

thickened sludge, digested sludge, slaughterhouse waste,

and pulp and paper recycling. The grinder has been tested to

assure consistent performance in the most difficult of

applications. It represents the next generation of the world’s

most reliable grinder.

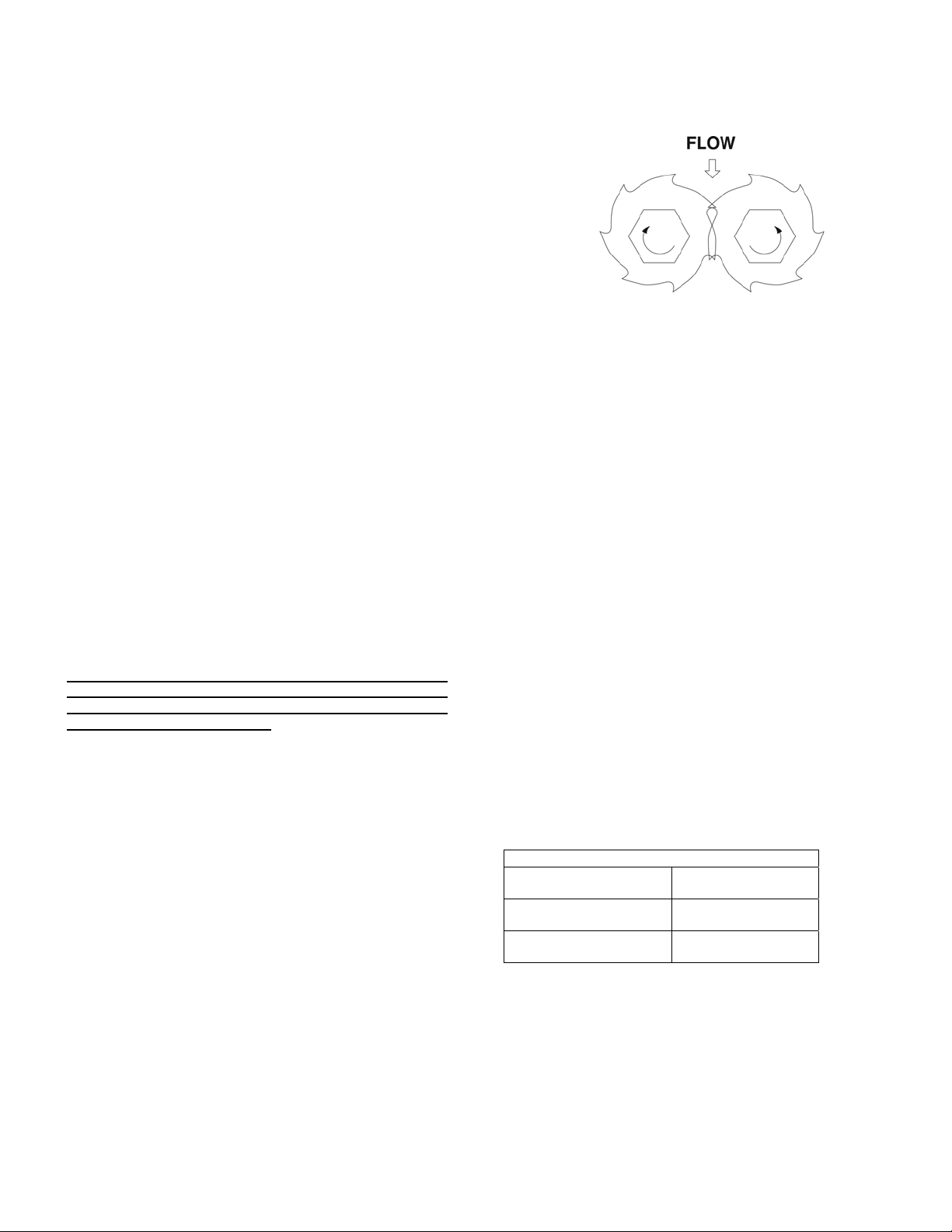

The Moyno®twin Annihilator utilizes an improved version of

the counter-rotating shaft design that has proven to be a

reliable method of shredding large solids (pieces of wood,

plastic bottles, cloth towels and rags, and aluminum cans,

etc.) into smaller pieces. The slow rotating shafts are ideal

for shredding solids that are large and dense. By utilizing a

slow speed gear motor, the cutters have high torque

capability and low impact while severing debris.

The Moyno Annihilator is designed with cutting teeth on both

the cutters and spacer cutters which increases the cutting

capability of rags over other twin shaft grinders and

eliminates the greatest cause of failure – that of stringy

material wrapping around the spacers.

The Moyno Annihilator product line is modular in concept

allowing for optimal utilization of cutters for channel or in-line

units to meet the requirements of the application. The cutter

cartridge assembly allows for the removal and replacement

of the entire cutting assembly as a single unit. The cutter

cartridges consist of a top and bottom housing, side rails,

seal cartridges, hex shafts, cutters, and spacer cutters

(Figure 1-1.).

The complete Annihilator unit consists of the cutter cartridge

assembly, reducer adapter, gearbox, motor (Figure 1-2).

Figure 1-2. Complete unit.

1-3. NAMEPLATE DATA

The grinder nameplate, located on the top housing, contains

important information relating to the operation and servicing

of the grinder. This information includes the model and serial

numbers (see Figure 1-3.). The grinder model number must

be used for reference when ordering a replacement cartridge

or spare parts.

Model:

M06C3 CE5R7R

MFG Serial: ASXXXXXX

Date: 10/04

Figure 1-3. Typical nameplate data

1-4. Model Number. The grinder model number consists of

two component parts: Frame Designation and a Trim Code.

A typical model number, for example, might be M06F3

CE7R5R as shown on the nameplate in Figure 1-3.

1-5. Frame Designation. The five characters in the frame

designation describe the particular combination of

construction and cutter height.

The first character in the frame designation, always a letter,

indicates the construction as either a complete unit (M) or

replacement cartridge (C).

Section: MOYNO®Annihilator™

Page: 1

Date: December 2007

Figure 1-1. Cutter cartridge.

The second and third characters, always numbers, indicate

either the flange size or cutter stack height.

The fourth character is a letter indicating whether it’s a flange

unit (F) or channel unit (C). If the fourth character indicates a

flange unit, the second and third characters indicate the

flange size in inches. If the fourth character indicates a

channel unit, the second and third characters indicate the

cutter stack height.

The fifth character indicates the series of the unit:

Series 2 -- 2½” hex shaft

Series 3 – 2” hex shaft, design after July 2003

Series 4 – 2” hex shaft, one-piece flange housing design

1-6. Trim Code. Also included in the Model Number is the

six character Trim Code which is used to identify grinder

construction.

The first letter identifies the materials of construction.

C -- Cast iron, ductile iron, and alloy steel

S -- Stainless steel

X -- Special

The second letter identifies the type of drive utilized.

E -- Electric motor and gear box

S -- Submergible motor and gear box

H -- Hydraulic motor with power package

X -- Special

The third and fourth characters identify the type of cutters on

the drive shaft:

5R – 5 tooth reversible

7R – 7 tooth reversible

7C – 7 tooth cam

11C – 11 tooth cam

The fifth and sixth characters identify the type of cutters on

the idler shaft:

5R – 5 tooth reversible

7R – 7 tooth reversible

7C – 7 tooth cam

11C – 11 tooth cam

If the trim code of your grinder is other than the variations

listed above contact your nearest Moyno representative for

clarification. Do not modify your grinder with any variations

unless you have determined that it is compatible with your

application.

1.7 EQUIPMENT DESCRIPTION

1-8. Grinder Unit. The Moyno Annihilator is a motor driven,

double shaft design stacked with intermeshing cutters and

spacer cutters positioned on the shafts. The shafts are

constructed of a hexagonal, 4140 steel and counter-rotate at

60 and 36 RPM. The shafts contain intermeshing cutters and

spacer cutters.

The Moyno Annihilator series 1 and 3 product lines, consist

of seven channel models ranging from 8 to 60 inch high

cutting chamber, and five flanged, in-line models from 4 to

12 inch flanged.

1-9. Motor. Each Moyno Annihilator is equipped with a

motor:

•TEFC or Explosion proof design

•3 or 5 HP

Page 2

•1725 RPM, 3/60/230/460V

•Baldor or Moyno choice

1-10. Reducer. Each Moyno Annihilator is equipped with a

cycloidal speed reducer:

•29:1 ratio

•60 RPM output

•Sumitomo or Moyno choice

•Model 6125Y…3HP and 5 HP

Note: See manufacturer’s service manuals for more

details.

2-1. INSTALLATION

2-2. GENERAL

Moyno Annihilators are lubricated and tested at the factory

prior to shipment and require minimum pre-start up

maintenance.

Accessibility to the grinder and adequate clearance should

be a prime consideration in any installation. Enough space

should surround the unit so that maintenance can be carried

out with ease.

2-3. Piping. For in-line flanged units, piping should generally

be the same size as the flange and supported, not applying

vertical or horizontal forces to the grinder flanges. Be sure

to mount the unit in the piping in the proper flow

direction. Check the flow direction arrow on the grinder.

2-4. FOUNDATION

Flanged units should be mounted on a concrete base. The

base should be 4-8 inches wider then the Grinder base.

Anchor bolts are not required to attach the grinder to the

concrete base.

Check the base surface with a carpenter’s level and shim

under the grinder at the places necessary to make the unit

level. Care should be exercised to ensure the grinder

flanges are mounted in line and without piping strain.

Channel units should be mounted in a suitable framework for

support.

2-5. Motor Controls. To protect the Moyno Annihilator from

potential damage, all Grinder units should be wired to a

Moyno control panel. In the event an unusually difficult

material engage the cutting chamber, the automatic controller

senses the overload and reverses the rotation of the cutters

to clear the object. The controller then returns the Grinder to

the forward direction of rotation. It is highly recommended

that this type of overload protection be provided for all

grinders to prevent damage to the unit.

Caution:

•Cutters and spacer cutters are very sharp. Keep

personnel clear of cutting chamber.

•Do not lift heavy equipment over the head of

personnel.

•Electrical hazard…Be sure power is off and locked

out.

3-1. OPERATION

3-2. INITIAL CHECK / START-UP

CHECKLIST

Before putting the grinder into operation, the following items

should be checked to ensure that each piece of equipment is

installed correctly:

•Recheck for proper line voltage connections at the

control panel and control transformer. Check the

transformer for continuity.

•Set the programmed controller (inside the door of the

Annihilator control panel) to the number of attempts

desired to clear jams or overloads before automatic

shutdown. The programmed controller is normally set at

3 reversals when shipped from the factory.

•Energize the incoming power lines by closing the

disconnect device. The amber light [“POWER ON”]

illuminates, indicating power is available to the control

circuitry.

•Turn the Selector Switch to the “LOCAL” position.

Depress the “Start” pushbutton. The blue light

[“GRINDER ENABLED”] will illuminate to indicate that

the control circuits are energized and the green light

[“GRINDER RUNNING”] will illuminate indicating the

drive motor should be operating.

•Check the direction of cutter rotation.

Reversible cutters denoted as 5R or 7R, can operate in

either direction of rotation. The cutters should rotate with the

teeth rotating inward, towards one another on the inlet side of

the flow. If the motor is rotating in the reverse direction,

disconnect the power to the control panel.

CAUTION: Using a volt meter double-check that the

incoming power lines L1, L2, and L3, as well as the

motor lines T1, T2, and T3 in the control panel all

indicate that the power is OFF.

Interchange any two of the motor leads in the control panel at

Terminal Blocks T1, T2, or T3. Do not change the

connections at the contactors. Repeat Steps 3, 4, and 5,

above.

However, cam cutters denoted as 7C or 11C, can only

operate in one direction of rotation. The cutters should also

rotate with the teeth rotating inward, towards one another on

the inlet side of the flow. With cam cutters you must first

install the unit in the piping in the correct flow orientation.

Interchange motor leads if the cutter direction is wrong.

•To test the reversing function of the programmed

controller, it is not necessary to attempt to physically jam

the grinder. Simply depress the “Test” button on the

controller inside the door of the panel. Each activation of

the “Test” pushbutton will initiate a reversal of the

grinder.

Page 3

Figure 3-1. Cutters rotating inward.

4-1. MAINTENANCE

Note: In this section, a number or a letter in parentheses will

follow the first reference to each grinder part ( ). These

numbers and letters are those used to identify the grinder

parts and hardware items in the section view diagram.

4-2. LUBRICATION

4-3. Motor Bearings. The motor bearings are lubricated at

the factory and will need to be re-lubricated after 12,000

hours of operation. See your motor maintenance manual for

details.

4-4. Gear Reducer. The gear reducer is filled with grease at

the factory and will require re-lubrication every 3-5 years.

See your reducer maintenance manual for details.

4-5. Cartridge Assembly. The grinder top housing is half

full of ACG-2 grease prior to shipment and is ready for

operation. The top housing contains two gears that only

need to be re-lubricated when the assembly is being

repaired. You can re-lubricate the housing via the pressure

release grease fitting (35). The pressure release grease

fitting is pre-set at 10 psi. At pressures greater than 10 psi,

the grease will be observed exiting the grease fitting via the

bypass. This feature prevents over packing the bearings with

grease and is available through Alamite.

The bottom bearing housing is sealed and gasketed and

requires no lubrication.

List of Lubricants (or Equivalents)

Motor Bearings See Mfg

Recommendation

Gear Reducer See Mfg

Recommendation

Top Housing ACG-2 (Dubois

Chemical)

4-6. DISASSEMBLY

Note: The following instructions cover grinder disassembly.

4-7. Disconnect Grinder

1. Flush the grinder (preferably with clean water) to remove

all debris from the unit.

2. Shut off grinder.

3. Close suction and discharge valves.

4. Disconnect power source.

Caution: Electrical hazard…Be sure power is off

and locked out.

5. Drain any fluid in grinder.

4-8. Cartridge Replacement

Note: The following instructions cover the removal of the

motor and gear reducer as an assembly to facilitate

replacement of the grinding cartridge.

1. Secure the motor/reducer with a nylon sling and support

with a hoist.

2. Remove cap screws connecting the reducer adapter (42)

to the housing adapter (9). Remove the reducer adapter,

reducer, and motor by lifting up with the hoist. Be

careful not to allow the assembly to tip over.

3. Loosen the jaw coupling (43) set screw and remove the

coupling half and key from the drive shaft (7).

4. Flanged Models….M04F3, M06F3, M08F3, M1031, and

M12F3

a. Remove the bolts and lock washers that connect the

flange housings (41) to the inlet and outlet flanges

of the pipe.

b. Remove the cutter cartridge / flange housing

assembly from the piping.

c. Remove the cap screws and lock washers

connecting the flange housings to the cutter

cartridge. Remove the gaskets (40).

5. Remove and replace the cutter cartridge with a new or

rebuilt cartridge from an Authorized Moyno

Representative.

4-9. Motor Removal

The grinder may remain in line during motor removal and

replacement.

Open and tag power disconnect in the control panel.

Disconnect and tag motor leads in the motor conduit box.

Remove the bolts connecting the motor (45) to the gear

reducer (44). Some gentle prying may be necessary to

remove the motor from the reducer.

Remove the key from the motor drive shaft.

4-10. Gear Reducer Removal

1. Remove the bolts connecting the gear reducer to the

reducer adapter (42). Pry the gear reducer off the

reducer adapter.

2. Loosen the jaw coupling (43) set screw and remove the

coupling and key from the reducer shaft.

Page 4

3. Remove cap screws connecting the reducer adapter (42)

to the housing adapter (9). Remove the reducer

adapter.

4-11. Cartridge Disassembly

1. Remove the socket head screws connecting the bottom

cover (5) to the bottom housing (2) and remove the

cover and gasket (3).

2. While holding the jaw coupling on the drive shaft,

remove both castle nuts (16) and washers (15) from the

drive and idler shafts.

3. Loosen the jaw coupling (43) set screw and remove the

coupling and key from the drive shaft (7).

4. Find a way to support the assembly upside down on the

work bench. 4 X 4 Inch blocks can be placed on either

side of the driveshaft in order to accomplish this.

5. Remove the hex screws connecting the side rails (4) to

the top and bottom housings. Remove both side rails

and gaskets (37).

6. Remove the bottom housing (2) from the drive and idler

shafts.

7. Remove the butt screws and washers holding the seal

cartridge in the bottomtop housing. Gently press both

cartridges out of their bores and remove the two spacers

(32).

8. Remove the excluder plates (19), cutters (10), and

spacer cutters (11) from both shafts. Be careful

removing the cutters and spacer cutters because

they are very sharp.

9. Turn assembly on its side.

10. Remove the socket head screws connecting the housing

adapter to the top housing (2). Remove the gasket (3)

and clean grease from the top housing.

11. Remove the retaining rings (31) from both the drive shaft

(7) and idler shaft (6).

12. Remove both gears (12, 13) and keys (30) from the

shafts.

13. Pull both shafts from the top housing. Remove the

excluder plates.

14. Remove the butt screws and washers holding the seal

cartridge in the top housing and press the seal cartridges

out of the housing.

15. Clean all parts in a suitable cleaning solvent being

careful to observe all safety precautions regarding the

use of solvent.

4-12. INSPECTION

1. Inspect all parts for wear and corrosion. Replace any

parts that worn.

2. Replace all seals, bearings, O-rings, and gaskets.

4-13. ASSEMBLY

The Moyno Annihilator is generally reassembled in the

reverse order of dismantling.

During the assembly process, cleanliness is important. To

avoid premature failure, bearings, and seal components must

be handled with care and kept clean.

4-14. Seal Assembly

The seal cartridge assembly can be purchased from Moyno

as a separate piece from the bearing and bearing sleeve for

a more economical method of rebuilding your grinder. (See

the parts list for part numbers). Follow the instructions below

for assembly.

1. Install the O-ring (24) in the ID of the seal sleeve (17).

Place the stationary portion of the seal on top of the

rotating face. Place the O-ring (23) in the OD of the seal

insert (19), push the entire assembly down on the seal

sleeve until the retaining ring groove can be seen.

Install the retaining ring (21) on the sleeve (17).

2. Carefully push the seal assembly (18,all parts mentioned

in step 1.), spring end first, onto the shaft (6 & 7). Be

careful not to damage the rubber o-rings as you slide it

onto the shaft, both I.D. and O.D.

3. Place the ball bearing (20) onto the bearing sleeve (58)

and install with bearing side first. The bearing sleeve will

bottom out against the seal sleeve, while the bearing

and seal insert should be in contact.

4. Repeat this procedure for each seal assembly.

4-15. Cartridge Assembly

1. Place the top housing (2) upside down on the work

bench and place the spacer (32) inside each bore.

Gently push two bearing / seal cartridges (seal end first)

into the bores. The ball bearing should be facing up

towards you.

2. Secure each cartridge with two butt screw and washers

(38, 39).

3. Turn the top housing so that it rests on it’s side. Place

two excluder plates (14) into position on the top of the

seal cartridge assembly.

4. Push the keyed end of both the drive and idler shafts

through the holes in the seal cartridge in the bottom

housing. Be careful not to damage the mechanical

seals.

5. Place a key (30) in the drive shaft and slide the small OD

gear (13) down over the key. Install the retaining ring

(31) in its groove above the gear.

6. Place a key (30) in the idler shaft and slide the large OD

gear (12) down over the key. You may have to turn the

shaft slightly to get the gear teeth to line up. Install the

retaining ring (31) in its groove above the gear.

7. With a hammer, tap the two spring dowels (8) into the

two counter bored holes in the top housing.

Page 5

8. Wipe a liberal amount of ACG-2 grease on and around

each gear and fill the top housing approximately half full

of grease.

9. Press the lip seal (25) into the housing adapter (9) with

the spring side down.

10. Place the housing gasket (3) on the top housing and

carefully slide the housing adapter over the drive shaft

and down on the gasket. Secure the housing adapter

with two socket head screws, two hex head screws and

four washers. The two socket head screws go in the

middle of the housing. The two hex head screw go in

the two holes on the idler shaft side of the housing.

11. Install the grease fitting (26) in the housing adapter.

12. Find a way to support the assembly upside down on the

work bench. 4 X 4 Inch blocks can be placed on either

side of the driveshaft in order to accomplish this.

13. Align both shafts so that the point of the hex is facing

toward you and perpendicular to the long edge of the

bottom housing. It does not matter which side the drive

or idler shaft is on; right or left. Please refer to the trim

code section 1-6 to identify the type of cutters to be

placed on the drive and idler shafts.

Figure 4-1

14. Each cutter and spacer cutter has only 1 of the 5 cutting

teeth radially in line with one point of the hex ID hole

(see figure 4-2). This tooth is denoted as the Assembly

Position (AP). To expedite the cutter/spacer stacking

process, all cutters and spacers should be separated

into separate piles for the drive shaft cutters, idler shaft

cutters, and spacer. Time should also be taken to

clearly mark and identify the AP for all cutters/spacers.

Figure 4-2

3

2

Shaft 1

1

6

4

5

Shaft 2

3

4

5

6

1

2

15. Place a large (L) cutter on Shaft 1 with the AP positioned

at Point 6 on the shaft 1 (See figure 4-1.). Place a small

(S) spacer cutter on Shaft 2 with the AP positioned at

Point 3.

Place a small (S) spacer cutter on Shaft 1 with the AP

positioned at Point 3, then place a large (L) cutter on

Shaft 2 with the AP positioned at Point 6.

Follow the pattern below until all cutters and spacer

cutters have been installed.

Cutters and spacer cutters are very sharp. Be careful

handling them.

Shaft 1 Shaft 2

6L 3S

3S 6L

1L 4S

4S 1L

2L 5S

5S 2L

3L 6S

6S 3L

4L 1S

1S 4L

5L 2S

2S 5L

6L 3S ÅRepeat Starts

3S 6L

Cutter and Spacer Stacking Arrangement

16. Place an excluder plate over the top of each shaft down

on top of the last cutter and spacer cutter.

17. Place the bottom housing (2) upside down on the work

bench and gently push two seal cartridges (seal end

first) into the bores. The ball bearing should be facing

you.

18. Secure each cartridge with two butt screw and washers

(38, 39).

19. Gently lower the bottom housing down over the ends of

each shaft being careful not to damage the mechanical

seals.

20. Place the flat washer and castle nut on the end of each

shaft. Tighten castle nuts approximately ¾ of the way,

leaving them loose at this point. The castle nuts are the

prevailing torque type and will have resistance the entire

way up the thread. It will be necessary to hold the shafts

while you install the nuts.

21. Carefully lay the unit down on its side. Before you

completely tighten the two castle nuts in the bottom

housing, it will be necessary to hold the drive shaft to

prevent it from turning. You can either hold the shaft by

temporarily mounting the coupling half (43) or by

carefully wedging a small piece of soft metal between

the teeth of the two gears. After you have secured the

shafts, tighten both castle nuts (70 ft-lbs).

22. Place the housing gasket (3) and bottom cover (5)

against the bottom housing and secure them with six

socket head cap screws (33).

Page 6

23. Place a side rail gasket (37) against one side of the

bottom housing and attached the side rail (4) with two

cap screws and washers (28). Leave the screws loose

at this point.

24. Slide another side rail gasket between the top housing

and side rail at the top and secure with two more cap

screws. Repeat this process on the other side and

tighten all eight screws evenly.

25. For Models….M04F3, M06F3, M08F3, M10F3, and

M12F3

1. Place the gasket (40) against one side of the

cartridge body and place a flange housing (41)

against the gasket. Secure the flange with the

screws and washer (57). Place the gasket (52) and

inspection plate (53) against the flange housing and

secure with studs, washers, and nuts (54, 56)

2. Repeat the above procedure on the other side with

the second flange housing.

4-16. Reducer / Motor Assembly

1. Slide the key (29) and coupling half (43) down on the

drive shaft and secure in place with the set screw. The

root of the coupling teeth should be lined up with the end

of the shaft.

2. Place the O-ring (46) in the groove in the housing

adapter and place the drive adapter (42) on the housing

adapter. Secure the drive adapter with four hex head

screws and washers. The two longer screws thread into

the top housing along the outside and the two shorter

screws thread into the housing adapter.

3. Slide the key (29) and coupling half (43) on the reducer

shaft and secure in place with the set screw.

4. Lower the gear reducer (44) onto the drive adapter

carefully aligning the coupling halves. Align the holes in

the flanges and install and tighten the six hex screws,

washers and nuts (49).

5. Place the key in the reducer shaft and lower the motor

(45) down onto the reducer while aligning the key and

keyway. Attach the motor to the reducer with four hex

screws and washers.

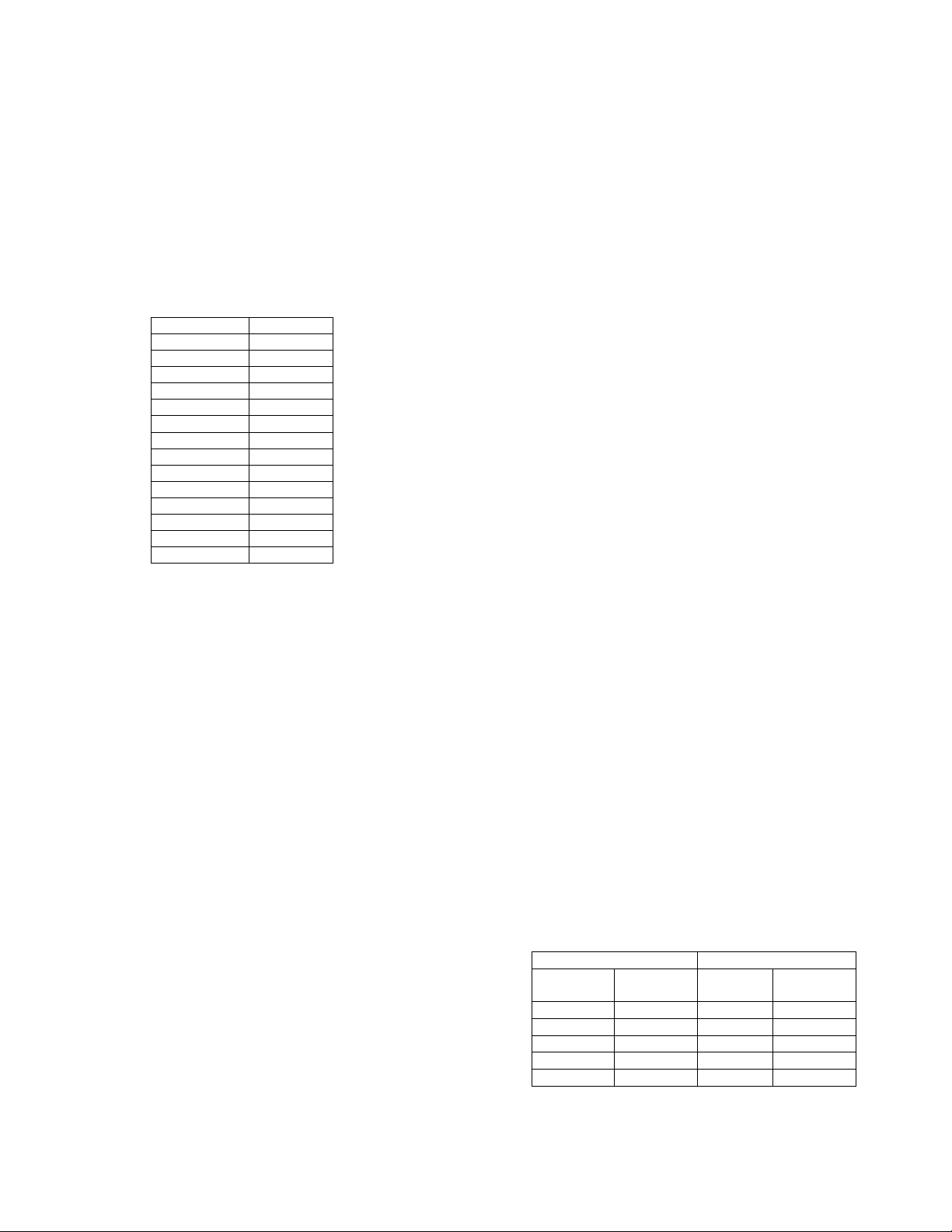

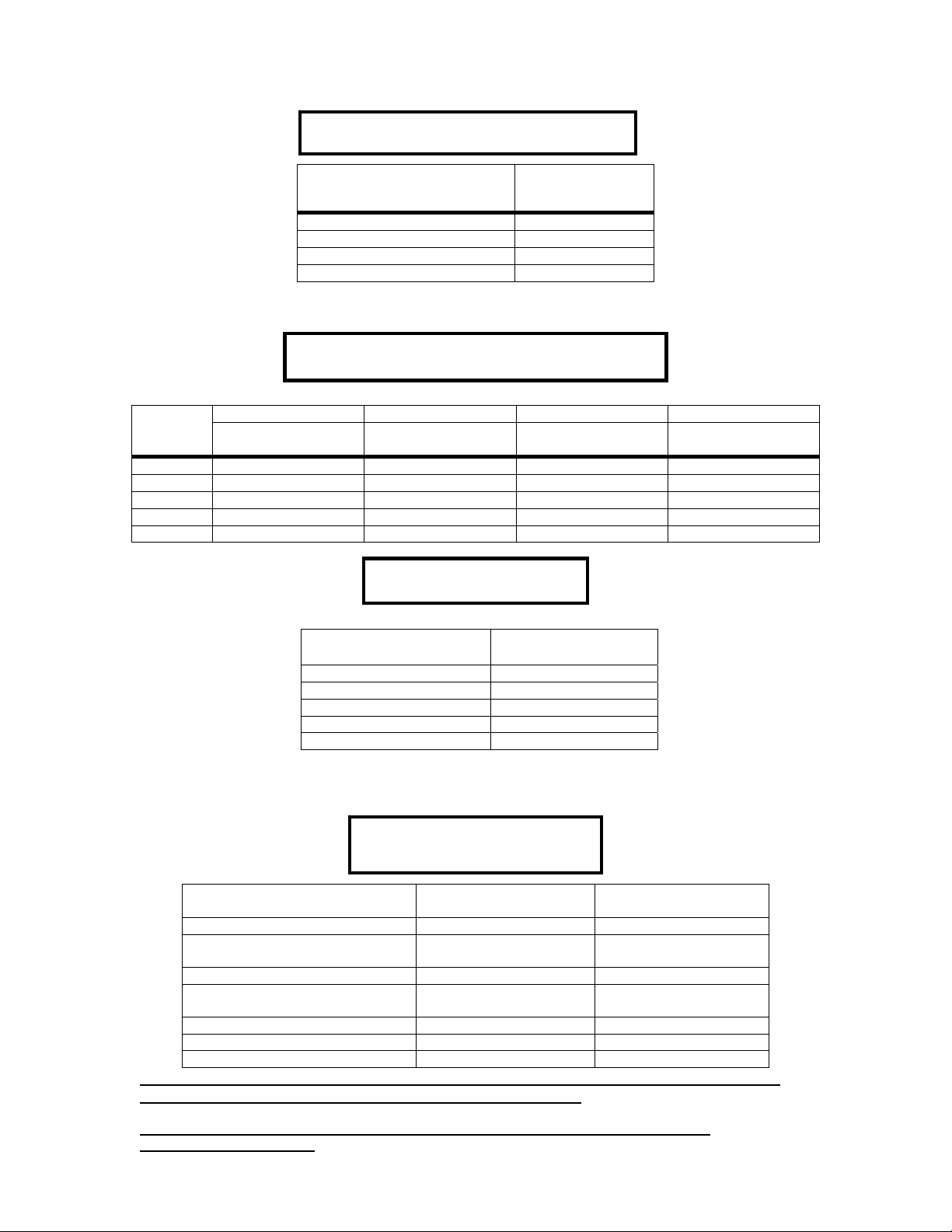

4-17. TORQUE GUIDELINES CHART

Stainless Steel Bolts Carbon Steel Bolts

Size Max

Torque Size Max

Torque

NO. 10-24 22.8 in. lb. 5/16 - 18 10 ft. lb.

1/4 – 20 75.2 in. lb. 3-/8 - 16 21.7 ft. lb

5/16 – 18 132 in. lb. ½ - 13 43.5 ft. lb.

3/8 – 16 236 in. lb. 5/8 – 11 86 ft. lb.

1/2 – 13 517 in. lb. ¾ - 10 152 ft. lb.

Note: Torque values are from the Industrial Fasteners

Institute and Craftsman Corp.

4-18. STORAGE

4-19. Short-Term Storage. Storage of 6 months or less will

not damage the grinder. However, to ensure the best

possible protection, the following is advised:

1. Store grinder inside whenever possible or cover with

some type of protective covering. Do not allow

moisture to collect around the unit.

2. See OPERATION Section before startup. Be sure all

lubricants are in good condition.

4-20. Long-Term Storage. If grinder is to be stored for up to

three years, perform the above short-term storage

procedures plus the following:

1. Apply rust inhibitor to all unpainted cast iron and

machined carbon steel surfaces.

2. Store in a dry area with dust cover.

3. Maximum temperature 120F, minimum temperature 30F.

4. Relative humidity should not exceed 60%. Provide

desiccation for moisture control above the maximum.

5. Vibration levels should not exceed 2 mils at 60 hertz.

Page 7

4-21. Hardware LIst

Your Moyno Annihilator has been designed and built to

minimize overall operating cost. All wearable parts are

replaceable. A recommended inventory of spare parts is

dependent upon the application and the importance of

continued operation.

Page 8

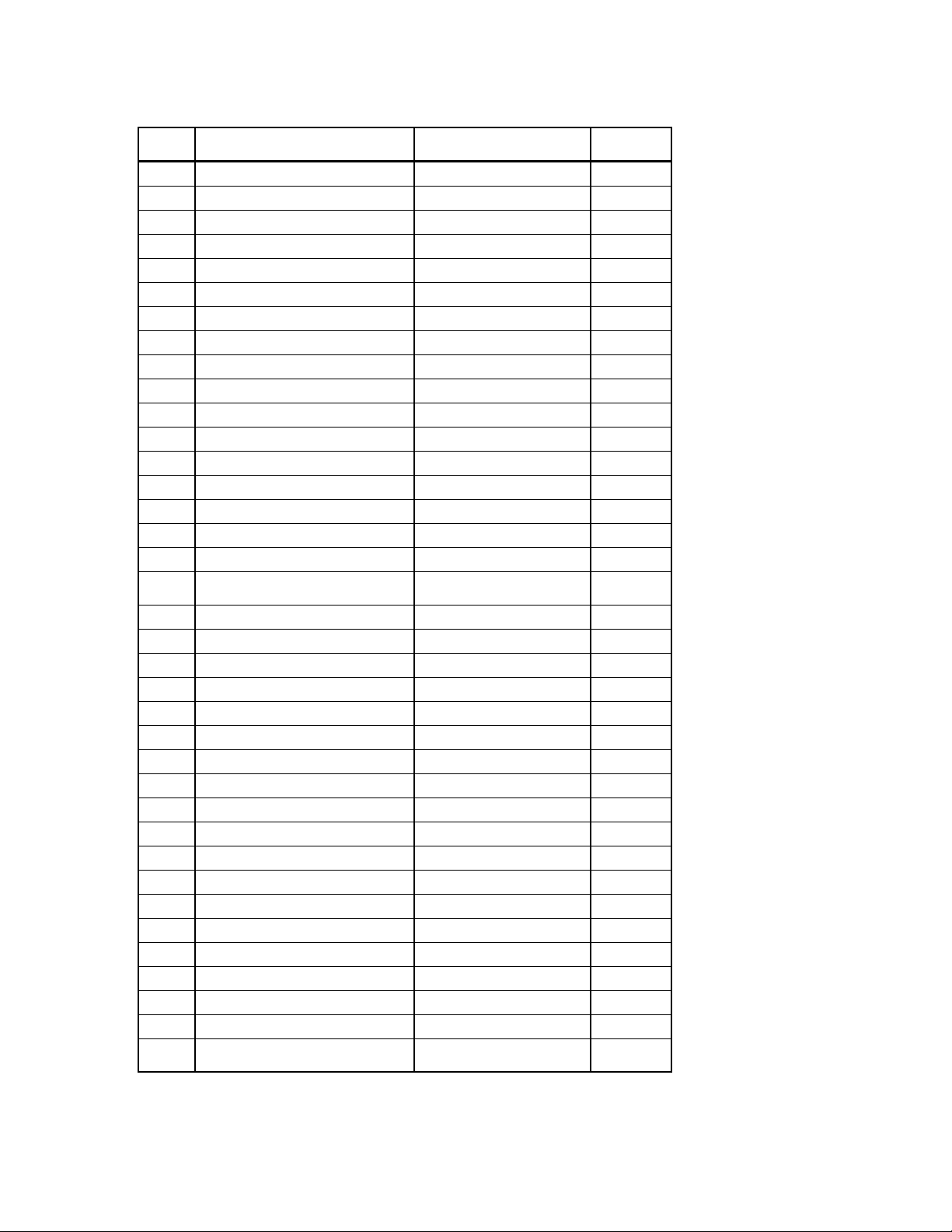

ITEM DESRIPTION LOCATION P/N QTY

51 HEXSCR .50-13 X 1.25, 18-8 SS MOTOR 6191552200 4

50 LCKWAH .500REG,18-8SS RED/MOT 6230012430 4

49 HEXSCR .375-16X1.50,18-8SS REDUCER 6191532240 6

48 HEXNUT .375-16,18-8SS RED/DRVADP 6140012110 6

47A HEXSCR .375-16X1.00,18-8SS DRIVE ADP 6191532160 2

36 HEXSCR .375-16X2.25,18-8SS DRIVE ADP 6191532360 2

DRIVE ADP 4

REDUCER 6

HOUSING ADP 4

27 LCKWAH .375REG,18-8SS

SIDERAIL

6230012410

8

35 SKTSCR .375-16X1.25,18-8SS HOUSING ADP 6191462200 2

47 HEXSCR .375-16X2.5LG,18-8SS HOUSING ADP 6191532400 2

34 LCKWAH .375,HI-COLLAR,18-8 HOUSING ADP 6230013010 2

28 HEXSCR .375-16X1.25,18-8SS SIDERAIL 6191532200 8

33 BUTSCR .375-16X1.00,18-8SS COVER PLATE 6191232160 6

38 PLNWAH .250 ZNCPLT HOUSING 6230070051 8

39 BUTSCR .250-20X.50LG,STL HOUSING 6191210083 8

15 PLNWAH 1.06X2.00X.13,ZNCPLT 6230020181 2

16 HEXNUT 1-14 ELASTIC,ZNCPLT DRIVE & IDLER SHAFT 6140320101 2

8 DOWEL .375 sping Dowel Housing 6160100711 4

ADDITIONAL FLANGED PARTS/HARDWARE LIST

27 LCKWAH .375REG,18-8SS FLANGE 6230012410 14

49 HEXSCR .375-16X1.50,18-8SS FLANGE 6191532240 14

54 STUD .312-18X1.25, ZNCPLT INSPECTION COVER 6040250101 9

56 HEXNUT .312-18X1.25, ZNCPLT

INSPECTION COVER 6140010101 9

57 LCKWAH .312-18REG, ZNCPLT INSPECTION COVER 6230010401 9

Page 9

4-22. PARTS LIST

REF.

NO. DESCRIPTION PART NUMBER Qty

2 HOUSING 4251462001 2

3 HOUSING GASKET 4230834001 2

4 SIDE RAIL See Table 2 2

5 COVER PLATE 4230837001 1

6 IDLER SHAFT See Table 3 1

7 DRIVE SHAFT See Table 4 1

9 HOUSING ADAPTER 4252411001 1

10 CUTTER See Table 5 Table 8

11 SPACER CUTTER 4230924001 Table 8

12 GEAR - IDLER SHAFT 4230729002 1

13 GEAR - DRIVE SHAFT 4230728002 1

14 EXCLUDER PLATE 4230827001 4

17 SEAL SLEEVE 4241821001(*) 4

18 SHAFT SEAL 4220751001(*) 4

19 SEAL INSERT 4230823001(*) 4

20 BALL BEARING 6300502081(*) 4

21 RETAINING RING 6011010157(*) 4

22 O-RING (Incl. w/ seal) or sold

separately 3207905233(*) 4

23 O-RING 3207905233(*) 4

24 O-RING Incl. w/ seal Assy 4

25 GREASE SEAL 6030021001 1

26 GREASE FITTING 4220692001 1

29 KEY 6110060200 1

30 KEY 6110040240 2

31 RETAINING RING 4220691001 2

32 SPACER 4220752001 2

37 SIDE RAIL GASKET/SHIM 4230817001/3632637001 4

40 GASKET See Table 6 2

41 FLANGE HOUSING See Table 6 2

42 DRIVE ADAPTER 4251673001 1

43 GRINDER COUPLING 4230733001 1

44 REDUCER 4230840001 1

45 MOTOR Per Application 1

46 O-RING 3207902252 1

52 INSPECTION PLATE GASKET SEE TABLE 6 2

53 INSPECTION PLATE SEE TABLE 6 2

58 BEARING SLEEVE (Incl. w/

seal) or sold separately 4231037001 4

(*)Seal Assembly (Moyno Part #4231036001) includes items 17, 18, 19, 20, 21, 22, 23, 24, & 58 .

Page 10

Table 2 (Ref. No. 4) ⎯Side Rail

Model Part Number

8C 4241505001

12C 4241506001

18C 4241507001

24C 4241508001

32C 4241509001

40C 4241510001

60C 4241511001

4F 4241512001

6F/8F 4241513001

10F 4241514001

12F 4241515001

Model Part Number

8C/4F 4251464001

12C/6F/8F 4251466001

18C/10F 4251468001

24C/12F 4251470001

32C 4251472001

40C 4251474001

60C 4251476001

Table 4 (Ref. No. 7) ⎯Drive Shaft

Model Part Number

8C/4F 4251465001

12C/6F/8F 4251467001

18C/10F 4251469001

24C/12F 4251471001

32C 4251473001

40C 4251475001

60C 4251477001

Table 3 (Ref. No. 6) ⎯Idler Shaft

Page 11

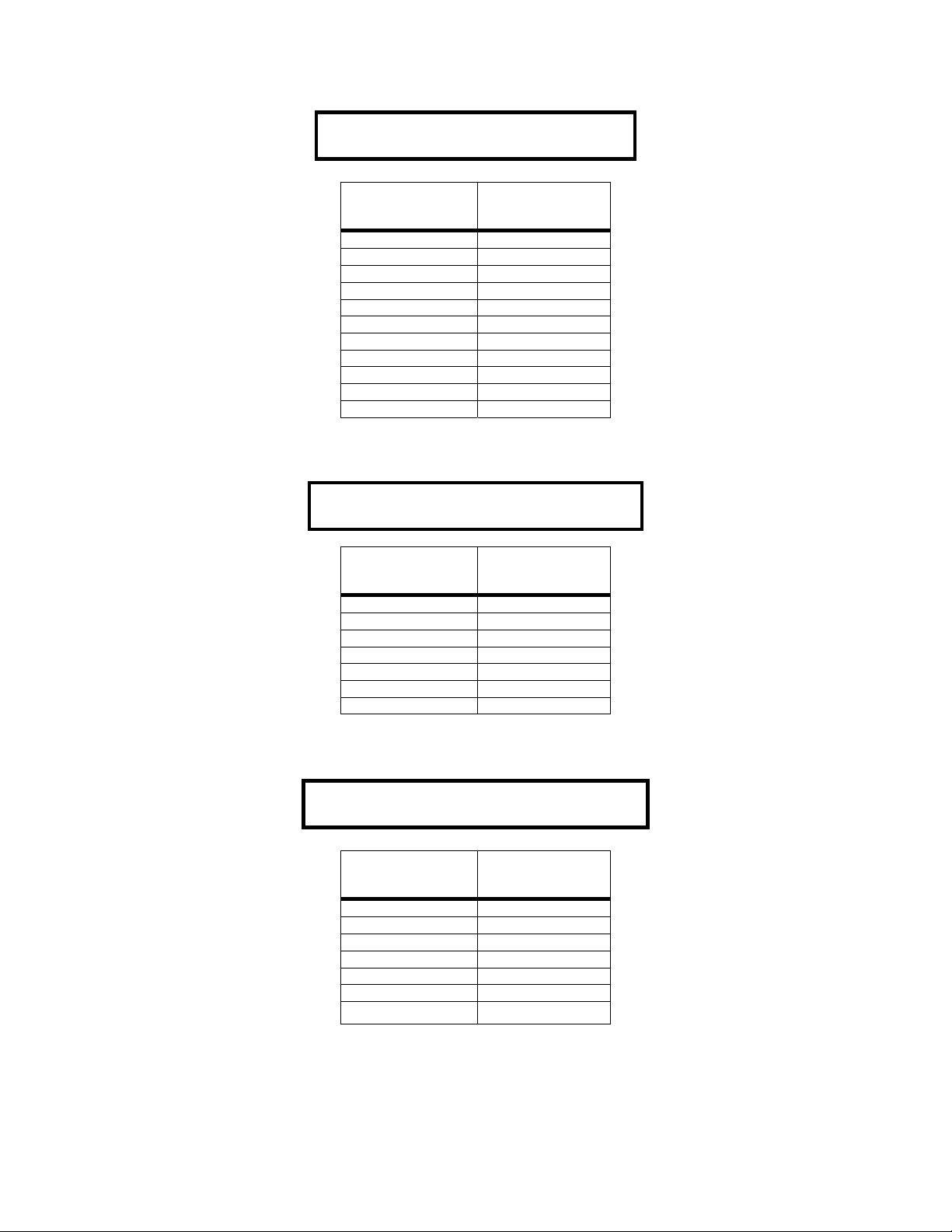

Style Part Number

5R, 5 Tooth Reversible 4230913001

7R, 7 Tooth Reversible 4230914001

7C, 7 Tooth Cam 4230724001

11C, 11 Tooth Cam 4230915001

Ref. No. 41 Ref. No. 40 Ref. No. 53 Ref. No. 52

Model Flange Housing Flange Housing

Gasket Inspection Plate Inspection Plate

Gasket

4F 4251300001 4230737001 4230741001 4230745001

6F 4251301001 4230738001 4230742001 4230746001

8F 4251302001 4230738001 4230742001 4230746001

10F 4251303001 4230739001 4230742001 4230746001

12F 4251304001 4230740001 4230742001 4230746001

Model Part Number

All Channel models KCHA30Q

M04F3 K04F30Q

M06F3/M08F3 K06F30Q

M10F3 K10F30Q

M12F3 K12F30Q

Note C: Channel model gasket kits include items 3 and 37.

Note D: Flanged model gasket kits include items 3, 37, 40, and 52.

Model Qty of Cutters Required Qty of Spacer Cutters

Required

M08C3, M04F3 24 24

M12C3, M06F3, M08F3

M04F4, M06F4, M08F4 38 38

M18C3 58 58

M24C3, M10F3, M12F3

M10F4, M12F4 78 78

M32C3 104 104

M40C3 130 130

M60C3 198 198

NOTE: For units containing different types of cutters on each shaft, half the quantity of

cutters need to be ordered for the cutter type on each shaft.

Pre-assembled replacement cutter cartridges are available. Consult your local Moyno

Representative for details.

Table 6 ⎯Flange Housing Arrangement

Table 5 (Ref. No. 10)

⎯

Cutter

Table 7

⎯

Gasket Kits

Table 8 ⎯Cutters and Cutter

S

p

acers Re

q

uired

Page 12

Exploded View

Table of contents