MPI APLEX4 Series User manual

Service Manual

2

Example serial plate

CE Compliance (for EU only)

This product complies with the requirements of EMC, RoHS and Machinery Directives including their

amendments.

CE marking is the responsibility of the manufacturer : Media Gest Software Logistic S.l., Pasatje de

L´Oest, 6c, 08329 Teia (Barcelona), Spain.

For a copy of the related CE Declaration of Conformity, please contact your Supplier.

The following information is for EU-member states only:

Disposal of products

(based on EU-Directive 2012/19/EU

Directive on Waste electrical and electronic equipment –WEEE)

The use of the symbol indicates that this product may not be disposed as unsorted municipal waste and

has to be collected separately. Integrated batteries and accumulators can be disposed of with the

product. They will be separated at the recycling centers.

The black bar indicates that the product was placed on the market after August 13, 2005.

By ensuring this product is disposed of correctly, you will help prevent potential negative consequences

for the environmental and human health, which could otherwise be caused by inappropriate waste

handling of this product.

For more detailed information about the take-back and recycling of this product, please contact your

supplier where you purchased this product.

Mantenimiento Periféricos Informáticos C/Canteras,22 28860 Paracuellos de Jarama Madrid Tel: 91 748 16 04 www.mpi.com.es

Service Manual

5

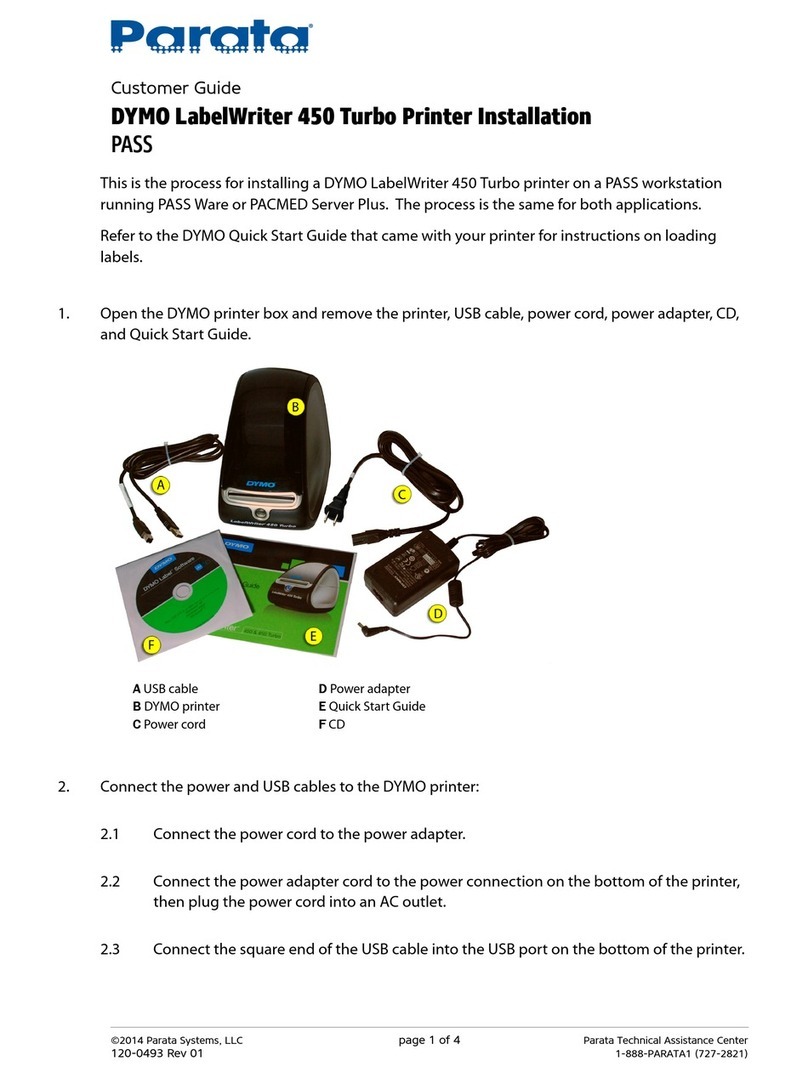

OPERATION PANEL

Front drawing

Test Button Print next label / Clear error

LCD screen

Normal mode Shows applied label counter

Config mode Shows configuration menus/values

Selection Button

Push Enter configuration menu

Rotate left & right Change selection

Push Select highlighted value

Note: Changes made on configuration menus will be applied just after the modification for testing but will be

saved only when EXIT to “Main Menu”.

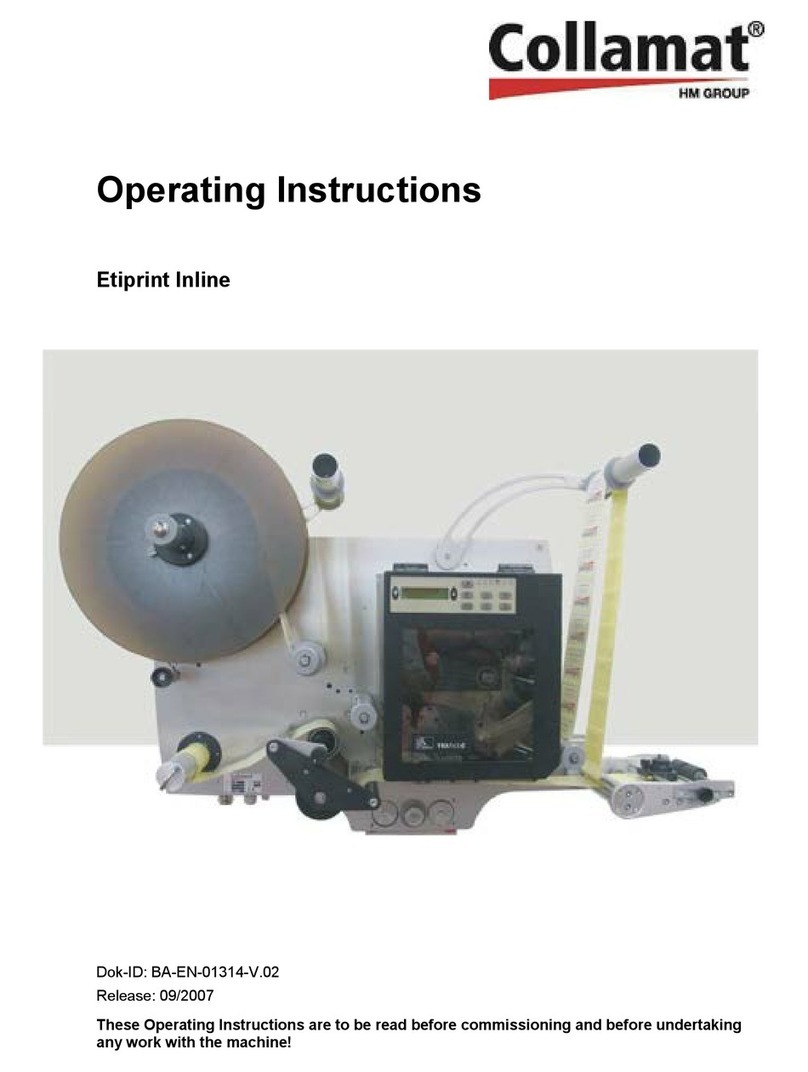

BODY

Front view Front view

(1) Control Unit

Contains: Pneumatic group / Connections PCB / Power Supply / LCD Screen / Buttons

(2) Piston

Monoblock Piston / Guides

(3) Printer Base Plate, for EX4

(4) Mounting Block, Ø50mm

(5) Light Indicator (Optional)

(6) Photo sensor, to detect the coming product

Reflex photocell, without mirror. Focus: 30-200mm

Mantenimiento Periféricos Informáticos C/Canteras,22 28860 Paracuellos de Jarama Madrid Tel: 91 748 16 04 www.mpi.com.es

Service Manual

6

Errors

APLEX4 communicates with EX4 printer using the I/O I/F on the following way:

- ISSUE signal is activated

- The printer starts to print and activates ISSUING signal

- When ISSUING is deactivated the printer has finished and ERROR signal is read

Note: sometimes it is needed to increase ‘Post-Delay’ parameter to max: 0,500 ms

If any error happens (end of ribbon/media):

- APLEX4 will stop and RED light will be ON. Piston arm won’t move and will keep on UP position

To clear the error follow the following procedure:

- Label/ribbon replacement

- Press RESTART on printer panel, one label will be feed and printer error will be cleared

- Press ‘Test button’ on the APLEX4, to clear APLEX4 error

With Program 0: we can continue working with any other operation

With Program 1: press again test button to initialize the cycle “Wait Up Apply/Print”

With Program 2: piston will go down to end error cycle. Press again test button to initialize the cycle

“Wait Down Apply/Print”

Errors on APLEX display

Different errors in the applicator are shown:

- MAIN PISTON ERROR: It occurs because the upper piston sensor is OFF when the piston has to

start to go down

- APPLICATOR ERROR: occurs when the lower sensor does not detect the piston contact (not turned

OFF), it may be because no air pressure to the piston to move and does not detect the end contact

- PERIMETRAL SECURITY: the security key is not connected on the CN2

- PRINTER ERROR: the printer is in any error situation

Mantenimiento Periféricos Informáticos C/Canteras,22 28860 Paracuellos de Jarama Madrid Tel: 91 748 16 04 www.mpi.com.es

Service Manual

8

Piston

1 2 (1) Piston

Monoblock Piston / Guides (7)

(2) Piston position sensors Down / Up

Sensor (2.2)acts as a position/contact sensor, can be

adjusted to increase/decrease contact pressure of the label

pad (5) against the product, moving the sensor up/down

±4mm.

The piston has an adjustment (3) to limit the maximum

movement (400mm) as a security element to avoid hits on the

line o as a waiting point when using blow labeling.

Sensor harness, piston movement air tubes and vacuum/blow

tube moves inside a guided chain (4).

This guided chain and the special mounting piston as a

monoblock allow the P&A to be used on any position without

further adjustments.

Tubes and harness comes to the control unit (10) inside a helical tape to prevent damages (8).

(5) Label pad

The unit comes with 100x100mm or 110x150 Label pad without holes. This pad should be

customized depending on customer’s label(s). The unit is factory adjusted, ready to work

(after label pad customization) and offers XYZ regulation (6) up/down and

forward/backward

(11) Air blow tube ‘air-assist’

While printing keeps the label parallel to the label pad, the blowing point is positioned on the center of the

label around 1/3 of the label. When using EX4T1 the position is fixed on the label center. For EX4T2 label is

left side position.

When testing, when the printer is ready to print, there is a test button (9) to print & apply one label and check

than the label pad (5) and air assist (11) are suitable. Also there are other configuration parameters available

on the configuration menu accessible with the operation panel (10) (see user’s manual).

Piston-Regulation

1 2 Altough the unit is factory adjusted, the label

pad (10) can be adjusted over the label exit on

Horizontal (3.1) and Vertical (3.2); also with the

air assist orientation adjust over label path (4)

we can adapt the unit to any condition.

Also time parameters can me modified using

operation panel (7).

When working in 'contact' mode, pressure can be set moving up/down piston sensor (2) loosening/tightening

the flange that holds it.

Also the piston stoppers can be set up (5) depending on the speed of movement to act before/after

smoothing the piston (1) stop.

Mantenimiento Periféricos Informáticos C/Canteras,22 28860 Paracuellos de Jarama Madrid Tel: 91 748 16 04 www.mpi.com.es

Service Manual

9

Cables / tubes coming from the control unit (6) are inside the chain (9) which is guided and anchored to the

base of the piston onto the same guides (8) forming a compact and factory adjusted unit (11) that allows to

work in any position (90-180-270°) with smoothness and accuracy.

The valve (1) free the piston pressure air for free movement up/down for maintenance purposes so as to

adjust the position of the piston stopper down, moving piston (4) on the rails (5) of the piston block (6) so that

the label pad (3) is in the desired position when working both blowing without contact with the product or for

safety and to limit the output of the piston in contact mode. Guided chain (2) of the tubes/wires allows

smooth piston operation.

Control Unit

Control unit (1) mounted at the left of the printer base (3)

controls electronically and pneumatically the piston (2).

It is below the Ø50mm tube adapter (4) to mount the unit on the production line.

Air input tube Ø8mm to the air control unit (5) with open/close valve. The rear panel (6) power input

connections and 220V-50Hz with switch and indicator light; connections: photocell(s) for product detection,

blocking signal connection, In/Out for EX4 printer, power for EX4 printer, air input from the regulator to the

control unit (see detail later).

The control unit has a cover that can be completely removed to allow to work easily with freedom of

movement, to adjust, repair or replace any parts

required.

Pneumatics - Connections Board / Power Supply (A)

Inside the Control unit there is block (A) Pneumatics

–Connections Board / Power Supply and block (B)

Screen/Keyboard

Block (A)

(1) Solenoid valves:

From left to right: Blow (1a) Air-Jet, Empty (1b), 'Air-

assist' (1c), Piston up/down (1d)

Mantenimiento Periféricos Informáticos C/Canteras,22 28860 Paracuellos de Jarama Madrid Tel: 91 748 16 04 www.mpi.com.es

Service Manual

10

(2) Regulators:

From left to right: Vaccum, 'Air-assist', Piston down, Piston up. The blow is regulated by time (parameter on

the menu).

(3) Air outputs are located such that the air

outlet is carried out to the outside, preventing

any dirt may reach the inside of the control

unit.

(4)Connections Board –Power Supply

The connection board distributes all the

harness between the CPU, solenoid valves,

piston sensors and the power supply (4a).

Power supply: input 220V-50Hz, grounded

and with stabilizer filter; output 24V DC for

solenoid valves and sensors and 3,5V DC for

the CPU PCB (4b).

Checking valves

Pressing blue button you can check is some of the corresponding valves are working:

1 BLOW function

2 VACUUM function

3 AIR ASSIST function

1

2 3

Mantenimiento Periféricos Informáticos C/Canteras,22 28860 Paracuellos de Jarama Madrid Tel: 91 748 16 04 www.mpi.com.es

Service Manual

11

Connection board schema

CPU –Screen/Keyboard (1) Screen

Serial connector to the CPU with power and data. It has its

own controller, only receives data from the CPU using an

special protocol, in the future can be replaced by other

type (i.e. tactile) without modifying the CPU PCB.

(2) Selection controller

Serial connector to the CPU with power and data. As the

screen it has its own controller.

(3) CPU PCB (behind)

Control the communication with the screen and keyboard

and with the connection board controls the input, outputs,

solenoid valves and piston sensors.

Mantenimiento Periféricos Informáticos C/Canteras,22 28860 Paracuellos de Jarama Madrid Tel: 91 748 16 04 www.mpi.com.es

Service Manual

12

(4) Cable protector

Protects the cables and air tubes from control unit to piston.

(5) Test button connector

To connect the test button (6) located on the control unit cover (10).

Control unit cover

Protects the control unit. Uses 6 screws (8), contains the

screen window (1) and the keyboard window (2) and the

regulators for the solenoid valves (7), the path for the cable

protector (4) and the test button (6) with the connector (5).

Connections (1) Air input to air control unit

Through the air group (1). Ø8mm tube.

(2) Signal connection to EX4 printer

To EX4 printer In/Out I/F, together with

power cable 220V-50Hz to the printer (2)

(3) Signal for: photo sensor for printing and

security signal (door open)

DIN connector for additional signals to

depending on selected configuration to

manage printing order and security signal

(door open) to stop all operations when

active

(4) Additional I/O board (optional)

(5) General power supply connection

AC inlet 220V-50Hz, to power all the system

(printer included). It has a switch and a red

LED indicator.

(6) Light indicator connector (optional)

DIN connector to connect the external optional light indicator

Green/Connected, Red/Error, Orange/Working. The semaphore has a 1,5m cable to connect to other place

different than standard one (see image) for example can be moved to the top of the optional support column

(APLEX4-SC). If the semaphore is not used, those signals can be used to connect to a PLC.

(7) External photo sensor connector

DIN connector to the photo sensor, to detect the coming product and depending the selected mode starts

print&apply cycle or apply signal

Mantenimiento Periféricos Informáticos C/Canteras,22 28860 Paracuellos de Jarama Madrid Tel: 91 748 16 04 www.mpi.com.es

Service Manual

13

General Air Controller

Gauge of general air inlet, to the unit.

Regulator / stabilizer 4-6 Bars of the air inlet to the unit, filter water and impurities,

with output at the end, with indicator pressure and open/close valve.

Delivered with inlet ØExt. 8mm.

Back panel connectors

CN1 connector (upper left). Trigger signals.

Pin

Name

Description

1

V24

Power 24V (50 mA max)

2

GND

0V ground

3

INP-0

Print&Apply signal or

Apply signal (apply) when printing signal is separated of apply signal

4

INP-1

Inhibit cycle signal

CN1: for PRINT&APPLY signal

(program 0) (or only APPLY

program 1-2) and INHIBITION

signal

CN2: for PRINT signal (program 1-

2) and PERIMETER security signal

CN3: for light indicator (optional)

CN4: I/O programable I/F (optional)

Mantenimiento Periféricos Informáticos C/Canteras,22 28860 Paracuellos de Jarama Madrid Tel: 91 748 16 04 www.mpi.com.es

Service Manual

14

Notes:

There is a PTC limitation on power output. Once it is triggered needs some minutes to work

again.

Input circuit: Activation (ON state) is made connecting INP signal to GND using

a contact or a NPN signal from a photocell, inductive sensor, etc.

In this state max current is 5mA.

On the contrary or in open circuit the signal is considered

deactivated (OFF state).

CN2 connector (upper right). Perimeter security and inhibition signals.

Pin

Name

Description

1

V24

Power 24V (50 mA max)

2

GND

0V ground

3

INP-2

Perimeter security signal

4

INP-3

Init cycle signal (printing) when printing signal is separated of apply signal

Notes:

There is a PTC limitation on power output. Once it is triggered needs some minutes to work

again.

Input circuit: Activation (ON state) is made connecting INP signal to GND using

a contact or a NPN signal from a photocell, inductive sensor, etc.

In this state max current is 5mA.

On the contrary or in open circuit the signal is considered

deactivated (OFF state).

Mantenimiento Periféricos Informáticos C/Canteras,22 28860 Paracuellos de Jarama Madrid Tel: 91 748 16 04 www.mpi.com.es

Service Manual

15

CN3 connector (bottom left). Light indicator.

Pin

Name

Description

1

V24

Power 24V

2

LG

GREEN light (Always ON)

3

LA

ORANGE light (IN OPERATION)

4

LR

RED light (ERROR)

Notes:

It is possible to use these signals to check APLEX status but always respecting the

maximum voltage and current values.

This signals are designed to be used with original APLEX light indicator. If used for

any other application, you have to take into account the maximum consumption supported

by the outputs and the use made of the 24V line. This line is the internal power of the

applicator, so you have to take good care of both consumption and noise injection, not to

vary the terms of the CE certificate, or disrupt the operation of the applicator.

Output circuit: The load is always between the 24V signal and the corresponding

OUT.

Each output supports a maximum of 25mA, though 60mA should never

be exceeded in all three. No supports inductive loads (relays, solenoid

valves, etc.)

Mantenimiento Periféricos Informáticos C/Canteras,22 28860 Paracuellos de Jarama Madrid Tel: 91 748 16 04 www.mpi.com.es

Service Manual

16

OUT1

Pin 1

Pin 2

OUT2

Pin 3

Pin 4

CN4 connector (bottom right). I/O signals (optional).

Pin

Name

Description

1

OUT1

Pin1 and Pin2 are a free-voltage contact when the OUT1 is ON

2

OUT1

3

OUT2

Pin3 and Pin4 are a free-voltage contact when the OUT2 is ON

4

OUT2

5

V24

Power 24V (external)

6

GND

0V ground (external)

Notes:

The connector is not supplied with the APLEX, only with the accessory.

There is an optional kit to use these signals. This kit includes the connector, in/out board,

harness and screws and instructions.

OUT1 & OUT2 functionality can be configured on APLEX configuration menu.

IN signal can be used to clear any APLEX error. This avoids the need to push the TEST

button when any error appears.

Output circuit: OUT1 & OUT2, normally OPEN

Input circuit:

IN

Pin 5 (+24V)

Pin 6 (GND)

Mantenimiento Periféricos Informáticos C/Canteras,22 28860 Paracuellos de Jarama Madrid Tel: 91 748 16 04 www.mpi.com.es

This manual suits for next models

1

Table of contents