TAKE-A-LABEL TAL-3000C User manual

Other TAKE-A-LABEL Label Maker manuals

TAKE-A-LABEL

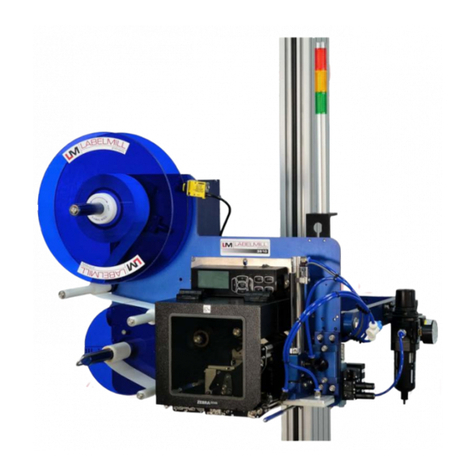

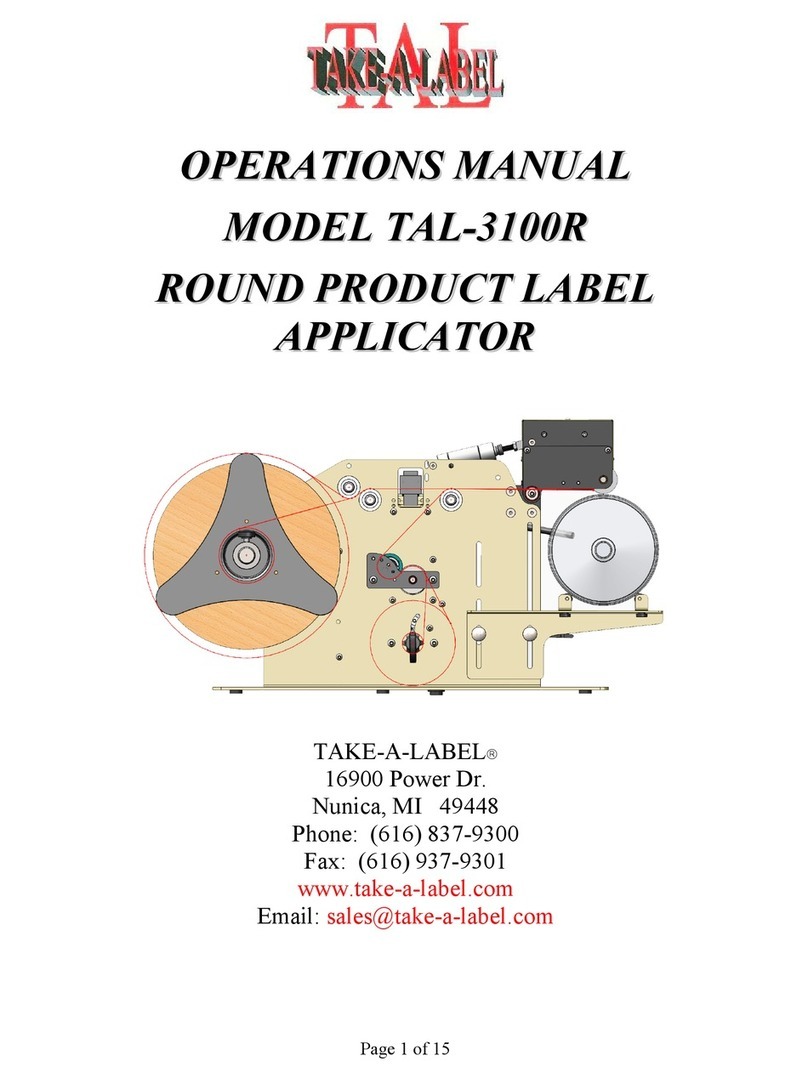

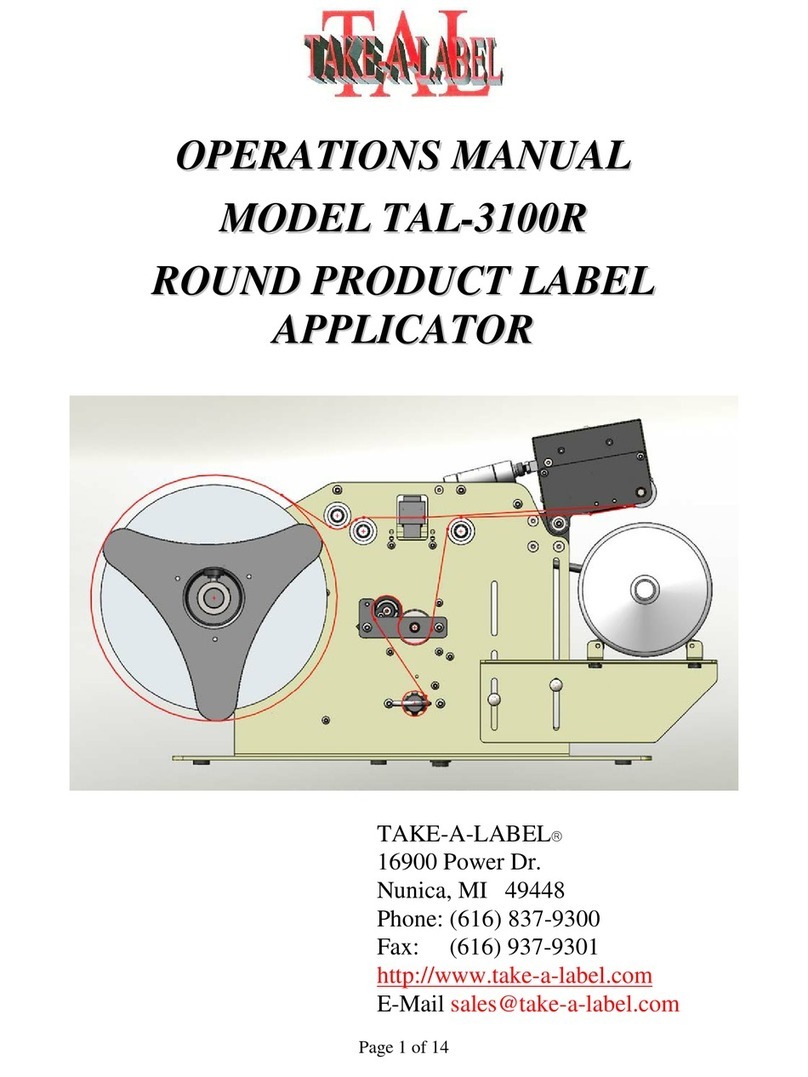

TAKE-A-LABEL TAL-3100R User manual

TAKE-A-LABEL

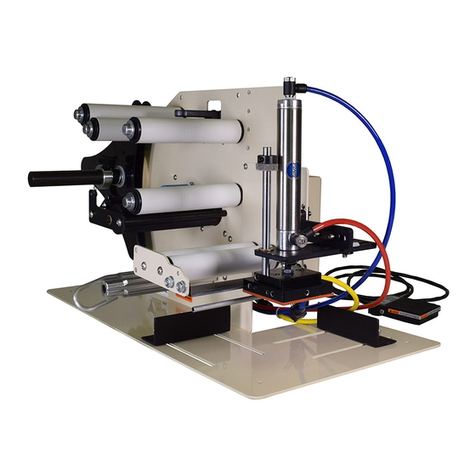

TAKE-A-LABEL TAL-3100T User manual

TAKE-A-LABEL

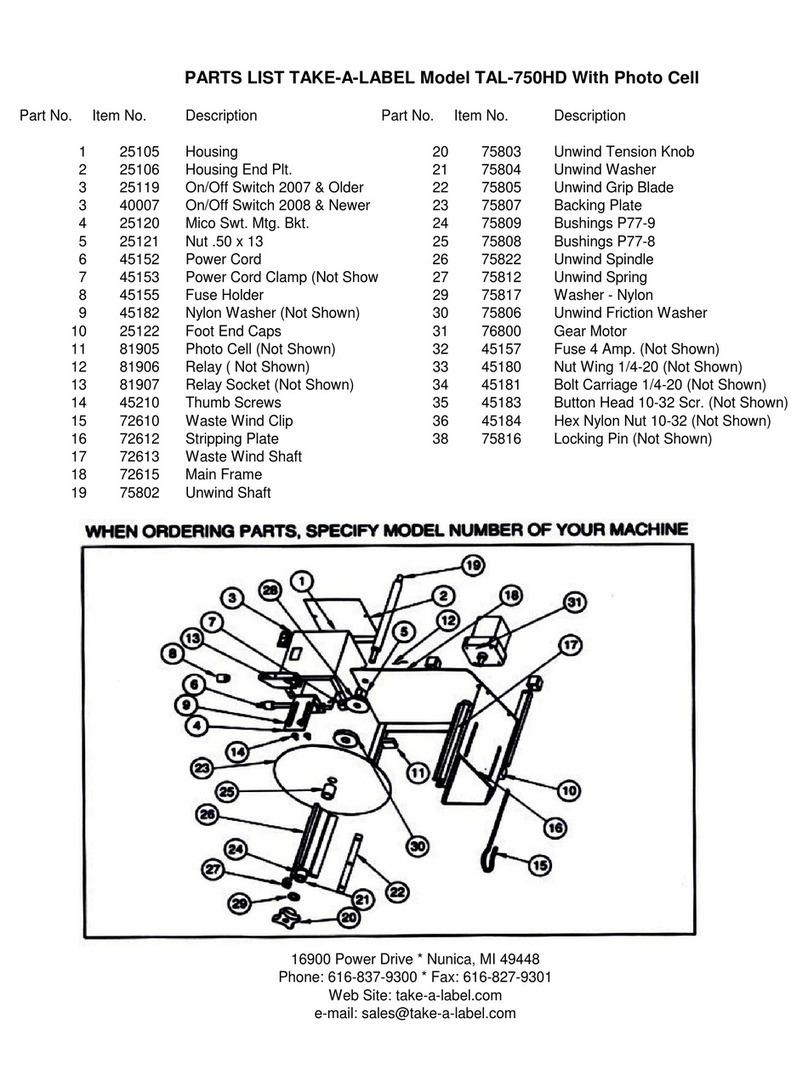

TAKE-A-LABEL TAL-750HD User manual

TAKE-A-LABEL

TAKE-A-LABEL TAL-2100ER User manual

TAKE-A-LABEL

TAKE-A-LABEL TAL-3000R User manual

TAKE-A-LABEL

TAKE-A-LABEL 250 User manual

TAKE-A-LABEL

TAKE-A-LABEL TAL-3100R User manual

TAKE-A-LABEL

TAKE-A-LABEL 250 User manual