Etiprint Inline

0HContent

3

1 General....................................................................................5

1.1 Information on these Operating Instructions..................5

1.2 Symbol explanations......................................................6

1.3 Limitation of liability........................................................7

1.4 Copyright protection.......................................................7

1.5 Spare parts ....................................................................8

1.6 Guarantee provisions.....................................................8

1.7 Customer service...........................................................8

1.8 Manufacturers declaration ............................................8

2 Safety ......................................................................................9

2.1 Intended use ..................................................................9

2.2 Responsibility of the operating company.....................10

2.3 Operating personnel ....................................................11

2.3.1 Requirements ...............................................11

2.3.2 Unauthorised persons ..................................12

2.4 Personal safety equipment ..........................................12

2.5 Work safety and special hazards.................................13

2.6 Conduct in dangerous situations or accidents.............17

2.7 Safety equipment.........................................................17

2.8 Securing against re-starting.........................................18

3 Technical data ......................................................................19

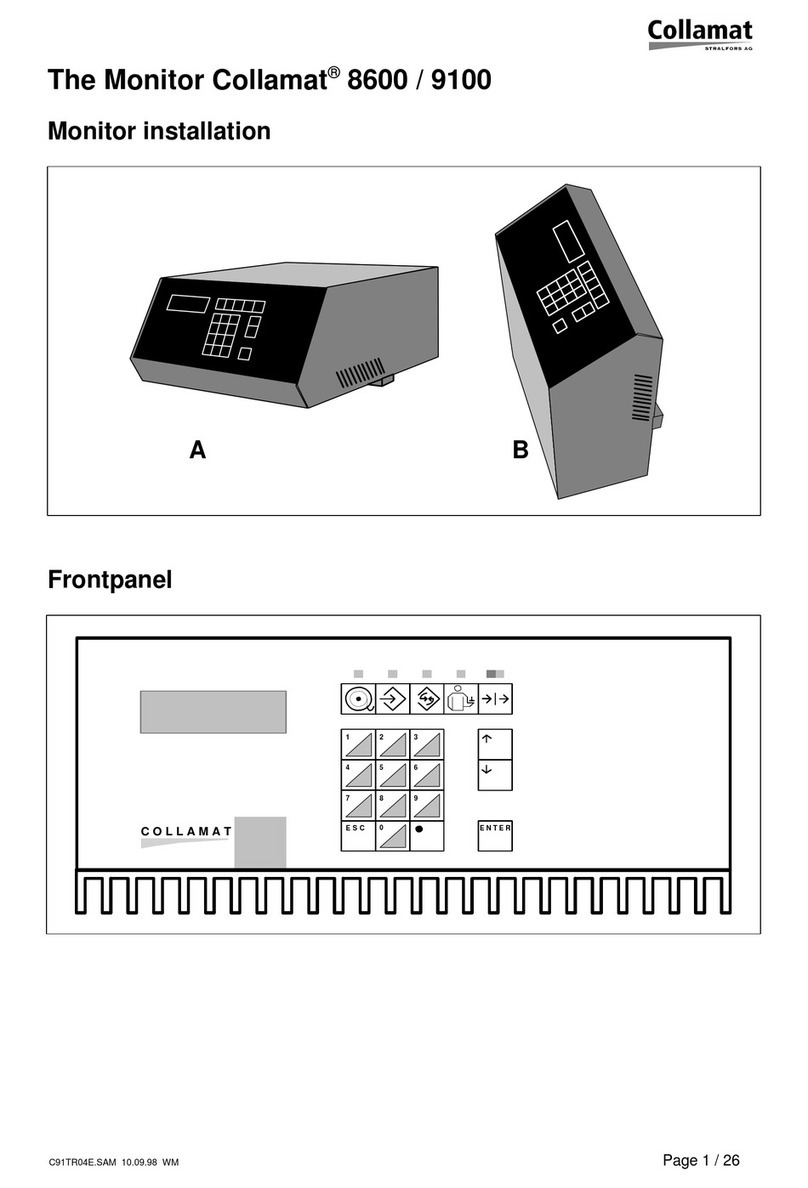

3.1 Dimensions of the Etiprint and monitor........................19

3.2 Technical data..............................................................20

3.3 Emissions.....................................................................20

3.4 Weight..........................................................................20

3.5 Performance values.....................................................21

3.6 Label roll dimensions ...................................................21

3.7 Mounting ......................................................................21

3.8 Name plate...................................................................21

4 Design and function.............................................................22

4.1 Equipment overview ....................................................22

4.2 Variants........................................................................23

4.3 Equipment design ........................................................23

4.4 Function .......................................................................23

4.5 Operating and display elements ..................................24

5 Transport, packaging and storage .....................................25

5.1 Safety information for transporting ..............................25

5.2 Symbols on the packing...............................................25

5.3 Transport inspection ....................................................26

5.4 Transport......................................................................26