MPP Solar LIO II-4810E User manual

User Manual

Version: 1.1

Wall-mounted

Lithium-Iron Phosphate

Battery module

Table of Contents

1. Overview................................................................................................................................................1

2. Introduction ...........................................................................................................................................2

2.1 Product Overlook.............................................................................................................................2

2.2 Menu Operation Instruction............................................................................................................5

2-3. The Working Principle.....................................................................................................................6

2-4. Product Features ............................................................................................................................7

2-5. Battery Active Equalization.............................................................................................................8

3. Installation Guide...................................................................................................................................9

3-1. Installation Precaution Notes .........................................................................................................9

3-2. Installation Procedure ..................................................................................................................11

3-3. Installation Method......................................................................................................................13

4. Maintenance........................................................................................................................................14

4-1. Electrical Maintenance.................................................................................................................14

4-2. Battery Maintenance....................................................................................................................14

4-3. Trouble Shooting Steps.................................................................................................................15

5. Specification.........................................................................................................................................16

5-1. Technical Specification..................................................................................................................16

5-2. Main performance index of the battery .......................................................................................17

5-3. Battery Characteristics..................................................................................................................19

6. Environment Protection.......................................................................................................................20

6-1. Environmental Label.....................................................................................................................20

6-2. Recycle..........................................................................................................................................20

7. APPENDIX.............................................................................................................................................21

7-1. Connection Cable..........................................................................................................................21

1

1. Overview

Thank you for purchasing Lithium battery module. This manual describes the installation and product

parameter settings etc. Please read this manual before you install the battery. Follow the instruction

carefully during the installation process and keep this manual in safety for further information.

Readers

This document provides technical details regarding the tools and infrastructure usedby the following

users:

Sales engineer

Technical support engineer

Installation engineer

Application engineer

Maintenance engineer

Conventions and used symbols

The following symbols may appear in this article, and they are represented as follows:

Symbol

Indication

Dangerous

Used as warning in an emergency, if not avoided, it will result indeath or

serious personal injury

Warning

Used as a warning of a middle or low potential hazards, if notavoided, it

may cause minor or normal injury.

CAUTION

Used as a warning of potential dangers, if ignore this information,it may

result in equipment broken, data lost, equipment performance decrease and

other unpredictable result.

INTRO

Represents the supplement information of main text to emphasizeor

replenish

2

2. Introduction

LIO II-4810E lithium iron phosphate battery is one of new energy storage products. It can be used to support

reliable power for various types of equipment and systems. LIO II-4810E is especially suitable for application scene

of high power, limited installation space, restricted load-bearing and long cycle life.

LIO II-4810E has built-in BMS battery management system, which can manage and monitorcells information

including voltage, current and temperature. What’s more, BMS can balance cells charging and discharging to extend

cycle life. Multiple batteries can connected in parallel to expand capacity and power in parallel for larger capacity

andlonger power supporting duration requirements.

Certification: UL 1642, UN38.3.

2.1 Product Overlook

1. Power on/off button

2. LCD display

3. Operation buttons

Terminal view

4. Battery connectors (including 2 positive poles and 2 negative poles): Using 4-pin terminals, from left to right is

defined as battery+, battery+, battery-, battery-, which is connected with the power transmission line for

charging and discharging.

5. On/Off indicator

6. RUN LED: During charging, the "RUN" light will be flashing.

7. ALM LED: When the battery is at fault, "ALM" LED is lighting red.

8. SOC LEDs: Four LEDs indicating battery capacity.

3

Capacity

●

●

●

●

75%-100%

¤

¤

¤

¤

50%-75%

¤

¤

¤

○

25%-50%

¤

¤

○

○

25%-50%

¤

○

○

○

INTRO:

¤

indicating LED is on.

○

indicating LED is off.

RUN, ALM and SOC LEDs will display battery status as below table.

Battery

status

Normal/Alarm/

Protection

RUM

ALM

Capacity LED

Description

Shutdown

Dormancy

Off

Off

Off

Off

Off

Off

All off

Standby

Normal

Flash 1

Off

According to the battery indicator

Standby

Alarm

Flash 1

Flash 3

The module of low

pressure

Charging

Normal

Light

Off

According to the battery indicator

(Maximum power indicator LED flash 2)

Overcharge alarm.

ALM does not

blink

Alarm

Light

Flash 3

Overcharge

protection

light

Off

Light

Light

Light

Light

Stop discharging.

ALM lighting.

Over temperature

over current, and

invalidation

protection

Off

Light

Off

Off

Off

Off

Stop charging.

ALM lighting.

Discharging

Normal

Flash 3

Off

Based on capacity

Alarm

Flash 3

Flash 3

Under voltage

protection

Off

Off

Off

Off

Off

Off

Stop discharging.

ALM lighting.

Temperature

overcurrent short

circuit reverse

connection failure

protection

Off

Light

Off

Off

Off

Off

Stop discharging.

ALM lighting.

Failure

Off

Light

Off

Off

Off

Off

Stop charging and

discharging.

ALM lighting

Note: Flash1- light 0.25s/off 3.75 seconds; Flash 2-0.5 slight /0.5s off; Flash 3 -0.5 slight/1.5s off.

9. RS485 & CAN: CAN Communication Terminal:(RJ45port) follow CAN protocol, for output battery information.

RS485

Use 8P8C vertical RJ45 socket

CAN

Use 8P8Cvertical RJ45 socket

RJ45 pin

Definition

RJ45 pin

Definition

9, 16

RS485-B1

1, 3, 6, 7, 8

NC

10, 15

RS485A1

5

CANL

11, 14

GND

4

CANH

12, 13

NC

2

GND

4

10. RS232 port: (RJ11 port) follow RS232 protocol, for manufacturer or professional engineer todebug or service.

RS232

Use 6P6Cvertical R11socket

RJ11 pin

Definition

2

NC

3

Tx

4

RX

5

GND

11. Grounding screw

12. RS485 ports: BMS signal transmission for battery modules and for battery capacity extension in parallel.

13. Dry contact: Dry Contact Terminal: provided 2 ways input and 2 ways output dry contact signal.

way 1 way 2

14. ADD: In parallel, band switch using four dip switch to address set cell system.The explanation of its dial switch

as shown in below table.

Address Code

ADD

PACK

Definition

Explanation

1

2

3

4

OFF

OFF

OFF

OFF

0

Use Alone

ON

OFF

OFF

OFF

1

PACK1

Use as SlavePack1

OFF

ON

OFF

OFF

2

PACK2

Use as SlavePack2

ON

ON

OFF

OFF

3

PACK3

Use as SlavePack3

OFF

OFF

ON

OFF

4

PACK4

Use as SlavePack4

ON

OFF

ON

OFF

5

PACK5

Use as SlavePack5

OFF

ON

ON

OFF

6

PACK6

Use as SlavePack6

ON

ON

ON

OFF

7

PACK7

Use as SlavePack7

OFF

OFF

OFF

ON

8

PACK8

Use as SlavePack8

ON

OFF

OFF

ON

9

PACK9

Use as SlavePack9

OFF

ON

OFF

ON

10

PACK10

Use as SlavePack10

ON

ON

OFF

ON

11

PACK11

Use as SlavePack11

OFF

OFF

ON

ON

12

PACK12

Use as SlavePack12

5

ON

OFF

ON

ON

13

PACK13

Use as SlavePack13

OFF

ON

ON

ON

14

PACK14

Use as SlavePack14

ON

ON

ON

ON

15

PACK15

Use as SlavePack15

15. Reset: Press RESET key for 5 seconds, then start the device, press the RESET key for 5 seconds again, then

shut down the device. When the system is running, should therebe an exception, use this button to reset the

system (press / release) to ensure the stability of the system.

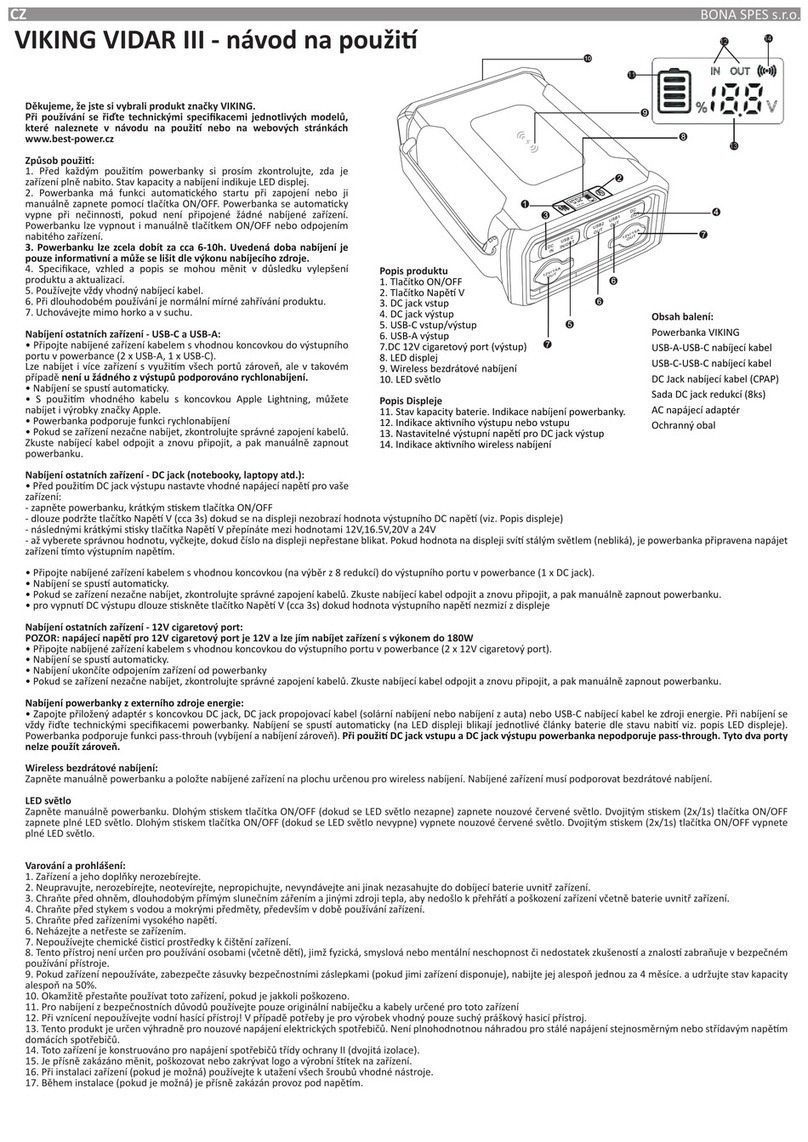

2.2 Menu Operation Instruction

The LCD display interface is user-friendly, as shown in below figure. It provides 320 * 240 dot matrix graphic display.

The LCD is able to display the alarm information inreal time, and provides the historical warning records for the user

to query, and provide a reliable basis for fault diagnosis.

Users can easily browse the battery parameters through the LCD interface, and obtain timely access to information

on the current state of the battery. The interfacedisplays a total of 5 menu keys, the functions described as follows.

The commonly used button function

Main menu

Confirm, enter

Page down

Return, launch

6

Operation Procedure

1. Press once, the LCD display screen light up, then the welcome interface will be shown.

2. Followed by the prompt and then click once to enter the main menu bar.

3. Scroll page up, Enter the Menu screen, when the points to the corresponding bar, press Enter

to confirm.

4. Go back on the menu bar, click button.

2-3. The Working Principle

Lithium battery pack is equipped with charging and discharging management moduleand monitoring module.

Charge and discharge management module protects battery charge and discharge functioning, prevents

overcharging, discharge over-current, the charging process bythe adapter charger to the DC input form, the

discharge process is completed by connecting the load discharge.

The monitoring module has the balance function and power, temperature and SOC.The monitoring module

transmits the real-time information collected in the operationof the product through the Telecom protocol network

to the monitoring platform, andthe user can observe the operation status of the battery in each group through the

display screen.

A single module has a 51.2V 100Ah, with a large capacity, can be used in accordance with user requirements

arbitrary combination as shown in below figure.

7

2-4. Product Features

Integrated lithium battery pack for Wall-Mounted has the followingremarkable characteristics:

The whole module is non-toxic, non-polluting and environmentally friendly;

The system can automatically manage charge and discharge state and balancecurrent and voltage of

each cell;

Flexible configuration, multiple battery modules can be in parallel for expandingcapacity and power

Adopted self-cooling mode rapidly reduced system entire noise;

The module has less self-discharge, up to 6 months without charging on shelf ;no memory effect,

excellent performance of shallow charge and discharge;

Working temperature range is from -20℃ to 60℃, (Charging 0~60℃; discharging -20~60℃)

with excellent discharge performance and cycle life;

Small size and light weight, standard of 19-inch embedded designed module iscomfortable for installation and

maintenance;

INTRO:

1. Telemetry: voltage, current, temperature, SOC, SOH (optional), etc.

2. Tel-signalling state of charge and discharge, overcharge / over-current, under voltage over-current alarm /

alarm, environment / battery /PCBA/ battery temperature alarm, low environmental temperature alarm, battery

capacity is too low, the battery temperature /voltage / current sensor failure alarm, batteryfailure alarm (just

not cut off the monomer pressure high limit alarm) (optional),battery failure alarm (optional).

3. Remote control: charge / discharge (optional), alarm sound off, intelligentintermittent charging mode, current

limiting charging mode.

4. Optional: Battery charge / discharge management parameters and the outputparameters of the switching

power supply system.

8

2-5. Battery Active Equalization

Because the battery capacity, internal resistance, voltage and other parameter values are not completely consistent,

this difference causes the battery with the smallest capacity to be easily overcharged and discharged during

charging, and the smallest battery capacity becomes smaller after damage, entering a vicious cycle. The

performance of single battery directly affects the charge and discharge characteristics of the whole battery system

and the reduction of battery capacity. BMS without balance function is just a data collector, which is hardly a

management system. BMS active equalization function can realize the maximum continuous 1A equalization current,

transferring the high-energy single battery to the low-energy single battery, or using the whole group of energy to

supplement the lowest single battery. During the implementation process, the energy is redistributed through the

energy storage link, so as to ensure the battery consistency to the greatest extent, improve the battery lifecycle and

delay the battery aging.

9

3. Installation Guide

3-1. Installation Precaution Notes

Comply with local laws and regulations

When operating the equipment, make certain to comply with local laws andregulations.

Personnel requirements

Technicians who are responsible for installation and maintenance are required to undertake strict training at

first. Master the correct methods for operation and safety, only then the installation, operation and

maintenance can be carried out.

In order to maximize the efficiency of the equipment, to obtain best possible operating results, and ensure

maximum lifespan, please pay careful attention to thecorrect installation and usage requirements.

Personal safety

Insulated tools and gloves should be used and worn at all times –During the installation process, watches,

bracelets, rings and other metal products shouldbe removed.

Avoid any fall or collision during the installation process.

Do not remove the battery components. The maintenance of the battery shouldbe carried out by a professional

engineer.

Should be operated and supervised by engineer who have experience and cantake preventive measures for

potential hazards of battery.

Field and environment

Site requirements

1. Cleanliness

Lithium battery packs cannot be placed in or near garbage disposals, or accidentally dropped or placed in smaller

disposal units, as their interaction with metals is likely tocause short circuits and endanger the system and personal

safety.

2. Fire protection

The room is prohibited to store flammable, explosive and other dangerous goods,and it should be equipped with

effective fire equipment (such as CO2 fire extinguishers).

3. Ventilation and heat dissipation

In order to facilitate the operation and maintenance of equipment for the heat, the equipment should be left around

(50~30) cm around at least, left about 50cm for theupper space. The space should be equipped with exhaust fan,

to maintain good indoor ventilation.

4. Installation requirements

Installation should be carried out as shown in figure 3-1 in order to avoid possiblerisks.

Put the lithium battery on the ground (to avoid tilt, uneven ground).

Avoid placing in the sunlight, rain or wet surfaces.

10

5. Environmental requirements

Ambient temperature: ( -10~+40) ℃.

Relative humidity level: 0%RH~95%RH, no condensation.

Cooling method: air cooler.

Height above sea level: match to the standard requirement of GB3859.2-93.

Verticality: no vibration and the vertical inclination does not exceed 5º.

Pollution level: Levelⅱ

Recommended operating temperature (20~25) ℃, humidity level control within 50%.

CAUTION

Do not install in the working environment with metal conduction typedust. Do not put

anything containing corrosive gases.

Do not put anything in the dust concentrated areas.

Do not place any items on the top of lithium-ion battery pack. People could notsit on

the battery.

Power Check

Before installation, please confirm that the load capability of inlet wire meets the requirements of the new

equipment. Check to see if the power supply corresponds tothe equipment nameplate of the voltage and frequency

and if the current capacity has decreased due to the aging of the wire.

If in doubt, please check with your local power supply Consultation Department.

Ground wire

Earthing terminal is ready; zero voltage required in the room cannot exceed 5V.DC output voltage and load capacity

Lithium-ion battery pack of rated DC output 51.2V.

DC output power

11

CAUTION

When installing the lithium-ion battery pack, the user should check the lithium-ion battery

pack in advance to make sure that the contacts and connectors are safely in place to avoid

an open circuit or short circuit fault.

During installation, do not connect the lithium batteries polarity in reverseor in any way

incorrectly, to avoid causing a short circuit.

Please do not connect the terminals with no security or insulation protection,so as to avoid

the risk of electric shock.

3-2. Installation Procedure

3-2-1. Unpacking and inspection

Lithium batteries and accessories use packaging of cardboard boxes or wooden boxes. When unpacking, be careful

when dismantling. Inspect the device and accessories according to the package list, to ensure it’s complete and

make certainnothing was damaged during shipping.

Before clearing the packaging, make sure that all parts are included. If equipmentor accessories are damaged in

transit, or incomplete or incompatible, the equipment, accessories and order contracts should be recorded andlocal

dealer should be contacted immediately.

The site needs to be tidied and inspected once again to make sure the audit documents are in order for the audit.

Before inspection, the site should be clean.

3-2-2. Installation Tools

Potential commonly used tools as shown in below tables the field technician willincrease or decrease the amount

according to the construction.

Table 1: General purpose tools

The appearance of the tools, parameters, and names

Adjustable

wrenches

Phillips screwdriver

Slotted screwdriver

Socket wrench

Torque wrench

Open-end

wrenches

Double offset ring

spanner

Diagonal cutting

pliers

Wire cutters

Needlenosed pliers

Marking pen

Working gloves

12

Ladder (2m)

Flashlight

Tape measure

Impact drill

Table 2: Tools for delivery and unpacking

The appearance of the tools, parameters, and names

Manual forklifts

Electric forklift

Sling

(weight≥400kg)

Leverage

(weight≥400kg)

Table 3: Electrical installation tools

The appearance of the tools, parameters, and names

Insulated gloves

Power cable

crimping plier

Wire stripping pliers

Electrical tape

Table 4: Measuring Tools

The appearance of the tools, parameters, and names

Clamp the flow table

13

3-3. Installation Method

1. Use expansion screws to fix the accessory bracket shown below on the wall.

2. Hang the battery box on the stand.

3. Use M6 screws to secure the case from both sides.

14

4. Maintenance

In order to ensure the lithium-ion battery pack achieves the longest life cycle, the maintenance technician should

carry out regular inspections and maintenance care. The maintenance records should be complete and routine, so

that subsequent verification of management parameters of the battery pack can be tracked.

4-1. Electrical Maintenance

Maintenance of the electrical parts may refer to table.

Items

The checking Points

Methods

Repair conditions

Repair solution

Electrical

Check if theOutput

of the voltage is

normal.

Multimeter

Battery voltage out of

range set

See the following

troubleshooting

section

Fault

inspection

Check if lights are

normal

Visual

inspection

Alarm

Cable

Insulation,

Terminal

Visual

inspection

Insulation cracks,

aging

Replace the cable.

Exfoliated,

corrosion of the

terminals

Replace the terminal

block

4-2. Battery Maintenance

Frequency

Items

Solutions

Monthly

Operating

environment

Stay away from heat source and avoid direct sunlight.

Visual

inspection

If there is any breakage, leakage or deformation,Isolate the

problematic battery pack, take a photograph and replace the

battery.

Quarterly

Visual

inspection

Use cotton cloth to clean the appearance. Be carefulduring cleaning

because the voltage is high.

Connection

status

Check each terminal, check the bolt, if it’s loose,and tighten

it again.

Check the reason if the cabletemperatureexceeds 40℃.

Every 6

months

Measure and

recordthe

voltage

At the final stage of charging, record the voltage; make sure

the positive and negative voltage of the battery are the same.

Otherwise, should check and repair the corresponding

connection cable.

Collect the discharging data at least once everysix months

for the first year.

In the second year, capacity is determined by every three

months. Through the RS232interfaceto view history, which

shows frequent overchargeof a battery in the alarm message,

indicating thatthe batteries have reached the charging and

discharging protection point. This may result in time for

preparing electricity is not enough and suggest changing the

battery immediately.

15

4-3. Trouble Shooting Steps

①Problem determination based on:

1. Whether the battery can turn on or not;

2. If battery is turned on, check the red light is off, flashing or lighting;

3. If the red light is off, check whether the battery can charge/discharge or not.

Preliminary determination steps

1. Battery cannot turn on, switch on the lights are all no lighting or flashing.

If the battery external switch is ON, the RUN light is flashing, and the external power supply voltage is 51.2V or

more, the battery still unable to turn on, pleasecontact local dealer or installer.

2. The battery can be turned on, but red light is lighting, and cannot charge or discharge. If the red light is

lighting, that means system is abnormal, pleasecheck values as following:

a. Temperature: Above 50℃or under -10℃, the battery could not work.

Solution: to move battery to the normal operating temperature range between -10℃and 50℃

b. Current: If current is greater than 100A, battery protection will turn on.

Solution: Check whether current is too large or not, if it is, to change the settingson power supply side.

c. High Voltage: If charging voltage above 54V, battery protection will turn on.

Solution: Check whether voltage is too high or not, if it is, to change the settingson power supply side.

d. Low Voltage: When the battery discharges to 44.5V or less, battery protection will turn on.

Solution: Charge the battery for some time, the red lightturn off

Excluding the four points above, if the faulty is still cannot be located, turn off battery andrepair.

3. The battery cannot be charged or discharged

a. Cannot be charged:

Disconnect the power cables, measure voltage on power side, if the voltage is 53~54V, restart the battery, connect

the power cable and try again, if still not work, turn off battery and contact local dealer or installer.

b. Unable to discharge

Disconnect the power cables and measure voltage on battery side, if it is under44.5V, please charge the battery; if

voltage is above 51.2V and still cannot discharge, turn off battery and contact local dealer or installer.

16

5. Specification

5-1. Technical Specification

The main physical dimensions for a single module is shown below and refer to below specification table for r a

single battery module.

Outline Drawing

17

Specification of one single module

Rated Capacity (5HR)

100 Ah

Nominal Voltage

51.2 V

Discharge ending voltage

43.2V

Charging limited voltage

58.4V

Max. charging current

50A

Max. continue discharge current

100A

Weight

Aprox. 43 kg

Display

With display screen

Protocol

CANBUS

Parallel connection

Parallel connection is up to 15 pcs

(optional)

Dimension (W x D x H) mm

450 x 500 x 140 mm

Design life

More than 15 years

Cycle life

3500 times @ 25°C 0.5C,80% DOD

IP class

IP65

Outer package material

White bake lacquer steel case

(optional)

Operating temperature

Charging: 0 to +60°C, Discharging: -20 to +60°C

Storage: -20 to +60°C

5-2. Main performance index of the battery

The electrical performance is listed below table.

Items for test

Testing methods

Requirements

0.1C

discharge

performance

Standard battery charge, 1h within 1h

with 0.1C discharge current to 43.2V,

Record the discharge time.

Discharge time ≥600min

0.5C

discharge

performance

Standard battery pack, 1h within 0.5C

discharge current to 43.2V, record the

discharge time.

Discharge time≥ 115min

High

temperature

performance

After the battery pack is charged in the

standard (60 ± 2) ℃ high temperature

box for 4 hours and thendischarged to

43.2V at 0.1C, record the discharge

time.

Discharge time≥ 600min

18

Low

temperature

performance

(-10 ℃)

After charging, the battery pack is put in

the low temperature box of(-10 ± 2) ℃

for 6 hours, then discharged to 43.2V at

0.2C at this temperature, record the

discharging time.

Discharge time≥ 180min

Low

temperature

performance

(-20 ℃)

After charging, the battery pack is

allowed to stand for 6 hours at (-20 ± 2)

℃, then discharged to 43.2V at 0.2C at

this temperature. Record discharge time.

Discharge time≥ 120min

Table of contents