MPS R60T User manual

Model Number R60T

Air Pressure Booster System • Installation and Operating Instructions

Midwest Pressure Systems, Inc.

RAV Rev. 0

MPS

M I DW E ST

PRESSURE

SY S T E M S

MPS

M I D W E S T

PRESSURE

S YS T E M S

MPS

M I D W E ST

PRESSURE

SYS T E M S

MPS

M I D W E S T

PRESSURE

SY S T E M S

MPS

M ID W E S T

PR ESSURE

S YS T E MS

MPS

M I D W E S T

PRESSURE

SYS T E M S

MPS Logos

12/5/91

1/2" Square

3/4" Square

1" Square

1-1/4" Square

1-1/2" Square

2" Square

MPS

M ID W E S T

PR ESSURE

S YS T E MS

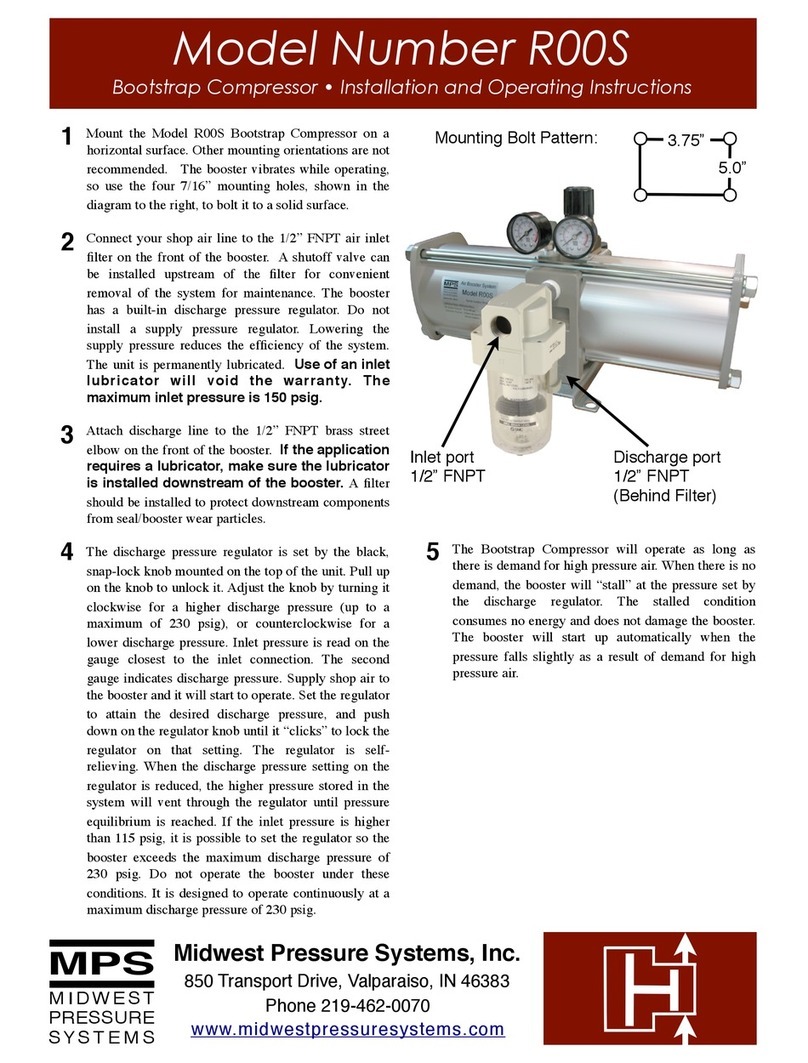

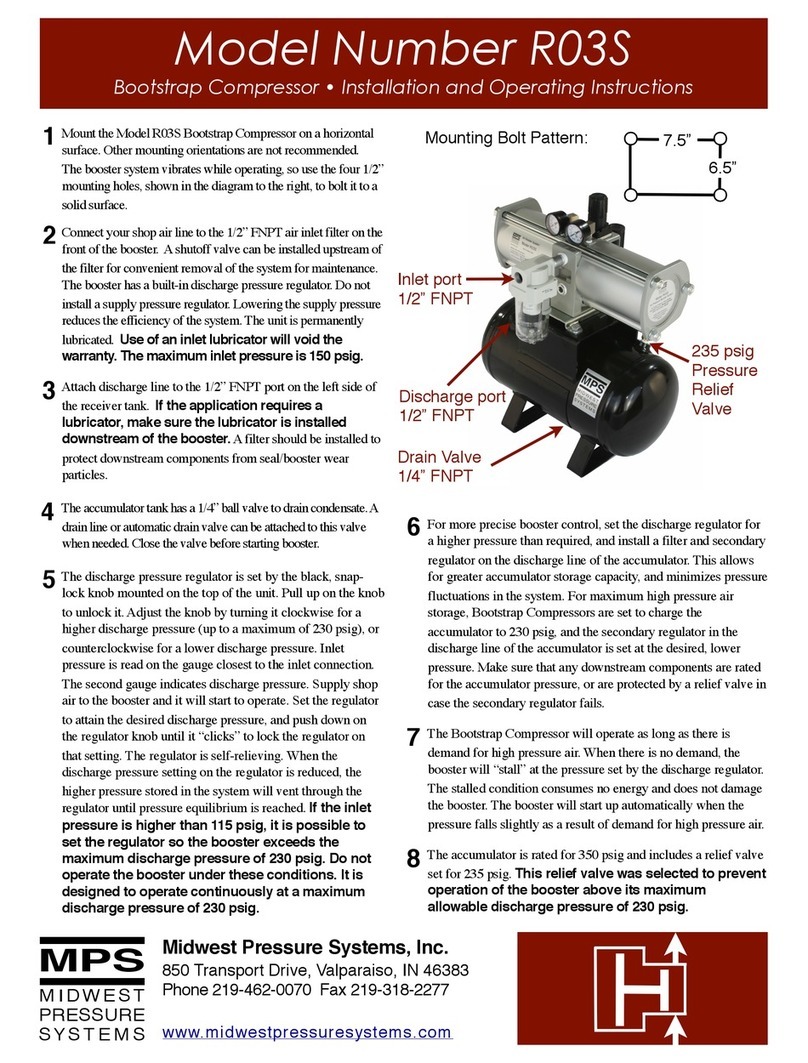

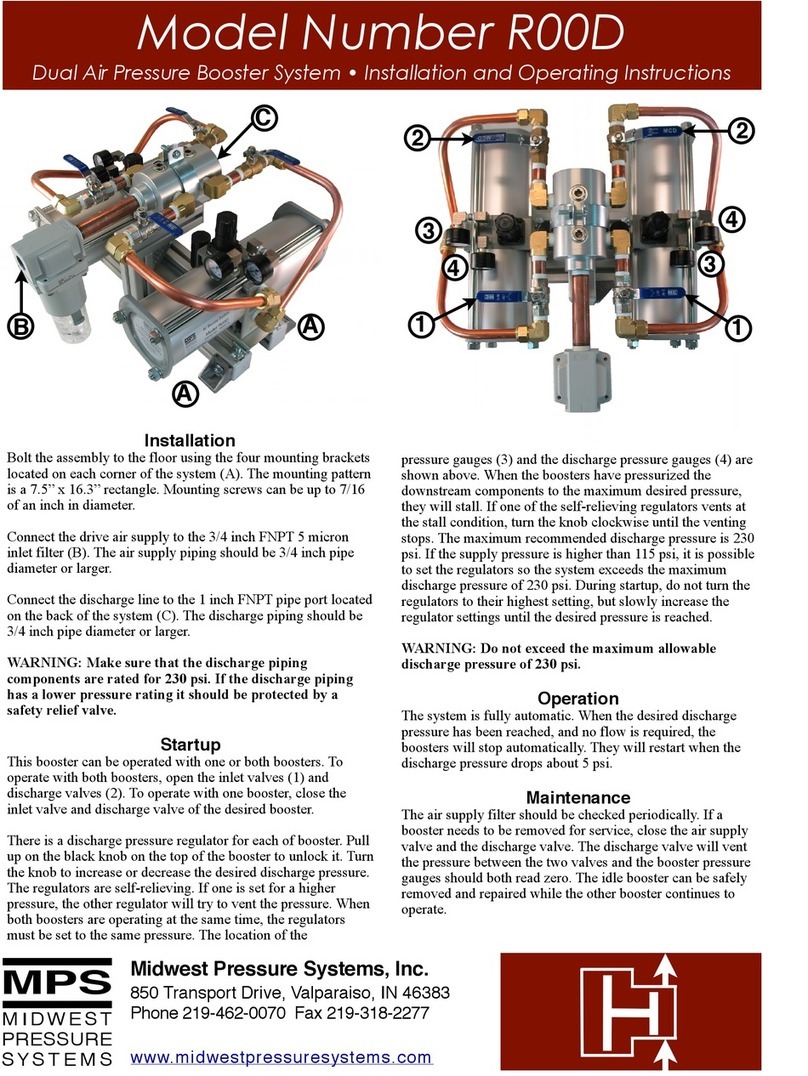

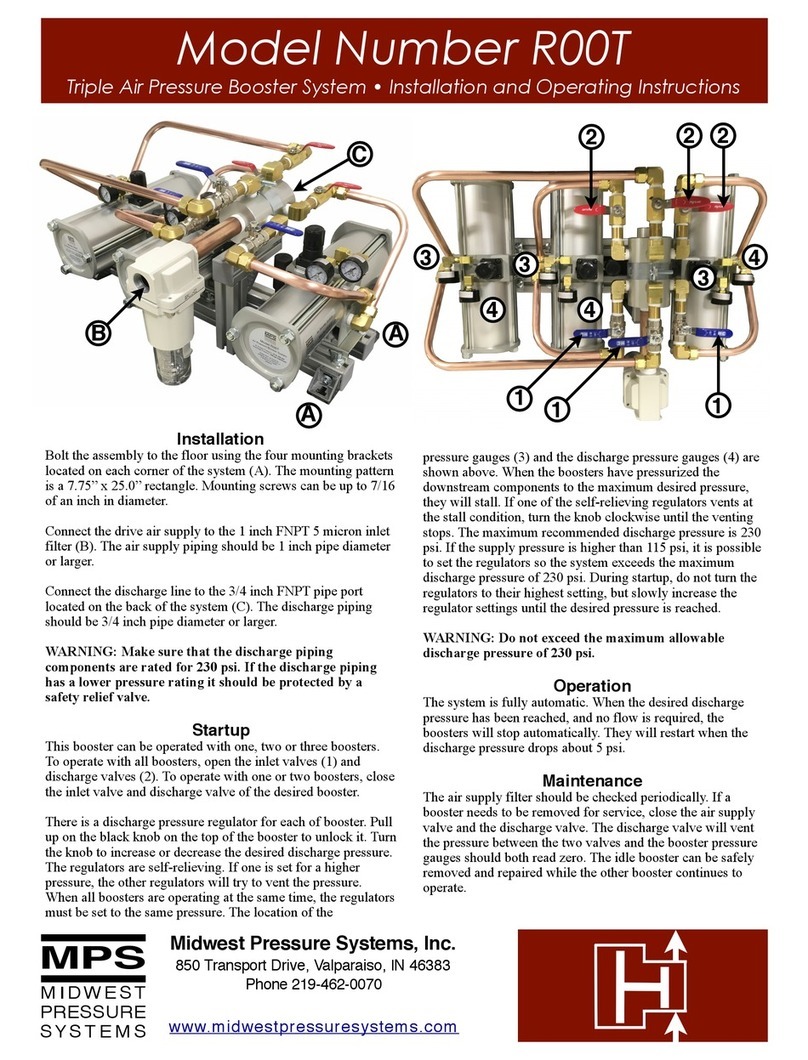

Installation

1 Bolt the tank to the floor using the four 1/2

inch diameter mounting holes (A).

2Connect your drive air supply to the 1

inch NPT inlet filter shown above (B). The air

supply piping should be 1 inch pipe diameter

or larger.

3Connect your discharge line to the 2 inch

NPT pipe port shown above (C). There are

several other plugged ports on the tank that

can be used for the discharge line.

4Attach your condensate drain line to the

1/4 NPT port on the valve shown above (D).

Make sure that your discharge piping

components are rated for 200 psi.

Startup

1This system can be operated with one, two, or all three boosters. To operate with all

three boosters, open the inlet (E) and discharge valves (F). To operate with one booster,

close the inlet and discharge valves of the idle boosters.

2There is a discharge pressure regulator for each booster. Pull up on the black

knob on the top of the booster to unlock it. Turn the knob clockwise for a higher

discharge pressure and counterclockwise for a lower pressure. If all of the boosters

are operating, set the regulators for the same discharge pressure. The regulators are

self relieving so if one is set for a higher pressure, the other regulators will try to vent

the pressure. The pressure gauges marked (G) indicate inlet pressure and the gauges

marked (H) indicate discharge pressure. When the boosters have pressurized the tank

to the maximum desired pressure, they will stall. If one of the regulators vents at the

stall condition, turn the knob clockwise until the venting stops. The maximum

recommended discharge pressure is 190 psi. The relief valve is set for 200 psi. If the

supply pressure is higher than 95 psi, it is possible to set the regulators so the system

exceeds the maximum discharge pressure of 190 psi. During startup, do not turn the

regulators to their highest setting, but slowly increase the regulator settings until the

desired pressure is reached.

Operation

The system is fully automatic. When the desired discharge pressure has been

reached, and no flow is required, the boosters will stop automatically. They will

restart when the pressure drops about 5 psi.

Maintenance

The air supply filters and condensate drain should be checked periodically. If a

booster needs to be removed for service, close the air supply valve and the discharge

valve. The discharge valve will vent the pressure between the two valves and the

booster pressure gauges should both read zero. The booster can safely be removed

and repaired while the system continues to operate.

A

A

B

C

D

E

E

F

H

G

F

G

H

F

E

H

G

Midwest Pressure Systems, Inc.

850 Transport Drive, Valparaiso, IN 46383

Phone 219-462-0070

www.midwestpressuresystems.com

Model Number R60T

Bootstrap Compressor • Operation and Warranty

Midwest Pressure Systems, Inc.

RAV Rev. 0

MPS

M I DW E ST

PRESSURE

SY S T E M S

MPS

M I D W E S T

PRESSURE

S YS T E M S

MPS

M I D W E ST

PRESSURE

SYS T E M S

MPS

M I D W E S T

PRESSURE

SY S T E M S

MPS

M ID W E S T

PR ESSURE

S YS T E MS

MPS

M I D W E S T

PRESSURE

SYS T E M S

MPS Logos

12/5/91

1/2" Square

3/4" Square

1" Square

1-1/4" Square

1-1/2" Square

2" Square

MPS

M ID W E S T

PR ESSURE

S YS T E MS

Compression

Chamber A1

Compression

Chamber A2 Drive

Chamber

B2

Drive

Chamber

B1

Piston 1 Piston 2

4-way

Valve

Switch

4-way

Valve

Switch

Pilot Signal to regulator

Built-in discharge regulator

Regulated drive air

Plant air

Exhaust air

Pilot signal to regulator

High pressure air Exhaust air

Regulated drive air

Please refer to the operating description on the right, and the

schematic above to gain an understanding of the design principles

and mechanical function of the R60T Model Booster System. The

moving parts of each Bootstrap Compressor are permanently

lubricated with a multipurpose grease (except for the check valves).

Operation with a lubricator upstream voids the warranty. If a

lubricator is required, it should be installed on the downstream

(discharge) side. A well-maintained 5 micron inlet air filter is

required to maintain the warranty by ensuring that no dust particles

enter the units and foul the seals, or cause premature wear of the

highly-polished seal surfaces. The wear parts in the boosters consist

of check valves, springs and dynamic seals. These parts are

designed for 1800 miles of piston travel. The four-way valve, which

controls movement of the pistons, is a lapped, stainless steel valve

with no elastomeric seals subject to wear. Under normal conditions,

this valve will provide many years of operation. The discharge

regulator built into the center of the unit sees very little wear, and is

designed to provide many years of service under normal conditions.

The wear parts are typically replaced 2 to 3 times before a valve or

regulator kit is required.

#KRW • Wear parts kit

#KRV • Valve kit

#KRR • Regulator kit

The plant air stream always fills Compression Chambers A1 and A2

directly, through a set of check valves. These two chambers are

always pressurized to the maximum initial air pressure available

(the R60T Model Booster System is not designed for inlet air

pressures higher than 150 psig). A branch of the plant air stream

flows through a pilot-activated regulator, which reduces the pressure

to the level required to attain the desired Bootstrap Compressor

discharge pressure (the discharge pressure is set manually by

adjusting the regulator handle). This regulated air stream flows

through a four-way valve which directs it to Drive Chamber B2. At

the same time, the four-way valve opens Drive Chamber B1 to

exhaust. The pressure force exerted on the interconnected pistons by

the pressures in Drive Chamber B2 and Compression Chamber A1,

is sufficient to compress the air in Chamber A2 to a higher pressure

(the maximum discharge pressure attainable is two times the plant

air pressure). At the end of its travel, Piston 2 switches the four way

valve, which opens Drive Chamber B2 to exhaust, and pressurizes

Drive Chamber B1 with regulated drive air, thus reversing the

direction of the interconnected pistons, until Piston 1 switches the

valve back to its original position. The interconnected pistons

shuttle back and forth continuously, producing a high pressure air

stream, determined by the discharge pressure set on the built-in

regulator. The R60T Model is designed to operate at a maximum

discharge pressure of 190 psig. Higher discharge pressures, though

possible, can result in catastrophic failure of the booster.

Operating Description

General Concerns

Midwest Pressure Systems, Inc. warrants the R60T Model Booster System to be free of defects in material and workmanship for a

period of one year after purchase, except piston seals, rod seals, and check valves which are warranted for six months after purchase. We

will either repair or replace a failed unit returned by the customer. No other warranty is expressed or implied. Proof of the purchase

date is required. This warranty does not apply to equipment which has been abused, and is voided by use of a lubricator, or failure to

use a well-maintained inlet filter. Customer must obtain a return authorization number before shipping the unit to the factory.

WARRANTY

Midwest Pressure Systems, Inc.

850 Transport Drive, Valparaiso, IN 46383

Phone 219-462-0070

www.midwestpressuresystems.com

Table of contents

Other MPS Air Compressor manuals

Popular Air Compressor manuals by other brands

GEA

GEA HGX34/130-4 ML CO2 T Assembly instructions

DeWalt

DeWalt DXCMV5048055 instruction manual

Craftsman

Craftsman 921.16475 owner's manual

Einhell Global

Einhell Global EURO 8/24 operating instructions

Clarke

Clarke RACER 9/100P (3PH) Operation & maintenance instructions

Sealey

Sealey SA9925/1.5 instructions

Senco

Senco PC1010N operating instructions

ESSVE

ESSVE C 5/10 manual

Ranger Products

Ranger Products R7580H-601 Installation and operation manual

King Canada

King Canada 8400 instruction manual

Campbell Hausfeld

Campbell Hausfeld FP204020 Operating instructions and parts manual

AllTrade

AllTrade 647376 instruction manual