MQ Whiteman WM-900S User manual

© COPYRIGHT 2001, MULTIQUIP INC.

PARTS AND OPERATION MANUAL

PLASTER / MORTAR MIXERS

WM-900S

WM-900P

Revision #7 (03/17/06)

Go to Discount-Equipment.com to order your parts

Discount-Equipment.com is your online resource for quality parts & equipment.

Florida: 561-964-4949 Outside Florida TOLL FREE: 877-690-3101

Need parts?

Click on this link: http://www.discount-equipment.com/category/5443-parts/ and

choose one of the options to help get the right parts and equipment you are looking

for. Please have the machine model and serial number available in order to help us

get you the correct parts. If you don’t find the part on the website or on one of the

online manuals, please fill out the request form and one of our experienced staff

members will get back to you with a quote for the right part that your machine needs.

We sell worldwide for the brands: Genie, Terex, JLG, MultiQuip, Mikasa, Essick, Whiteman,

Mayco, Toro Stone, Diamond Products, Generac Magnum, Airman, Haulotte, Barreto,

Power Blanket, Nifty Lift, Atlas Copco, Chicago Pneumatic, Allmand, Miller Curber, Skyjack,

Lull, Skytrak, Tsurumi, Husquvarna Target, Stow, Wacker, Sakai, Mi-T-M, Sullair, Basic,

Dynapac, MBW, Weber, Bartell, Bennar Newman, Haulotte, Ditch Runner, Menegotti,

Morrison, Contec, Buddy, Crown, Edco, Wyco, Bomag, Laymor, EZ Trench, Bil-Jax, F.S.

Curtis, Gehl Pavers, Heli, Honda, ICS/PowerGrit, IHI, Partner, Imer, Clipper, MMD, Koshin,

Rice, CH&E, General Equipment ,Amida, Coleman, NAC, Gradall, Square Shooter, Kent,

Stanley, Tamco, Toku, Hatz, Kohler, Robin, Wisconsin, Northrock, Oztec, Toker TK, Rol-Air,

APT, Wylie, Ingersoll Rand / Doosan, Innovatech, Con X, Ammann, Mecalac, Makinex, Smith

Surface Prep,Small Line, Wanco, Yanmar

PAGE 2 —WHITEMANWM-900S,900P — PARTS & OPERATION MANUAL — REV.#7 (03/17/06)

Go to Discount-Equipment.com to order your parts

PAGE 4 —WHITEMANWM-900S,900P — PARTS & OPERATION MANUAL — REV.#7 (03/17/06)

TABLE OF CONTENTS

NOTE: Specification and part number

are subject to change without notice.

Here's How To Get Help.......................................... 3

Table of Contents .................................................... 4

Parts Ordering Procedures .....................................5

Rules for Safe Operation & Safety Decals.............. 6

Warranty.................................................................. 7

WHITEMAN — 900S & 900P

Operations ......................................................... 8-10

Specifications ........................................................ 11

Explanation Of Codes In Remarks Column .......... 12

Suggested Spare Parts......................................... 13

Drum Head Assembly ...................................... 14-15

Paddle Shaft Assembly .................................... 16-17

Steel Drum (S) ................................................. 18-19

Polyethylene Drum (P) ..................................... 20-21

Gas Engines, Pulleys & Cab Assembly............ 22-23

Electric Motor & Pulleys ................................... 24-25

Axle & Wheel Group......................................... 26-27

Terms and Conditions Of Sale — Parts ................ 28

Go to Discount-Equipment.com to order your parts

PAGE 6 —WHITEMANWM-900S,900P — PARTS & OPERATION MANUAL — REV.#7 (03/17/06)

RULES FOR SAFE OPERATION & SAFETY DECALS

The safety instruction decal is P/N 924801

SAFETY INSTRUCTIONS

1. Read owners manuals before operating.

2. Keep unauthorized and untrained people away from machine during operation.

3. Make sure all safety devices are in place before this machine is started.

4. Make sure engine is turned off and spark plug wire is disconnected before cleaning the

machine.

5. Keep hands and fingers away from moving objects.

6. Do not operate machine in an enclosed area. Proper ventilation is required.

7. Never leave machine unattended when operating.

8. Always stop engine and allow engine to cool before adding fuel or oil.

Ñ Ñ ,

■

Do not operate or service this equipment

beforereadingtheoperatingandmaintenance

instructions manual or serious injury may

result.

■

Do not operate this equipment unless all

guards and safety devices are attached and

in place.

■

Stop the engine when leaving the

equipment.

■

Block theunit whenleaving or when using

on a slope

■

Maintainthisequipmentinasafeoperating

conditionat alltimes.

■

Caution must beexercised whileservicing

thisequipment.Rotatingandmovingpartscan

causeinjuryif contacted.

■

Stop the engine before servicing, adding

fuel and oil.

■

When towing, an adequate safety chain

mustbefastenedtotheframe,refertopage 9.

■

Keep all inexperienced and unauthorized

peopleaway fromthe equipmentat alltimes.

■

Unauthorizedequipmentmodifications will

voidall warranties.

■

Checkallfastenersperiodicallyfortightness.

Also check towing tongue bolt, lock nut and

wheellug nutsforwear.

■

Wear safety glasses at all times when

workingaround machinery.

■

Stop the engine and disconnect the spark

plug before allowing anybody’s hands in the

mixingdrum.

■

Never pour or spray water over the engine

orelectric motor.

■

Always stand clear of dump handle when

mixer is in operation. Any binding of material

betweenthemixerbladesand drumwillcause

drum and handle to quickly move in the

dischargeposition.

The safety instruction decals shown must be on all Whiteman Mixers

Caution Decal is:

P/N EM948423

CAUTION!CAUTION!

CAUTION!CAUTION!

CAUTION!

SHUT OFF ENGINE BEFORESHUT OFF ENGINE BEFORE

SHUT OFF ENGINE BEFORESHUT OFF ENGINE BEFORE

SHUT OFF ENGINE BEFORE

PUTTING HANDS IN MIXING DRUMPUTTING HANDS IN MIXING DRUM

PUTTING HANDS IN MIXING DRUMPUTTING HANDS IN MIXING DRUM

PUTTING HANDS IN MIXING DRUM

Go to Discount-Equipment.com to order your parts

WHITEMANWM-900S, 900P— PARTS &OPERATION MANUAL— REV. #7(03/17/06) —PAGE 7

WARRANTY

Therearenowarranties,expressorimplied, made byMultiquip

Inc. hereunder on Products manufactured or distributed by it

exceptthewarrantyagainstdefectsinmaterialandworkmanship

on new Products to the original purchaser, as hereinafter set

forth.

Multiquip Inc. warrants Products manufactured by it to be free

from defects in material and workmanship under normal and

properuseand servicing fortheperiods specifiedonthe bottom

ofthispage.Warrantyontheenginessuppliedwiththe Products

islimited tothe warrantyextendedbytheengine manufacturer.

MultiquipInc.’soleobligationunderthis warrantyislimitedtothe

replacement or repair, at its Carson, California facility, or such

authorized facility, of only such part or parts thereof as shall

appearto MultiquipInc.uponinspection at such facility,to have

beendefectiveinmaterial and workmanship.

Astatementgivingmodelandserialnumberofthe Product, date

ofsale to originalpurchaser and date and description of failure

shallaccompany all parts.

AnypartorpartsdeterminedbyMultiquipInc.tobedefectivewill

bereplaced freeof charge,F.O.B.Carson,California.Returned

parts subject to warranty must be shipped prepaid to Multiquip

Inc.within30daysfromthedate thedefectivepartor partswere

removed.Thiswarrantydoesnotapplytoanypartorpartswhich

havebeen subject toabuse or unauthorizedrepairs

WarrantywithrespecttoProducts,componentsandaccessories

not manufactured by Multiquip Inc. is limited to the warranty

extendedbythe manufacturerof thoseitems.

There are no warranties, express or implied, in addition to the

above except as may be provided in writing by Multiquip Inc.

MULTIQUIPINC.SHALLNOTBELIABLEFORANYSPECIAL,

INDIRECTORCONSEQUENTIALDAMAGES.

THEFOREGOINGWARRANTIESAREINPLACEANDINLIEU

OF ALL WARRANTIES OF MERCHANTABILITY AND

FITNESS AND SETS FORTHTHE ENTIRE OBLIGATION OF

MULTIQUIP INC.

To avoid misrepresentations with respect to Products sold

hereunder, the Dealer agrees that no warranties, or other

operatingguarantiesonanyProductscoveredbythisAgreement

shallbe made inexcess of those made byMultiquip Inc.

Multiquip Inc.Warranty Periods:

WM-900 ........................ 12months

Go to Discount-Equipment.com to order your parts

PAGE 8 —WHITEMANWM-900S,900P — PARTS & OPERATION MANUAL — REV.#7 (03/17/06)

WM-900S,900P — OPERATIONS

GENERAL

TheWhitemanWM-700andWM-900Seriesplasterandmortar

mixersare quality mixersthat havea batchcapacity of2.5 and

3.5bagsrespectively.Withpropercare,theywillgivecontinuous

serviceyear-after-year.

BEFORE STARTING

Before starting the engine, read the engine owners manual

and thoroughly understand the safety information.

Check the items listed below:

Oil Levels. Be sure to check the oil levels in the engine and

engine reduction unit before starting the unit.

Hardware. Check all hardware on the mixer before starting.

Periodically inspect all hardware. Loose hardware can

contribute to early component failure and poor performance.

Use the torque chart below as a general guideline and keep

all hardware tight:

HARDWAREDIA TORQUE(LB./FT.)

%/16

"-18 14

#/8"

-16 24

#/8"

- 24 37

½" - 13 39

½" - 13 (Grade 8) 90

GASOLINE ENGINE CARE

For care and operation of the gasoline engine, refer to the

engine manufacturer’s operating instructions furnished with

the engine.We recommend draining and refilling the engine

crankcase at least every thirty hours of operation.Check the

engine oil level daily.

Referto the followingchart. Forrecommend plugsizes.

CONTROLS

KILL SWITCH: (Gasoline EngineOnly) Locatedon the sideof

theengine cover.

ENGINETHROTTLEANDCHOKECONTROLS: Pleaserefer

to the engine owners manual for specific instructions. The

electricmotorswitch (electricmotor only)locatedon themotor

— is used to start and stop the mixer.

DUMP LATCH: To dump the tub, grasp the dump handle and

lift the dump latch, then rotate the tub to discharge the mix.

After, discharge,returnthetub tothe vertical mixingposition.

ROTOM Ø1TLOV511 007MW Ø1TLOV032 009MW

ESROH REWOP

PACLIATGIP /AMEN NAMETIHW

YDOBNNOC /AMEN NAMETIHW

PACLIATGIP /AMEN NAMETIHW

YDOBNNOC /AMEN NAMETIHW

PH3&½1 545049/P03-5L645049/R03-5L055049/P51-6L155049/R51-6L

CLUTCH

The paddle shaft and mixing blades are engaged and

disengaged by tightening and loosening the drive belts with a

springloaded idlerpulley.Toengagetheclutch, rotatethelever

counterclockwise.Thespringmaintainsthecorrectbelttension.

Todisengagethe clutch,rotate theleverclockwiseagainst the

leverstop.The enginebaseisslotted toadjustforbeltwearand

tobring the idlerpulley into operating range.

CAUTION: Stop the engine before allowing anybody to put

theirhands in themixing drum.

WHEEL BEARINGS

Afterevery3monthsofoperation,removethehubdustcapand

inspect the wheel bearings. Once a year, or when required,

disassemblethewheelhubsremovetheoldgreaseandrepack

the bearings forcing grease between rollers, cone and cage

with a good grade of high speed wheel bearing grease (never

usegreaseheavier than 265A.S.T.M.penetration(“No.2.”)Fill

the wheel hub with grease to the inside diameter of the outer

races and also fill the hub grease cap. Reassemble the hub

and mount the wheel. Then tighten the adjusting nut, at the

same time turn the wheel in both directions, until there is a

slight bind to be sure all the bearing surfaces are in contact.

Thenback-offthe adjustingnut

!/6

to¼ turn ortothe nearest

locking hole or sufficiently to allow the wheel to rotate freely

withinlimitsof.001"to.010"endplay.Lockthenutatthisposition.

Installthe cotter pin and dustcap, and tightenall hardware.

ELECTRIC MOTOR CARE

Forlubricationcare andoperationof theelectricmotor,referto

yourelectricmotorinstructionbookletfurnishedwiththemotor.

Protect the electric motor from dust as much as possible and

keep ventilating openings clean. Do not spray water on the

electricmotor.

Go to Discount-Equipment.com to order your parts

WHITEMANWM-900S, 900P— PARTS &OPERATION MANUAL— REV. #7(03/17/06) —PAGE 9

WM-900S,900P — OPERATIONS

BEARING BRACKET

Greasethe bearingbracket everymonth.

COUNTERSHAFT

The countershaft rotates on two self-aligned pillow block

bearings.Grease theseevery 40 hoursusing grade#1 Lithium

Basegrease.

GEAR ALIGNMENT

The countershaft and driven pinion are mounted on a slotted

base.To align gears,loosenthepillowblockmountingbolts and

movethem untilthe necessary alignment hasbeen made.

GEAR LUBRICATION

The surface of the pinion and the bull gear

shouldbeverylightlygreasedevery250hours.

IMPORTANT! AVOID OVER-GREASING.

EXCESS GREASE WILL ACCUMULATE

CONTAMINATESAND CAUSEPREMATURE

WEAR.

IMPORTANT — DRUM HEAD SEAL CARE

Greasesealsevery40hoursofoperationusing

any grade #1 lithium base grease. Apply

grease until visible inside of mixing tub

(overgrease). This will purge seal system of

contamination.

DRUM GRILL

The drum opening is covered by a steel grill that is hinged for

easycleaning.Thisgrillshouldbe closedatalltimeswhen mixer

is in use.Do not remove the grill or grill opening bar.Keep the

grill clean by washing it down daily.

CAUTION:Stoptheenginebeforeallowinganybodytoputtheir

handsin the mixingdrum.

TOWING — Before towing, check with local and state

laws for proper compliance.

The tow bar and chain must be properly attached to the mixer

and towing vehicle prior to towing. Refer to the following

installationinstruction:

Step 1. InserttheDrawBarintothemainframe.Secure,utilizing

the¾"bolt (grade5)andnylocknut.Tighten to100footpounds.

Step 2. Install the chain through the hole located between the

framegussetandframeangle.Loopthechaintogetherandplace

underthe Draw Bar.Securewith connectorlink.

Step 3. Extend the chain along the length of the Draw Bar,

remove excess chain (slack) and secure to bottom connector

link.Securethe chaintothe towingvehicle,using theconnector

link.

NOTE: Itiscriticalthat thelengthof chainbeproperlyadjusted

toprevent theDraw Barand frontmixer standfrom

droppingto theground (contact)in theevent theDraw

Barbecomes disconnectedfrom thetowing vehicle.

BOLT & NUT

DRAWBAR

STEP 1

VEHICLE

CONNECTORLINK

CONNECTORLINK

FRAME ANGLE

FRAME GUSSET

INSERTCHAINTHROUGH

THE HOLE

DRAW BAR

BOTTOMCONNECTORLINK

REMOVE EXCESS

CHAIN(SLACK)

STEP 3

STEP 2

DRAWBAR

SAFETY CHAIN .........................................P/N 3148

CONNECTOR LINK ...................................P/N01004

Go to Discount-Equipment.com to order your parts

PAGE 10 —WHITEMANWM-900S,900P — PARTS & OPERATION MANUAL — REV.#7 (03/17/06)

END SCRAPEREND SCRAPER

END SCRAPEREND SCRAPER

END SCRAPER

WM-900S,900P — OPERATIONS

BALL HITCH COUPLER

1. Checkvehiclehitch, ball,and couplerfor signs ofwear or

damage. Replace any parts that are worn or damaged

beforetowing.

2. Useonlythe2"balldiameteras indicatedonyourcoupler.

Use of any other ball diameter will create an extremely

dangerousconditionwhich canresult in separationof the

coupler and ball or ball failure.

3. Be sure the coupler is secured to the hitch ball and the

locklever is down tightand locked.

Rechecktightness againafter towingabout 50 miles.

4. Checkthattrailer safetychains areproperly connected.

DANGER If housing is deformed,

replace complete coupler.

USE ONLY GENUINE

FULTON REPAIR KITS.

DANGER BEFORETOWING

RECOMMENDEDMAINTENANCE

1. Smear ball socket and clamp face with chassis grease.

Periodically oil pivot points and solutions surfaces of

couplerwith SAE 30wt. motoroil.

2. Whenparking or storingyourtrailer.Keepthecoupler off

the ground so dirt will not build up in the ball socket.

CLEANING — BLADE ADJUSTMENTS

Alwaysdisconnectthesparkplugwirebeforecleaningtheinside

ofthedrum.

Never pour or spray water over the gasoline engine or electric

motor.

For consistent performance, long life and high quality mixing,

thoroughly clean the mixer inside and out at the end of each

day’s operation.To prevent lumps of dried mortar from forming

and contamination of future batches, do not allow a buildup of

materialsto form on the bladesor anywhere insidethe drum.

SIDE SCRAPERSIDE SCRAPER

SIDE SCRAPERSIDE SCRAPER

SIDE SCRAPER

2) POLYETHYLENE DRUM MIXERS

Thepoly blade shouldcome asclose aspossible tothesurface

withouttouching.If materialbuildsupon thedrum,you mayuse

arubbermallettodislodge thematerialwithoutadverseeffect to

thedrum.

IMPORTANT NOTICE

EPOXYCOMPATIBILITY—Therearesomeexpoxiesandother

chemicals used in certain applications that are not compatible

withpolyethylene tubs.

Since Whiteman Industries cannot control the end user’s

applicationof thisproduct, wewill notassume responsibility for

theresultingdamageswhenexposedtoincompatiblechemicals.

Thefollowing is therecommended wiper bladeadjustments:

1) STEEL DRUM MIXERS

Go to Discount-Equipment.com to order your parts

WHITEMANWM-900S, 900P— PARTS &OPERATION MANUAL— REV. #7(03/17/06) —PAGE 11

WM-900S,900P — SPECIFICATIONS

WM-900S SPECIFICATIONS

MODEL U.S.(inch) METRIC

CAPACITY ....................................................9 CUBIC FEET ....................................................... 248 LITERS

BAG CAPACITY .............................................2½ - 3½ ............................................................ 2½ - 3½

WEIGHT (APPROX.) ........................................870 LBS. ............................................................. 395 KG.

L XW XH ..................................................71 X50 X59 IN. .................................................. 180 X127 X150 CM.

LENGTH W/TOW BAR ......................................98 IN. ................................................................. 248 CM.

HEIGHT W/DUMP HANDLE ................................77 IN. ................................................................. 195 CM.

DISCHARGE HEIGHT.......................................21 IN. ................................................................. 53 CM.

DRIVE .........................................................V-BELT TO GEAR ..................................................... —

DUMP ACTION ..............................................MANUAL ............................................................... —

WM-900P SPECIFICATIONS

MODEL U.S.(inch) METRIC

CAPACITY ....................................................9 CUBIC FEET ....................................................... 248 LITERS

BAG CAPACITY .............................................2½ - 3½ ............................................................ 2½ - 3½

WEIGHT (APPROX.) ........................................870 LBS. ............................................................. 395 KG.

L XW XH ..................................................71 X50 X59IN.................................................... 180 X127 X150 CM.

LENGTH W/TOW BAR ......................................98 IN. ................................................................. 248 CM.

HEIGHT W/DUMP HANDLE ................................77 IN. ................................................................. 195 CM.

DISCHARGE HEIGHT.......................................21 IN. ................................................................. 53 CM.

DRIVE .........................................................V-BELT TO GEAR ..................................................... —

DUMP ACTION ..............................................MANUAL ............................................................... —

NOTE: In accordance with our established policy of constant improvement, we reserve the right to amend these specifications at anytime without notice.

Go to Discount-Equipment.com to order your parts

PAGE 12 —WHITEMANWM-900S,900P — PARTS & OPERATION MANUAL — REV.#7 (03/17/06)

EXPLANATION OF CODE IN REMARKS COLUMN

How to read the marks and remarks used in this parts book.

Section 1: Items Found In the “Remarks”Column

Serial Numbers-Where indicated, this indicates a serial

number range (inclusive) where a particular part is used.

Model Number-Where indicated, this shows that the

corresponding part is utilized only with this specific model

number or model number variant.

Section 2: Items Found In the“Remarks”Column

SerialNumbers-Whereindicated, thisindicatesa serialnumber

range(inclusive) where aparticular part isused.

Model Number-Where indicated, this shows that the

correspondingpartisutilizedonlywiththisspecificmodelnumber

ormodel numbervariant.

Section 3: Items Found In the“Items Number”Column

Allparts withsame symbolin thenumber column,*, #, +,%, or

■

,belong tothe sameassembly orkit.

Note: If more than one of the same reference number is listed,

thelast one listed indicates newest(or latest) part available.

NOTE

If more than one of the same reference number is

listed,thelastonelisted indicatesnewest(orlatest)

partavailable.

NOTE

The contents of this catalog are

subjecttochangewithout notice

.

Go to Discount-Equipment.com to order your parts

WHITEMANWM-900S, 900P— PARTS &OPERATION MANUAL— REV. #7(03/17/06) —PAGE 13

WM-900S,900P — SUGGESTED SPARE PARTS

WM-900S/P

1 to 3 Units

Qty. P/N Description

3 .........EM505834........... V-BELT

3 .........491115 ................ V-BELT,w/ELECTRIC MOTOR

6 .........491010 ................ LATCHASSY

3 .........EM200863........... BLADE KIT STEEL DRUM

3 .........EM204625........... BLADEKITPOLYDRUM

2 .........EM902153........... BEARING,DRUMHEAD

2 .........3131.................... O-RING, DRUM HEAD

2 .........3530.................... SEALKIT

1 .........3351.................... PINIONGEAR

WM-900S/P

5+ Units

Qty. P/N Description

5 .........EM505834........... V-BELT

5 .........491115 ................ V-BELT,w/ELECTRIC MOTOR

10 .......491010 ................ LATCH ASSY

5 .........EM200863........... BLADE KIT STEEL DRUM

5 .........EM204625........... BLADEKITPOLYDRUM

4 .........EM902153........... BEARING,DRUMHEAD

4 .........3131.................... O-RING, DRUM HEAD

1 .........EM940734........... SWITCH, ON/OFF

2 .........3351.................... DRIVENPINON GEAR

1 .........509171 ................ DUMPHANDLE, POLYDRUM

1 .........EM201537........... DUMP HANDLE, STEEL DRUM

4 .........3530.................... SEALKIT

2 .........3065.................... SEAL,AXLE

2 .........3469.................... DUST CAP AXLE

2 .........EM903049........... BEARING CONEUPTOS/N HL60000

2 .........EM903113........... BEARINGCONESTARTINGS/N JA00000

2 .........EM903012........... BEARINGCUP

NOTE

Part numbers on this Suggested

Spare Parts List may supercede/

replace the P/N shown in the text

pages of this book.

Go to Discount-Equipment.com to order your parts

PAGE 14 —WHITEMANWM-900S,900P — PARTS & OPERATION MANUAL — REV.#7 (03/17/06)

WM-900S,900P — DRUM HEAD ASSEMBLY

25 26

Go to Discount-Equipment.com to order your parts

WHITEMANWM-900S, 900P— PARTS &OPERATION MANUAL— REV. #7(03/17/06) —PAGE 15

WM-900S,900P — DRUM HEAD ASSEMBLY

DRUMHEAD ASSEMBLY

NO. PART NO. PART NAME QTY.REMARKS

2 EM200297 U-BOLT 2

EM968011 NUT HEX ½-13 4

3 EM200292 U-BOLT INSERT 4

4 3249 DUST CAP ............................................................................. 1 ................ REPLACES50017

5 EM902153 BEARING 2

6 500076 BRACKET, DUMPBEARING .................................................. 2 ................ S/N 750002THRU 750179

6 EM507720 BRACKET, DUMPBEARING .................................................. 2 ................ S/N 750180 & UP

7 EM916019 GREASEZERK ...................................................................... 2 ................ REPLACES491705

8 5028B COTTER PIN 1/8 X 2.............................................................. 2 ................ REPLACES491690

9 8164 CASTLE NUT ........................................................................ 2 ................ REPLACES 502246

10 3047 SPACER ................................................................................. 2 ................ REPLACES 500089

11 3131 O-RING .................................................................................. 2 ................ REPLACES491040

12*13002 SEAL ...................................................................................... 2 ................ REPLACES504749

13 3291 DRUMHEAD,BEARINGBOSS .............................................. 2 ................ S/N 750002,THRU 750179

REPLACES500085

13 507719 DRUMHEAD,BEARING BOSS .............................................. 2 ................ S/N 750180 & UP

14 3024 SPRING.................................................................................. 2 ................ REPLACES491930

15 3061 THINSEAL SPACER .............................................................. 14 .............. REPLACES 500088

25*3019 SEAL ...................................................................................... 4 ................ REPLACES500086

26*3494 SEAL URETHANE.................................................................. 2 ................ REPLACES500613

3530 SEALKIT, PADDLESHAFT .................................................... 1 ................ INCLUDES ITEMS w/*

Go to Discount-Equipment.com to order your parts

PAGE 16 —WHITEMANWM-900S,900P — PARTS & OPERATION MANUAL — REV.#7 (03/17/06)

WM-900S, 900P — PADDLE SHAFT ASSEMBLY

Go to Discount-Equipment.com to order your parts

WHITEMANWM-900S, 900P— PARTS &OPERATION MANUAL— REV. #7(03/17/06) —PAGE 17

WM-900S, 900P — PADDLE SHAFT ASSEMBLY

PADDLESHAFTASSEMBLY

NO. PART NO. PART NAME QTY.REMARKS

46 EM200297 U-BOLT 2

47 EM968011 NUT ½"-13 4

48 EM200292 U-BOLT INSERT 4

49 507269 PADDLE SHAFT 1

50 EM200293 PADDLE ARM-TOW END 1

51 EM200294 PADDLE ARM-CENTER 1

52 EM200296 PADDLE ARM-ENGINE END 1

53 EM200295 PADDLE ARM-CENTER 1

54*# EM203432 CENTER BACK-UP BLADE 4

55*# EM203433 END BACK-UP BLADE 2

56*EM200212 TOP RUBBER BLADE (STEEL) DRUM ONLY 4

56# EM507519 TOP PLASTIC BLADE (POLY) DRUM ONLY 4

57*EM200213 END RUBBER BLADE (STEEL) DRUM ONLY 2

57# EM507518 END PLASTIC BLADE (POLY) DRUM ONLY 2

58 EM963837 BOLT ½-13 X 5-½ 1

59 6109180 LOCKWASHER ½" 1 REPLACES EM923638

60 EM968011 HEX NUT ½-13 1

61 507270 SPACERBULLGEAR 1

EM200863 BLADEKIT,(STEEL)DRUM ONLY .........................................1............... INCLS ITEMS w/*AND MTG.HDWR

EM204625 BLADEKIT,(POLY) DRUMONLY ............................................1............... INCLS ITEMS w/# AND MTG.HDWR

EM203028 HARDWAREKIT, (RUBBER/POLYBLADES)...........................1............... INCLUDED IN BLADE KITS

REFERTO PAGES 14 & 15 FOR DRUM HEAD BREAKDOWN

Go to Discount-Equipment.com to order your parts

PAGE 18 —WHITEMANWM-900S,900P — PARTS & OPERATION MANUAL — REV.#7 (03/17/06)

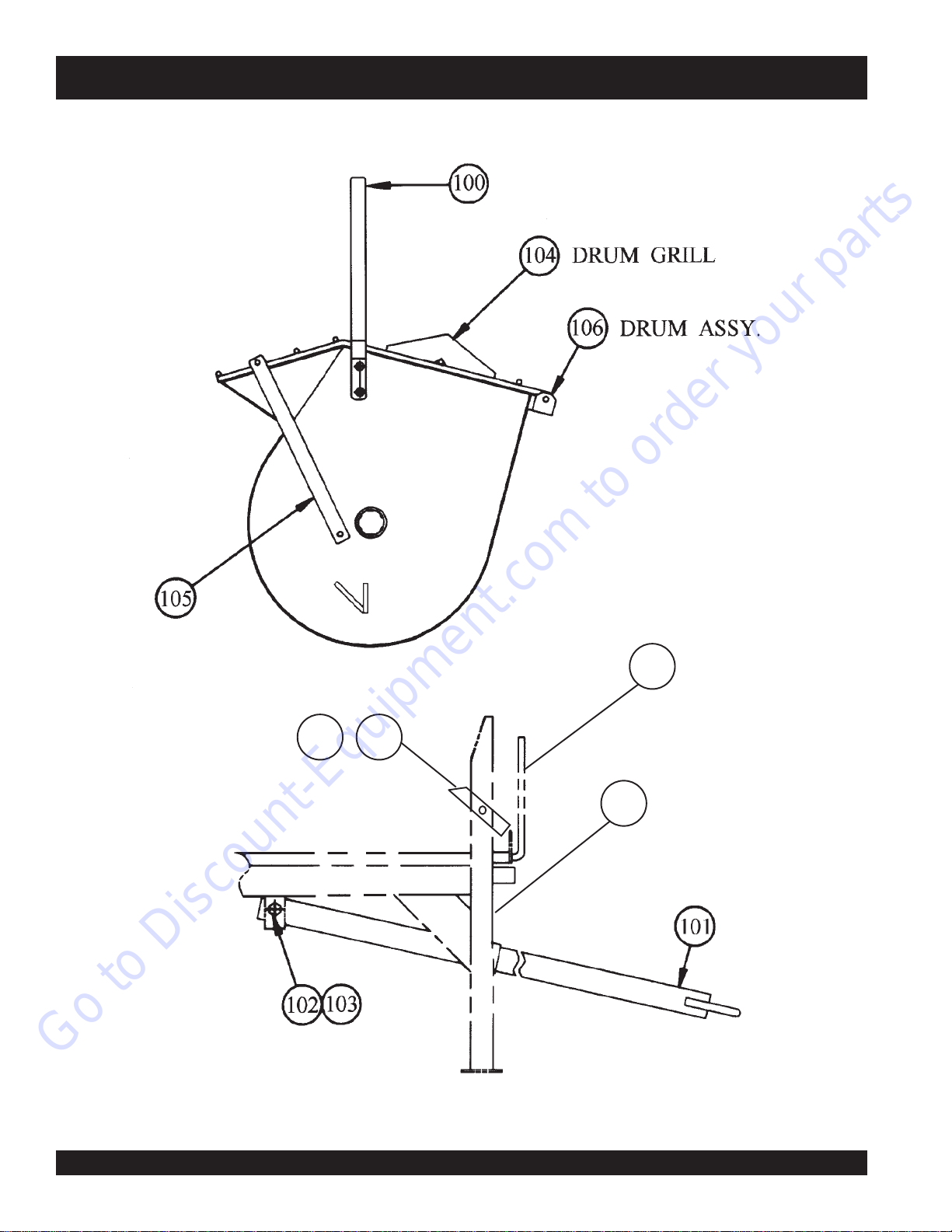

WM-900S — STEEL DRUM

STEEL DRUM

110 111

108

109

Go to Discount-Equipment.com to order your parts

WHITEMANWM-900S, 900P— PARTS &OPERATION MANUAL— REV. #7(03/17/06) —PAGE 19

WM-900S — STEEL DRUM

STEELDRUM

COMMON PARTS

NO. PART NO. PART NAME QTY.REMARKS

100# EM201537 DUMP HANDLE 1

101 ELC1 TOWINGTONGUE (P.EYE) ................................... 1 ..............NOLONGERAVAILABLE

101 EPC1

TOWINGTONGUE (PIN HOLE) ............................. 1 .............. CONTACTDISCOUNT-EQUIPMENT./ACCESSORYITEM

101 EBC1

TOWINGTONGUE (BALL HITCH) ......................... 1 .............. CONTACTDISCOUNT-EQUIPMENT./ACCESSORYITEM

102 EM963580 CAP SCREW ......................................................... 1..............REPLACES 505067

103 EM969038 LOCK NUT............................................................. 1..............REPLACES 505069

108 EM506309 MAIN FRAME 1

109 507264 CLUTCH LEVER 1

110 EM507421 DUMP LATCH 1

111 EM507835 CLEVISPIN 1

104# EM203332 DRUMGRILL 1

105# EM507484 GRILL OPEN BAR 1

106% 508095 DRUM ASSY (STEEL) ............................................ 1..............INCLS. ITEMSw/#

508096 DRUM & SHAFT ASSY (COMPLETE) (STEEL) ..... 1..............INCLS.ITEMS w/% AND DRUM HEAD &

PADDLE SHAFT ASSY

❑

3148 SAFETY CHAIN ...................................................... 1 .............REPLACES13363

❑

01004 5/16" CONNECTOR LINK 2

❑

ILLUSTRATED ON PAGE 9

Go to Discount-Equipment.com to order your parts

PAGE 20 —WHITEMANWM-900S,900P — PARTS & OPERATION MANUAL — REV.#7 (03/17/06)

WM-900P — POLYETHYLENE DRUM

POLYETHYLENE

DRUM

116

121 122

123

124

125

126

123

124

Go to Discount-Equipment.com to order your parts

WHITEMANWM-900S, 900P— PARTS &OPERATION MANUAL— REV. #7(03/17/06) —PAGE 21

WM-900P — POLYETHYLENE DRUM

POLYETHYLENEDRUM

NO. PART NO. PART NAME QTY.REMARKS

115# 506432 PLASTIC DRUM(W/O GRATES) 1

116 507549 SUPPORT DRUM 1

117# 507416 STATIONARY GRATE 1

118# 507417 MOVEABLE GRATE 1

119# 507517 GRATE OPEN BAR 1

120# 509171 DUMP HANDLE 1

EM509077 DRUM & SHAFT ASSY (COMPLETE) (POLY) ....................... 1 ..................... INCLS ITEMS w/# AND DRUM

HEAD & PADDLE SHAFT ASSY

121 EM963610 HHCS 3/8" NC X 1 ¼" G-5 7 REPLACES 492376

122 EM969013 LOCK NUT 3/8" NC 7 REPLACES 492583

123 5041987 FHCS ¼" NC X 1" G-5 8 REPLACES 504987

124 EM969079 LOCK NUT ¼" NC 8 REPLACES 492581

125 504943 FHCS 3/8" NC X 2" G-5 12

126 EM969013 LOCK NUT 3/8" NC 12 REPLACES 492583

Go to Discount-Equipment.com to order your parts

This manual suits for next models

1

Table of contents

Other MQ Construction Equipment manuals

Popular Construction Equipment manuals by other brands

Leica Geosystems

Leica Geosystems Piper 100 user manual

AGP

AGP EV10ELM Original instructions

S&B Lawn Systems

S&B Lawn Systems GENERATION 3 LAWN STRYPER GEN-61522B owner's manual

Zoomlion

Zoomlion QTZ250 operating instructions

Marshalltown

Marshalltown SHOCKWAVE 2.0 POWER SCREED manual

Altrad Belle

Altrad Belle RTX 50 Operator's manual