ECOLINER™SP

ALWAYSwearsafetygogglesorprotectiveeye‐wearwhenoperatingtheunit!

1700JasperSt.,UnitF,Aurora,CO80011T800.624.6706F303.364.7796•Newstripe.com

EcoLiner™SPManual/4621.0517

Page5of11

PARTSLIST

ItemDescriptionPart

Number

Item DescriptionPart

Number

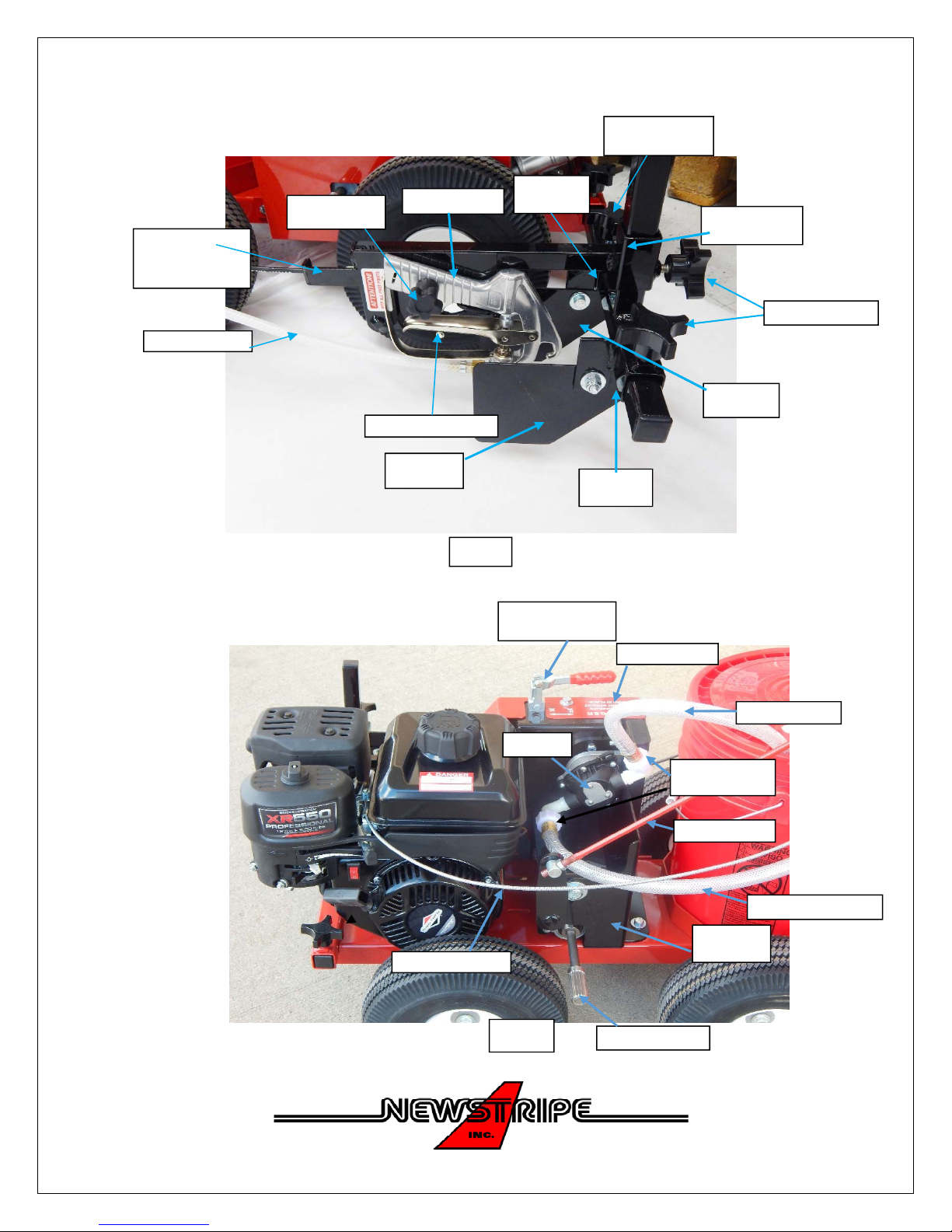

1Chassis10004610 31BrassTfitting,½”10004111

2Engine,SubaruEX13 10004707 32Reducer,½”–¼”10002481

3AirfilterelementforEngine(NotShown

Briggs&StrattonP/N)

79697031BrassTfitting,½”10004111

4Wheelassembly(4required)10000012 32Reducer,½”–¼”10002481

5Handle,weldment10003469 33Pumpprimevalve10000233

6Handlesupportbraces(2)10004612 34Brasselbow10000159

7Controlcable 10000820 35Cross,brass10000235

8Controllever 10002951 36Brasselbow10004131

9Throttlecable 10000696 37Plug10000113

10Drivelever10002072 38Ballseatfitting10000731

11Driverod10002087 39 Pumpengagementlever10001817

12Hose,paint10000695 40Beltguard10002030

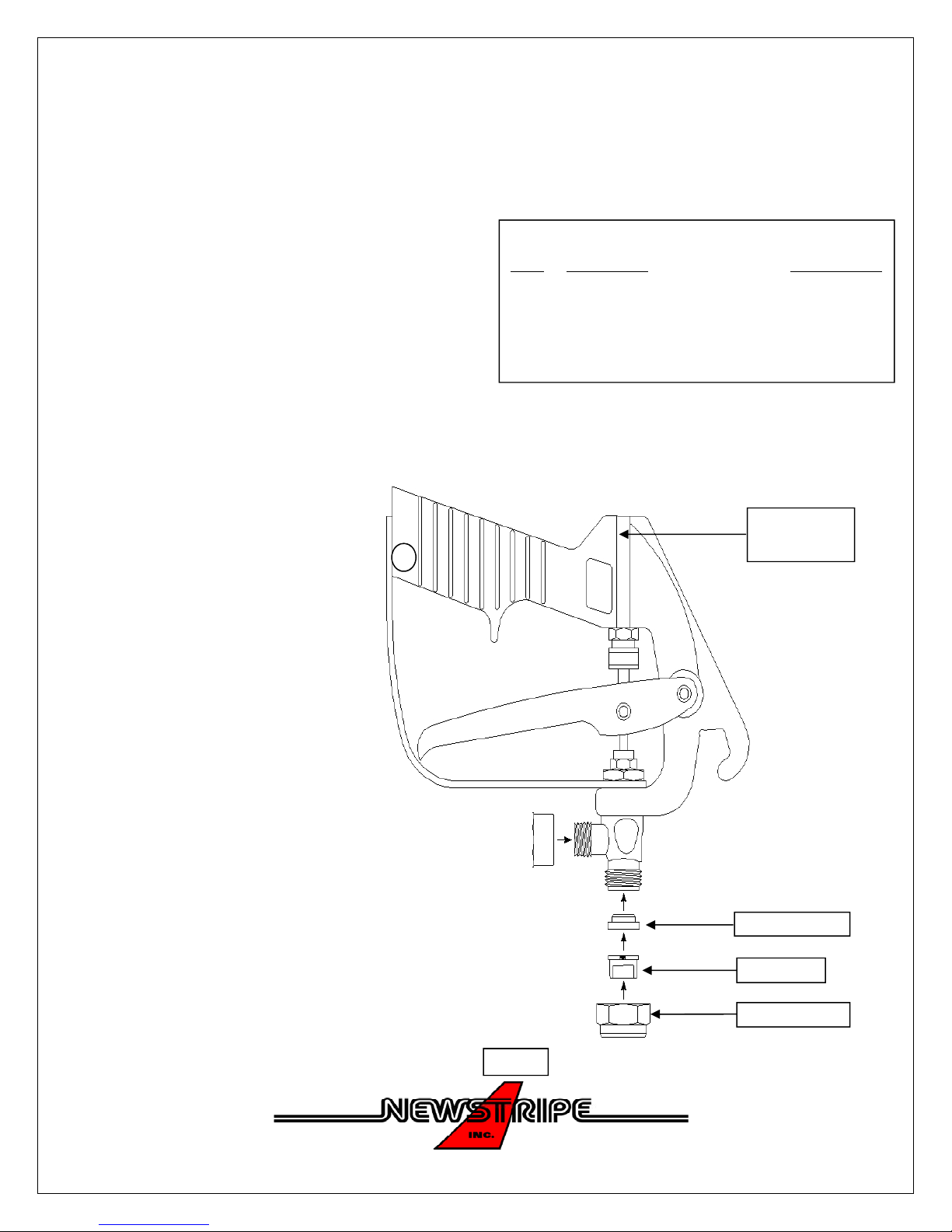

13 Hose,suctionwithfitting10004470 41 Pumpelbowfittings10004459

14Filterscreen,suctionhose(Notshown)10002842 42Pump,diaphragm10003367

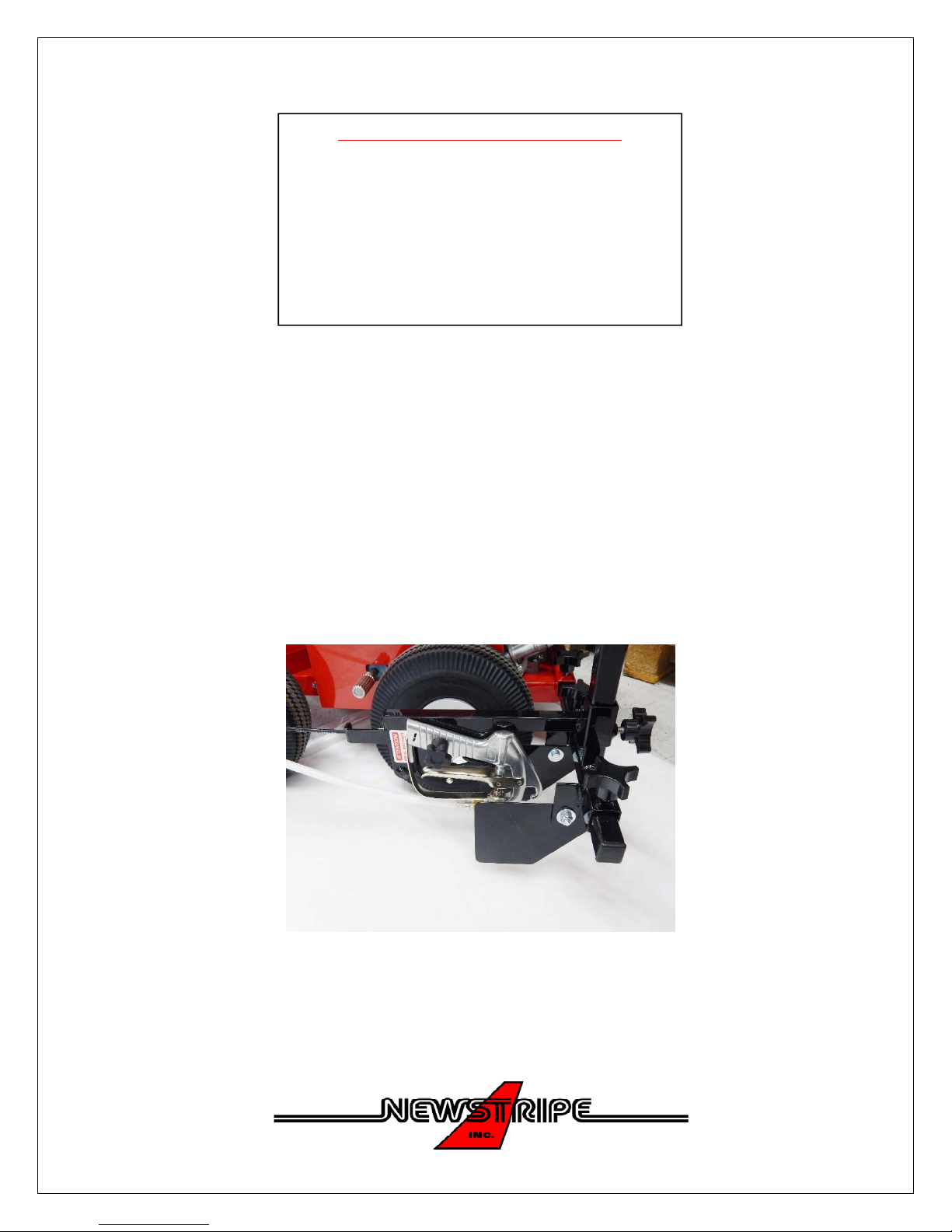

15Spraygunmountingarm10004616 43 Driveassembly10002088

16Spraygunassembly10001949 44Driverollers(2)10003387

17Spraygunsupportarm10003550 45Gunmountstarknob10004480

18Pivot,Right10001229 46Drivebelt,engine(4L280)10001757

19Pivot,Left10001228 47Drivebelt,pump(3L260)10001755

20Sprayshields(2)10003562 48Pulley,idler,pumpengagement10001111

21Starknobs,common(5)10000007 49Pulley,idler,drive10001111

22Cableadjusterwithnut10000018 50Pulley,frictiondrive10001115

23Cablestop10001577 51Pulley,engine10001739

24PressurevalveadjustingcapN/A52Pulley,pump(notshown)10003368

25LockingringN/A53Spring,tension,pump

26PressurelimitercollarN/Aengagementlever10000649

27PressureValve10003478 54Spring,tension,idlerarm10000692

28Hose,re‐circulating10003692 55Bearing,pumpshaft(2) 10003131

29Hose,pumpoutletwithfitting10004469 56Pumpshaft(NotShown)10003365

30Hose,pumpprimevalve10003692