5

FB160 / FB170 / FB175 / FB235 / FB255 / FB265

Dok: 101497C-GB 2126

FB 235

Net weight.................................240 kg

Base plate, w x l........................550 x 790 mm

Speed ........................................approximately 25 m/min

Permitted inclination ................20°

Centrifugal force .......................40.000 N

Vibration frequency ..................79 Hz

Drive engine..............................Honda GX 270

Engine power ............................6.0 kW

Engine RPM .............................3200 RPM

Fuel tank volume.......................6 liter

Fuel type....................................Unleaded petrol,

95-98 octane

FB 255

Net weight.................................265 kg

Base plate, w x l........................550 x 790 mm

Speed.........................................approximately 25 m/min

Permitted inclination.................20º

Centrifugal force .......................40.000 N

Vibration frequency ..................79 Hz

Drive engine..............................Yanmar L70N

Engine power ............................4.5 kW

Engine RPM .............................3200 RPM

Fuel tank volume.......................3.5 liter

Fuel type....................................Diesel MK1

Battery.......................................12V 40Ah

TECHNICAL DATA

FB 265

Net weight.................................265 kg

Base plate, w x l........................550 x 790 mm

Speed.........................................approximately

25 m/min

Permitted inclination.................20º

Centrifugal force .......................40.000 N

Vibration frequency ..................79 Hz

Drive engine..............................HATZ 1B30

Engine power ............................4.8 kW

Engine RPM..............................3200 RPM

Fuel tank volume.......................3.5 liter

Fuel type....................................Diesel MK1

Battery.......................................12V 40Ah

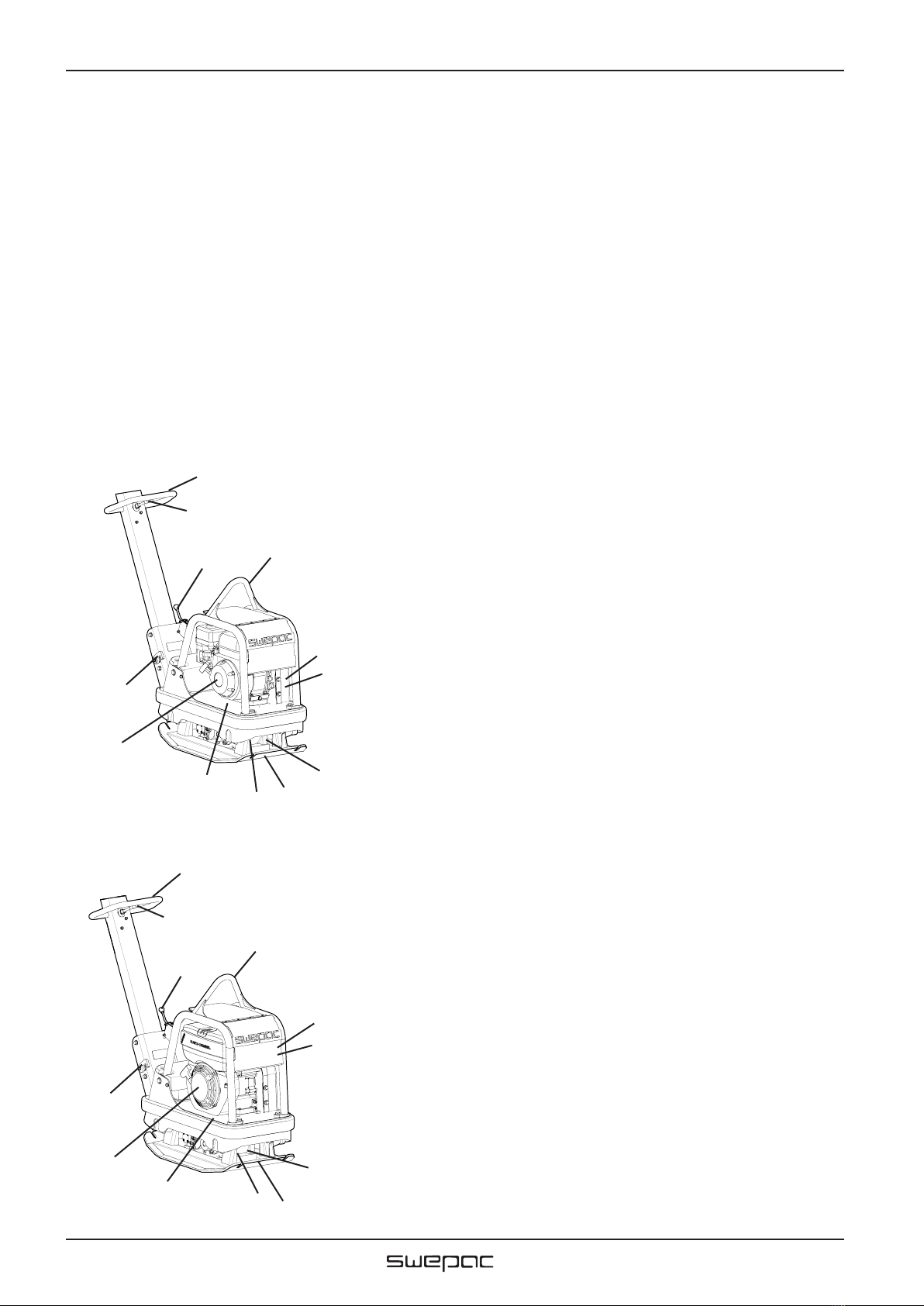

FB 160

Net weight.................................160 kg

Base plate, w x l........................450 / 550 x 720 mm

Speed ........................................approximately 25 m/min

Permitted inclination ................20°

Centrifugal force .......................32.000 N

Vibration frequency ..................82 Hz

Drive engine..............................Honda GX 200

Engine power ............................4,9 kW

Engine RPM .............................3250 RPM

Fuel tank volume.......................3.6 liter

Fuel type....................................Unleaded petrol,

95-98 octane

FUEL and OIL RECOMMENDATIONS

Fuel FB160 / FB235..........Unleaded petrol 95-98 octane

Fuel FB 170/ FB175 / FB 255 / FB265..................Diesel

Engine oil.............................SAE 10W-30

Engine oil change petrol engine: rst oil change after 20

hours then every 100 hours of operation.

Oil quantity, crankcase FB160.......................0,5 liter

FB235..........................1 liter

Engine oil change diesel engine: rst oil change after 50

hours then every 200 hours of operation.

Oil quantity, crankcase FB170........................1 liter

FB175........................1 liter

FB255........................1 liter

FB265........................1 liter

Hydraulic oil ..............................HydraWayBIO PA 22

Quantity FB170 / FB160 / FB175......1,65 liter

FB235..................................1,65 liter

FB255 / FB265....................1,65 liter

Oil type/quantity, vibration unit.......SAE10W-30

FB170 / FB160 / FB175........0,30 liter

FB235 / FB255 / FB265........0,35 liter

FB 175

Net weight.................................163 kg

Base plate, w x l........................550 / 450 x 720 mm

Speed ........................................approximately 25 m/min

Permitted inclination ................20°

Centrifugal force .......................32.000 N

Vibration frequency ..................82 Hz

Drive engine..............................Yanmar L48

Engine power ............................3,1 kW

Engine RPM .............................3250 RPM

Fuel tank volume.......................3 liter

Fuel type....................................Diesel MK1

FB 170

Net weight.................................163 kg

Base plate, w x l........................550 / 450 x 720 mm

Speed ........................................approximately 25 m/min

Permitted inclination ................20°

Centrifugal force .......................32.000 N

Vibration frequency ..................82 Hz

Drive engine..............................Hatz 1B20

Engine power ............................3,1 kW

Engine RPM .............................3250 RPM

Fuel tank volume.......................3 liter

Fuel type....................................Diesel MK1