Depending on the Luminator battery

used, the cap lamp is designed to

operate at full brilliance for a minimum

of an 8-10 hour shift, with reserve

energy if needed. At the end of each

shift the battery is recharged in a sin-

gle- or multiple-station charging unit.

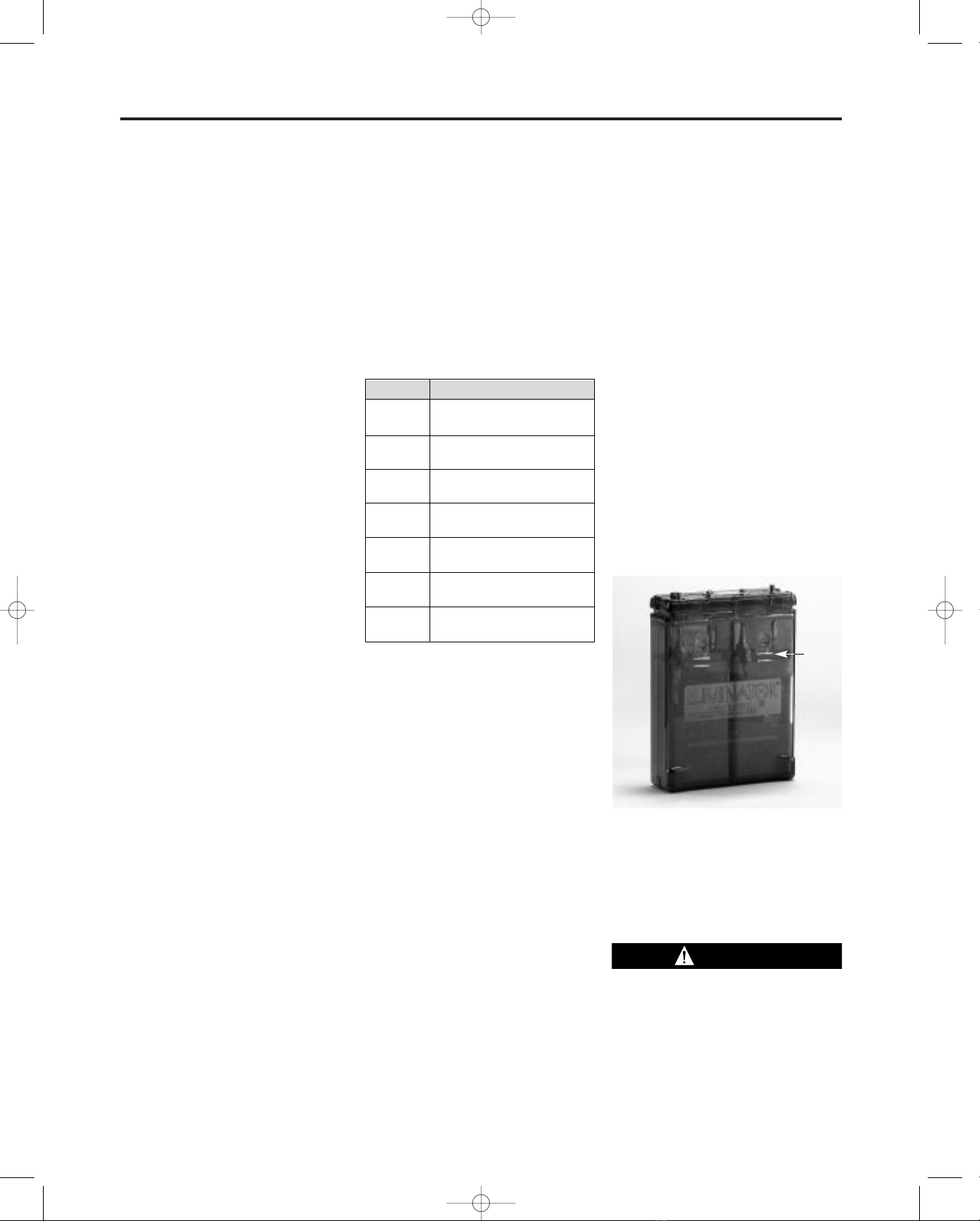

The Luminator Power Cell (13 AH) is

designed to operate at cycle routines

of 8-10 hours discharge/16-14 hour

recharge 5 days/week (max). If the

routines are increased, the Luminator

Power Cell Plus (16 AH) is recom-

mended. Battery charging connection

is made through the headpiece, using

either a parallel or modular charging

system. Each battery has a transpar-

ent case with molded-in electrolyte

level indicators below the filling ports.

Remote Power Connections

The Remote Power Connection allows

the Cap Lamp to be used as a power

source for an external remote device

while still operating as light source.

MSHA regulation permits this configu-

ration as long as the external remote

device current requirement does not

exceed 275 milliamps.

If using the Remote with the Ultralight

or ML-2 Cap lamps, the Luminator

Power Cell Plus 16 Ah battery is rec-

ommended, due to higher battery

demands. However, the Luminator

Power Cell 13 AH has been approved

with the Remote Power Connection

for Ultralight Cap Lamp use only.

Preparing the Ultralight and ML-2

Cap Lamps for First Time Use

Battery Charging

Every battery must be charged before

it is used for the first time. A battery

may be charged with parallel or modu-

lar systems, in either standard or low

profile racks, or in a single station

charger. Various MSA chargers and

part numbers are listed in the chart

below:

1. Set power supply or charging sta-

tions to 5.0 ± .05 VDC.

2. Connect the battery to the charg-

ing station, following the instruc-

tions supplied with the charger.

3. To check that charging current is

flowing, look at the meter (located

either just above or just below the

battery on rack-mounted charg-

ers). The meter needle should

swing to the far right.

Note

In some cases there will not be a

meter on the charger. See the instruc-

tions for the appropriate charger.

4. Allow the battery to remain on

charge for 24 hours.

5. As the battery charges, the meter

needle should gradually move to

the left to OFF. In other chargers,

the LED lights will indicate

charged condition.

6. Top off each cell with distilled water

if necessary (see Watering section).

Routine Battery Maintenance

1. Routine Charging on Standard

Rack and Charger. All batteries in

this category must be charged

immediately after each period of

use in the following manner:

a. Set power supply or charging

stations to 5.0 ± .05 VDC.

b. Connect the battery to the

charging station following the

instructions supplied with the

charger.

c. Check meter, the needle

should swing to right indicating

charge, (or check LED lights).

d. Allow battery to remain in the

rack until it is recharged.

(Needle of meter will return to

“OFF” or LED lights will indi-

cate charged condition).

e. To remove lamp and stop

charge, rotate the headpiece

counterclockwise to a full stop,

then lift headpiece from key and

battery form the charging rack.

Note

Batteries which do not perform satis-

factorily, should be removed from ser-

vice and cycled - charged 16 hours,

discharged 8 hours. Repeat several

times until battery responds. If battery

does not respond after three or four

cycles, it should be replaced.

f. After weekly shifts, the battery

should be placed on the

charger following the instruc-

tions included with the charg-

er, and left to charge the

remainder of the weekend.

g. If cap lamp needs cleaning,

use a mild detergent and wipe.

Do not submerge.

2. Storage of Batteries.

All stored batteries with acid

should be boost charged for 24

hours every 3 months, and imme-

diately before being placed into

regular service. Recommended

storage temperatures 32˚F to 80˚F.

3. Watering.

The electrolyte level should be

maintained between the two lines

indicated below the filling and

venting hole i.e. slightly above the

top of the battery plate.

Normally topping up should not be

necessary more often than once

every 3-4 weeks, and should

always be carried out when the

battery is fully charged. Only dis-

tilled or deionized water should be

used in topping up.

The Electrolyte is corrosive and can

cause burns. Take proper precau-

tions to avoid skin and eye contact.

Contact MSA for battery Materials

Safety Data Sheet (MSDS). Phone

1-800-MSA-2222.

TAL 998 (L) Rev. 2 - 817184 3

General Description