TABLE OF CONTENTS

INTRODUCTION.........................................................................................................................3

1DESCRIPTION AND OPERATION OF THE PRODUCT.................................................4

1.1 Description ...............................................................................................................................4

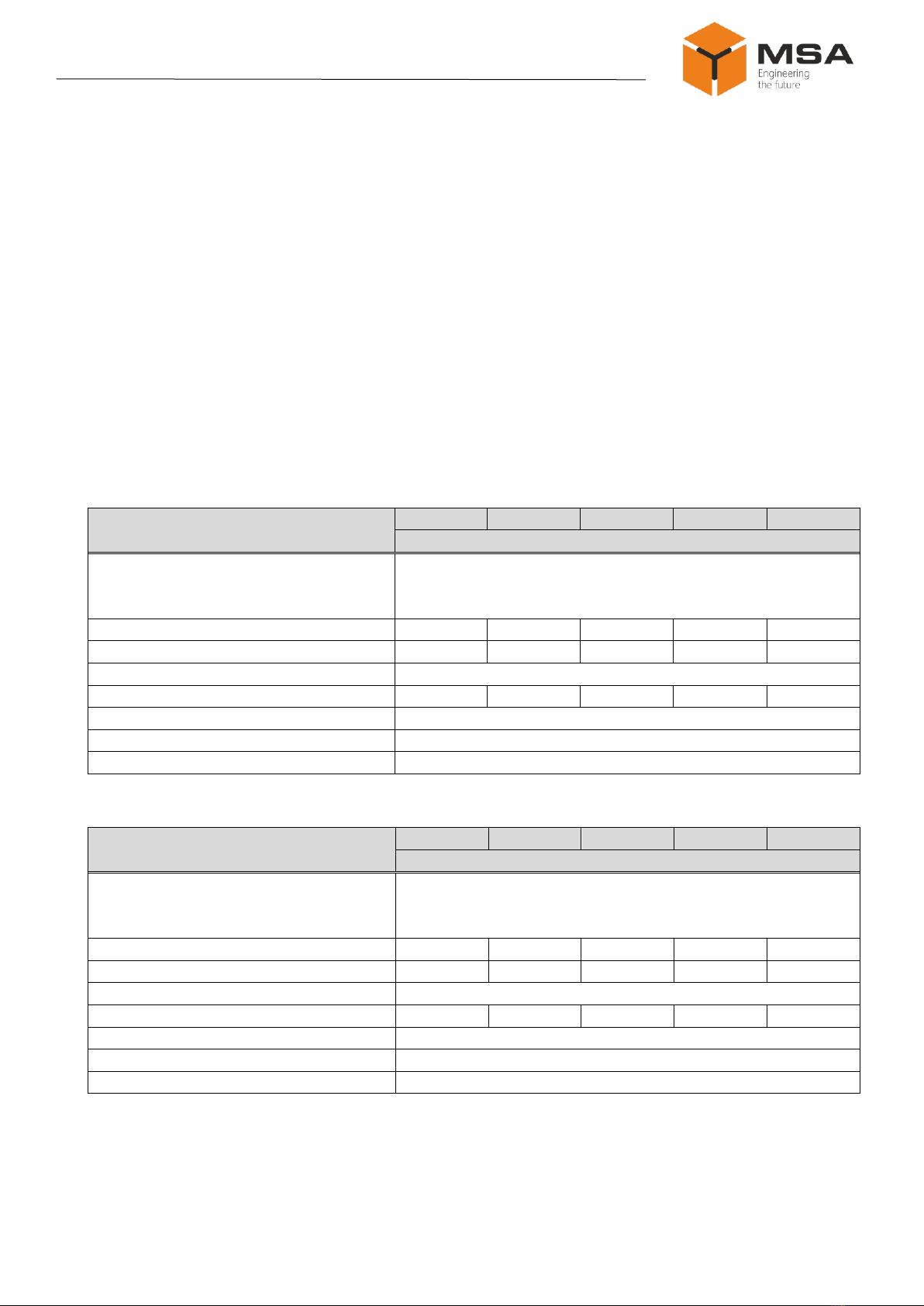

1.2 Technical specifications ...........................................................................................................4

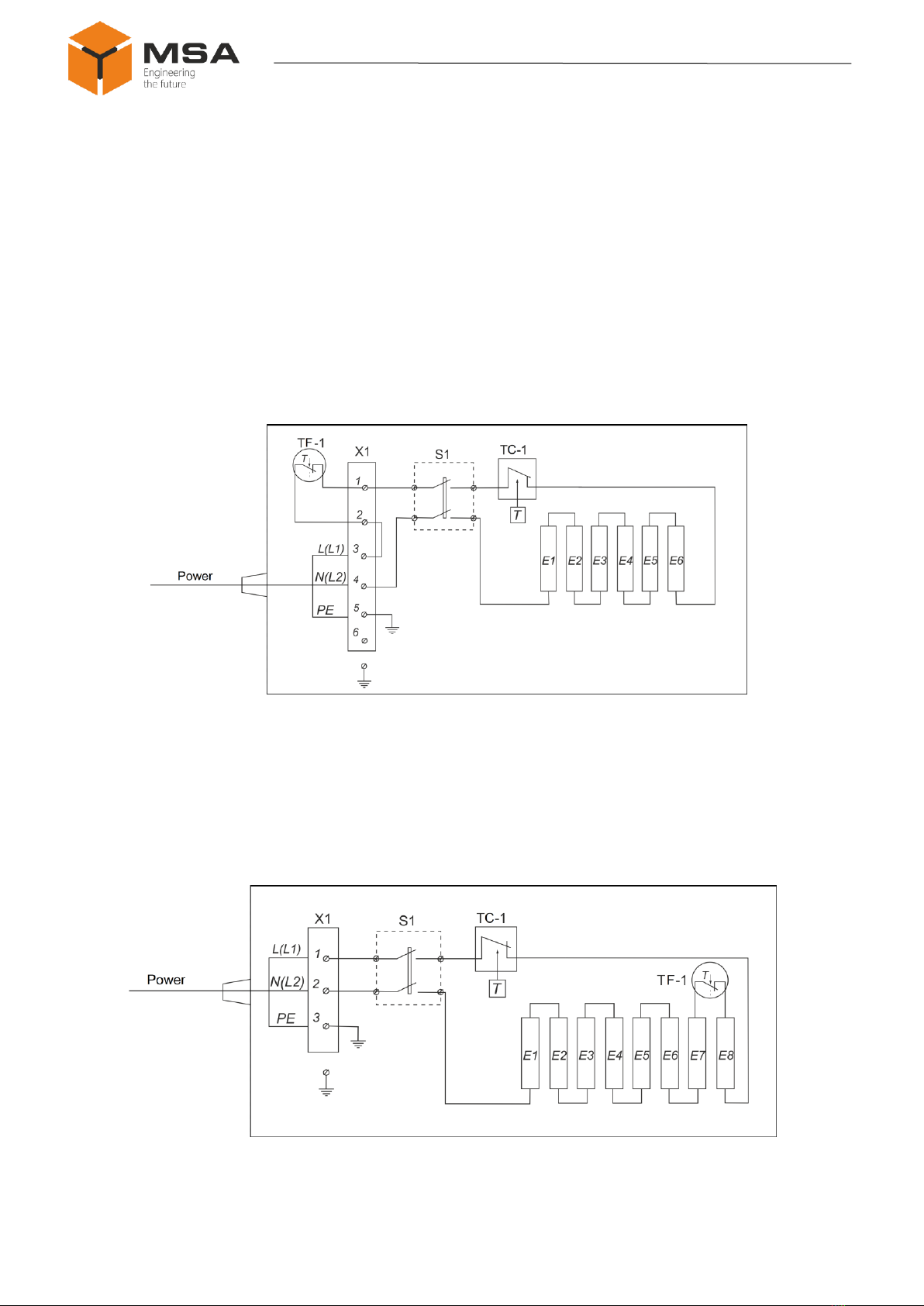

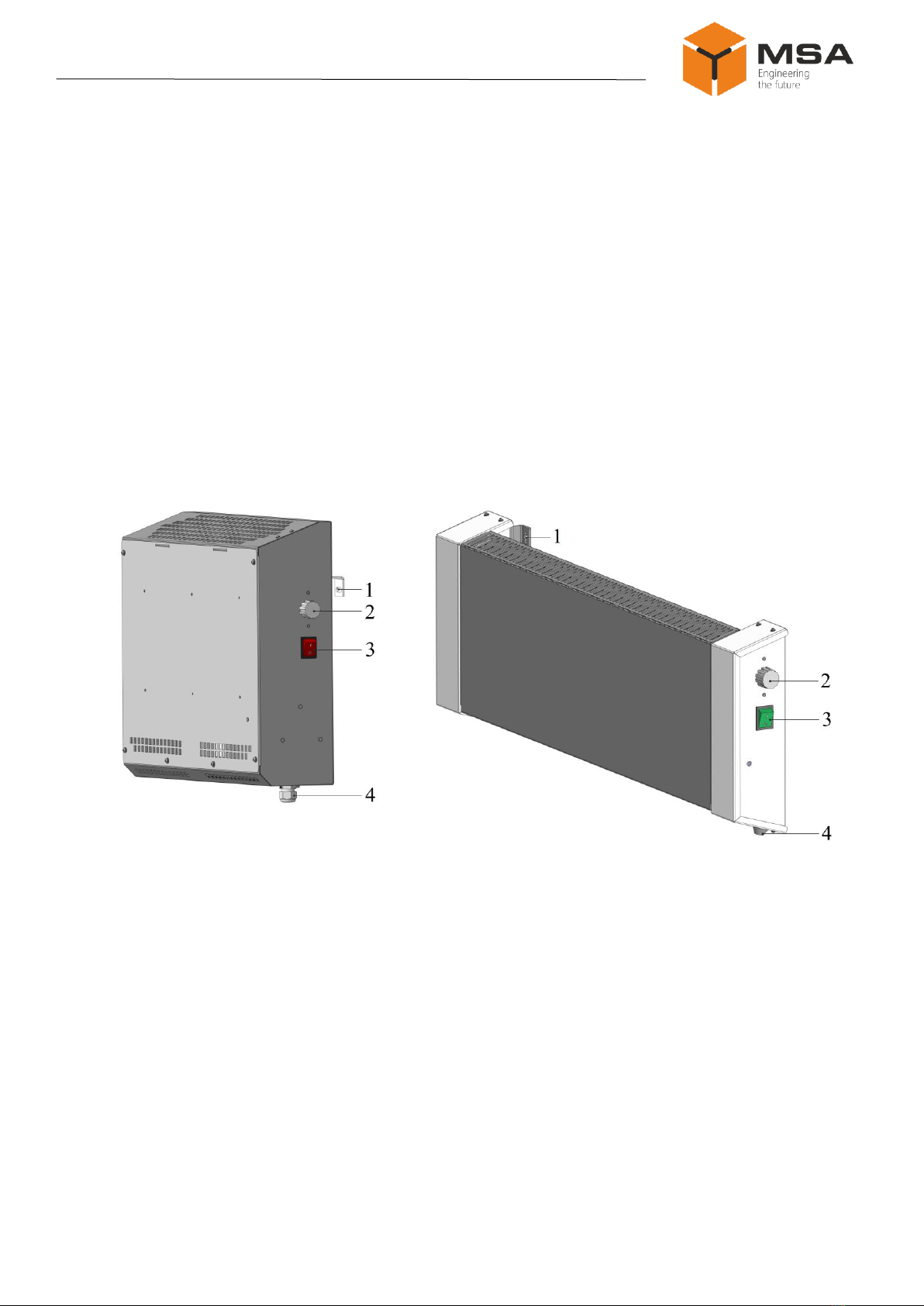

1.3 The Product’s structure and operation......................................................................................5

1.4 Measurement tools, instruments and appliances......................................................................7

1.5 Marking and sealing.................................................................................................................7

1.6 Packaging .................................................................................................................................7

2INTENDED USE.......................................................................................................................8

2.1 Operational constraints.............................................................................................................8

2.2 Preparation for the Product operation.......................................................................................8

2.3 Usage of the Product ................................................................................................................9

3TECHNICAL SERVICE OF THE PRODUCT...................................................................13

3.1 General instructions................................................................................................................13

3.2 Safety features ........................................................................................................................13

3.3 Maintenance routine...............................................................................................................13

3.4 Preservation............................................................................................................................15

4CURRENT REPAIR OF THE PRODUCT..........................................................................16

4.1 General description.................................................................................................................16

4.2 Safety features ........................................................................................................................16

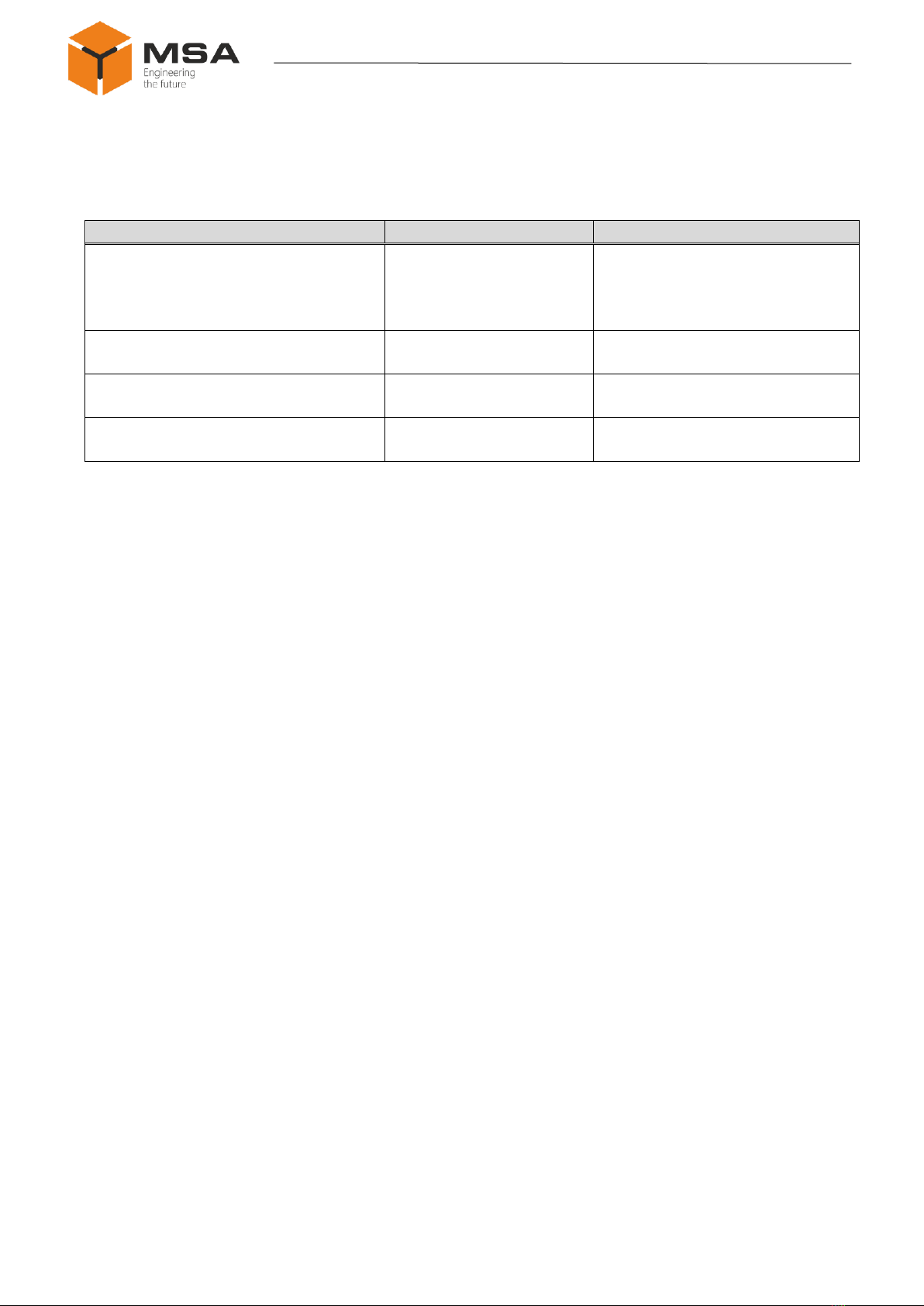

4.3 Сurrent repair..........................................................................................................................16

5STORAGE .............................................................................................................................17

6TRANSPORTATION.............................................................................................................18

7DISPOSAL .............................................................................................................................19

8WARRANTY ..........................................................................................................................20

ANNEX А OUTLINE AND INSTALLATION DIMENSIONS OF THE PRODUCT.........21