7 Eco Trolley Manual revision 01/10

3 SAFETY RULES

3. 1 GENERAL WARNINGS

The Operator shall carefully read the information given in this Manual, especially the Safety rules and pre-

cautions specified in this section.

Moreover, it is fundamental that the Operator follows these warnings:

• keep the Exhauster and the work area clean and in order;

• use the Exhauster in normal psychophysical conditions;

• Use the Exhauster on plane and without depressions surfaces only;

• Wear appropriate clothes and personal protection gear suitable for products in use;

• do not remove or tamper with the Manufacturer nameplates on Exhauster;

• do not remove or make inoperative any of the Exhauster Safety systems.

• Do not use this unit in rooms subjected to risk of explosion.

3. 2 INTENDED USE

The Exhauster is designed for removing non-explosive dust in general or similar material.

3. 3 UNSUITABLE USE

Do not use the Exhauster:

• for different purposes than those indicated in 3.2;

• to take in substances that could result in a flammable and/or explosive environment;

• in environments featuring explosive, aggressive atmosphere or with high dust or oily content;

• in environments with a serious fire hazard;

• outdoors, exposed to any weather condition;

• to take in red-hot parts and/or parts on fire;

• in a different way than stated in safety installation rules given herein.

3.4 DANGEROUS AREAS

Although the Exhauster does not involve any particular danger for exposed persons, it shall be used taking

some precautions, considering that:

• the operator can come into contact with dangerous chemical products by accident and without being

aware of the resulting danger.

• Before use, the person in charge of production shall evaluate unit use conditions according to the

danger possibly caused by products and take suitable protection measures such as: work in a room

featuring a guaranteed minimum change of air.

• Pay utmost attention when removing the dust bag. Carefully follow the filter removal proce-

dure described in the manual and shown in the figures on the package.

• Please pay attention during the machine handling! Risk of foot squeezing!

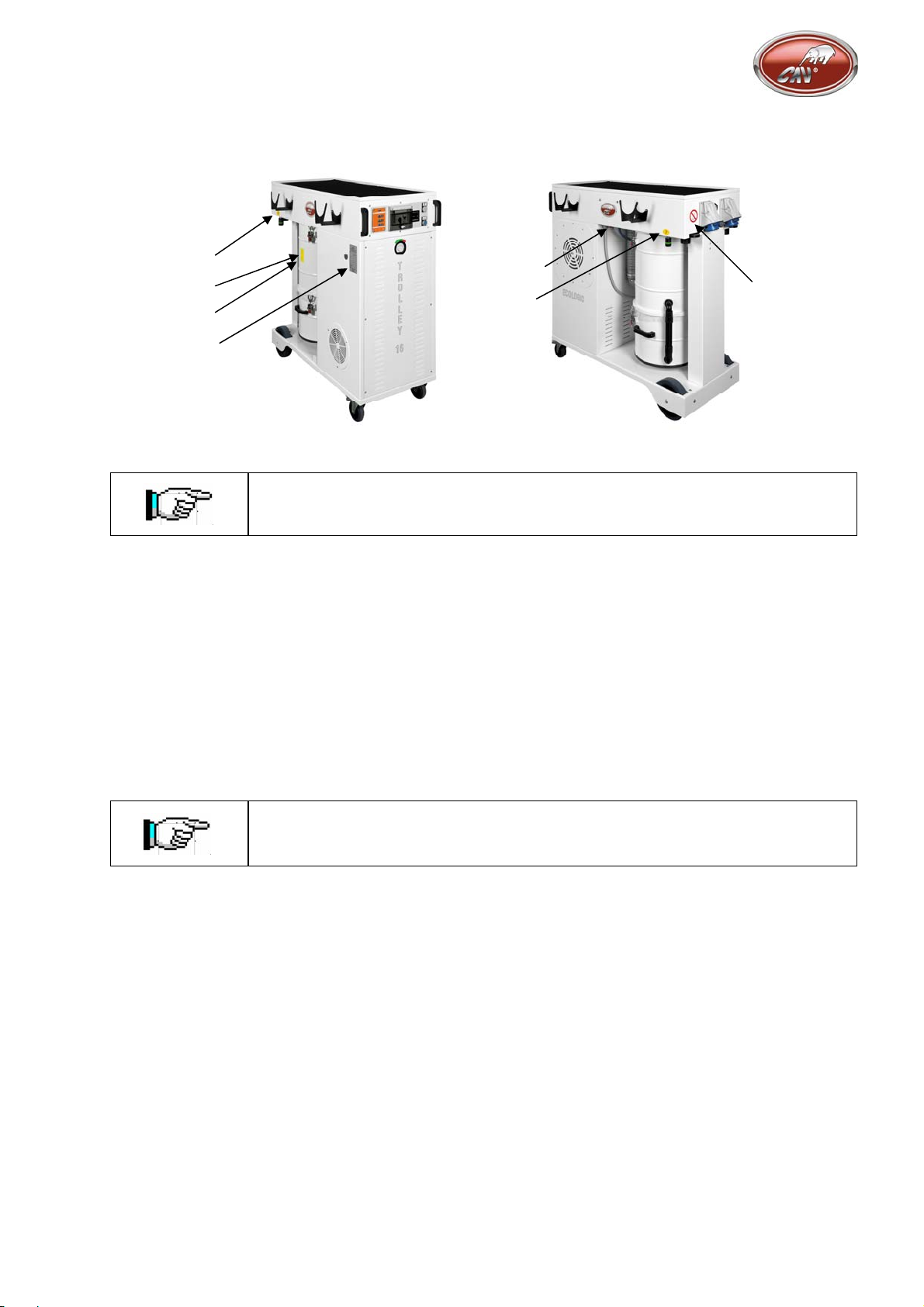

3. 5 SAFETY DEVICES

The Exhauster comes complete with suitable guards to protect the persons exposed to risks due to moving

organs, risks connected to power supply, and so on.

The unit fits the following safety devices:

• metal barrier all around the mobile parts. Basically, the enclosures are a barrier for any potentially

dangerous parts.

• The emergency stop is performed via the control panel main switch.

• The plug disconnection allows for the machine cut-out in order to perform maintenance under safety

conditions.

• Safety release on the levers for removing the dust collector cylinder metal body.

The User is requested to install the following safety devices:

• Electrical equipment with TT system : automatic circuit breaker with differential protection against

direct and indirect contacts on machine power control panel ( uncontrolled stop of all actuators and

power cut-off);

• Electrical equipment with TN or IT system : refer to control panel specifications to install the suita-

ble protections.