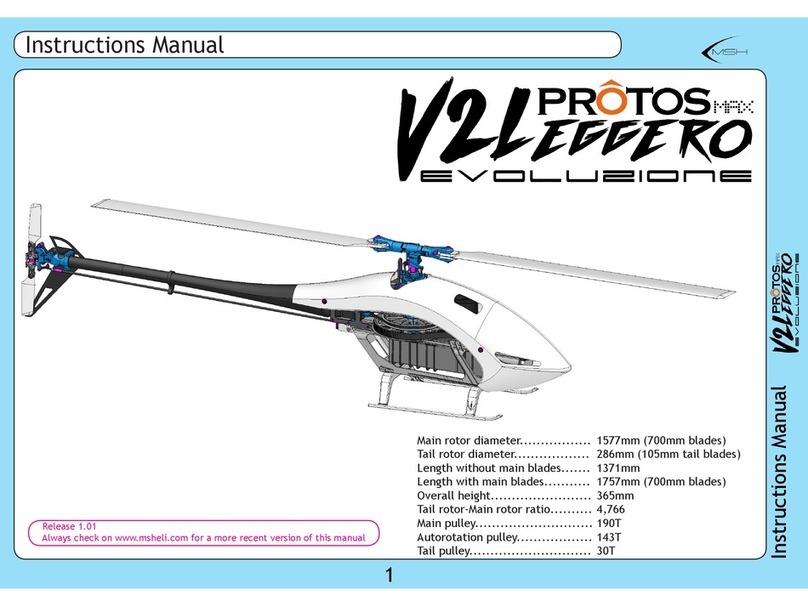

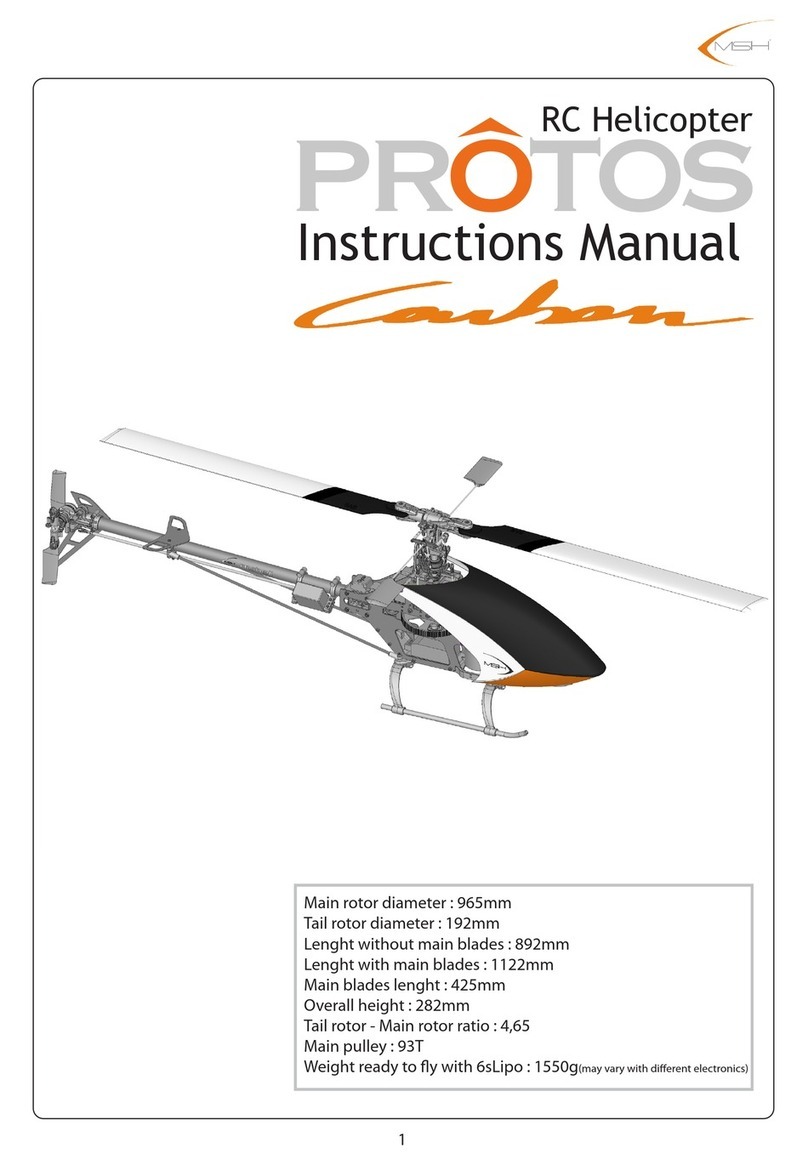

instructions manual

Always follow these rules for safety

.

.

.

.

.

.

!

s

Operate the helicopter in open areas with no people nearby.

Do NOT operate the helicopter in the following places and situations (or else you risk severe

accidents):

-in places where children gather or people pass through

-in residential areas and parks

-indoors and in limited space

-in windy weather or when there is rain, snow, fog or other precipitation

If you do not observe these instructions you may be held reliable for personal injury or property damage!

Always check the R/C system prior to operating your helicopter.

When the R/C system batteries get weaker,the operational range of the R/C system decreases

Note that you may lose control of your model when operating it under such conditions

Keep in mind that other people around you might also be operating a R/C model.

Never use a frequency which someone else is using at the same time.

Radio signals will be mixed and you will lose control of your model

If the model shows irregular behavior, bring the model to a halt immediately and disconnect the batteries.

Investigate the reason and fix the problem.

Do not operate the model again as long as the problem is not solved, as this may lead to further trouble

and unforeseen accidents.

In order to prevent accidents and personal injury, be sure to observe the following:

Before fying the helicopter, ensure that all screws are tightened.

A single loose screw may cause a major accident

Replace all broken or defective parts with new ones, as damaged parts lead to crashes

Never approach a spinning rotor. Keep at least 10 meters/yards away from a spinning rotor blades

Do not touch the motor immediately after use. It may be hot enough to cause burns.

Perform all necessary maintenance.

PRIOR TO ADJUSTING AND OPERATING YOUR MODEL, OBSERVE THE FOLLOWING

Operate the helicopter only outdoors and out of people’s reach as the main rotor operates at high rpm

While adjusting, stand at least 10 meter

Novice R/C helicopter pilots should always seek advice from experienced pilots to obtain hints with assembly

and for pre-fight adjustments.

Note that a badly assembled or insuffciently adjusted helicopter is a safety hazard!

In the beginning, novice R/C helicopter pilots should always be assisted by an experienced pilot

and never fy alone!

MSHeli Srl

Italy

y alone!

3