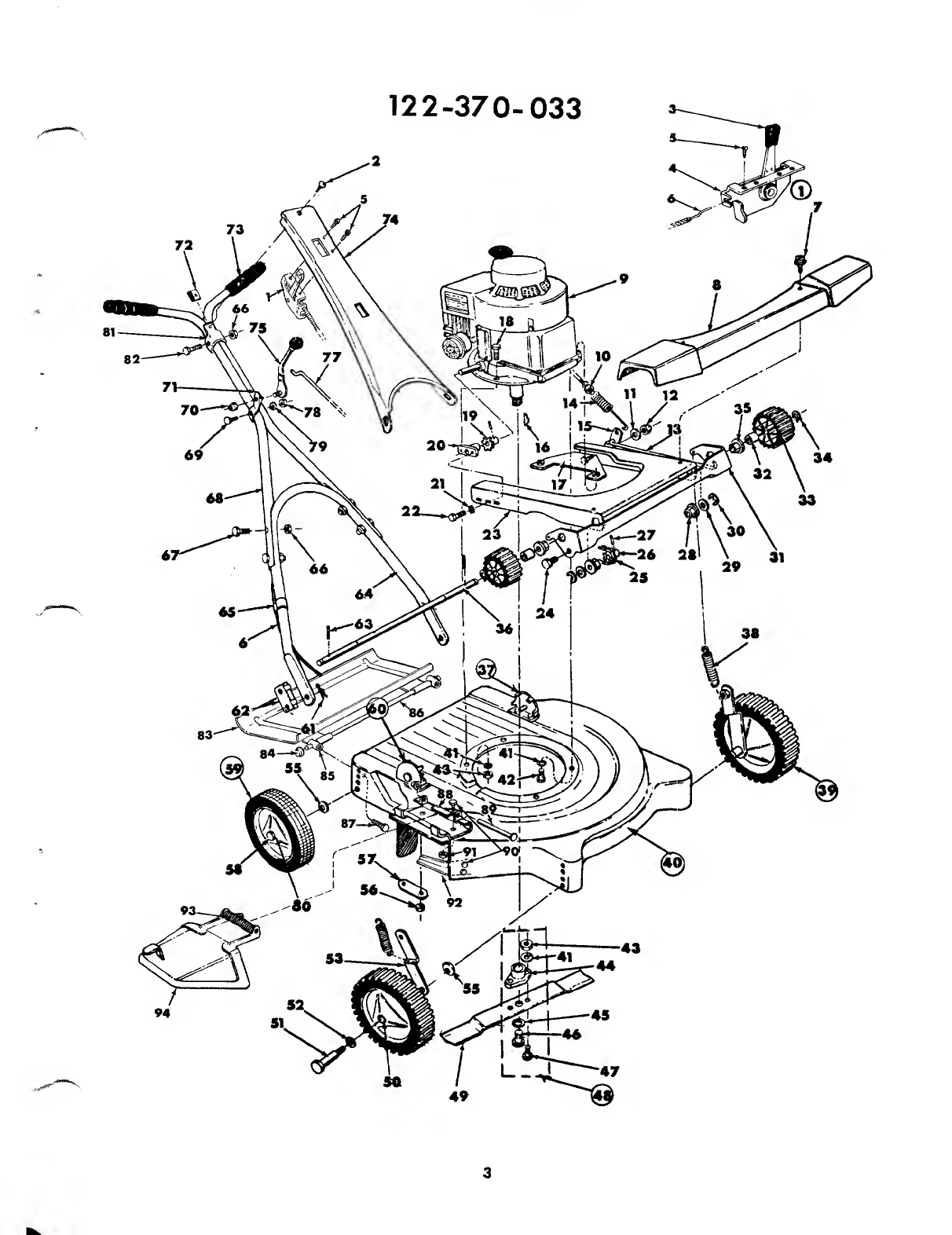

MTD 122-370-033 User manual

Other MTD Lawn Mower manuals

MTD

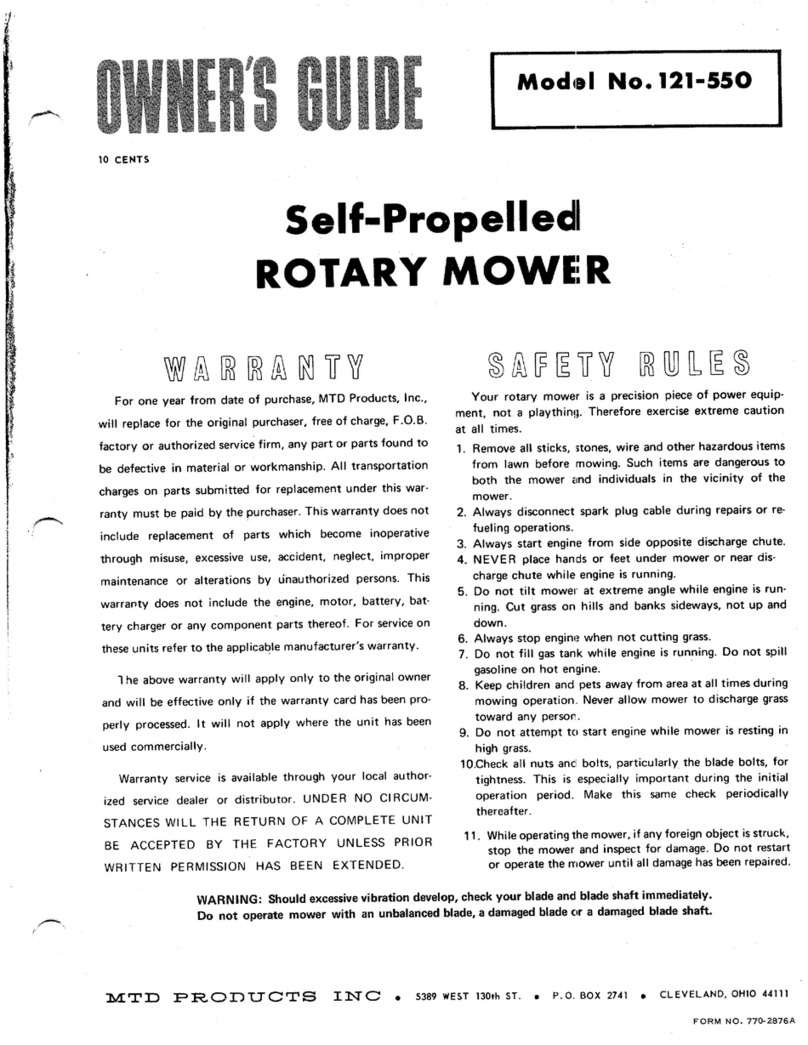

MTD 121-550 User manual

MTD

MTD 132-400-300 User manual

MTD

MTD 617 User manual

MTD

MTD 11A-436Q095 User manual

MTD

MTD J15 User manual

MTD

MTD 540 Series User manual

MTD

MTD 124-224-000 User manual

MTD

MTD 116-808T000 thru 116-809C000 User manual

MTD

MTD Cub Cadet 1000 Series User manual

MTD

MTD Series 770 User manual

MTD

MTD 11B-439Q755 User manual

MTD

MTD 810 series Parts User manual

MTD

MTD 808H Series User manual

MTD

MTD 189-421-000 User manual

MTD

MTD 141-990 User manual

MTD

MTD 139-530-000 User manual

MTD

MTD 124-294-000 User manual

MTD

MTD Cub Cadet 2000 Series User manual

MTD

MTD 124-232A000 124-238H000, 124-2 User manual

MTD

MTD 13A226JD309 User manual

Popular Lawn Mower manuals by other brands

DEWEZE

DEWEZE ATM-725 Operation and service manual

Weed Eater

Weed Eater 180083 owner's manual

Husqvarna

Husqvarna Poulan Pro PP185A42 Operator's manual

Better Outdoor Products

Better Outdoor Products Quick Series Operator's manual

Cub Cadet

Cub Cadet 23HP Z-Force 60 Operator's and service manual

Toro

Toro Groundsmaster 3505-D Service manual