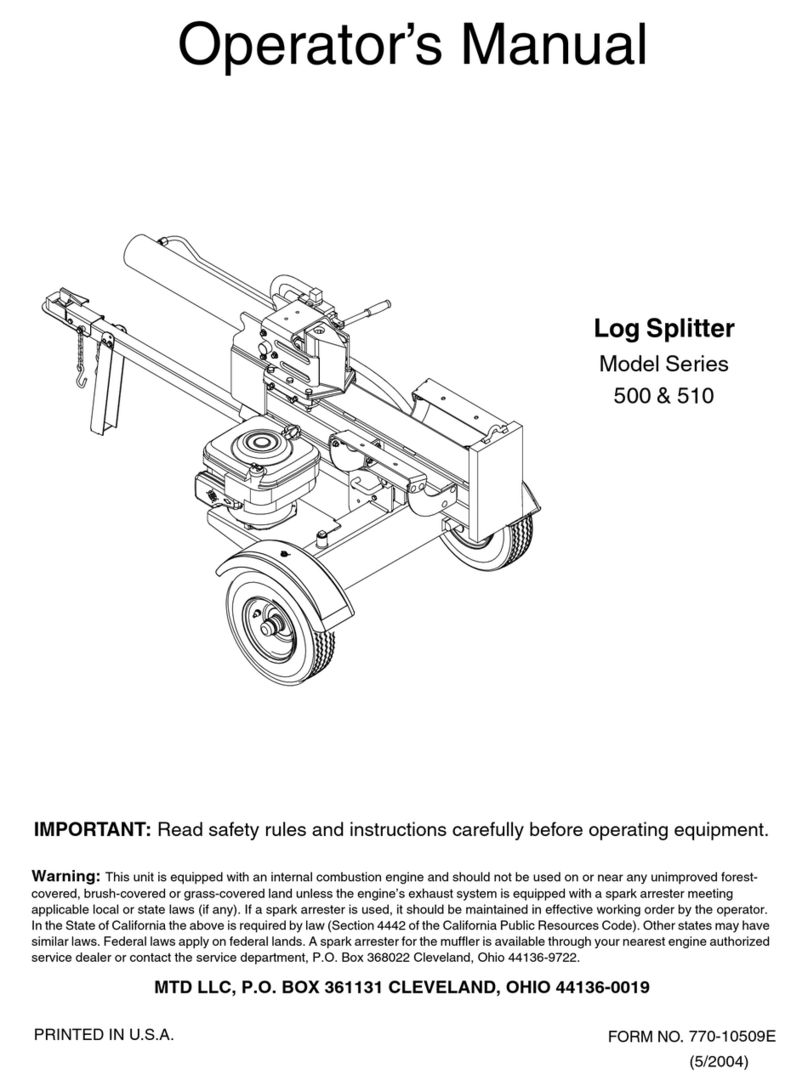

MTD 245-642-000 User manual

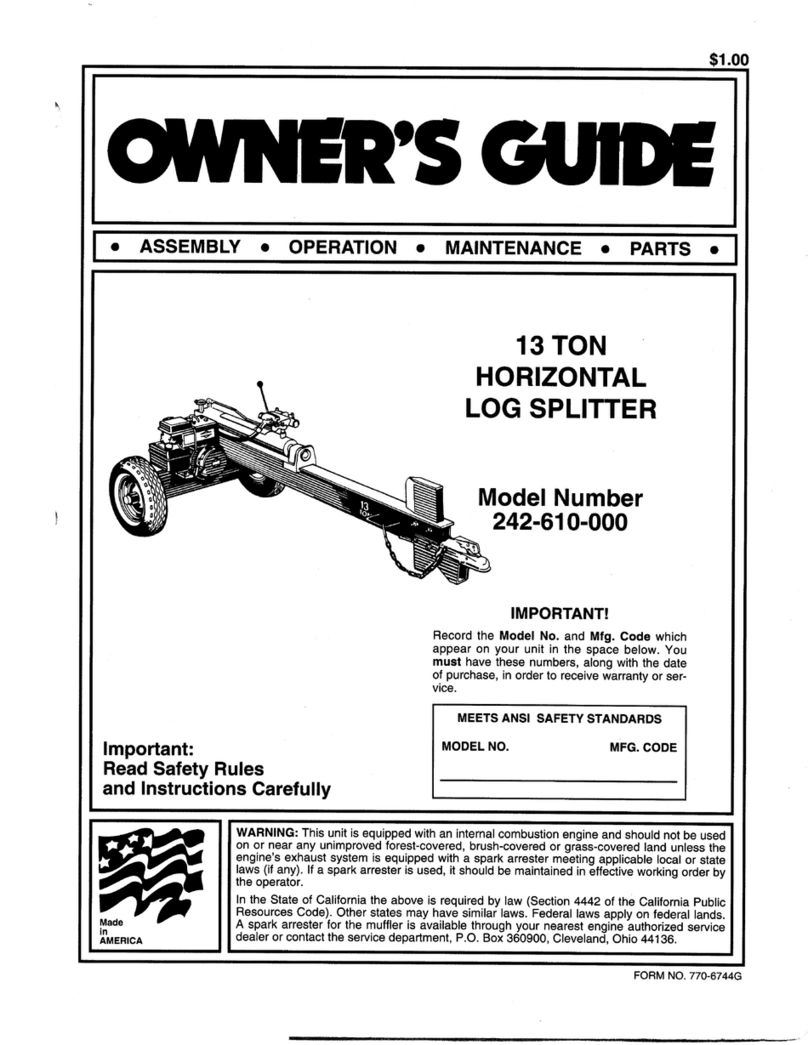

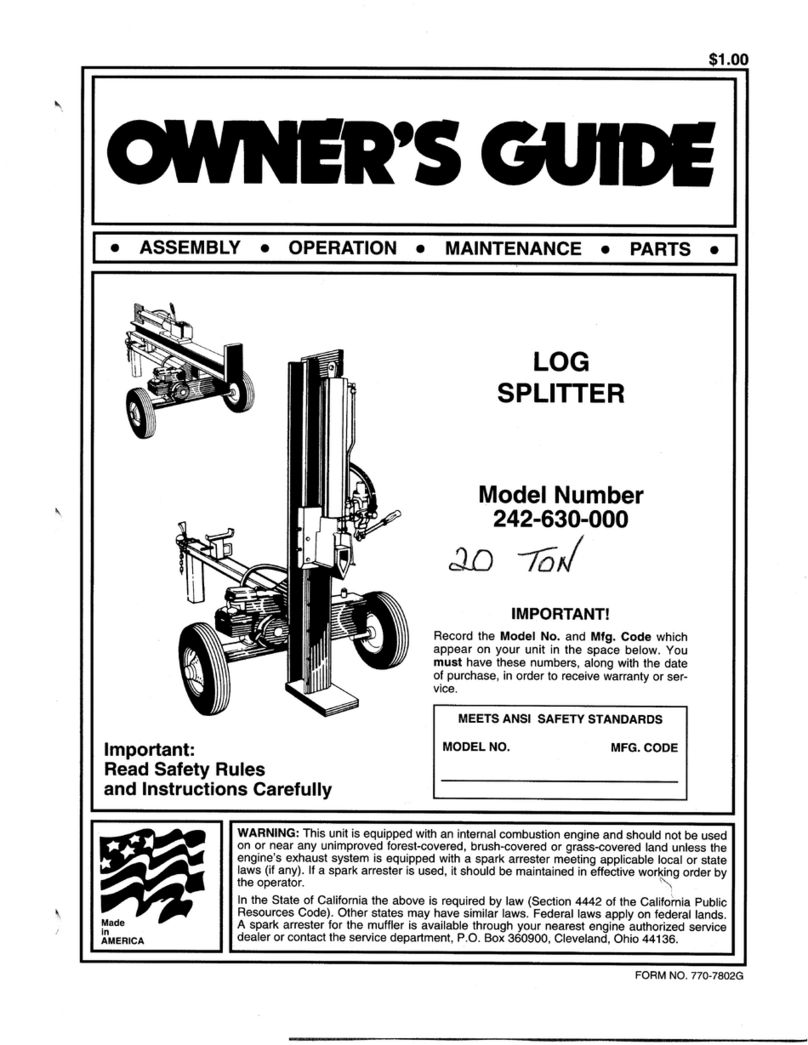

Other MTD Log Splitter manuals

Popular Log Splitter manuals by other brands

Scheppach

Scheppach OX 3-1000 Translation from the original instruction manual

Swisher

Swisher 21200 owner's manual

Elem Garden Technic

Elem Garden Technic FBHT65-22TCH instructions

Champion Power Equipment

Champion Power Equipment 90720 Owner's Manual and Operating Instructions

Villager

Villager LSP 12 T Original Operator's Manual

Boss Industrial

Boss Industrial ES5T20 owner's manual