WARNING: EngineExhaust, someof its constituents,and certain vehiclecompo- /

nentscontainor emit chemicalsknown to Stateof Californiato cause cancerand

birthdefects or other reproductive harm.

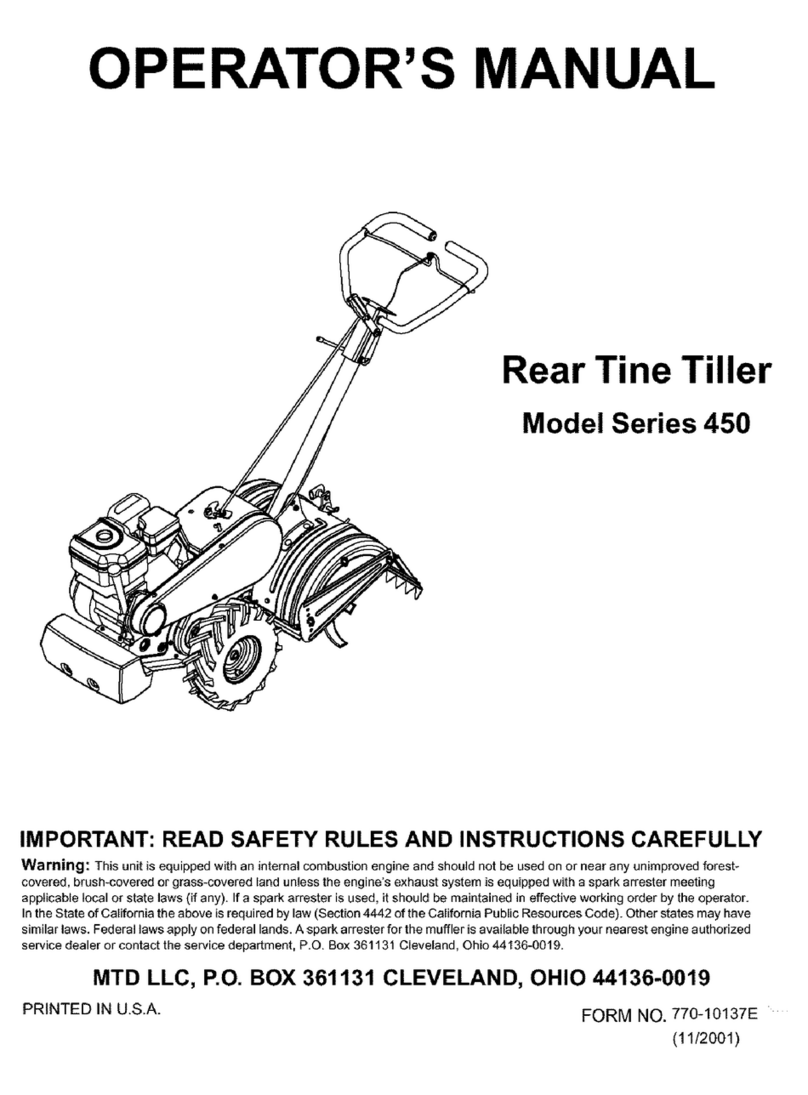

DANGER: This machinewas built to beoperatedaccordingto the rubs for safeoperationin this

manual.As with anytype of powerequipment,carelessnessor erroron thepart of theoperatorcan

resultin serious injury.Thismachine iscapable ofamputating handsand feet and throwingobjects.

Failuretoobserve the following safety instructionscould resultin seriousinjury or death.

Operation s. Neverallowchildrenunder14yearsoldto operatethis

Safe HandlingOf Gasoline:

1. Toavoidpersonalinjuryor propertydamageuseextreme

carein handlinggasoline.Gasolineisextremelyflammable

andthe vaporsareexplosive.Seriouspersonalinjurycan

occurwhengasolineisspilledonyourselforyourclothes

whichcanignite.

2. Washyourskinandchangeclothesimmediately.

3. Useonlyan approvedgasolinecontainer.

4. Neverfillcontainersinsideavehicleoron atruck ortrailer

bedwitha plasticliner.Alwaysplacecontainersonthe

groundawayfromyourvehiclebeforefilling.

5. Removegas-poweredequipmentfromthe truckor trailer

andrefuelit ontheground.Ifthisis notpossible,thenrefuel

suchequipmenton atrailer witha portablecontainer,rather

thanfromagasolinedispensernozzle.

6. Keepthe nozzleincontactwiththe rim ofthe fueltankor

containeropeningatall timesuntilfuelingiscomplete.Do

notuseanozzlelock-opendevice.

7. Extinguishallcigarettes,cigars,pipes,andothersources

of ignition.

8. Neverfuelmachineindoorsbecauseflammablevaporswill

accumulateinthe area.

9. Neverremovegascapor addfuelwhile engineis hotor

running.Allow enginetocoolat leasttwo minutesbefore

refueling.

10.Neveroverfillfueltank. Fill tanktono morethan_J2inch

belowbottomoffillernecktoprovideforfuel expansion.

11.Replacegasolinecapandtightensecurely.

12.Ifgasolineisspilled,wipeit offthe engineandequipment.

Moveunitto anotherarea.Wait5 minutesbeforestarting

engine.

13.Neverstorethe machineorfuelcontainernearan open

flame,sparkor pilotlightason a waterheater,spaceheater,

furnace,clothesdryer,or othergasappliances.

14.Toreducefire hazard,keepmowerfree ofgrass,leaves,

or otherdebrisbuild-up.Cleanup oilor fuelspillageand

removeanyfuelsoakeddebris.

15.Allowa mowerto coolatleast5minutesbeforestoring.

GeneralOperation

1. Read,understand,andfollowallinstructionsonthemachine

and in themanual(s)beforeattemptingto assembleand

operate.Keepthismanualinasafe placefor futureand

regularreferenceand for orderingreplacementparts.

2. Befamiliarwithall controlsandtheirproperoperation.Know

howtodisengagethemquicklyandstopthe machine.

4,<

5.

8<

9.

10.

11.

machine.Children14yearsoldandovershouldreadand

understandtheoperationinstructionsand safetyrulesin

thismanualandshouldbetrainedand supervisedbya

parent.

Neverallowadultstooperatethismachinewithoutproper

instruction.

Keepbystanders,helpers,pets,andchildrenat least75feet

fromthe machinewhileit is inoperation.Stopmachineif

anyoneentersthe area.

Thoroughlyinspectthe areawherethe equipmentisto be

used.Removeal stones,sticks,wire,andotherforeign

objectswhichcould betrippedoverandcausepersonal

injury.

Wearsturdy,rough-soledworkshoesandclose-fitting

slacksandshirts.Loosefittingclothes orjewelrycanbe

caughtin movableparts.Neveroperatethismachinein

barefeetorsandals.

Disengageclutchleversandshift(if provided)into neutral

(N) beforestartingthe engine.

Neverleavethis machineunattendedwith theengine

running.

Neverattempttomakeanyadjustmentswhileengineis

running,exceptwherespecificallyrecommendedinthe

operator'smanual.

Toavoidpersonalinjuryor propertydamageuseextreme

carein handlinggasoline.Gasolineisextremelyflammable

andthe vaporsareexplosive.Seriouspersonalinjurycan

occurwhengasolineisspilledonyourselforyourclothes

whichcan ignite.Washyourskinandchangeclothes

immediately.

a. Use onlyanapprovedgasolinecontainer.

b. Extinguishall cigarettes,cigars,pipes, andother

sourcesof ignition.

c. Neverfuel machineindoors.

d. [',leverremovegascap or addwhile the engineis

hot or running.

e. Allowengine tocool atleasttwo minutesbefore

refueling.

f. Neveroverfillfuel tank. Filltank to nomorethan

1/2 inch belowbottom offiller neckto provide

spacefor fuel expansion.

g. Replacegasolinecap andtighten securely.

h. Ifgasolineis spilled,wipe it offthe engine and

equipment.Movemachineto anotherarea.Wait5

minutesbeforestartingthe engine.

out important safety

instructionswhich, if

notfollowed,could

Readandfollow all

instructionsin this man-

ual beforeattempting to

operatethis machine,

Failureto comply with

resultin personalinjury,

When youseethis

symbol,

HEED ITS WARNING!

3