Roth & Rau Muegge GmbH – Hochstraße 4-6 – 64385 Reichelsheim

Tel.: +496164 9307 0 – Fax: +496164 9307 93

MH3000S-211CV00008100102.doc

- 3 -

4.2 Unpacking............................................................................................................................................ 16

4.3 Safety precautions prior to use...................................................................................................... 16

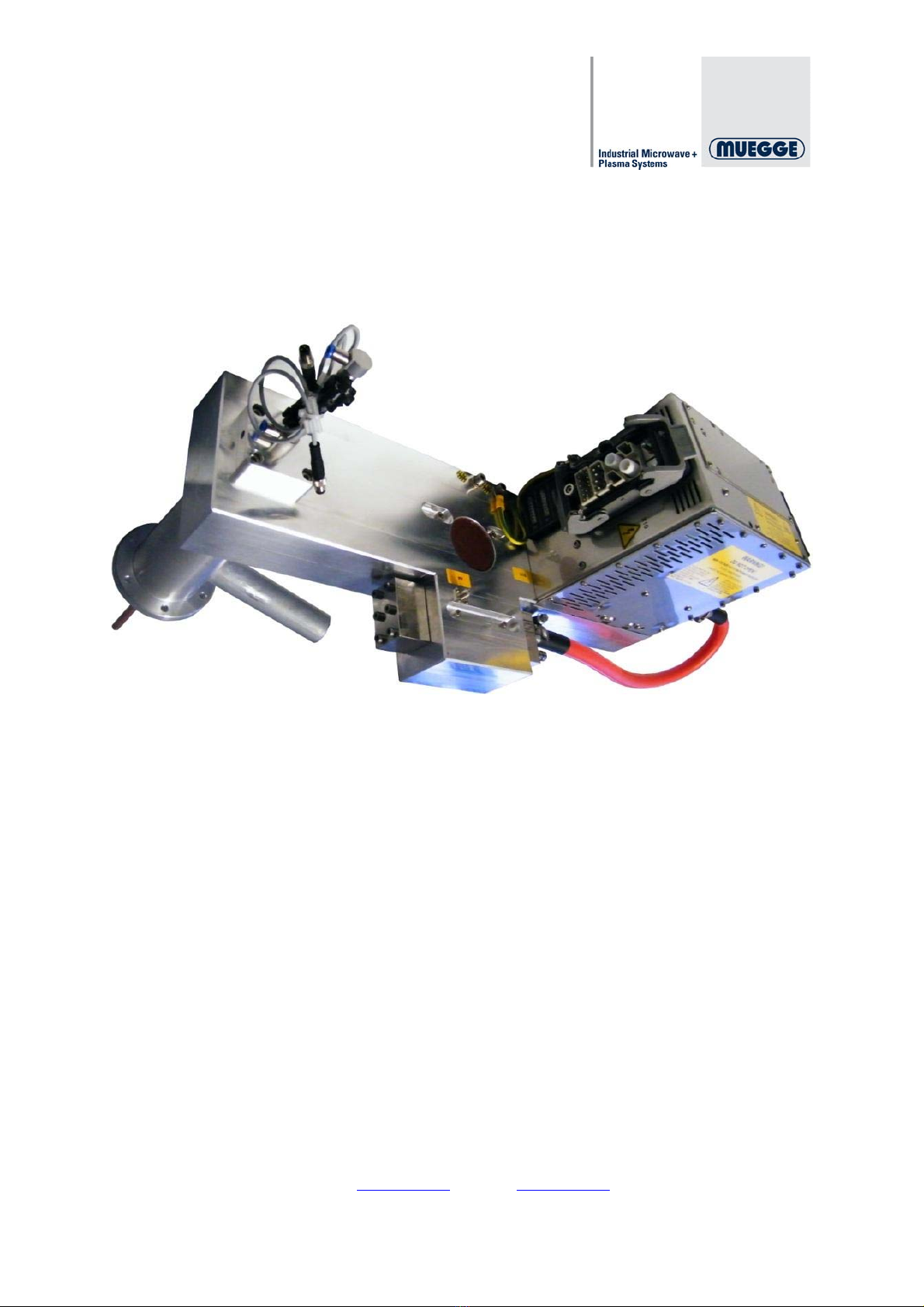

4.4 Overview of the components.......................................................................................................... 17

4.4.1 Legend of the components......................................................................................................... 19

4.5 Installation and assembly................................................................................................................ 20

4.6 Storage and protection..................................................................................................................... 21

4.7 User qualifications............................................................................................................................. 21

4.7.1 Operating personnel..................................................................................................................... 21

4.7.2 Maintenance personnel............................................................................................................... 22

4.7.3 Service personnel......................................................................................................................... 22

4.8 Where to store the instructions ..................................................................................................... 22

5. OPERATING INSTRUCTIONS ......................................................................... 22

5.1 Operation of the magnetron head ................................................................................................. 22

6. PROTECTION OF PERSONS .......................................................................... 23

7. MAINTENANCE AND CLEANING.................................................................... 23

7.1 Safety precautions............................................................................................................................. 23

7.2 Troubleshooting, diagnosis and measures................................................................................ 24

7.3 Maintenance plan for the operating and maintenance staff................................................... 24

7.4 Maintenance work for the maintenance staff ............................................................................. 25

7.4.1 Replacing the magnetron unit................................................................................................... 25

7.4.2 How to replace the magnetron unit.......................................................................................... 26

7.4.3 Replacing the antenna................................................................................................................. 27

7.4.4 How to replace the antenna........................................................................................................ 28

8. MAINTENANCE AND REPAIR BY THE CUSTOMER SERVICE .................... 29

8.1 Maintenance cycles for safe operation........................................................................................ 29

8.2 Contact details for our Customer Service................................................................................... 29

9. LIST OF SPARE PARTS AND CONSUMER GOODS ..................................... 30

10. APPENDIX .................................................................................................... 31

10.1 Table of illustrations......................................................................................................................... 32