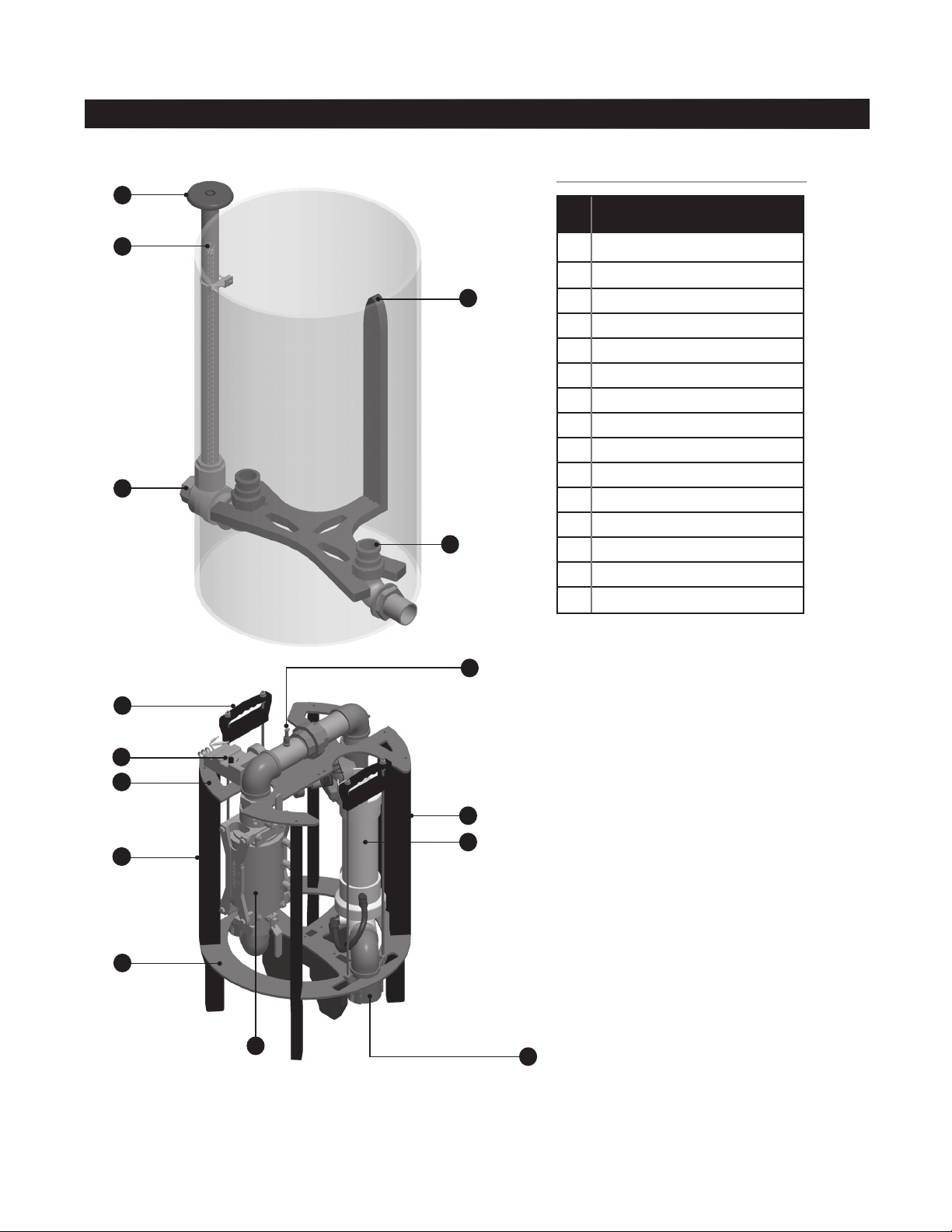

HYDRO-GUARD® HG-8 Warm Climate Flushing System

Programming Unit

4

2. Press +or –key to change station

RUN TIME from 1 minute to 6

hours.

3. Press PRG key to add a RUN

TIME to another program.

4. Press RETURN/ENTER key to

proceed to next programming

function, or allow controller to

return to idle mode.

Setting Flushing Days

1. Press RETURN/ENTER key until

CALENDAR icon is displayed. The

program letter (A, B, or C) will be

displayed. Arrows point at specic

days of week in which ushing will

occur.

2. Press LEFT or RIGHT ARROW to

scroll though days.

3. Press + key to activate that day

for program displayed, or –key to

cancel watering for that day. The

arrow will show on ushing days

for active program.

4. Press PRG key to set days to ush

for a different program, if desired.

5. Press RETURN/ENTER key to

proceed to next programming

function, or allow controller to

return to idle mode.

Manual Flushing

Manual ushing allows user to test

the Hydro-Guard®unit or a program

for a specied run time.

Make sure controller is in Idle Mode.

1. Press and hold RIGHT ARROW

until HAND icon is displayed. The

station number (always #1) will

be displayed in lower left side of

display along with RUN TIME.

2. Use the LEFT or RIGHT ARROW

to select #1 station if not already

displayed, and + or – key to set

manual ushing time.

3. To manually activate a program,

press PRG key. Program letter (A,

B, or C) will show on screen. If a

different program is needed, press

PRG key until desired program is

displayed.

6. All 4 numbers are shown with

two numbers on the left ashing,

representing the HOUR. Press +

or –key to change the hour. Press

RIGHT ARROW key to proceed to

setting MINUTES.

7. All 4 numbers are shown with

two numbers on right ashing,

representing MINUTES. Press

+or –key to change minutes.

(Pressing RIGHT ARROW key will

return to YEAR setting at step #2.)

8. Press RETURN/ENTER key to

proceed to next programming

function, or allow controller to

return to idle mode.

Setting Flush Sequence

Start Times

1. Press RETURN/ENTER key until

CLOCK icon is displayed.

2. The START TIME will be displayed

ashing, along with the program

letter (A, B, or C) and start time

number (1, 2, 3, or 4) in the upper

left. Up to 4 different start times

can be set for each program.

3. Use +or –key to change START

TIME for program displayed. Each

press of key will change start time

in 15-minute increments.

4. Press RIGHT ARROW key to

add an additional START TIME

to program displayed. The start

time number is shown in upper left

corner of display.

5. Press PRG key to add START

TIME to a different program.

6. Press RETURN/ENTER key to

proceed to next programming

function, or allow controller to

return to idle mode.

Setting Flush Duration Times

1. Press RETURN/ENTER key until

HOURGLASS icon is displayed.

RUN TIME will be displayed

ashing. Also shown is program

letter (A, B, or C) and active station

number (always #1– all other

stations not used) on lower left

side of display.

4. To stop MANUAL FLUSHING

cycle press – key until time is

reduced to zero.

5. Press RETURN/ENTER key to

proceed to next programming

function, or allow controller to

return to idle mode.

NOTE:

– Pressing + or – key when

running in MANUAL FLUSH mode

will modify FLUSH TIME for that

station.

– Pressing the button when a

station is running in manual

watering will stop irrigation on the

current station and advance to the

next station.

– Pressing the button when a

station is running in manual

watering will stop the irrigation on

the current station and revert to

the previous station.

Turn System Off

To turn off controller, press RETURN/

ENTER key button until icon

resembling water spray and OFF

is displayed on screen. To return

controller to auto programming mode,

press RETURN/ENTER key. The

controller will immediately return to

auto programming mode and will

display time and battery life indicator.

NODE Quick Check

This circuit diagnostic procedure can

quickly identify “shorts” commonly

caused by faulty solenoids or when

bare common wire touches a bare

station control wire. To initiate NODE

Quick Check procedure:

1. From Idle Mode, press and hold

+, –, LEFT ARROW, and RIGHT

ARROW keys.

2. Display will show all segments.

Release keys.

3. Press + key to initiate NODE

Quick Check test.

4. Controller will then activate

ushing unit for 1 second to verify

operation.