Wilo

= Factory settings

Factory setting

Variable differential

pressure - Δp-v

Constant differential

pressure - Δp-c

Constant speed

PUMP CURVE

I, II, III

CONTROL MODE

NORMAL

OPERATION FAULT

NORMAL

OPERATION

FAULT

CONTROL MODE

Variable differential

pressure - Δp-v

Constant differential

pressure - Δp-c

Constant speed

PUMP CURVE

I, II, III

Wilo Display

7

LED displayHold Status

Locked

8 sec

Unlocked

8 sec

Factory

setting

Venting

4 sec 1 sec

Last settings

2143

1 sec

1 sec

1 sec

3 sec 10 min

Factory

setting

Venting

Hold LED display Last settings Status

Locked

Unlocked

LED

Indicator

Meaning Diagnostic Cause Remedy

lights green Pump in

operation

Pump runs

according its

setting

Normal operation

lights

orange

Pump is in

PWM mode

Pump is speed

controlled

by the PWM

signal

Normal operation

blinks red/

green

Pump in

function but

stopped

Pump restarts

by itself after

the fault is

disappeared

1. Undervoltage U<160 V

or Overvoltage U>253 V

2. Modul overheating:

temperatur inside motor

too high

1. Check voltage supply

195 V < U < 253 V

2. Check water and

ambient temperature

blinks red Pump out of

function

Pump stopped

(blocked)

Pump does not restart by

itself due to a permanent

failure

Change pump

blinks

orange

Pump out of

function

Pump stopped Pump is not starting Change pump

LED off No power

supply

No voltage on

electronics

1. Pump is not connected

to power supply

2. LED is damaged

3. Electronics are damaged

1. Check cable connection

2. Check if pump is running

3. Change pump

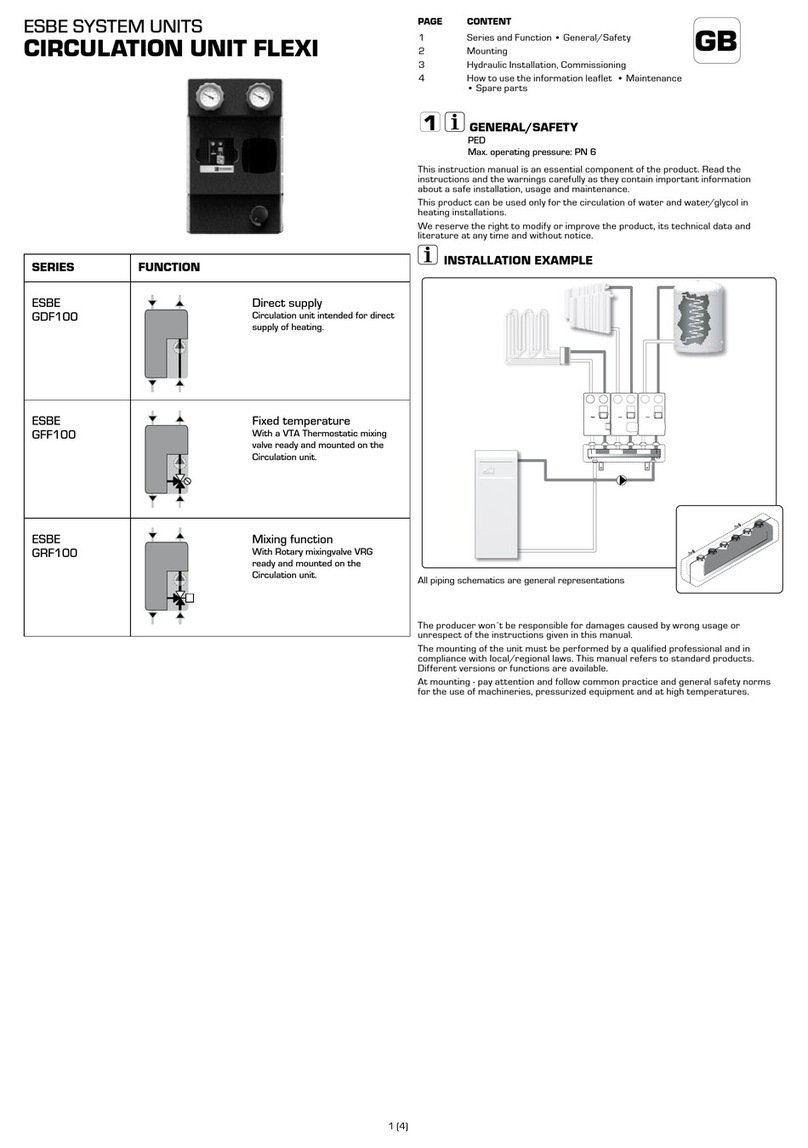

http://www.esbe.eu/global/en/

products/circulation units

WILO - Faults, Causes and

Remedies

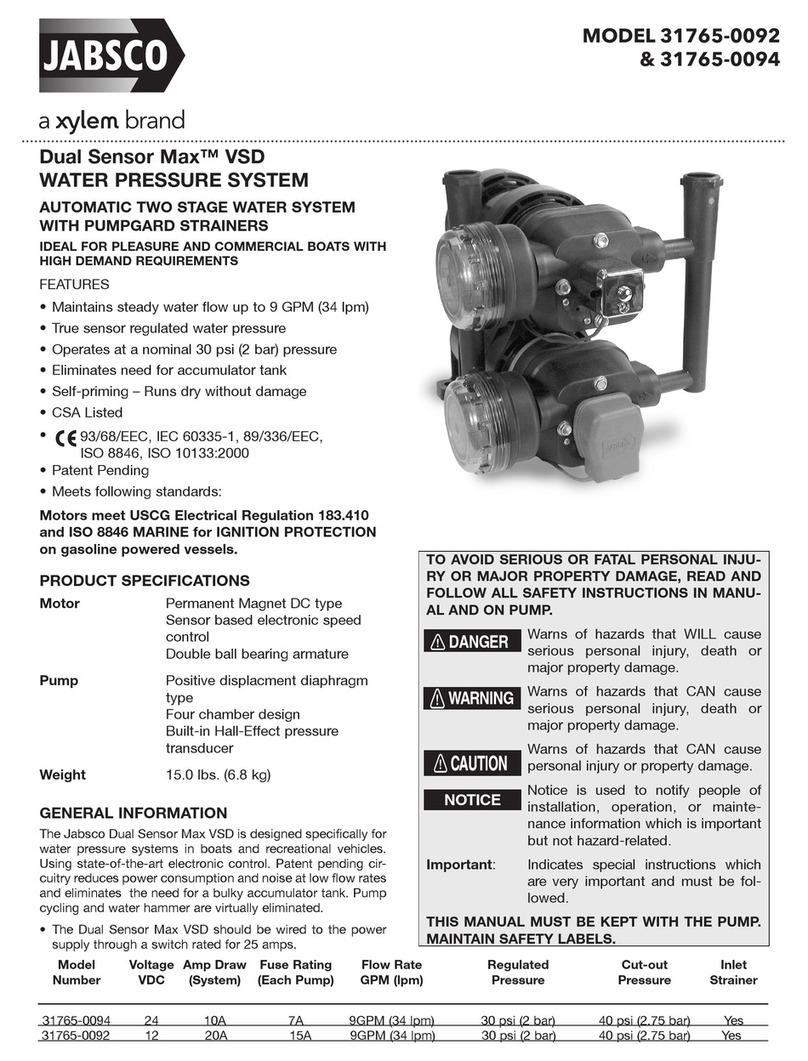

LED displayclick Control mode Pump curve

Recomended

Alt.

1Constant speed II

Constant speed I

Variable differential

pressure

Δp-v III

Variable differential

pressure

Δp-v II

Variable differential

pressure

Δp-v I

Constant differential

pressure

Δp-c III

6

Constant differential

pressure

Δp-c II

Constant differential

pressure

Δp-c I

Constant speed III

2

3

4

5

7

8

9

Recommended Alternative

Click LED display Control mode Pump curve

Constant speed

Constant speed

Variable differential

pressure Δp-v

Variable differential

pressure Δp-v

Variable differential

pressure Δp-v

Constant differential

pressure Δp-v

Constant differential

pressure Δp-v

Constant differential

pressure Δp-v

Constant speed

Settings navigationsPump Settings