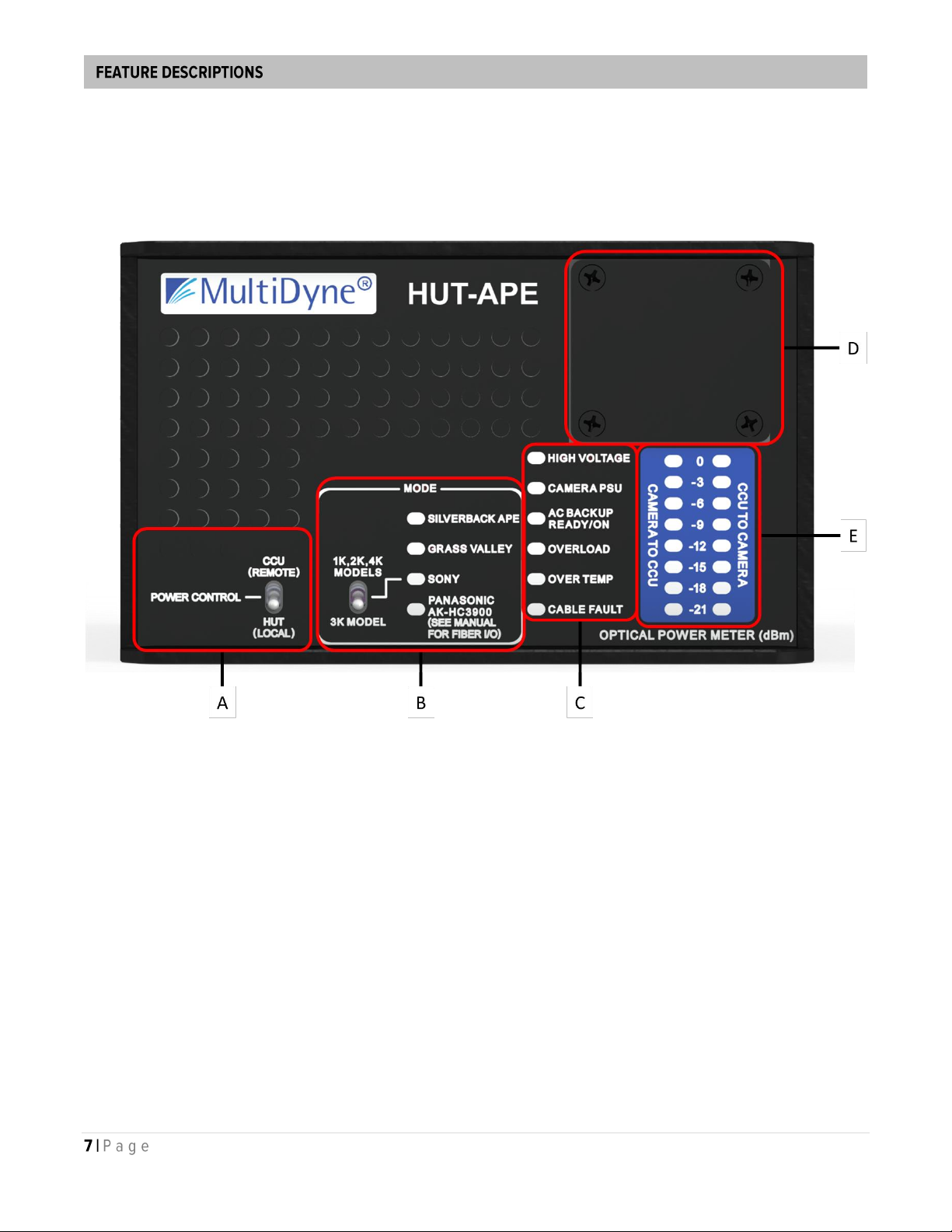

SILVERBACK APE –Green LED indicating the Multidyne Advanced Power Extender (APE) is

connected to the SMPTE output.

GRASS VALLEY –Green LED indicating a Grass Valley LDX camera is connected to the SMPTE

output.

SONY –Green LED indicating a Sony 1K, 2K, 3K or 4K series camera is connected to the SMPTE

output.

PANASONIC AK-HC3900 –Green LED indicating a Panasonic AK-HC3900 camera is connected

to the SMPTE output. See Section 7 for reference on the note about Fiber I/O.

C. Status Indicators

HIGH VOLTAGE –This indicator is off when the HUT-APE is in the start-up/standby mode (i.e., low

voltage output), lights up green when the camera is connected with its power switch in the ON

position, and red if the high voltage is on but the output voltage is lower than the specified operating

range.

Each of the camera systems, as well as the Multidyne APE power supply, initially power-up using a

low voltage in the 15 –45 VDC range to operate low power detection and startup circuitry providing

a handshake between the camera and the CCU thereby establishing a valid connection.

CAMERA PSU –Lights up red when no communication has been established between the HUT-

APE and one of the above compatible devices or green when a functional link is detected.

AC BACKUP READY/ON –Off if no secondary/backup source is present; lights up green when the

HUT-APE is operating on the main power source with the backup power source present (“normal”

dual AC source operating mode), lights red when the main power has dropped/failed with the unit

now relying on the backup power source, and then alternates between red and green when the

main power source is re-applied, and monitored for 30 seconds to verify stability before another

seamless transition back to the main power source; in which case the LED returns to solid green.

The HUT-APE is equipped with “Main” and “Backup” AC inlets that provides seamless transition to

a secondary AC mains power source in case the main power source either drops below the

specified operating voltage range of the HUT-APE (brown-out condition) or fails completely. No

variation in the HUT-APE output voltage will occur, thereby maintaining glitch-free video/sound

performance from the connected camera system.

OVERLOAD –Off under normal operating conditions, lights up red when the HUT-APE output is

loaded beyond 90% of the total output rating, and flashes between red and orange if the over-

current detection has been triggered, placing the HUT-APE in the 20 second retry interval cycle.

OVER TEMP –This Indicator displays multiple fault conditions related to the cooling of the HUT-

APE

1. Locked rotor indication –If the rotor is locked by an obstruction or failure of the motor, the

LED will light red.

2. Internal overheating –If the internal operating temperature exceeds a safe limit for the

electronic components, the LED will flash red as the HUT-APE enters a 2-minute shutdown