DIS185SSI4F AIR COMPRESSOR — HOSE REEL INSTALLATION INSTRUCTIONS P/N EE60468 — REV. #0 (04/16/18) — PAGE 2

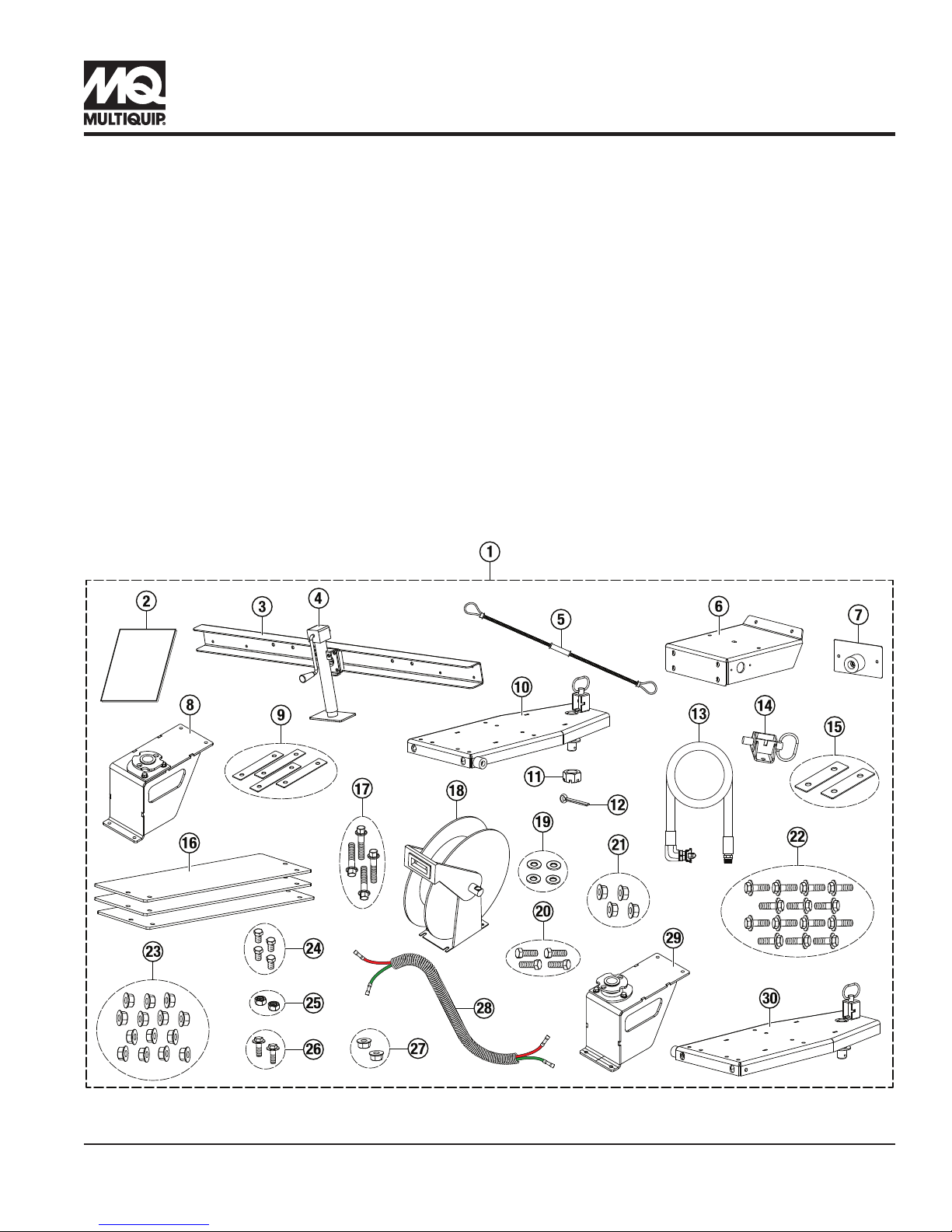

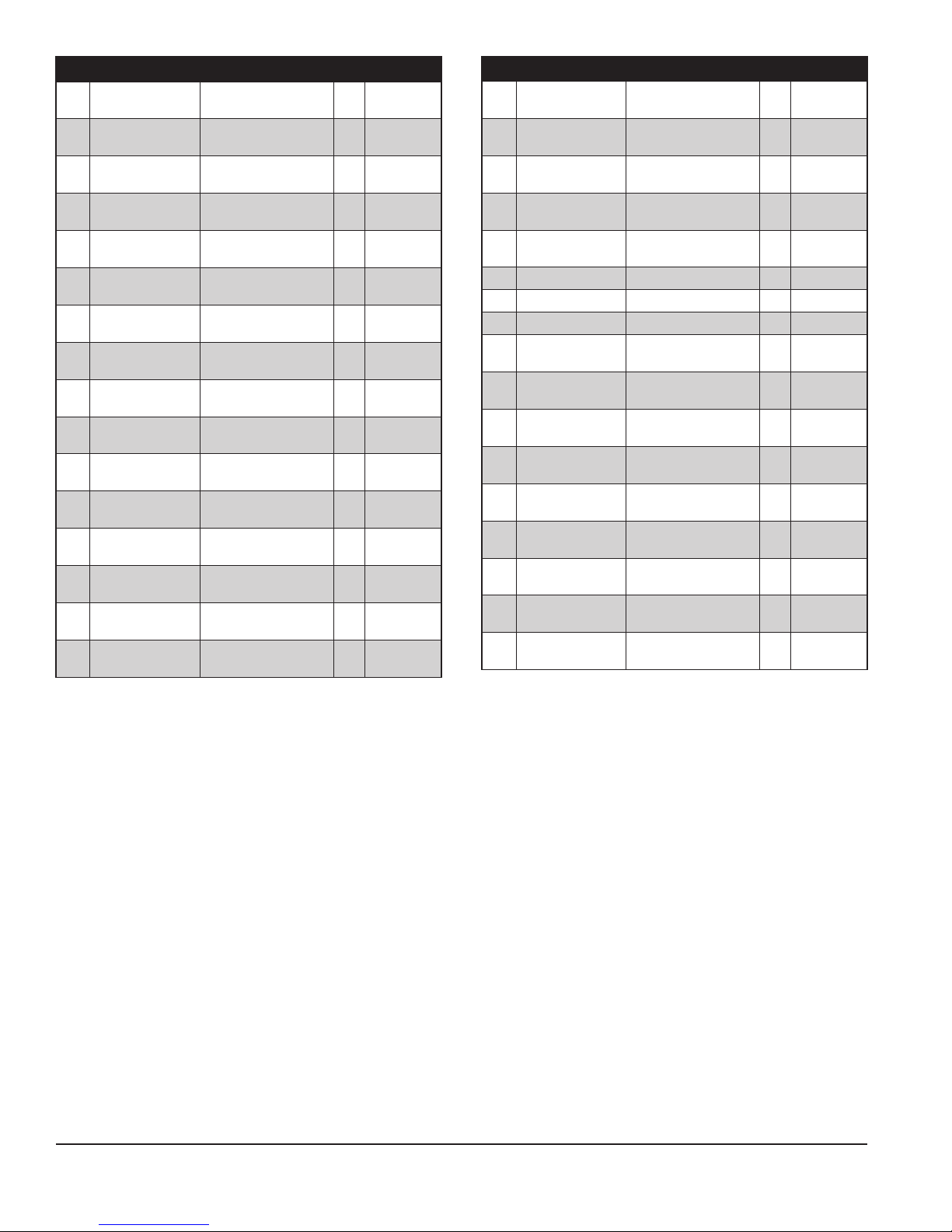

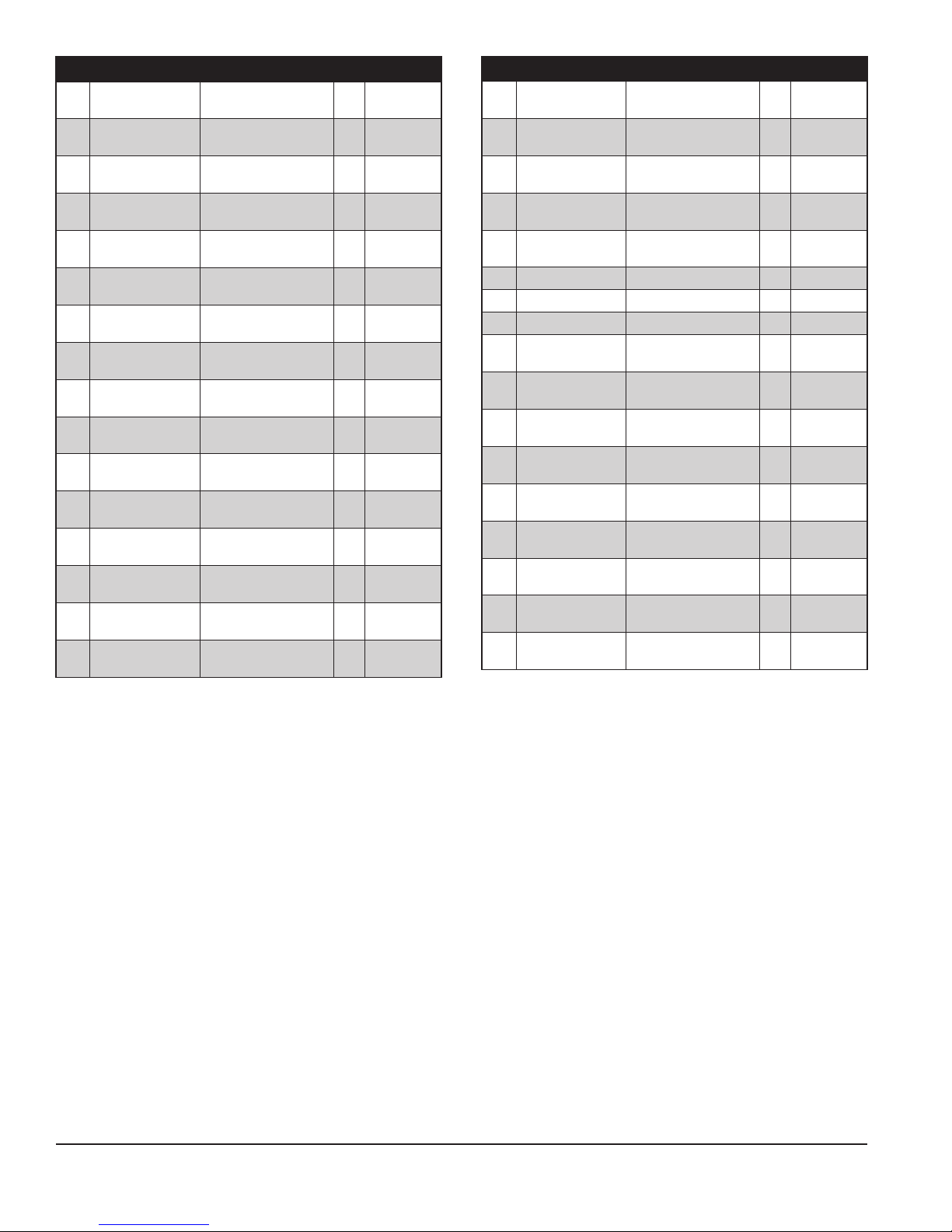

Table 1. DIS185SSI4F Hose Reel Installation Kit

Item

No. Part No. Description Qty. Remarks

1MQPSINGLEREEL50 Reel Kit Assembly, DIS185

50', Right 1Includes

items 2–28

1 MQPDUALREEL50 Reel Kit Assembly, DIS185

Dual 50' 1Includes

items 2–30

2 EE60468 Work Instruction, Reel Kit,

DIS185SSI4F 1

3 59269 Bumper Assembly,

Hose Reel Kit 1

4 29479 Jack, Sidewind 10"

Bolt-On, .5 Pin, Foot 1

5 59274 Safety Cable Hose Whip

1/8 × 20" 1Double qty.

for dual kit

6 59234 Plate, Pivot Base Mt 1 Double qty.

for dual kit

7 59267 Bump Stop Assembly,

Rear 1Double qty.

for dual kit

8 59272 Pivot Base Assembly,

Right 1

9 59286 Shim, Pivot Plate Mt,

.075 Thk 4Double qty.

for dual kit

10 59275 Reel Mount Assembly,

Right 1

11 EM968481 Nut, Hex Slotted, 1-14 1 Double qty.

for dual kit

12 38709 Pin, Cotter 3/16 × 2" 1 Double qty.

for dual kit

13 59265 Hose Assembly 1 Double qty.

for dual kit

14 59251 Lock Pin Assembly 1 Double qty.

for dual kit

Table 1. DIS185SSI4F Hose Reel Installation Kit (Continued)

Item

No. Part No. Description Qty. Remarks

15 59289 Shim, Lock Latch 2 Double qty.

for dual kit

16 59290 Plate, Tongue Ballast,

DIS185 2Qty. of 3 in

dual kit

17 42346 Bolt, HHFS,

M8-1.25 × 40 mm 4Includes

items 19–20

18 59263 Reel, 3/4" × 50',

Spring Return 1Double qty.

for dual kit

19 0447 Washer, Flat SAE, 1/2" 4

20 5218 Bolt, HHC, 1/2-13 × 1-1/2" 4

21 26328 Nut, HFS, 1/2"-13 4

22 1023 Hex Flange Bolt

3/8-16 × 1-1/4" 14 Double qty.

for dual kit

23 21781 Nut, HFS, 3/8"-16 14 Double qty.

for dual kit

24 28922-083 Screw, HHC,

M4-0.7 × 12 mm 4Double qty.

for dual kit

25 32664 Nut, Hex, M4 2 Double qty.

for dual kit

26 36720 Screw, HHFS,

5/16-18 × 3/4" Gr5 2Double qty.

for dual kit

27 49071 Nut, HFS, 5/16"-18 2 Double qty.

for dual kit

28 59291 2-Wire Extension

Harness, Split Loom 1Double qty.

for dual kit

29 59273 Pivot Base Assembly, Left 1 For dual kit

only

30 59276 Reel Mount Assembly, Left 1 For dual kit

only